Pressure-regulating grease nipple

A grease nipple and pressure regulating technology, which is applied in the field of lubrication, can solve problems such as lack of oil injection and pressure regulation, and achieve the effect of increasing oil injection pressure and oil output pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

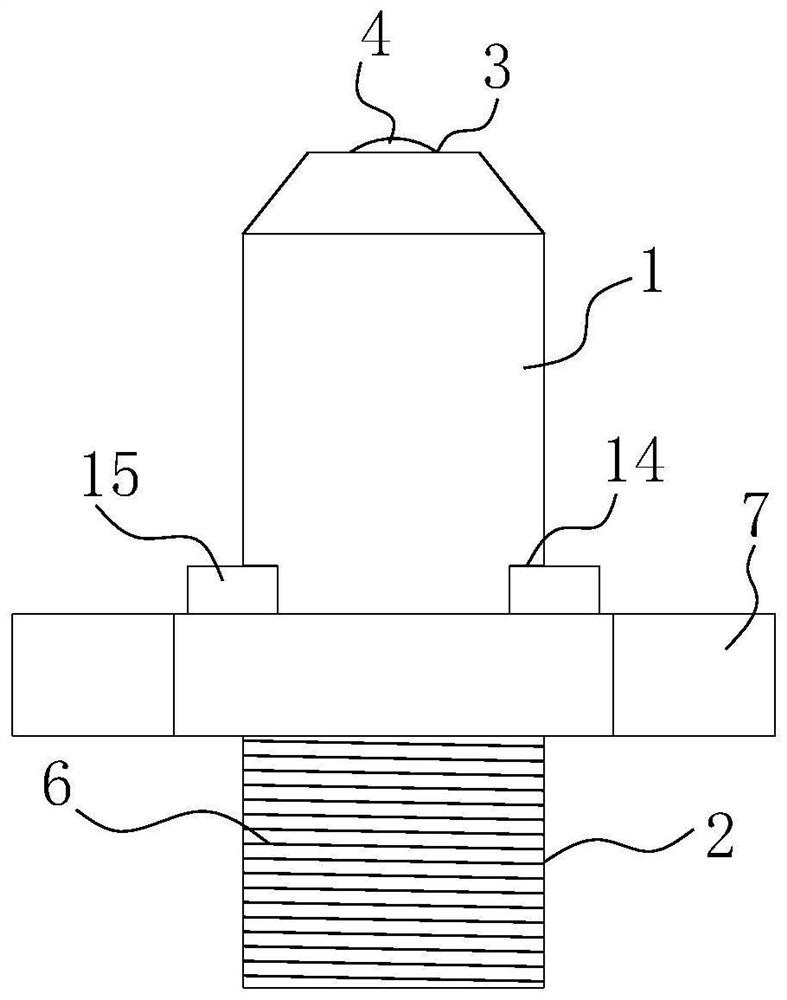

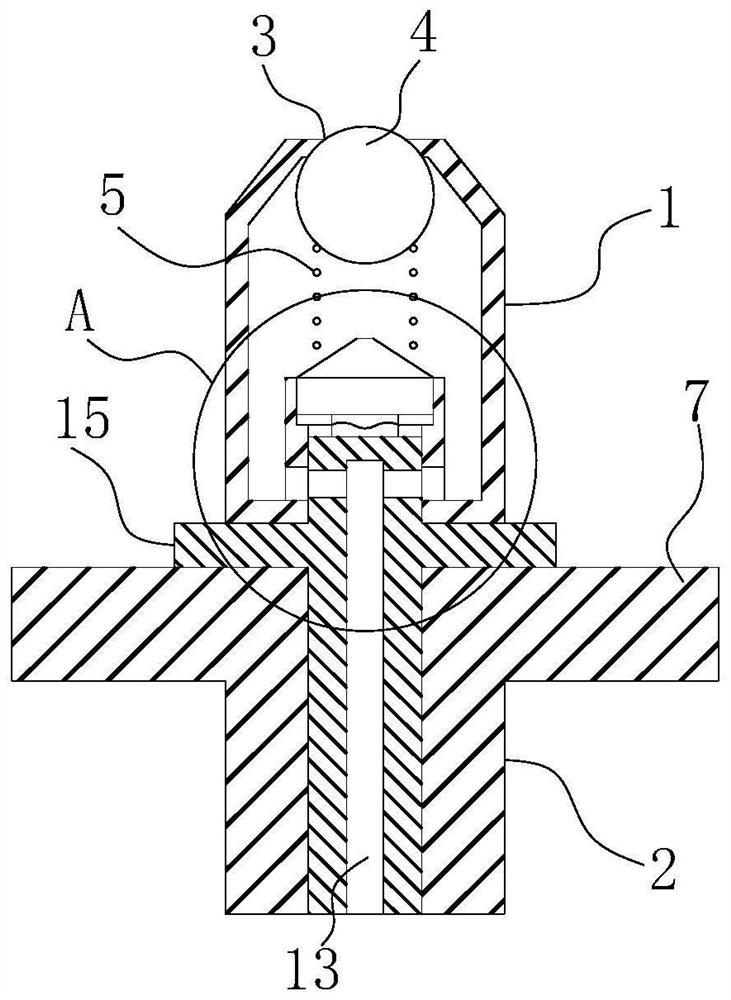

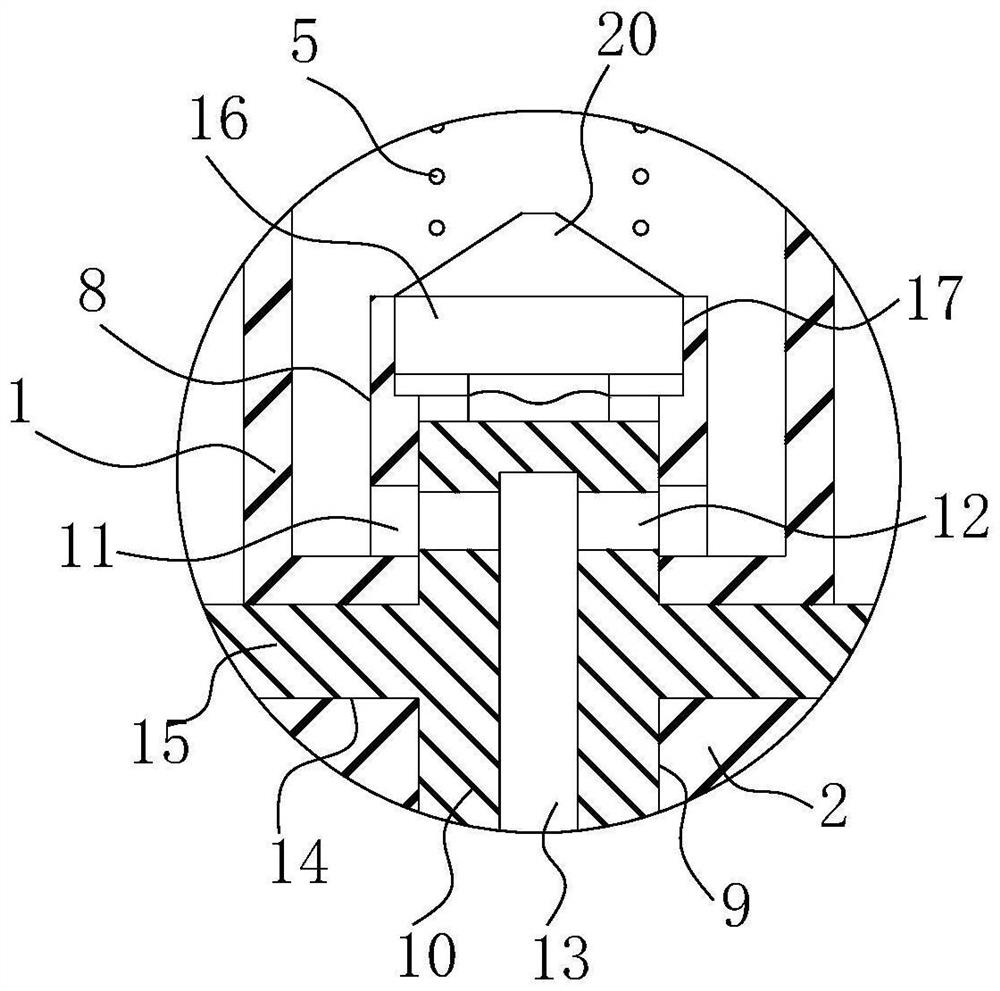

[0024] like Figure 1-7 As shown, a pressure regulating grease nipple includes a grease nipple body, and the body generally adopts a steel body, such as figure 1 and 2 As shown in the figure, the main body is composed of a hollow head section 1 located at the upper part and a root section 2 located at the lower part. The peripheral surface of the lower part of the root section 2 is provided with an external thread 6, and is rooted in the to-be-to-be-threaded 6 through the external thread 6. For the corresponding parts of the lubricating machine, such as joints, bearings, etc., in order to facilitate the installation of the main body, a screwing head 7 is provided on the peripheral surface of the upper part of the root section 2. Generally, the screwing head 7 adopts an external hexagonal screwing head. Hexagon sockets, etc. can realize quick installation and tightening.

[0025] The top of the head section 1 is provided with an oil filling port 3, and the nozzle of the greas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com