Facility for eliminating negative pressure of bottom plate at torrent diffusion slope-variable section of flood discharging tunnel

A flood tunnel and bottom plate technology, applied in water conservancy projects, sea area engineering, coastline protection, etc., can solve problems such as damage to the bottom plate of the flood discharge tunnel and affecting the safety of discharge structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Embodiments of the present invention are given below in conjunction with drawings and drawings, and the present invention will be further described through the embodiments. What needs to be specially explained here is that the specific implementation of the present invention is not limited to the forms in the examples. According to the disclosure of the present invention, those skilled in the art can also implement in other specific ways. Therefore, the implementation examples It should not be understood as a specific embodiment that the present invention can only implement.

[0055] Engineering example

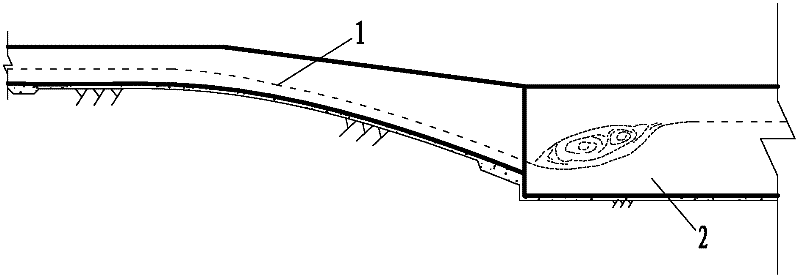

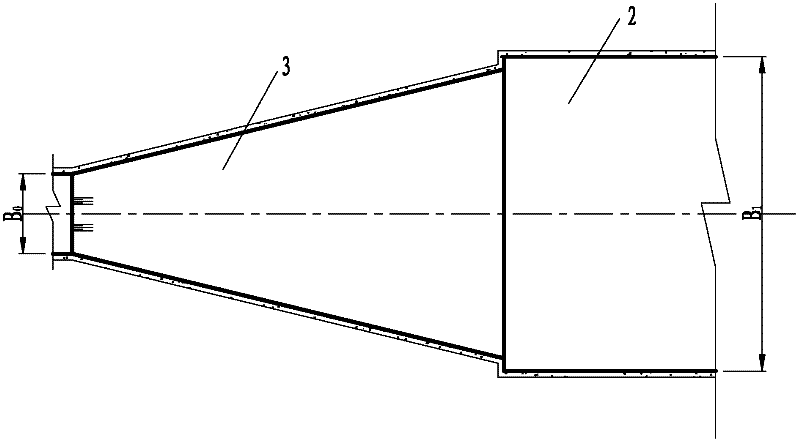

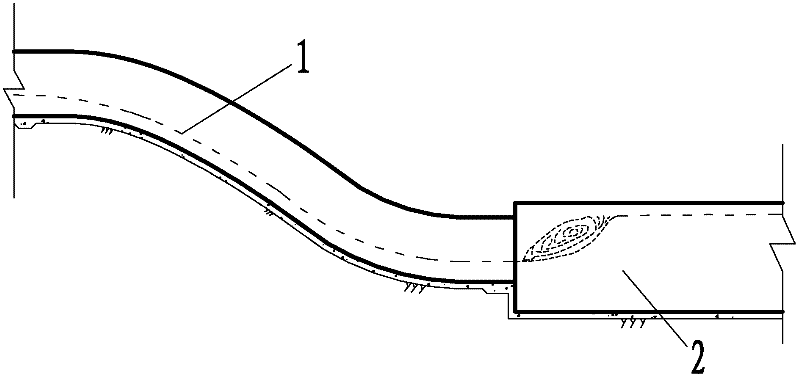

[0056] The example of this project is a flood discharge tunnel on the bank of a large power station. The outlet stilling basin is in the form of falling sill bottom flow energy dissipation, and the bottom plate of the rapid flow diffusion and slope section is parabolic. The parabolic equation is Such as Figure 5 As shown, when there is no flat pressure facility in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com