Supercharged grease sharp nozzle

A grease nozzle and butter technology, which is applied in the field of pressurized butter tip nozzles, can solve problems such as waste, grease leakage, and environmental pollution, and achieve the effects of saving grease, increasing oil injection pressure, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in detail below with reference to the embodiments and accompanying drawings.

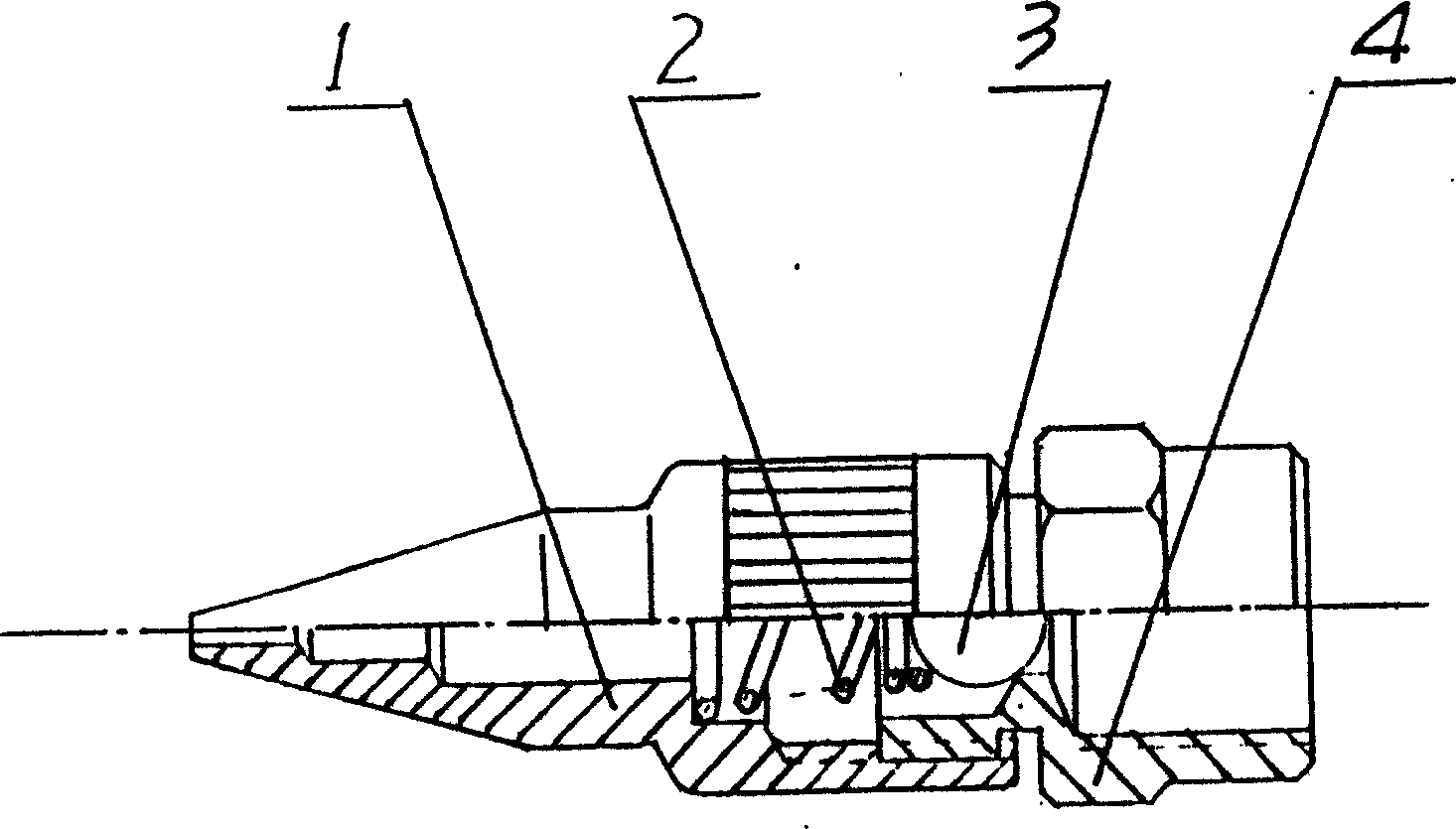

[0013] like figure 1 As shown, it has the external structure of the mouth cover 1, and also has a mouth body 4, and a sealing cut-off mechanism composed of a steel ball 3 and a spring 2, wherein the mouth body 4 and the mouth cover 1 are screwed together; the spring 2 and the steel ball 3 are installed in the mouth In the cover 1, the spring 2 is located on the side of the mouth body 4 close to the mouth, and the steel ball 3 is located on the side of the mouth cover 1;

[0014] The mouth body 7 in the external structure adopts a universal size and pitch interface structure, which is compatible with all kinds of grease guns; the outer side of the mouth cover 1 has straight knurling for easy operation.

[0015] The working process of the present invention is as follows:

[0016] When the oil gun is working, put the tip of the nozzle cover 1 against the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com