Particle jet impact pipe cleaning device

A technology of jet impact and pipeline cleaning, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of pipeline wall damage, poor effect, pipeline corrosion damage, etc., to increase safety and stability performance, improve cleaning efficiency and quality, and quickly and efficiently remove the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing:

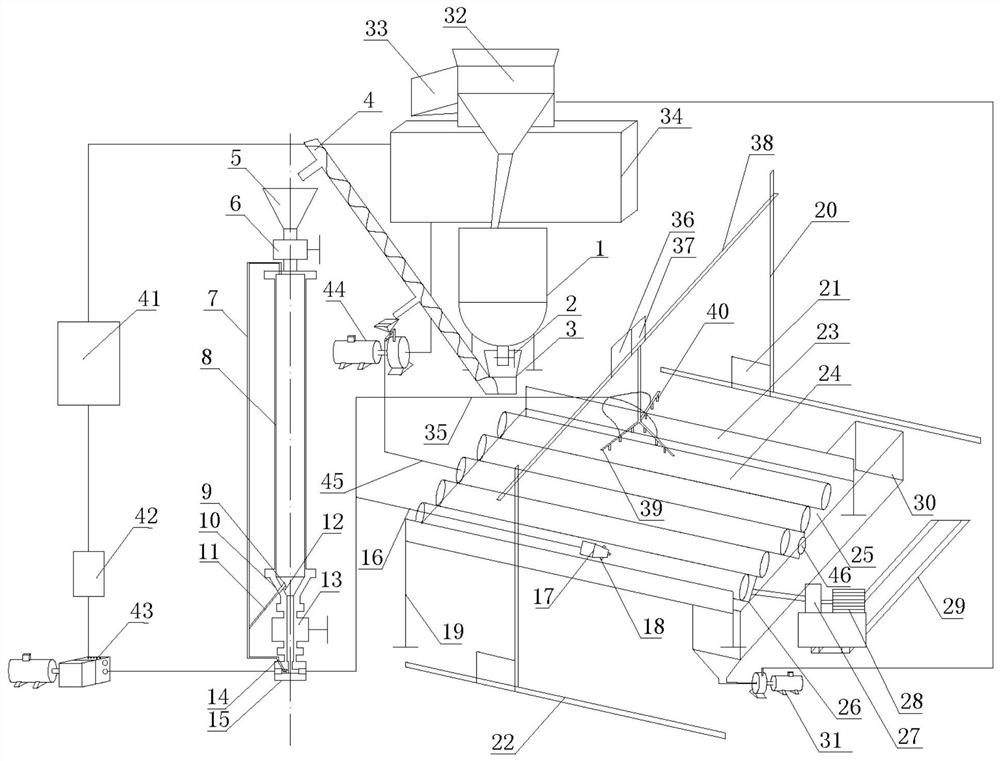

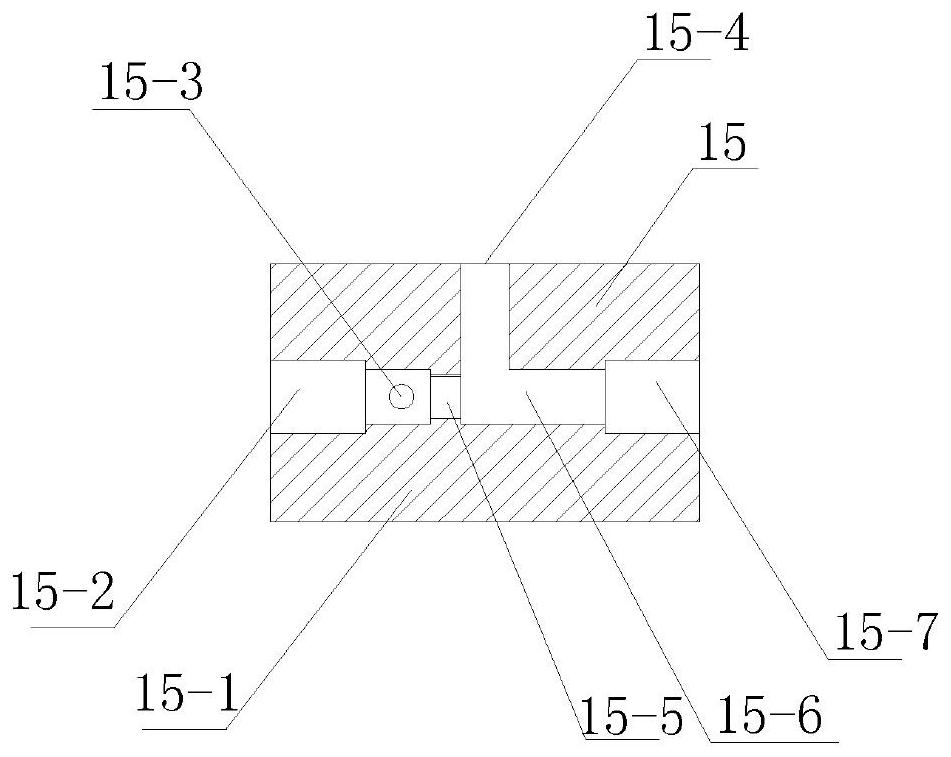

[0015] Such as figure 1 As shown, the particle jet impact pipeline cleaning device of the present invention includes a particle storage tank 1, a control valve 2, a material receiving funnel 3, a screw conveyor 4, a high-pressure cylinder funnel 5, a high-pressure cylinder inlet valve 6, and a pressure balance pipeline 7 , high-pressure cylinder 8, nozzle cover 9, primary mixing chamber 10, liquid supply pipeline 11, inclined nozzle 12, high-pressure cylinder outlet valve 13, diversion pipeline 14, secondary mixing chamber 15, internal washing high-pressure pipeline 16, nozzle 17, internal washing Nozzle 18, pipe support 19, vertical support 20, vertical support driver 21, outer washing track 22, baffle plate 23, pipe 24, bottom surface 25, conversion joint 26, reducer 27, rotating device 28, ground track 29 , receiving box 30, circulating slurry pump 31, magnetic separato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com