A manufacturing process for manufacturing integral stainless steel oil rail forgings

A manufacturing process, stainless steel technology, applied in the manufacturing process field of manufacturing integral stainless steel oil rail forgings, can solve the problems of reduced reliability, thin-walled oil leakage, and the influence of oil rail performance without consideration, etc., to reduce manufacturing unloading , the effect of increasing the difficulty of manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

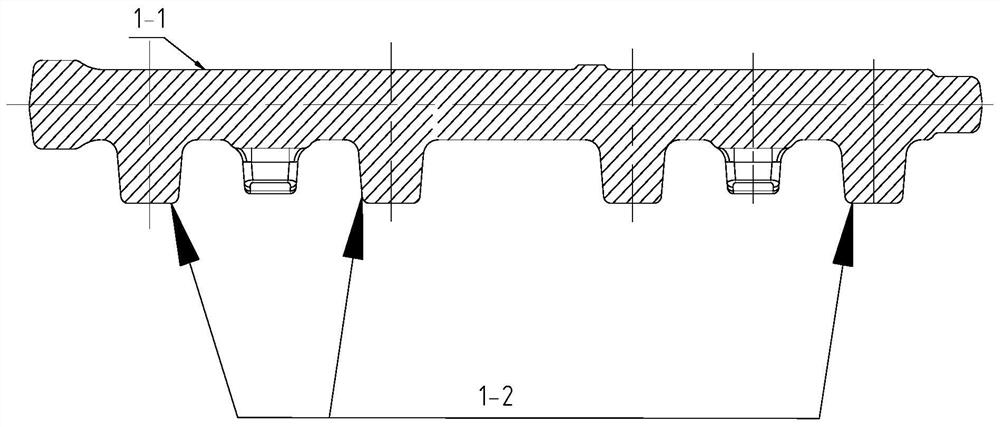

[0042] A stainless steel fuel rail forging of the present invention includes a main pipe part and a fuel injector seat part. The key point is to limit the straightness and position of the main pipe part. more than 1mm.

[0043] Such as Figure 8 As shown, a manufacturing process for manufacturing integral stainless steel oil rail forgings includes the following steps,

[0044] S1 blanking, S2 heating, S3 die forging, S4 trimming, S5 post-forging treatment, among which,

[0045] (1) The trimming correction compound mold increases the deformation compensation amount through the punch, and the compensation amount is ±0.3mm, so as to ensure that the straightness of the long axis is within 0.6mm, and the position degree is within 1mm.

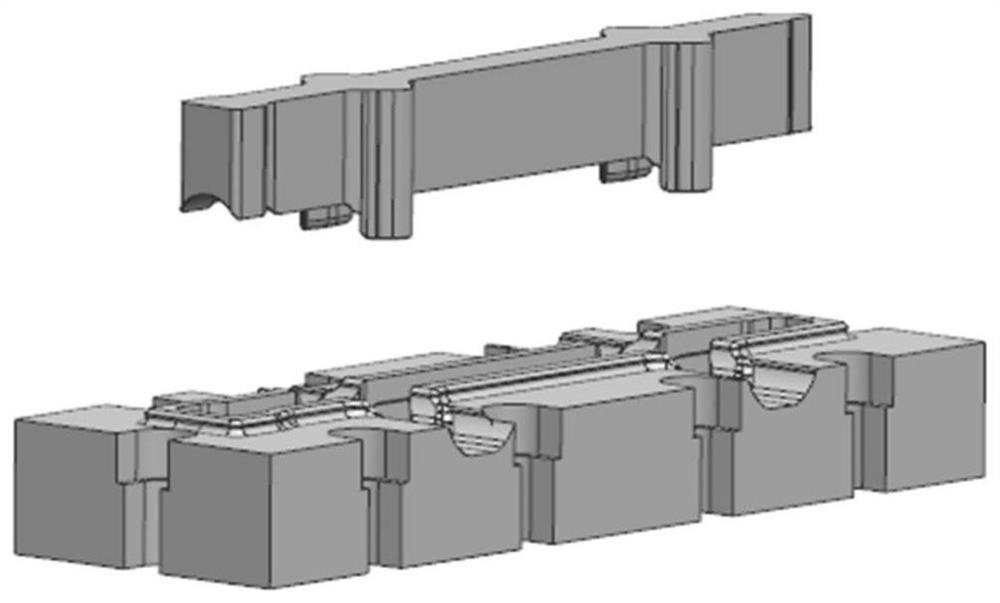

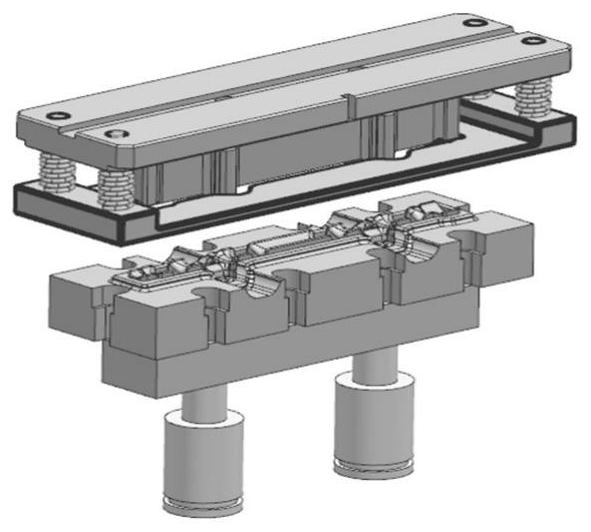

[0046] Among them, the trimming correction compound die structure of stainless steel oil rail forgings includes:

[0047] upper mold assembly,

[0048] The upper mold assembly includes a discharge plate, a punch, a discharge elastic part and a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com