Spool component resistant to cavitation erosion and erosion wear for regulating valve

A wear adjustment and valve core assembly technology, applied in safety valves, balance valves, valve devices, etc., can solve the problems of short life of the regulating valve, aggravated valve core damage, pipeline erosion and wear, etc., to achieve uniform erosion and wear, reduce The effect of erosion wear and cavitation damage reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments of the present invention will be further described below in conjunction with the drawings.

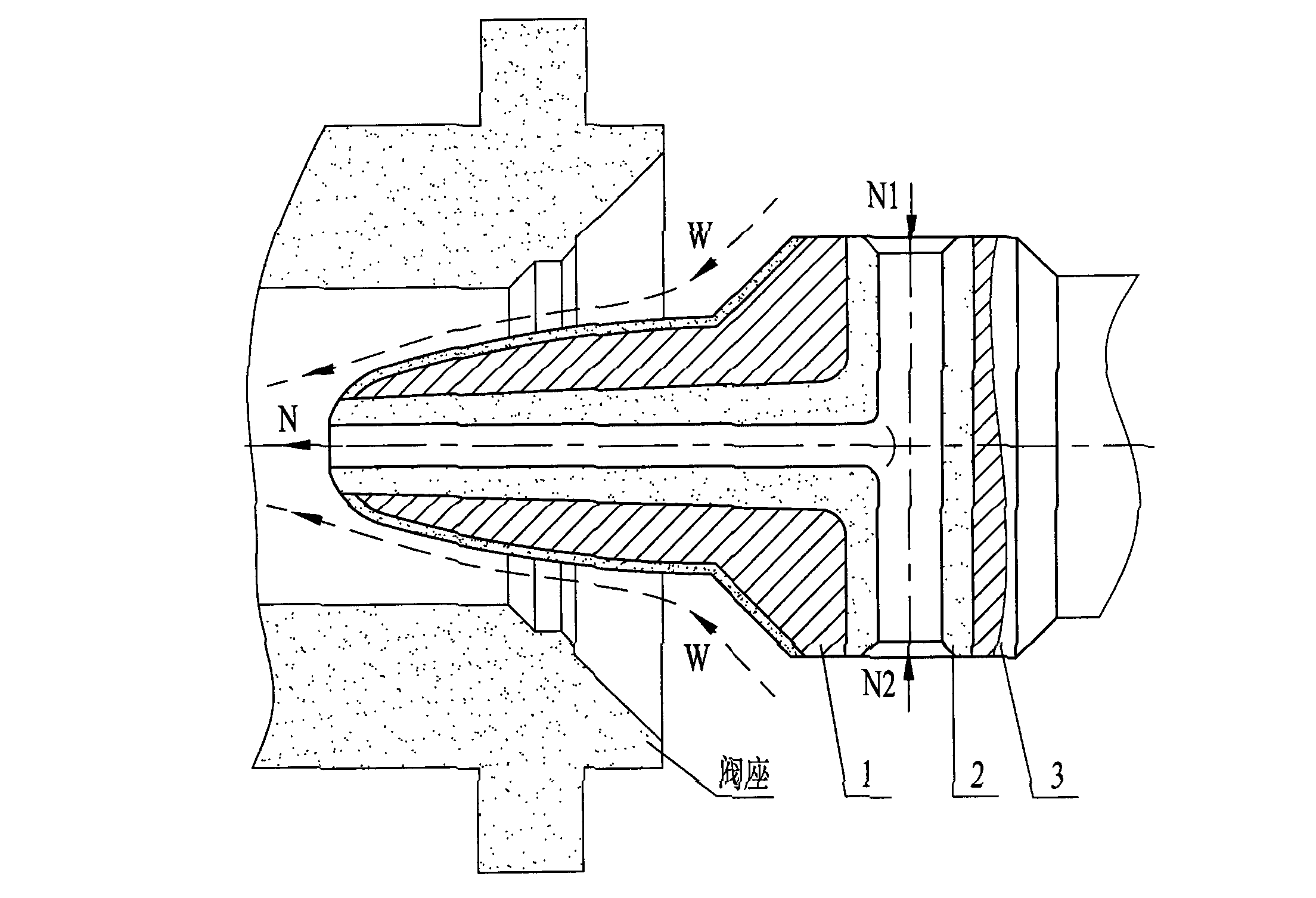

[0025] Such as figure 1 As shown, the valve core assembly of the present invention includes a valve core head 1, a valve core built-in throttle 2 and a valve core tail 3; the horizontal section of the valve core built-in throttle 2 is inserted into the central hole of the valve core head 1. The vertical section of the built-in throttle of the valve core is embedded in the hole formed by the connection between the valve core head 1 and the valve core tail 3. The connection described in this embodiment is welding, so that the regulating valve is formed during operation. There are two transmission passages between the head surface of the valve core and the valve seat, and in the internal throttle 2 of the valve core.

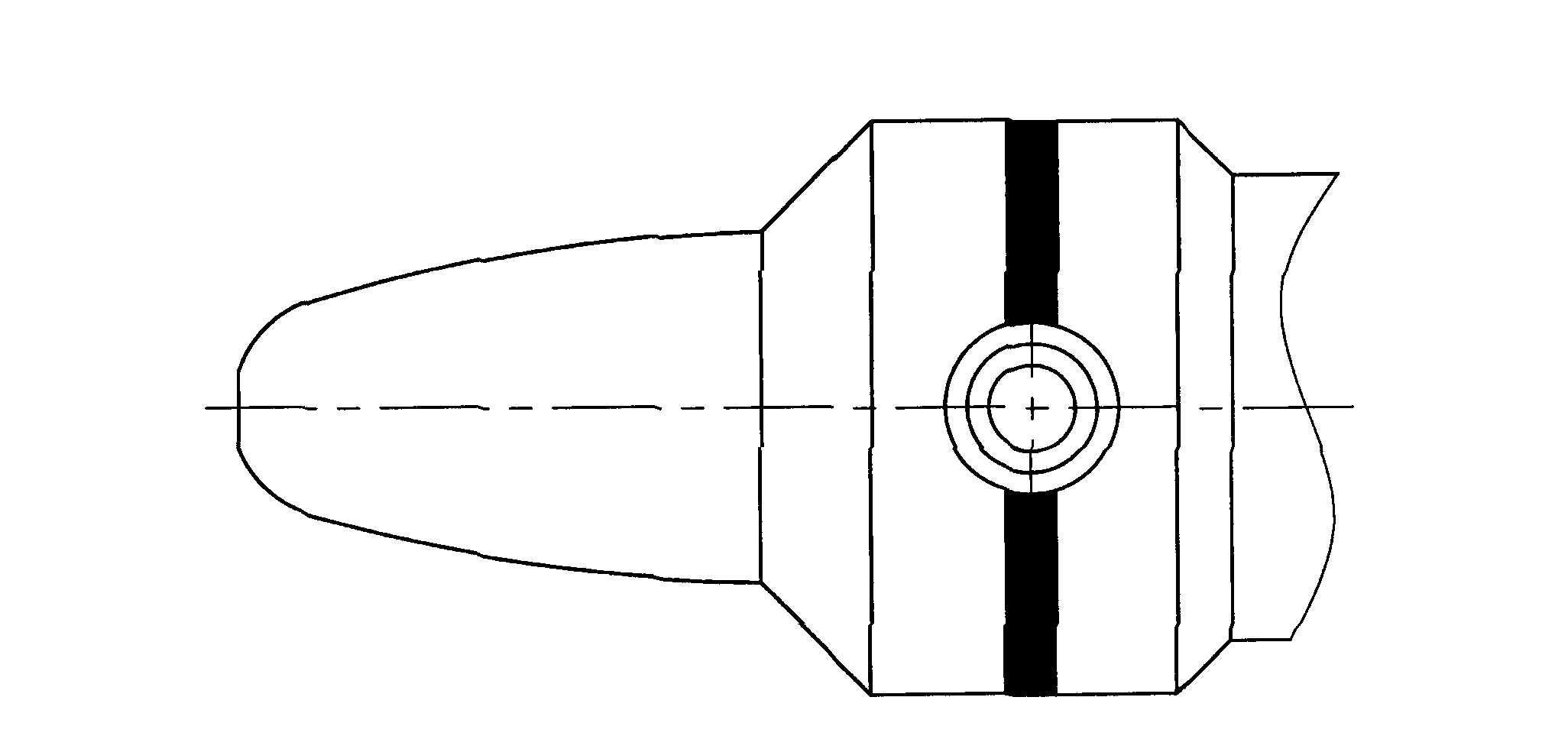

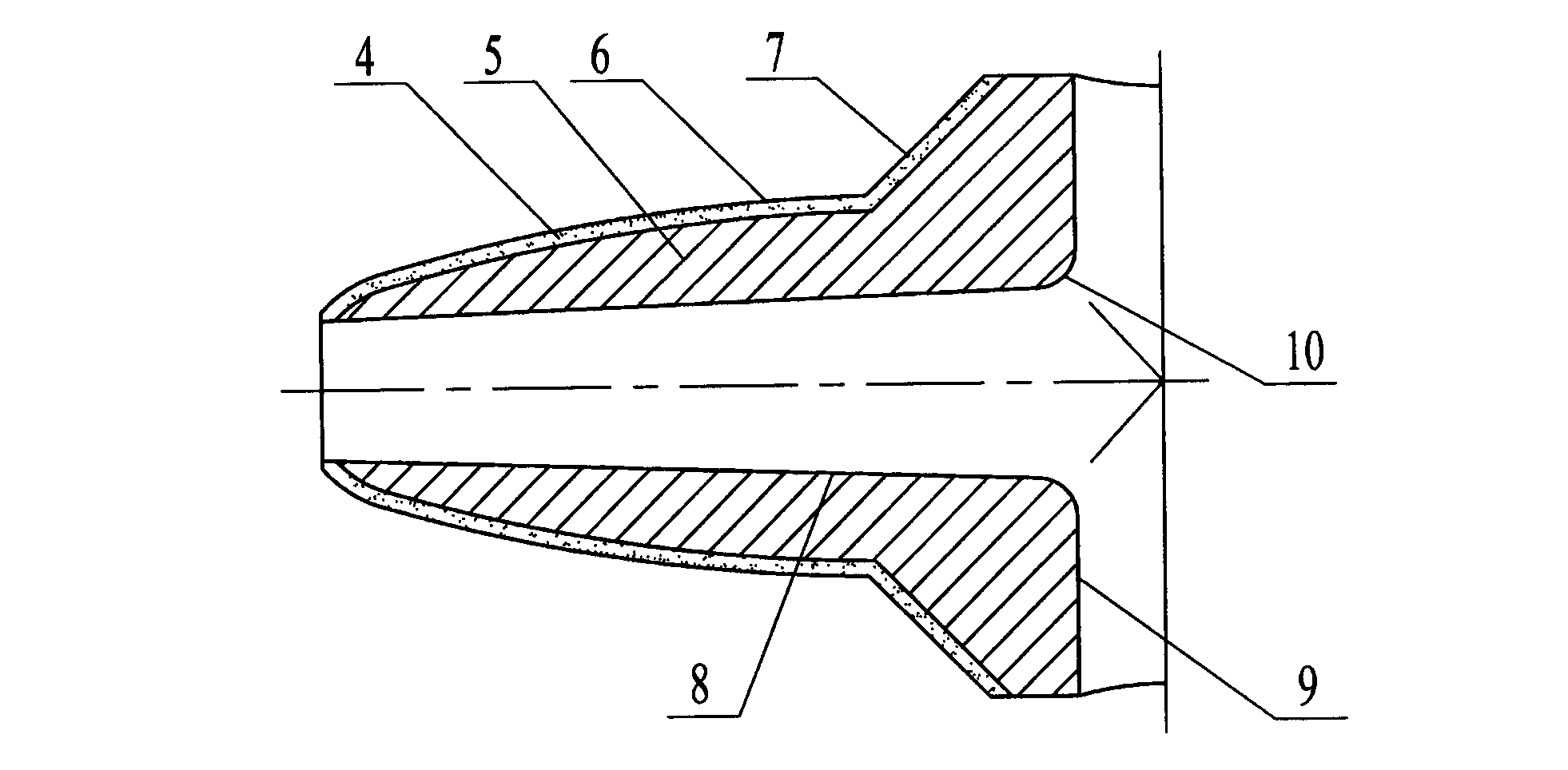

[0026] Such as figure 2 with image 3 As shown, the valve core head 1 includes a valve core surface layer 4 and a valve core head base body 5. The valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com