Discharge chute with projections

A technology of protruding body and chute, which is applied in the field of chute of drainage structures in water conservancy and hydropower projects, can solve problems such as cavitation damage and erosion damage, reduce energy dissipation and anti-scouring pressure, increase frictional resistance, and improve flood discharge safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

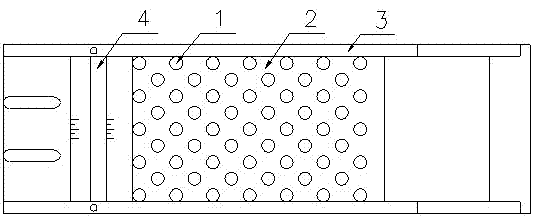

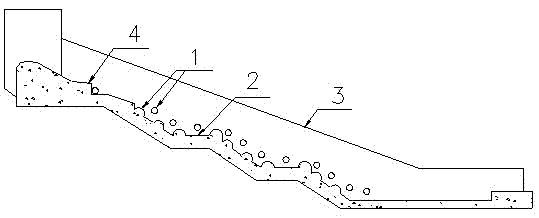

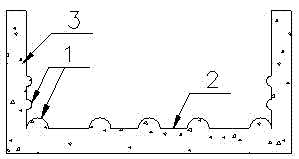

[0013] Such as Figure 1-Figure 3 As shown, an embodiment of the present invention includes a base plate 2 and side walls 3 on both sides of the base plate. Streamlined, the height of the protrusions is 0.5m-2.0m, the protrusions 1 are arranged in a staggered manner; the average slope of the bottom plate 2 is 5-60 0 ; The aeration and corrosion reduction facility 4 is connected to the upstream end of the bottom plate 2;

[0014] The size of the protrusion 1 should be determined according to the hydraulic conditions of the chute. When a hemispherical protrusion is used, the ratio of the hemispherical height to the diameter of the bottom circle can be controlled between 1:2 and 1:8; the longitudinal distance between the protrusions 1 Or the lateral spacing can be controlled between 2 to 8 times the diameter of the hemispherical bottom circle to obtain the maximum roughness value, and the roughness value can be controlled between 0.04 and 0.12; The body can be directly installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com