Rotating scaling type abrasion-cavitation erosion coupling test method and device

A test method and technology of test equipment, which are applied in the field of rotary scaling type abrasion-cavitation coupling test, can solve the problems of high power consumption, large size of the device, low wear efficiency, etc. low heat effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Embodiments are given below in conjunction with the accompanying drawings and the present invention is described in detail. It is necessary to point out that the following examples are only used to further illustrate the present invention, and can not be interpreted as limiting the protection scope of the present invention, some non-essential improvements made by those skilled in the art according to the content of the present invention above And adjustments still belong to the protection scope of the present invention.

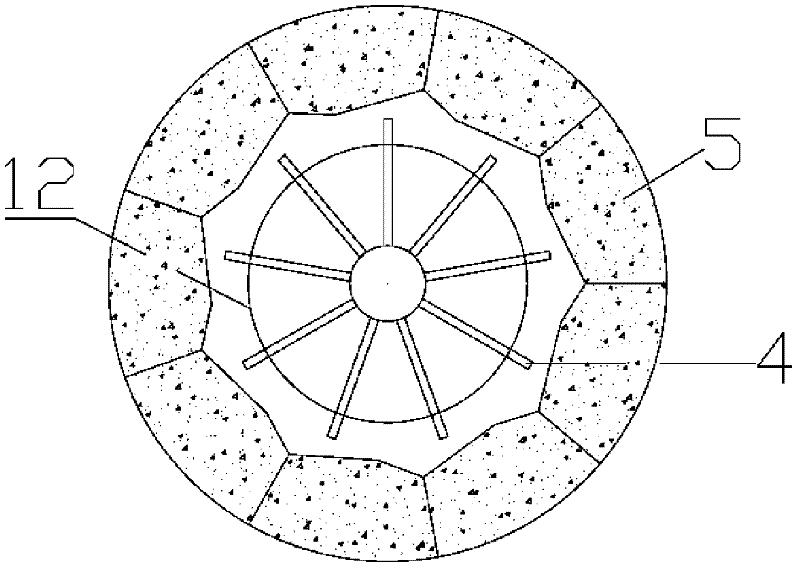

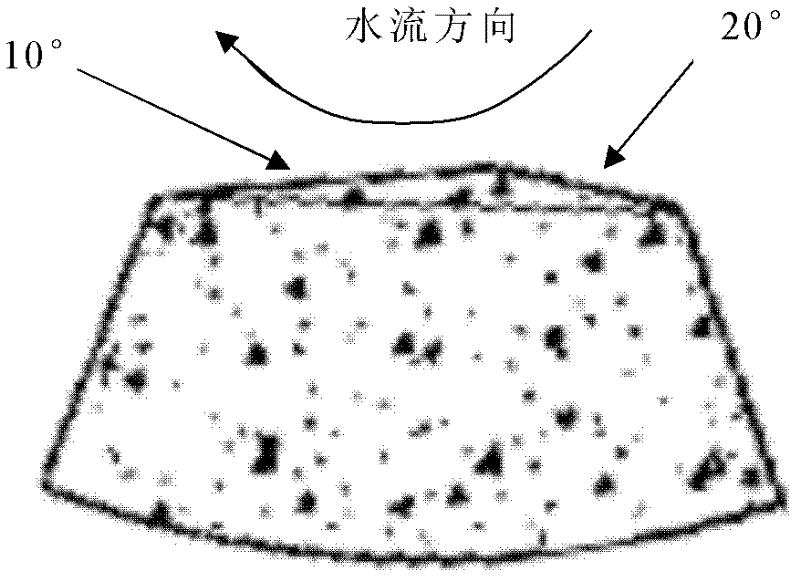

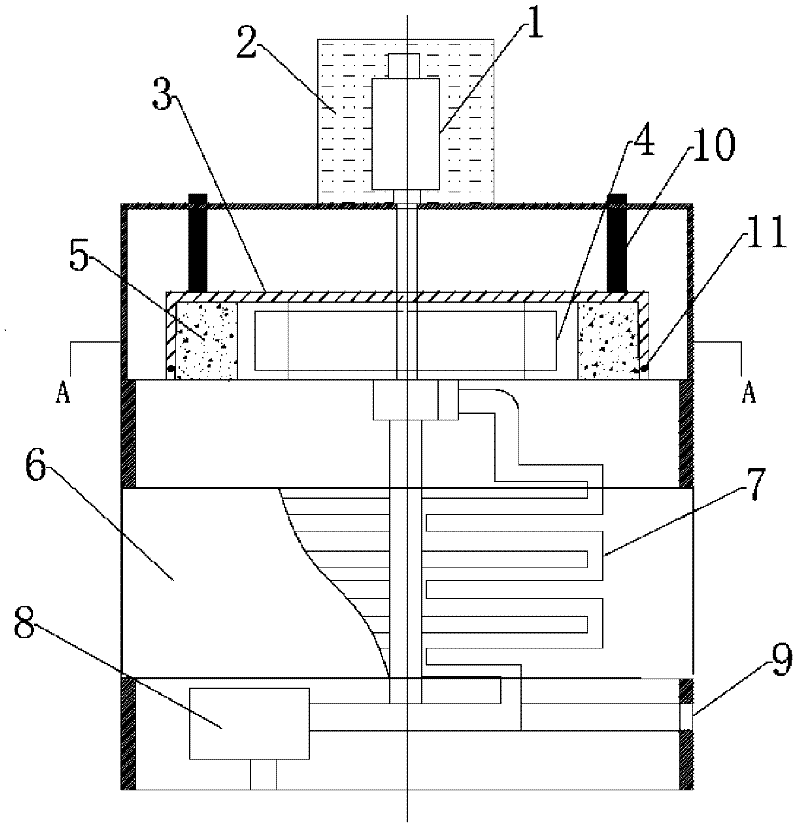

[0044] Such as figure 1 As shown, the inner edge of the test piece 5 provided in this embodiment is protruding, and the side lengths on the left and right sides of the protuberance are different, and the included angle is as shown in the attached figure 2 As shown, the inner side of the tested object 5 cooperates with the rotating water jet sand impeller 4 to form a zoom-type water flow channel.

[0045] The rotary scaling type abrasion-cavitation c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com