Cavitation erosion test equipment for testing material performance and test method thereof

A cavitation cavitation erosion and material performance technology, applied in the analysis of materials, instruments, etc., can solve problems such as difficult operation and maintenance, complex test process, and insufficient simulation level, and achieve stable cavitation cavitation test performance and simple process operation , the effect of a small number of working parts

Inactive Publication Date: 2011-09-07

DALIAN MARITIME UNIVERSITY

View PDF5 Cites 19 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The research on cavitation and cavitation erosion performance evaluation of materials is mainly based on indoor experiments. The research on existing cavitation and cavitation equipment shows that the common problem of this type of equipment is the cavitation and cavit

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

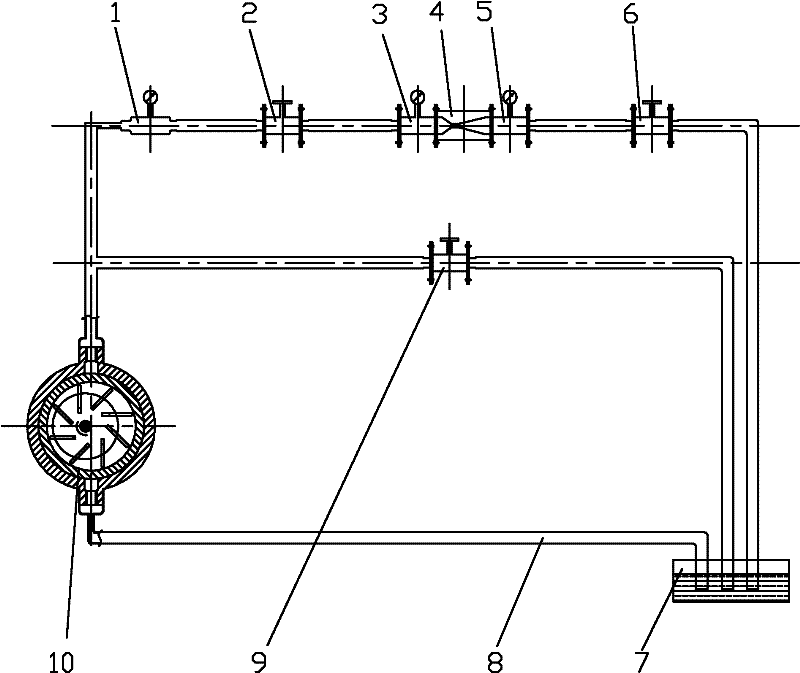

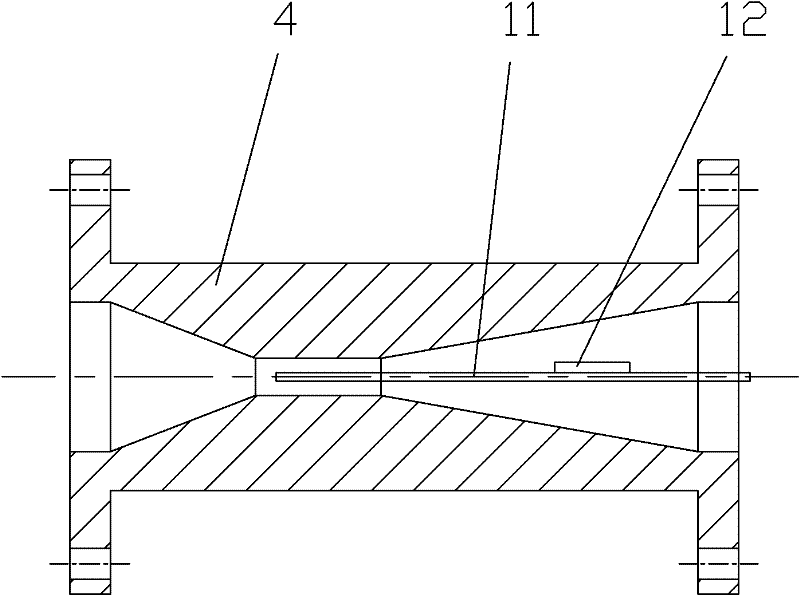

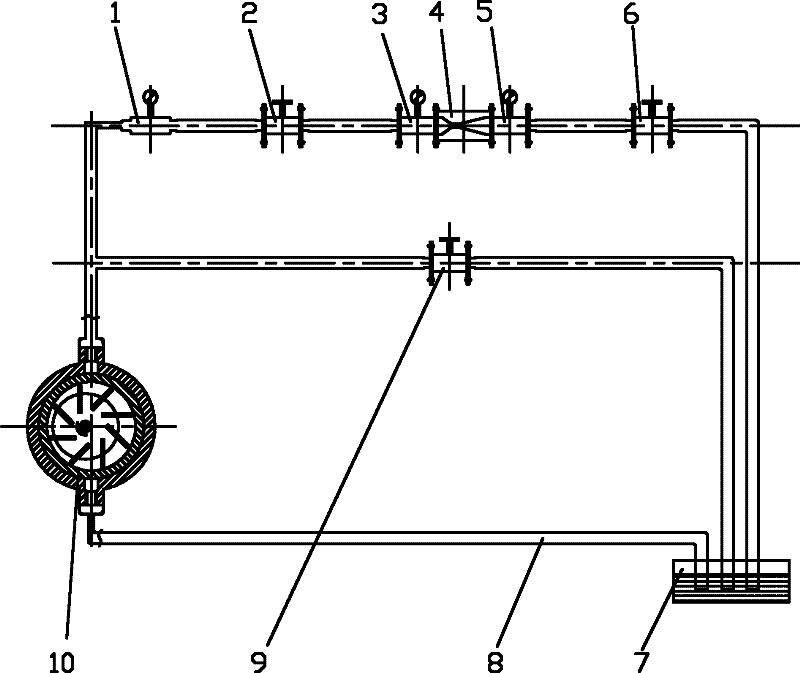

The invention discloses cavitation erosion test equipment for testing material performance and a test method thereof, wherein the equipment comprises a Venturi tube, a water tank, a centrifugal pump, a pipe system, a pressure meter A, a pressure meter B, a flow meter, a flow regulation valve A, a flow regulation valve B and a flow regulation valve C, wherein the front end of the Venturi tube is respectively connected with the pressure meter A, the flow regulation valve A, the flow meter, the centrifugal pump and the water tank through the pipe system in sequence; and the rear end of the Venturi tube is respectively connected with the pressure meter B, the flow regulation valve B and the water tank through the pipe system in sequence. The flow regulation valve A and the flow regulation valve B are regulated so that an inlet end and an outlet end of the Venturi tube has a certain pressure difference, and cavitation phenomena occur at the tail end of the neck part of the Venturi tube and the front part of an outlet taper angle. The test method is closer to the generating process of the cavitation erosion in fluid under the actual working conditions. The equipment disclosed by the invention needs few workpieces and has low cost, simple operation process and stable performance in the cavitation test.

Description

Technical field [0001] The invention relates to a material performance test technology, in particular to a cavitation cavitation test equipment and a test method for testing the material performance. Background technique [0002] Cavitation and cavitation are a microscopic, instantaneous, random, and multiphase complex process. They are also one of the main causes of damage to hydraulic machinery, involving instantaneous gas-liquid phase transitions, energy transfer, and material response. Cavitation and cavitation involve many fields, such as aerospace, national defense, navigation, chemical industry, atomic energy, biology and medicine. Therefore, studying the occurrence mechanism of cavitation and cavitation phenomenon and the technical methods to suppress cavitation not only have far-reaching theoretical significance, but also have great practical value. There are currently two test methods used by humans to study the cavitation and cavitation performance of materials: one i...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N7/10

Inventor 张会臣李杰

Owner DALIAN MARITIME UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com