Anti-cavitation erosion adjusting valve capable of cutting

A technology for regulating valves and anti-cavitation, which is applied in the direction of lifting valves, valve details, valve devices, etc., can solve the problems of unavoidable cavitation, cavitation cannot be prevented, and high cost, so as to eliminate cavitation and ensure sealing performance , The effect of simple internal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with drawings and embodiments.

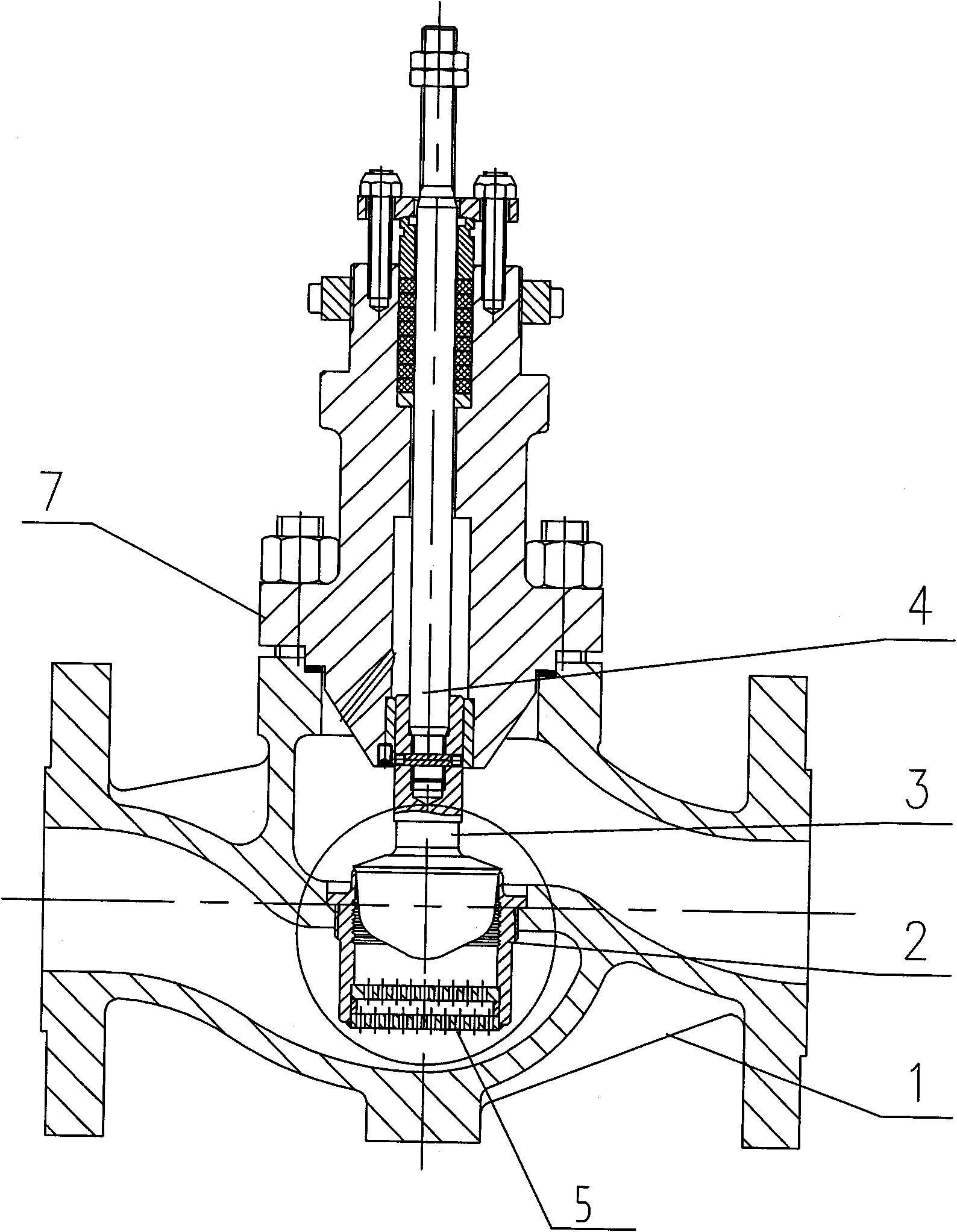

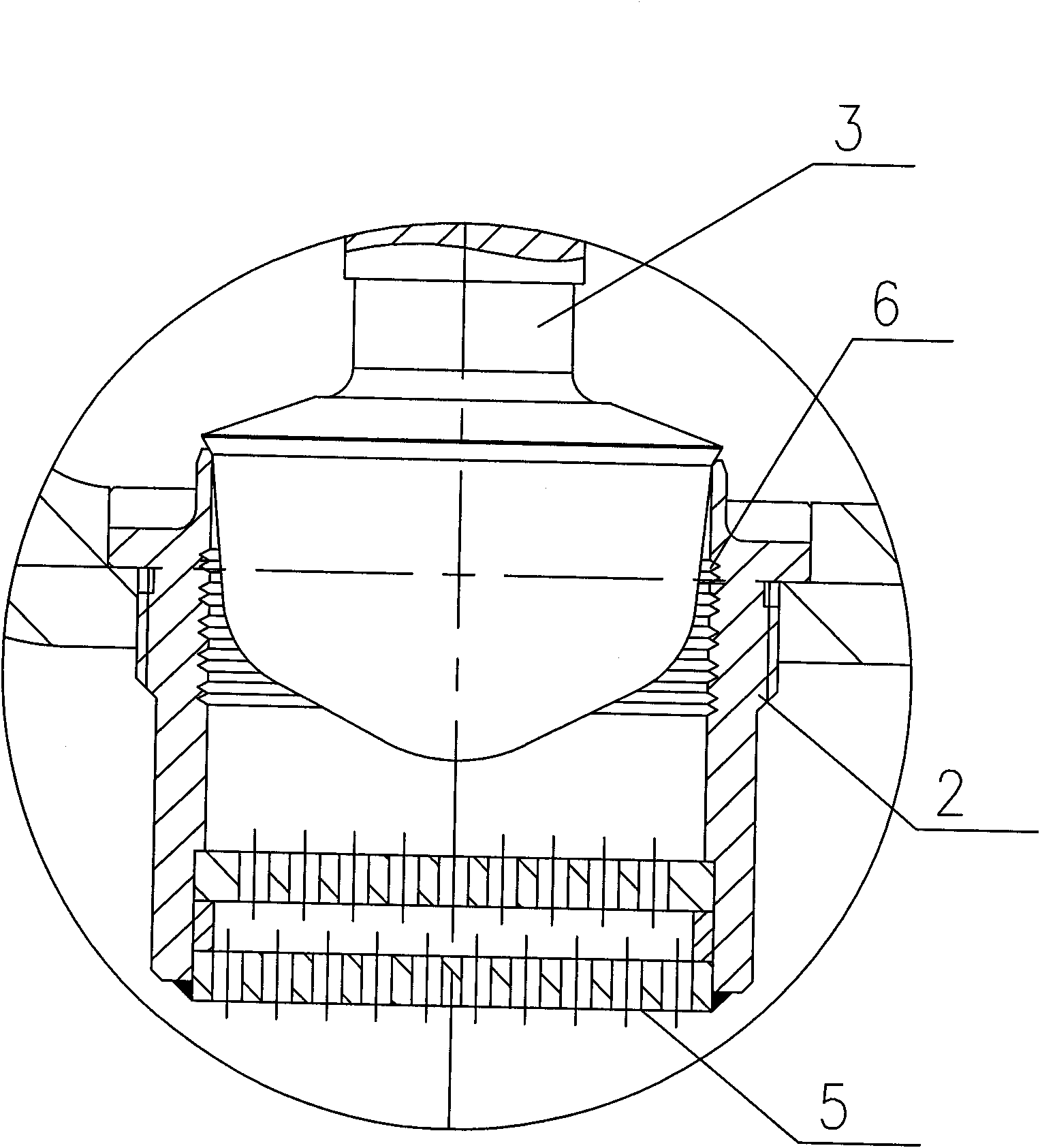

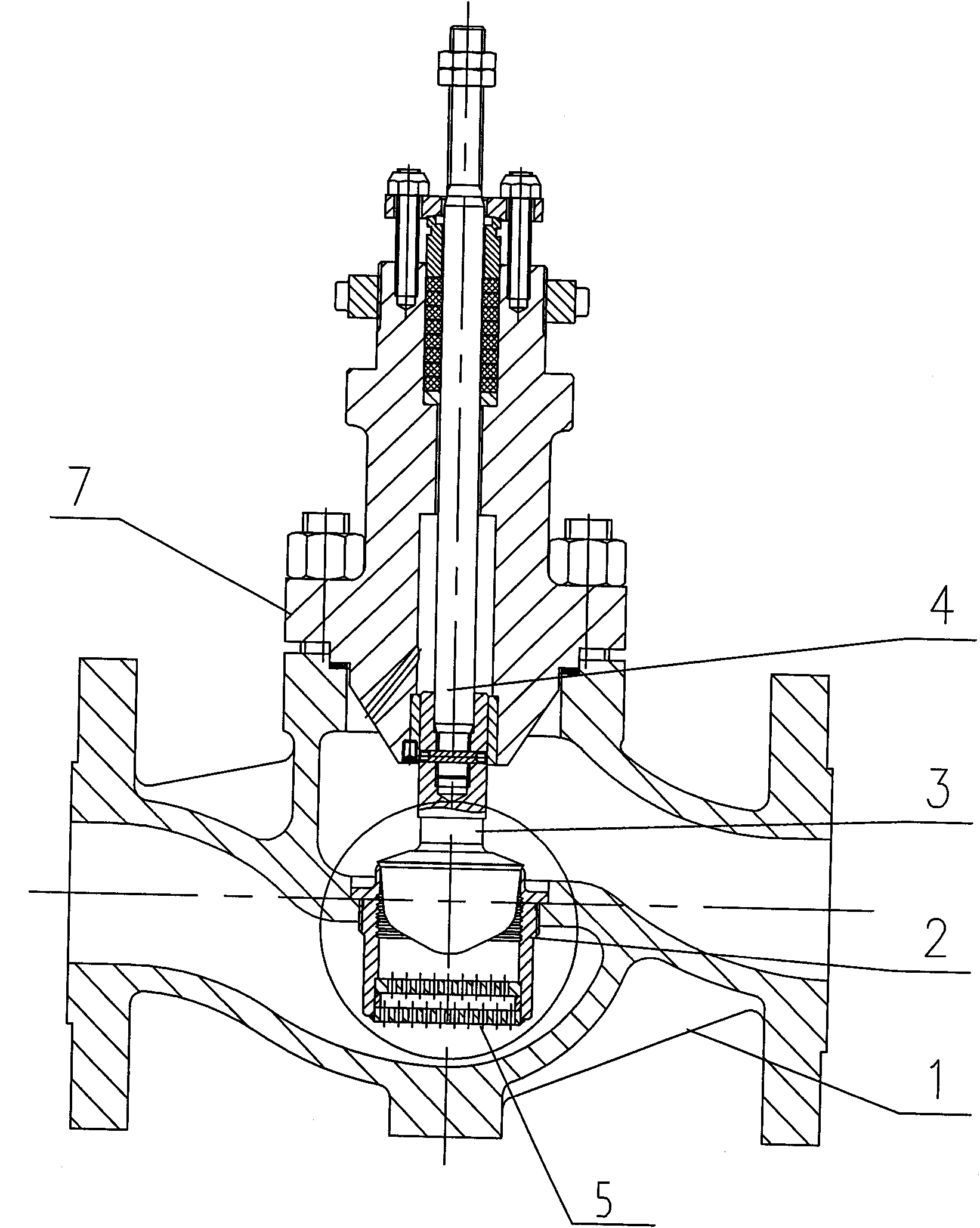

[0014] Such as figure 1 , 2 As shown, the present invention comprises valve body 1, valve seat 2, valve core 3 and valve stem 4, and valve seat 2 is screwed in the seat hole of valve body 1, and valve stem 4 is screwed in the valve stem hole of valve core 3 and valve core 3 fastening, the sealing surface of the valve seat 2 has a sharp cut, and the upper side of the valve core sealing surface of the valve core assembly 3 also has a sharp cut, the sealing surface of the valve core is in close contact with the sealing surface of the valve seat 2; the lower part of the valve seat 2 is set There are two or more layers of throttling orifice plates 5 parallel to each other, and the throttling orifice plates 5 are densely covered with small holes. The valve stem 4 and the valve core 3 are assembled in the upper cover 7 . The upper end of the valve stem is equipped with a pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com