A porous oil nozzle for oil and gas well testing

A technology for oil and gas wells and nozzles, which is used in wellbore/well components, wellbore/well valve devices, and earth-moving drilling. It can solve problems such as equipment damage and safety hazards, high replacement costs, and environmental pollution. Effects of floor area, high throttling differential pressure, simplified complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

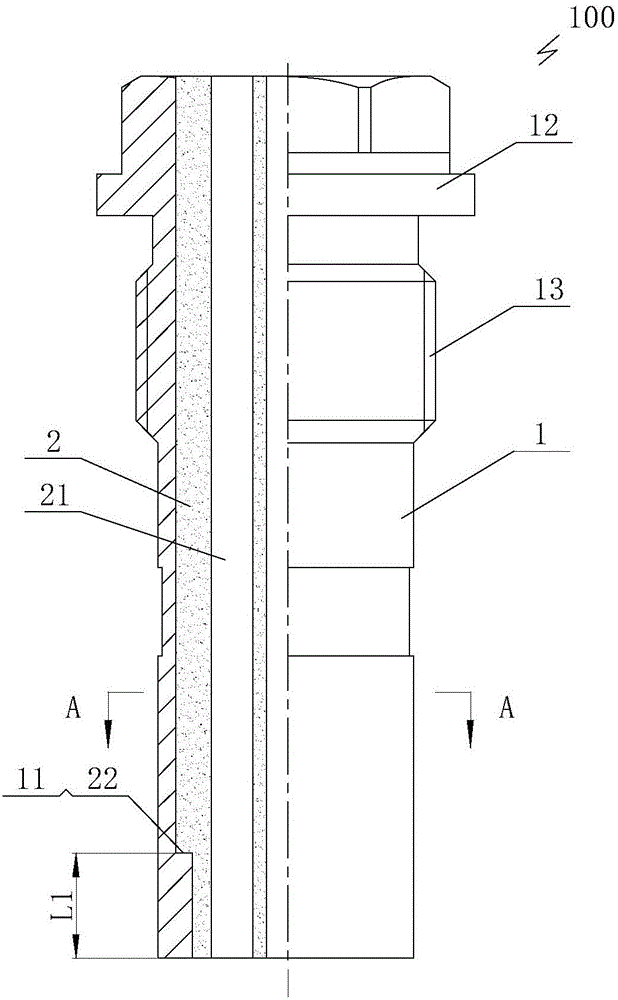

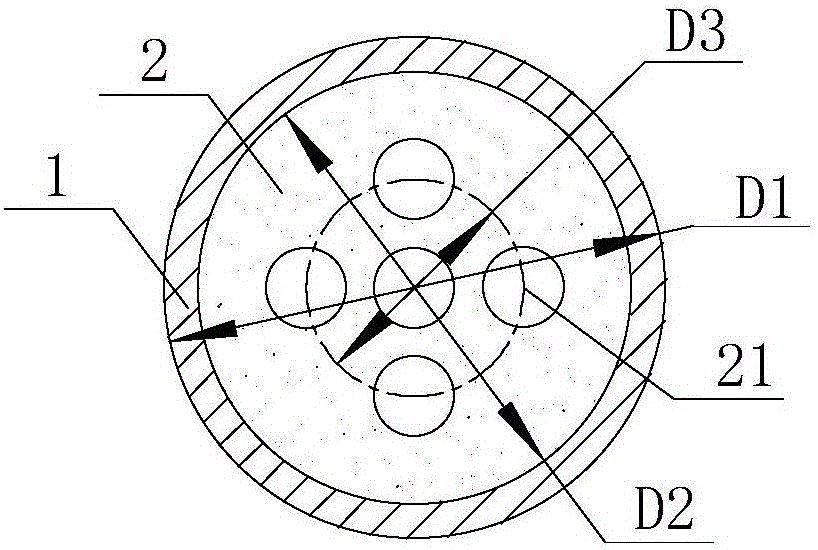

[0031] Such as figure 1 , figure 2 As shown, the porous nozzle 100 for oil and gas well testing provided by the present invention includes a hollow nozzle outer sleeve 1, the inner sealing of the nozzle outer sleeve 1 is fixedly provided with a nozzle inner core 2, and the nozzle inner core 2 is provided with a plurality of Inner core channels 21 that penetrate up and down and are arranged in parallel. Generally, the top end of the inner core channel 21 is the inlet end, and the bottom end of the inner core channel 21 is the outlet end. The inner core channels 21 have a small diameter and are arranged according to certain rules. In this embodiment, the ratio range of the sum of the flow cross-sectional areas of the multiple in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com