A kind of anti-cavitation microstructure surface layer

A technology of surface layer and microstructure, applied in mechanical equipment, fluid flow and other directions, can solve the problems of reduced efficiency and failure of turbine machinery, and achieve the effect of good anti-cavitation effect, convenient processing and reduction of cavitation damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

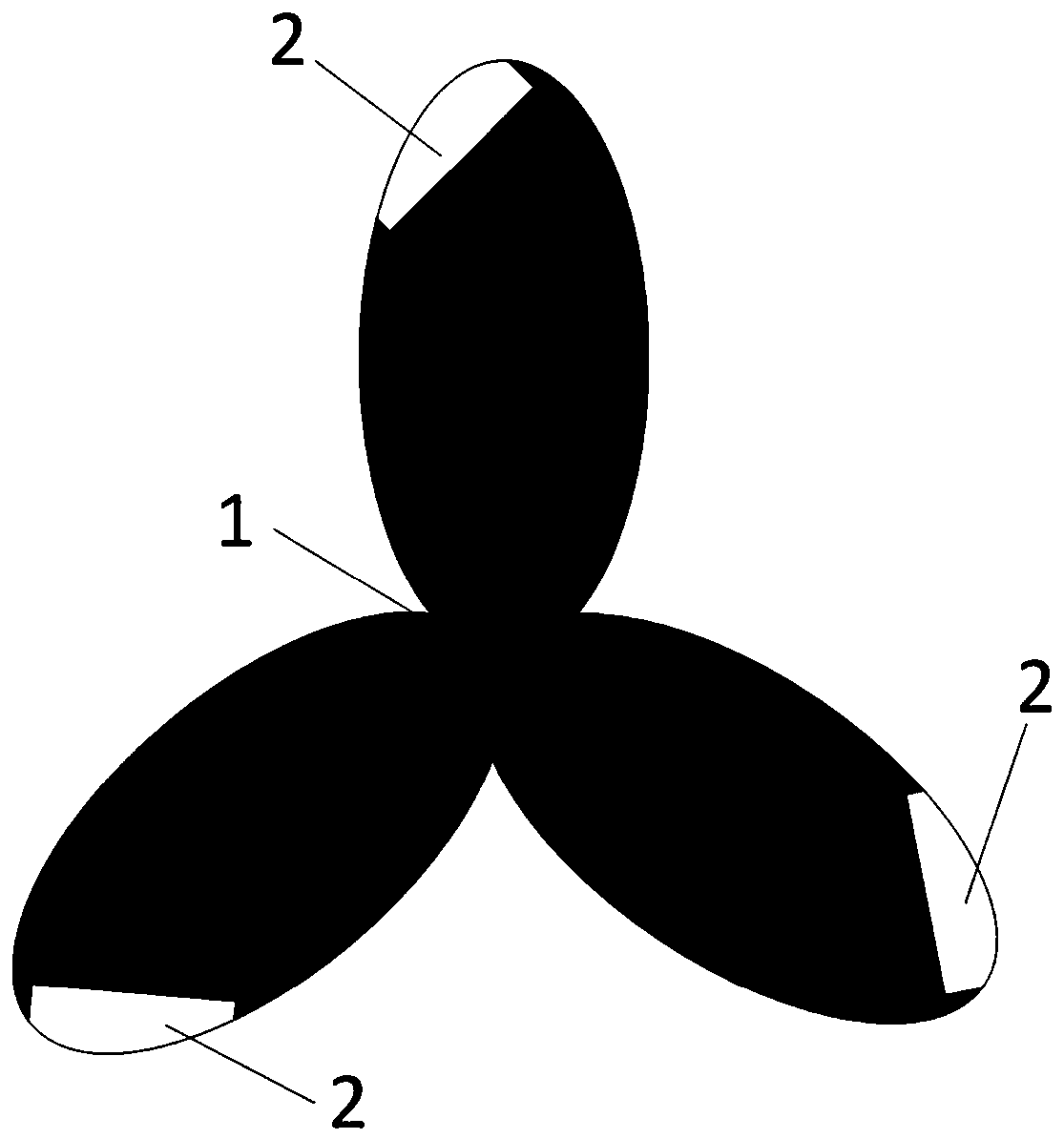

[0031] Such as figure 1 and image 3 As shown, the surface layer includes a base and microprotrusions disposed on the surface of the base. The base 1 is a propeller, and columnar micro-protrusions are arranged on the surface of the lowest pressure part of the propeller, which is away from the direction of the incoming flow.

[0032] During the implementation, the water flow is impacted and passed through the valve core. After testing, it is found that:

[0033] In the absence of microprotrusions, the cavitation bubble collapsing jet forms cavitation erosion towards the propeller surface.

[0034] When micro-protrusions exist, the cavitation bubble-collapsing jet deviates from the elastic surface of the propeller, avoiding cavitation erosion.

Embodiment 2

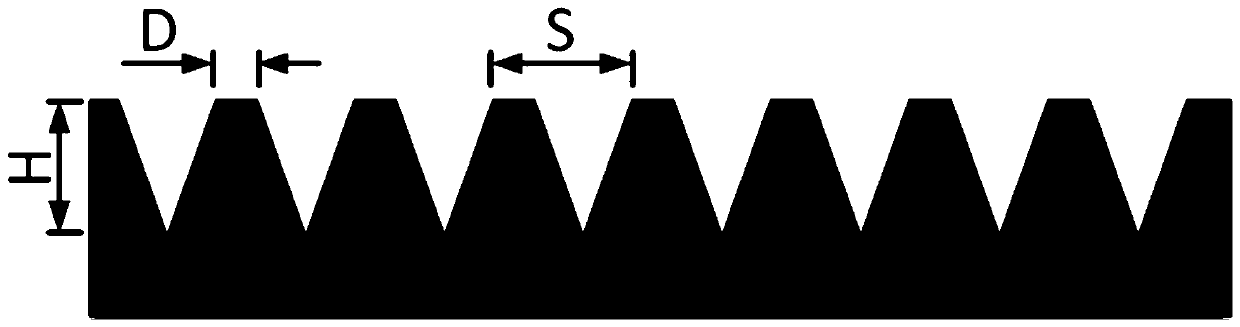

[0036] Such as figure 2 and Figure 4 As shown, the surface layer includes a substrate and microgrooves disposed on the surface of the substrate. The base 1 is a valve core, and an inverted triangular micro-groove is provided on the surface of the valve core where the pressure is the lowest.

[0037] During the implementation, the water flow is impacted and passed through the valve core. After testing, it is found that:

[0038] When the microgroove does not exist, the cavitation bubble collapse jet flows towards the surface of the valve core to form cavitation erosion.

[0039] When micro-grooves exist, the cavitation bubble collapse jet deviates from the elastic surface of the valve core to avoid cavitation erosion.

[0040] From this implementation, it can be seen that the present invention greatly reduces the velocity of the micro-jet when the cavitation bubble collapses, and even changes the direction of the micro-jet away from the surface of the structure, thereby ef...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com