Balance disc used in solid-liquid two-phase flow conveying

A technology of balance disk and phase flow, which is applied to the components of pumping devices for elastic fluids, liquid fuel engines, non-variable pumps, etc. Set vibration and noise and other problems to achieve the effect of reducing cavitation damage, prolonging service life and reducing mechanical wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with drawings and embodiments.

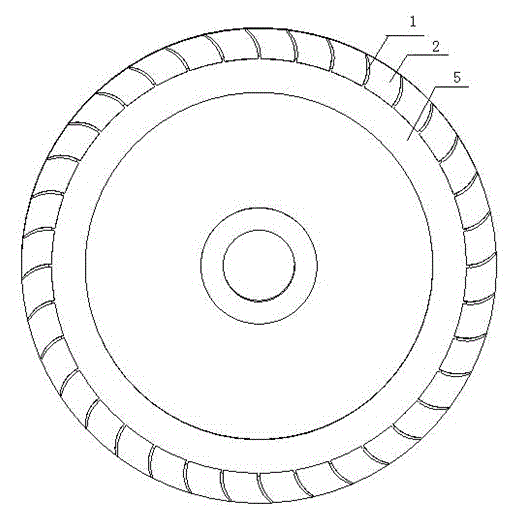

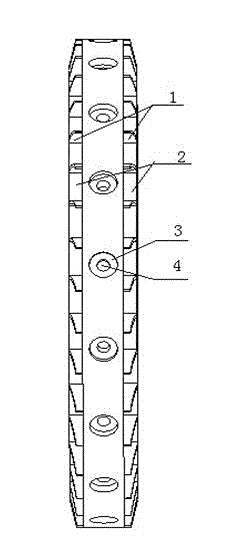

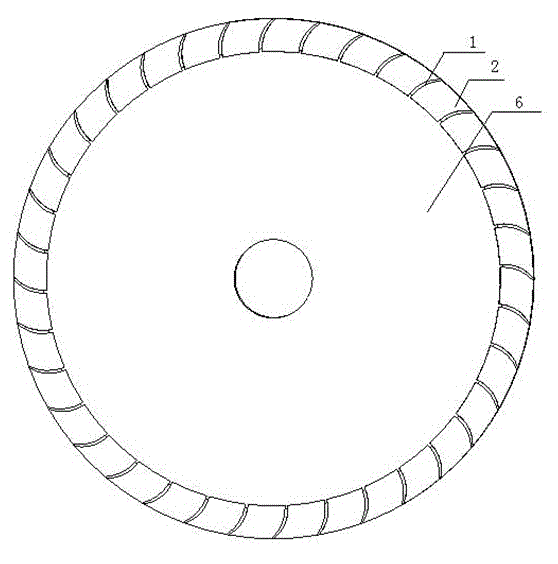

[0025] like figure 1 , image 3 As shown, the peripheral surfaces on both sides of the balance disk are the working surface and the non-working surface respectively, one side of the working surface of the balance disk is provided with an annular convex surface 5, and the edges of the peripheral surfaces on both sides of the balance disk are provided with blades 1 evenly spaced along the circumference, The blades 1 on both sides are located on the same plane as the circumferential surfaces on both sides, and there is a notch between two adjacent blades 1, such as figure 2 , Figure 4 As shown, blind holes are evenly distributed on the side of the cylinder of the balance plate, and the blind holes on both sides symmetrically in the center of the balance plate are equipped with bolts 7 for adjusting the counterweight of the balance plate, and spring plates 8 are install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com