An oil injection device for an ultra-high pressure vessel

An oil injection device, ultra-high pressure technology, applied in distribution devices, special distribution devices, liquid distribution, transportation or transfer devices, etc., can solve the problems of container failure, damage, container material yield, etc., to improve reliability and simplify oil injection equipment , The effect of high oil injection pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

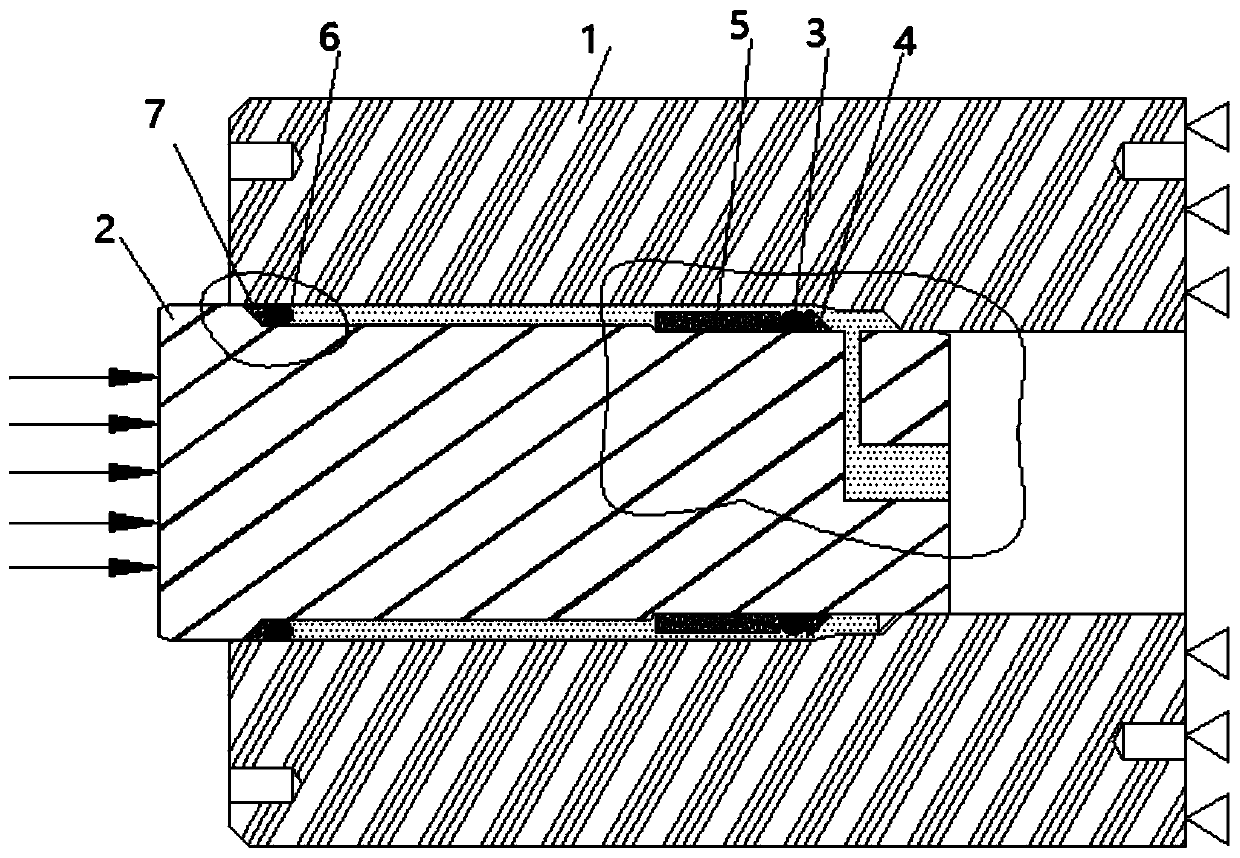

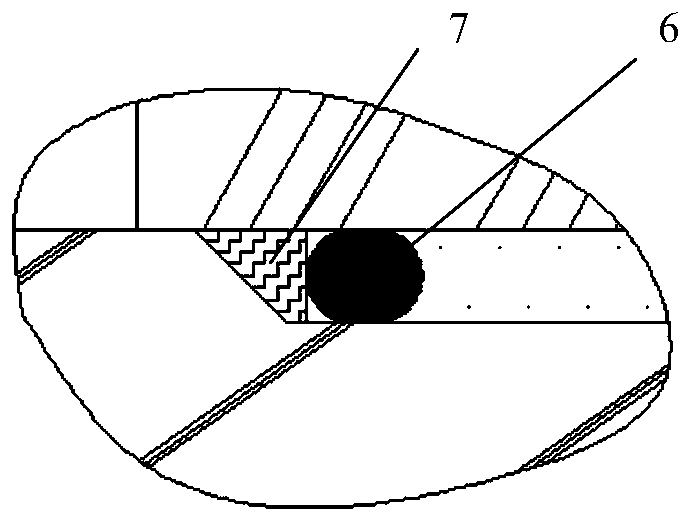

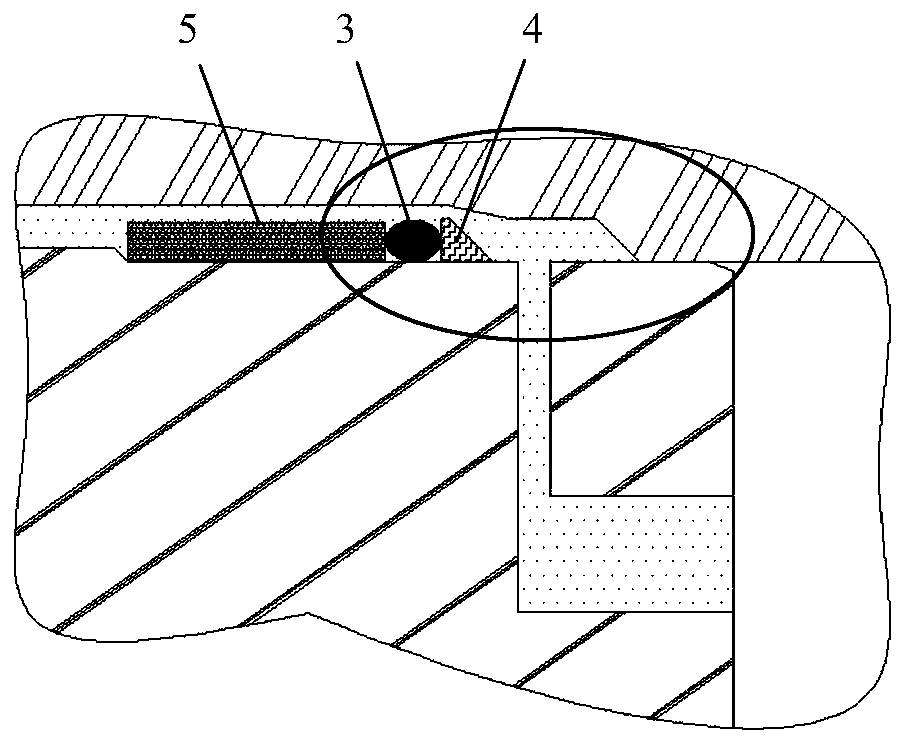

[0023] As an embodiment, the second sealing device includes a first sealing ring 3 and a second sealing ring 4; the first sealing ring is an elastic sealing ring, which acts as a low-pressure sealing; the second sealing ring is a metal sealing ring Ring, which acts as a high-pressure seal; the front end of the third round shaft 2-3 is covered with a first sealing ring 3 and a second sealing ring 4; the second sealing ring 4 is located at the front end of the first sealing ring 3; the third A positioning structure is provided on the round shaft 2-3 to axially position the first sealing ring 3; when pressure is applied to the rear end of the piston rod 2, the second sealing ring 4 is pushed to the second circular hole 1-2 and the third On the stepped surface of the round hole 1-3, the first sealing ring 3 is located in the second round hole 1-2, that is, when the pressure applied to the piston rod 2 is small, the first sealing ring 3 acts as a seal; when the pressure continues to...

Embodiment

[0035] The cylinder body 1 of the present invention does not have any oil injection holes, assuming that the inner diameter of the first round hole 1-1 of the cylinder body 1 is 81mm, and the outer diameter of the cylinder body 1 is 180mm; the diameter of the second round shaft 2-2 of the piston rod 2 is 68mm; Body 1 and piston rod 2 are both hot work die steel, yield strength σ s It is 1542MPa; Utilize ANSYS Workbench software to simulate and analyze the stress distribution state of cylinder body 1 in 500MPa hydrostatic sealing pressure environment, the result shows that the oil injection device of the present invention just does not have the small hole stress concentration problem, as Figure 9 shown; Figure 10 The stress distribution state of the cylinder with oil holes in the traditional technology cylinder, under the same sealing pressure and the same size conditions, the simulation results show that serious stress concentration occurs due to the connection between the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com