Patents

Literature

77 results about "Grease fitting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A grease fitting, grease nipple, Zerk fitting, or Alemite fitting is a metal fitting used in mechanical systems to feed lubricants, usually lubricating grease, into a bearing under moderate to high pressure using a grease gun.

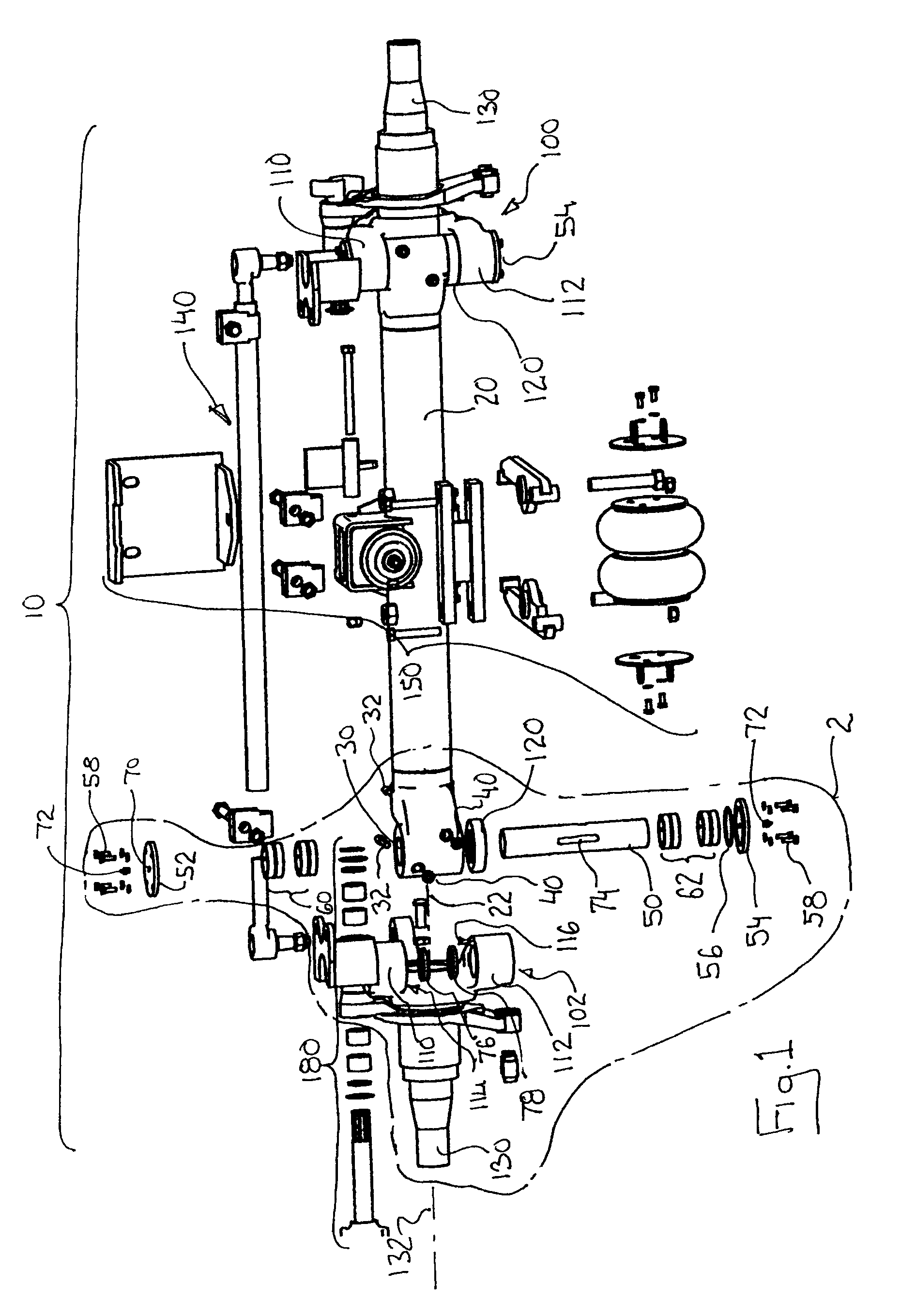

Trailer tongue jack

InactiveUS6926261B1Improve the lubrication effectVehicle fittings for liftingVehicle cleaning apparatusGrease fittingJackscrew

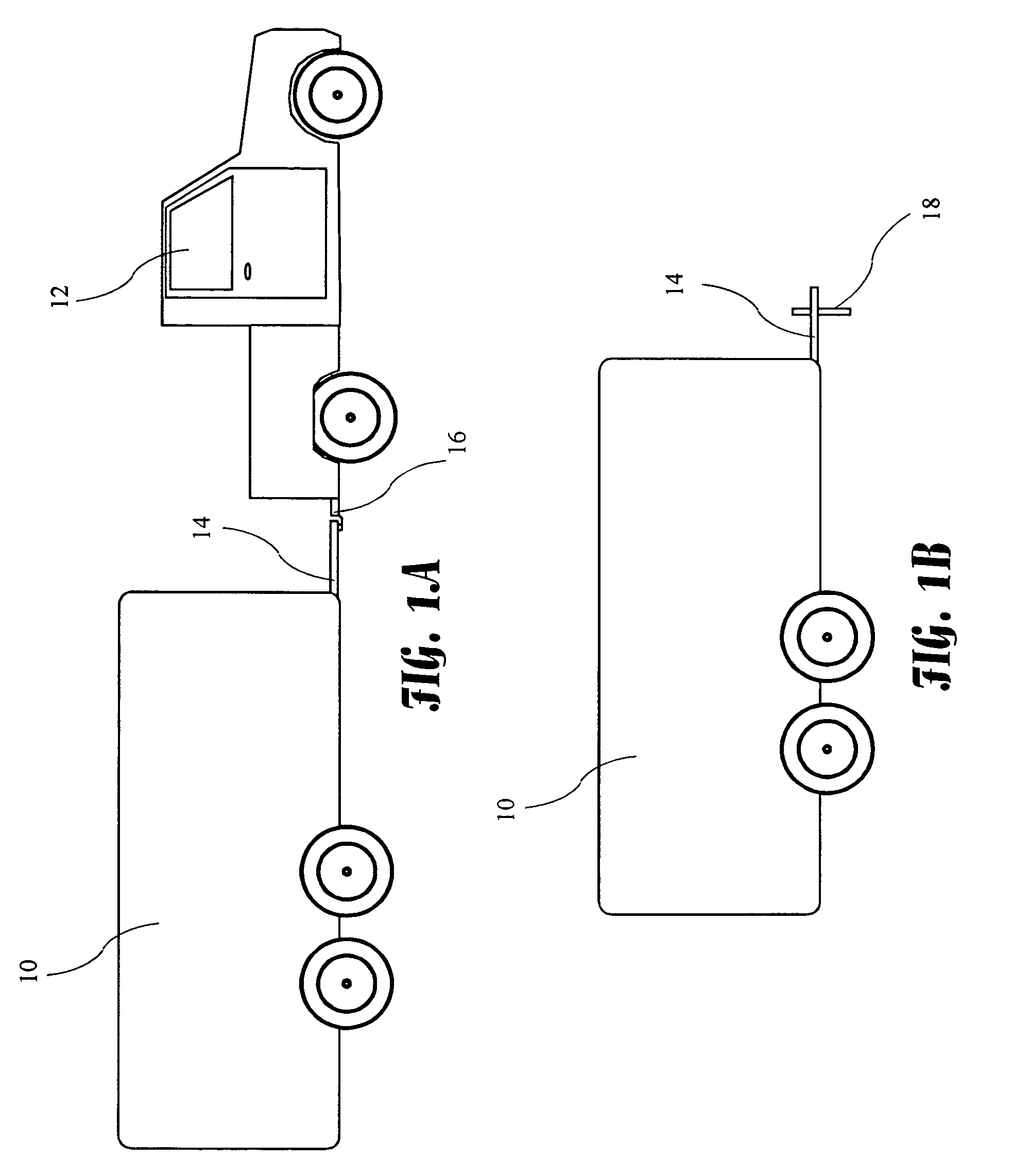

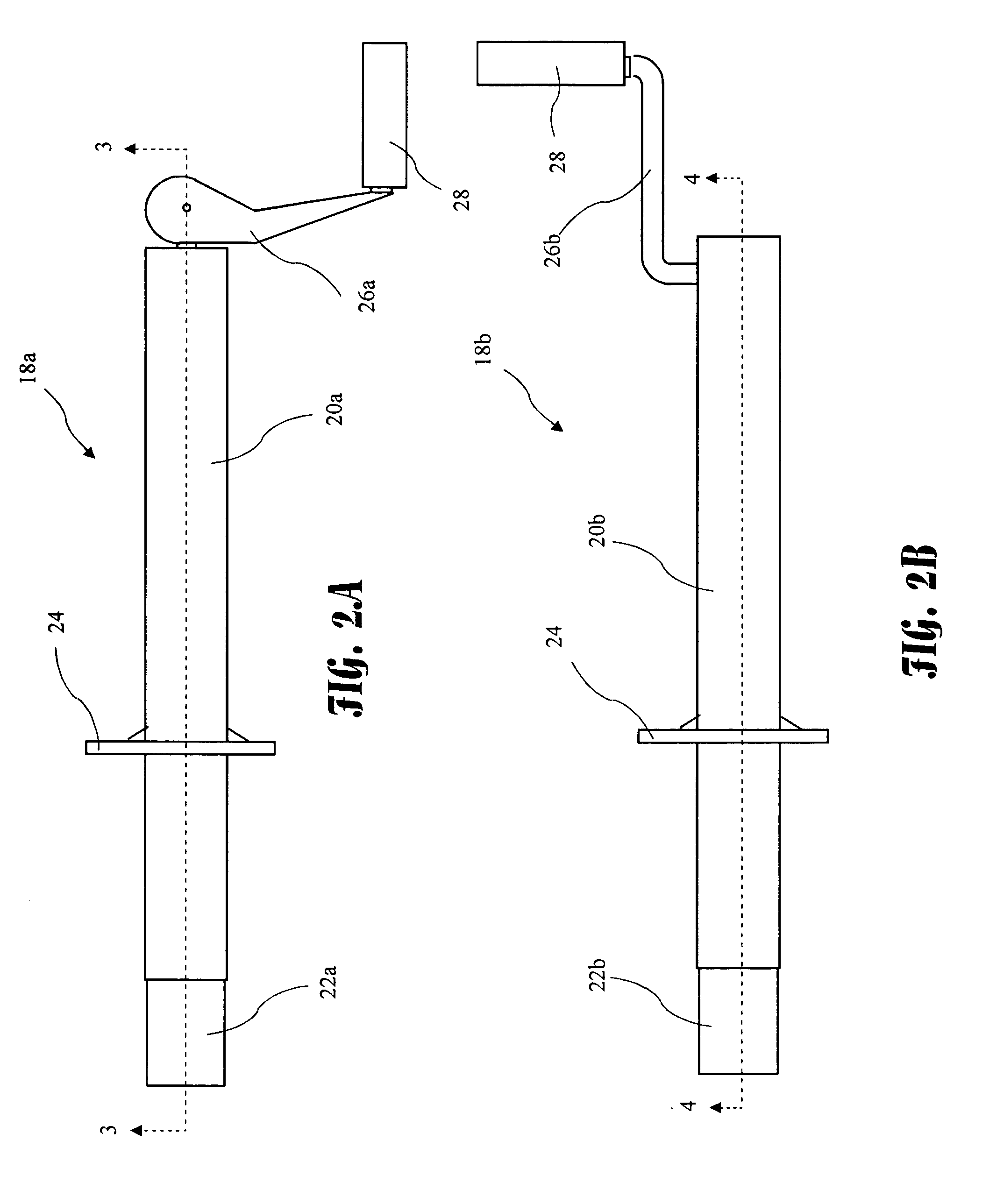

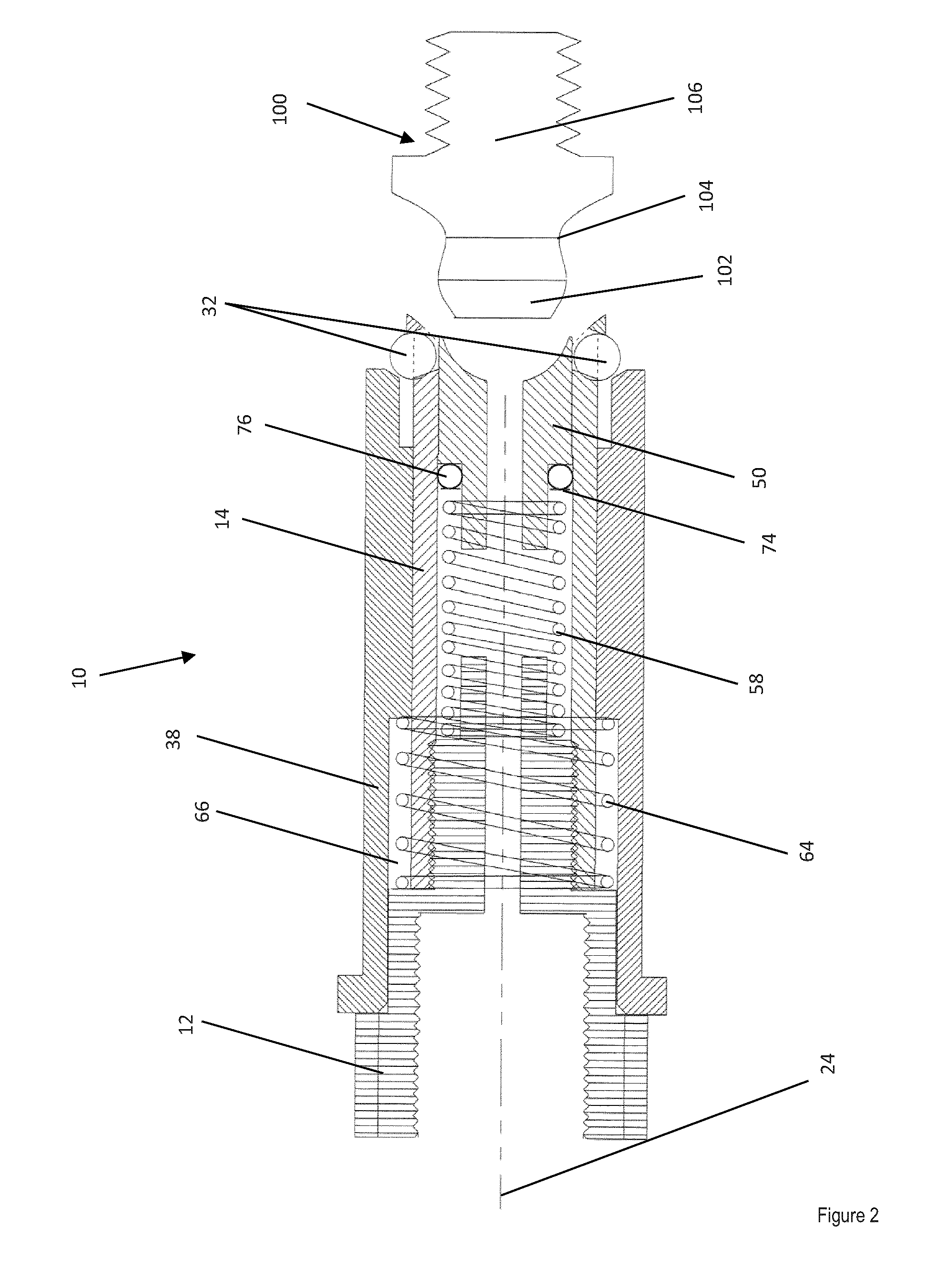

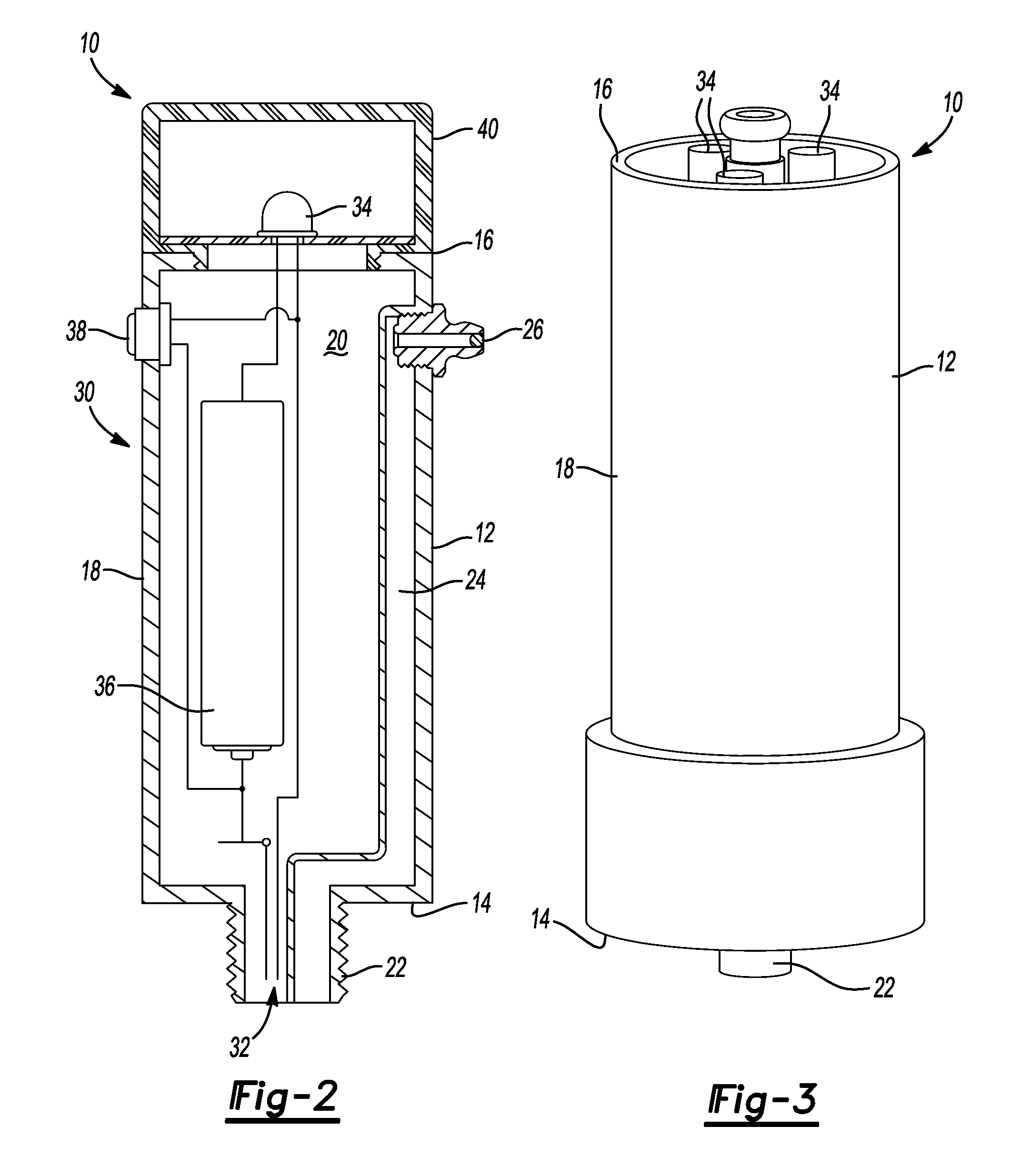

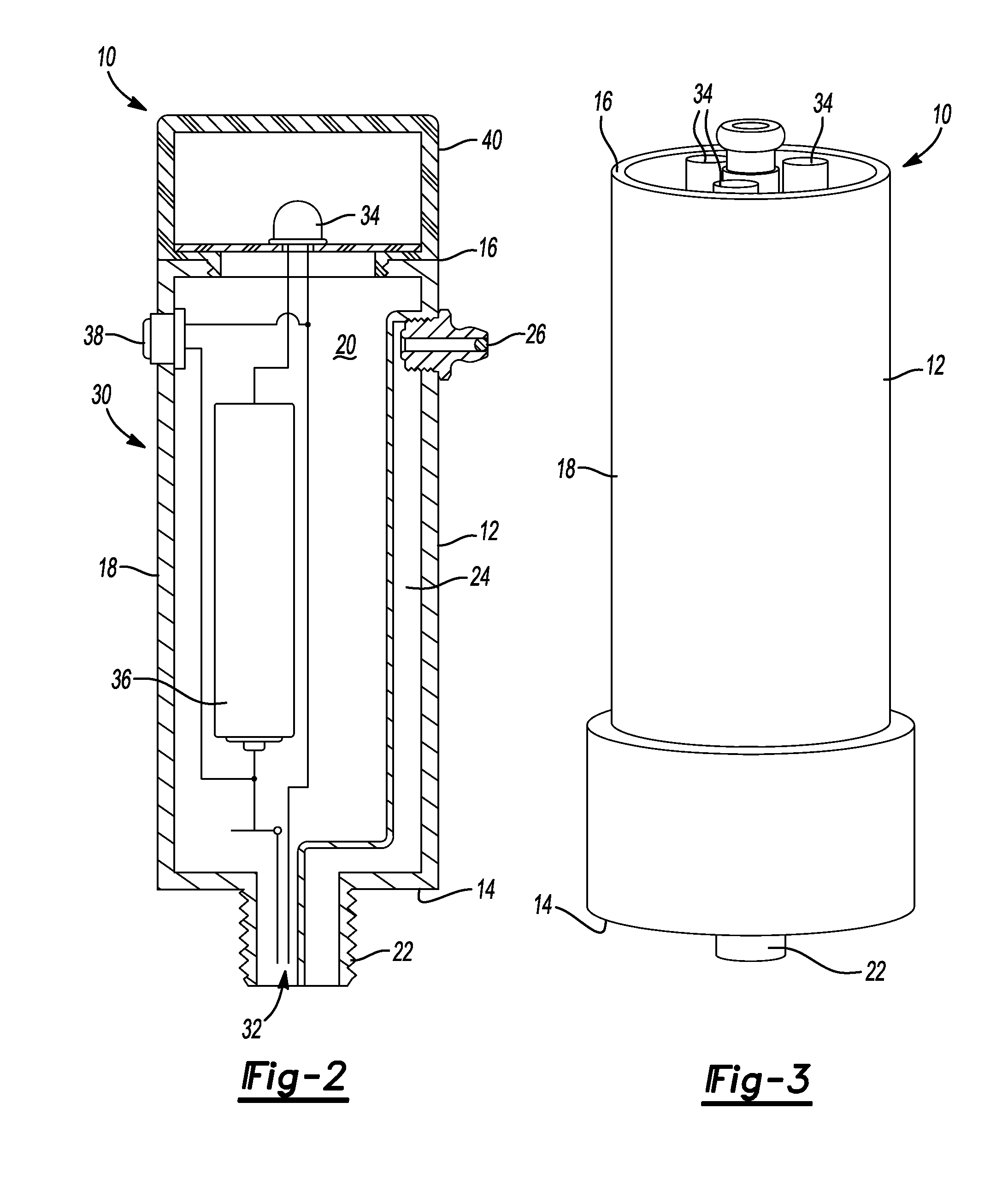

A trailer tongue jack includes a grease (or zerk) fitting for providing grease to internal parts The jack includes an outer tube and an inner telescoping tube. A threaded insert (or nut) is fixedly attached inside an upper end of the inner telescoping tube. A screw shaft threadedly cooperates with the insert to extend or retract the inner telescoping tube from a lower end of the outer tube. A crank is provided to turn the screw shaft either directly or through gears, and a thrust bearing carries a vertical load between the screw shaft and the outer tube. The grease fitting allows the internal parts, and the thrust bearing in particular, to be easily lubricated.

Owner:KAPER II

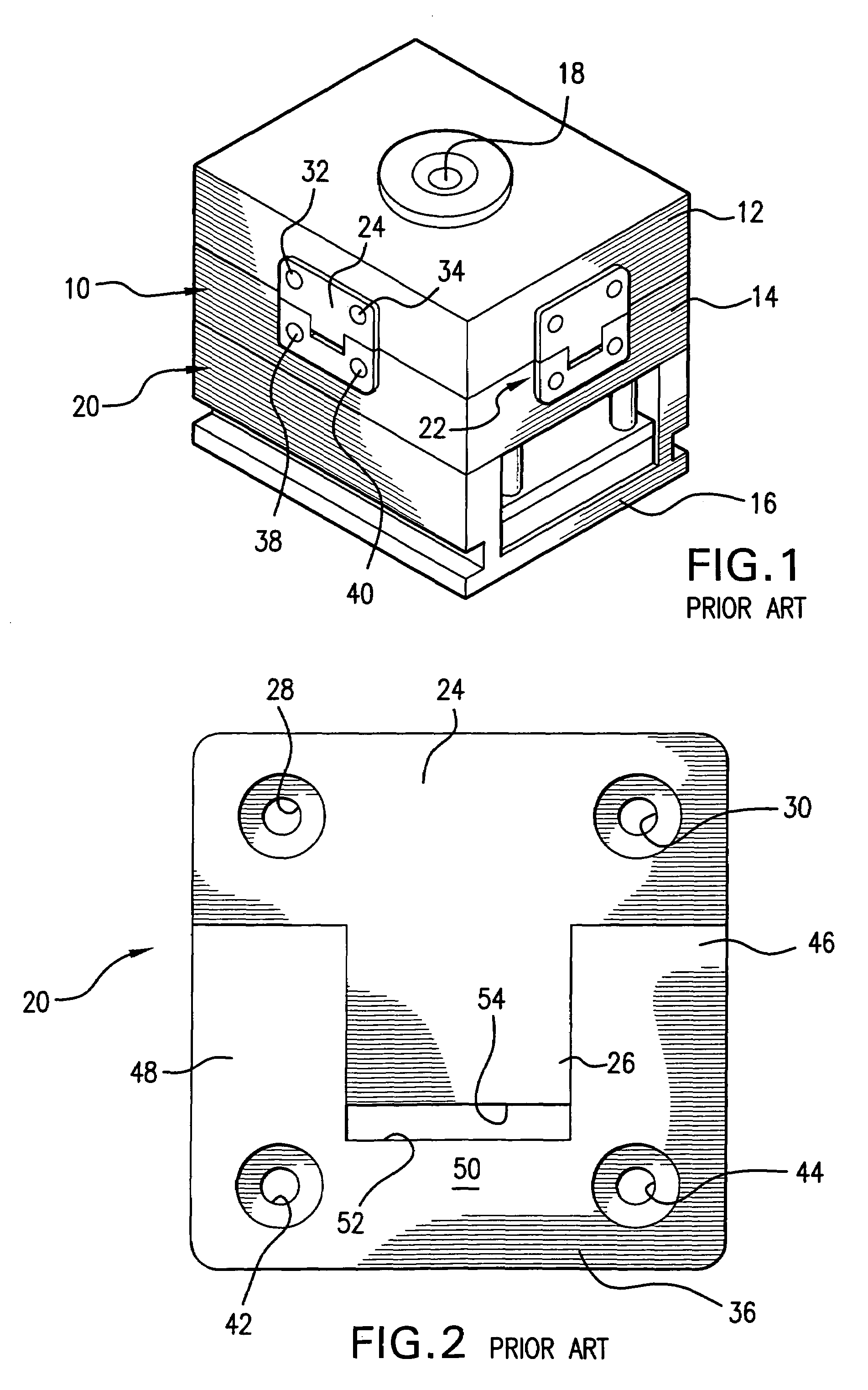

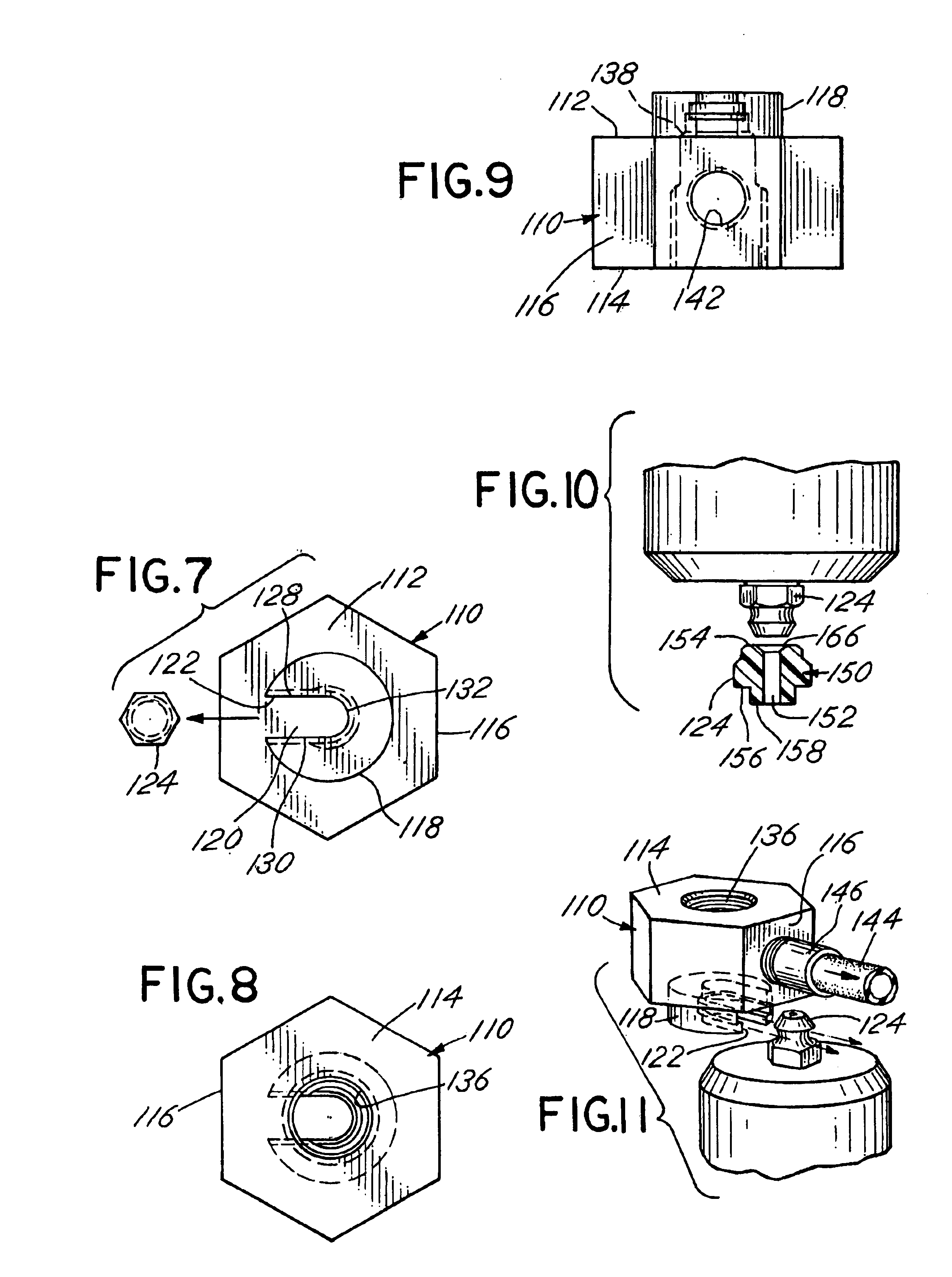

Mold lock with lubricating grooves

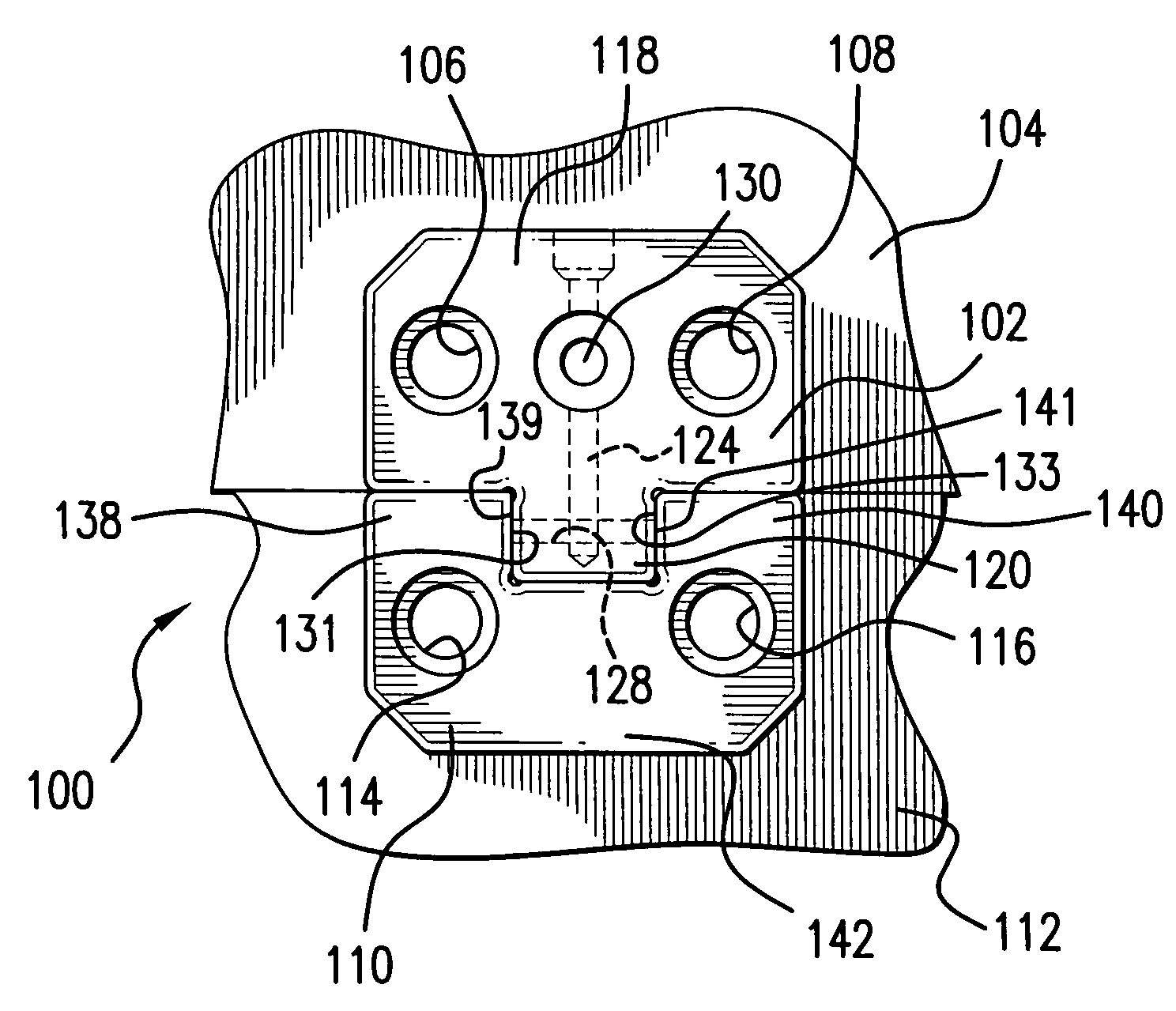

A mold for maintaining alignment between mold halves despite a thermal differential between the mold halves. The lock comprises (1) a T-shaped member, consisting of an enlarged, rectangular head and a tongue extending therefrom, and (2) a receptacle with an outwardly opening U-shaped pocket to receive the tongue of the T-shaped member, when the mold halves are pressed together. A vertical conduit is formed in the head and tongue of the T-shaped member, and a horizontal channel, extending through the tongue, intersects the lower end of the conduit. At lest one groove is defined in each side wall of the conduit. A grease fitting is located in a blind hole in the head of the T-shaped member, so that lubricant flows through the vertical conduit, into the horizontal channel, and into the grooves in the opposite side walls of the tongue. The grooves are usually formed in pairs, and are configured in an intersecting X configuration. The midpoint of the X configuration corresponds to one end of the horizontal channel in the receptacle. The grease fitting, vertical conduit, horizontal channel, and grooves in the opposite side walls of the tongue deliver a film of lubricant into the limited clearances between the side walls of the tongue and the interior walls of the pocket to prevent metal-to-metal, line-to-line contact therebetween. In an alternative embodiment, the grooves are located in the parallel side walls of the U-shaped pocket, and are configured in an intersecting X configuration, to deliver the film of lubricant.

Owner:LEMKIN JACK

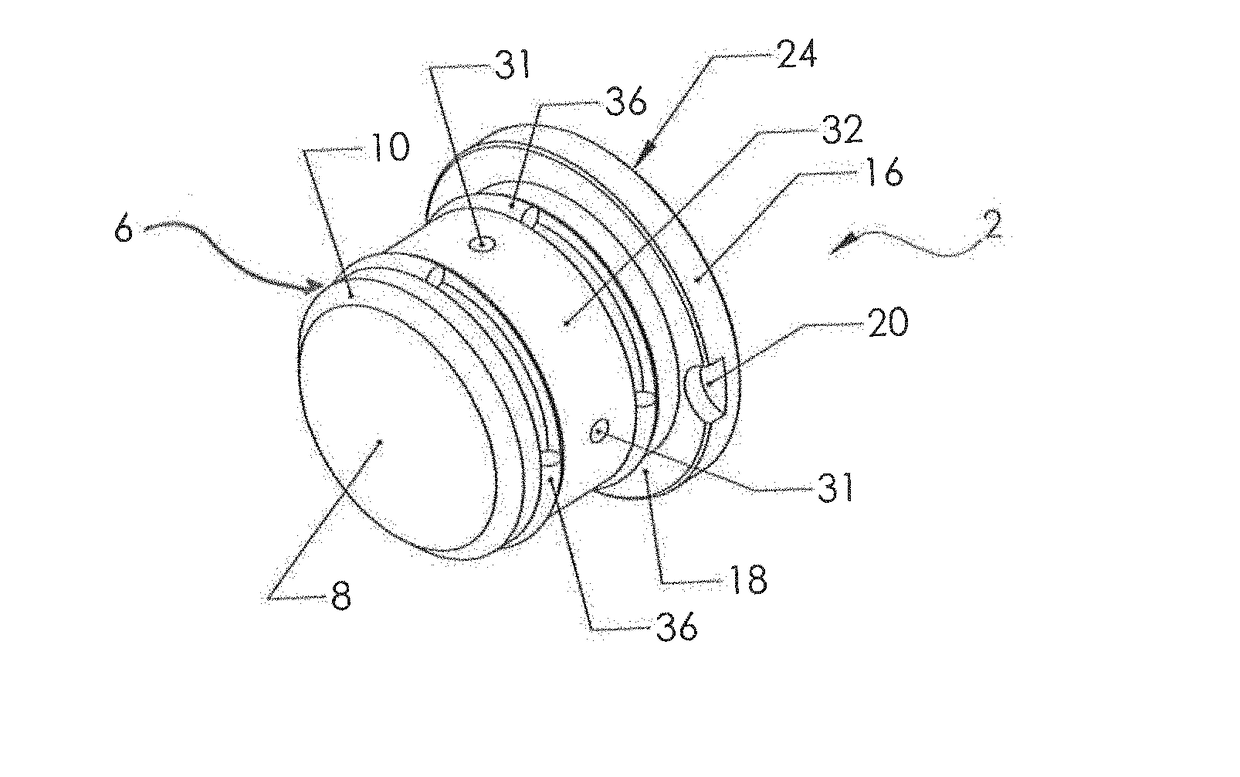

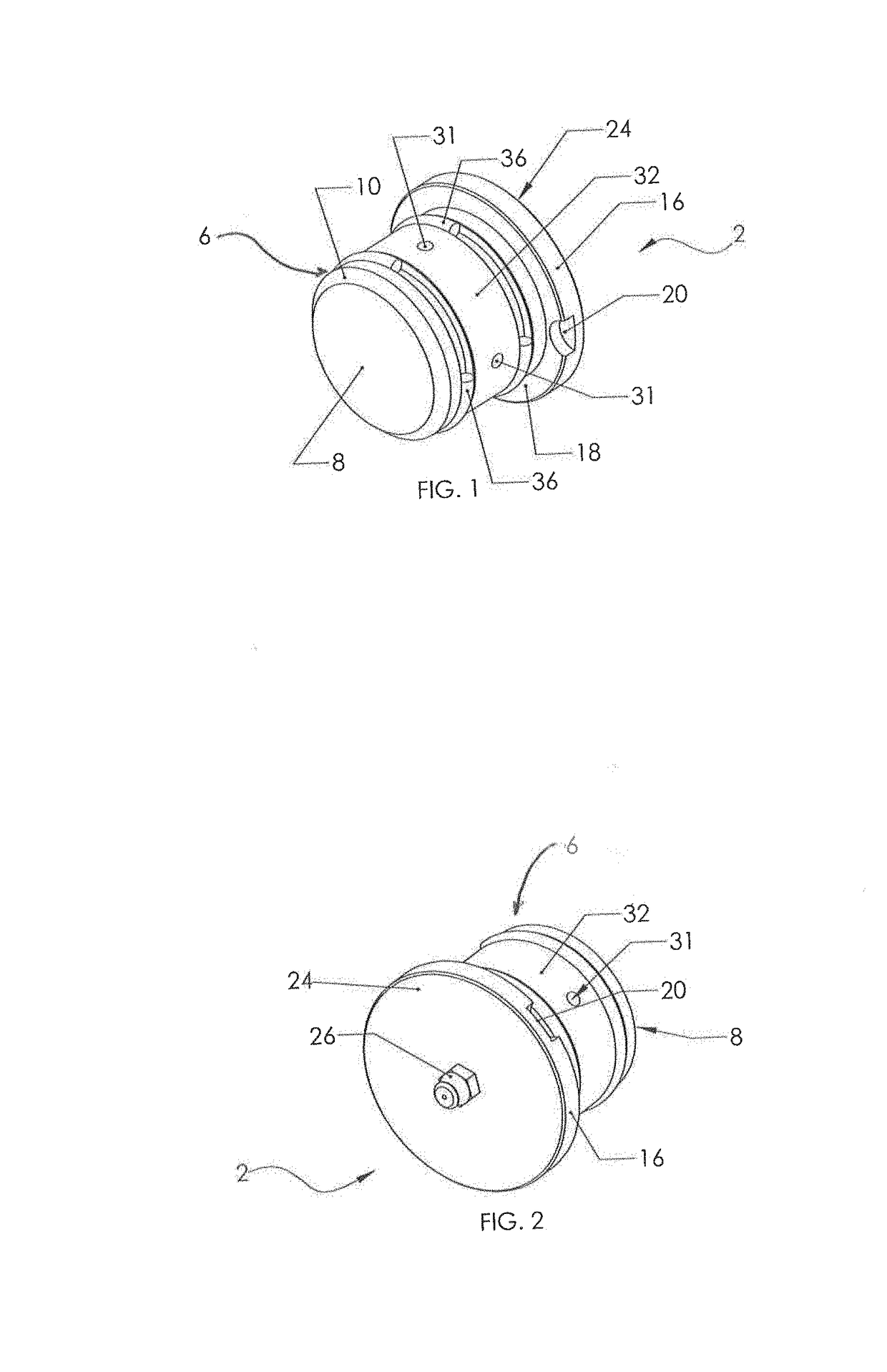

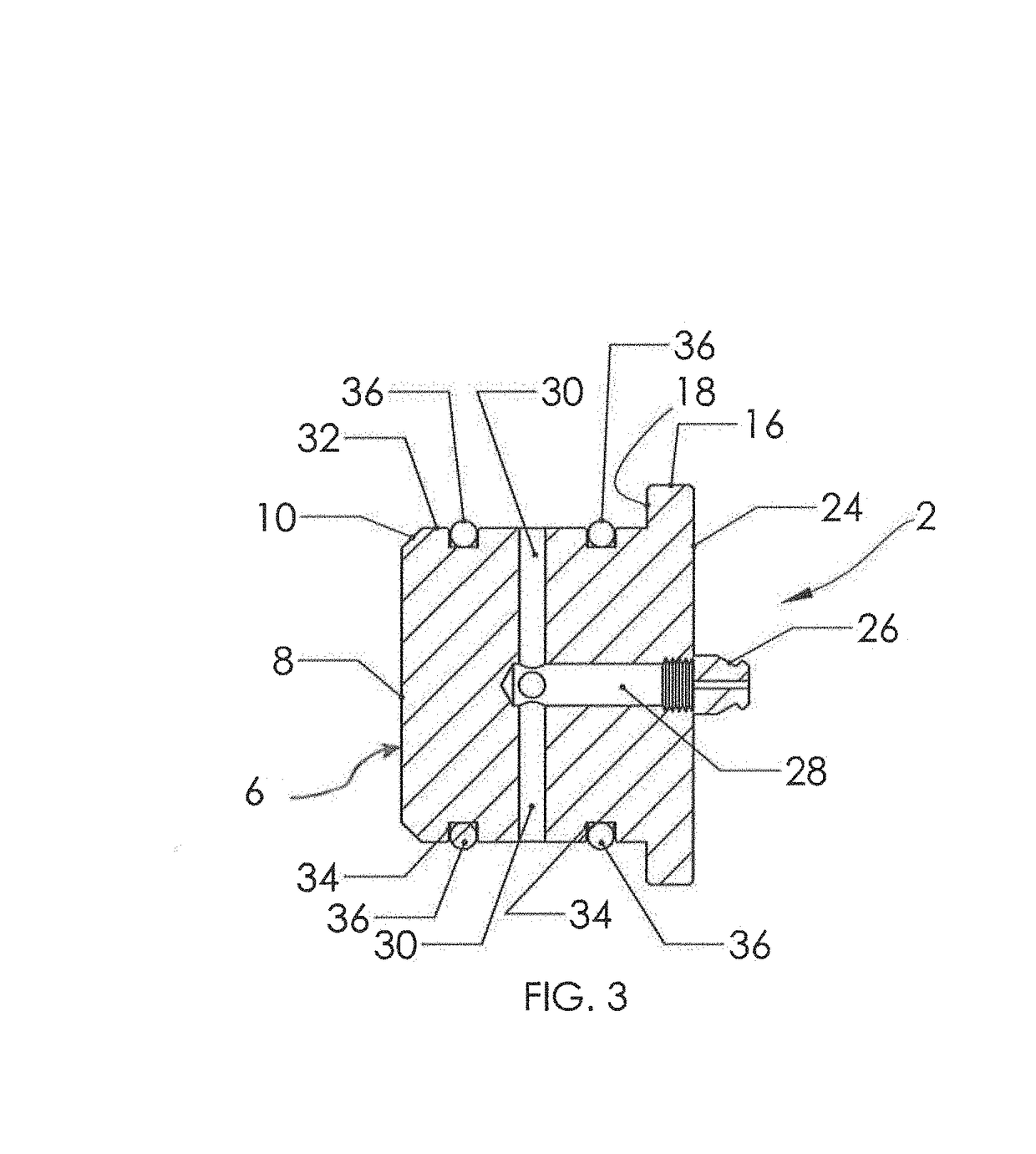

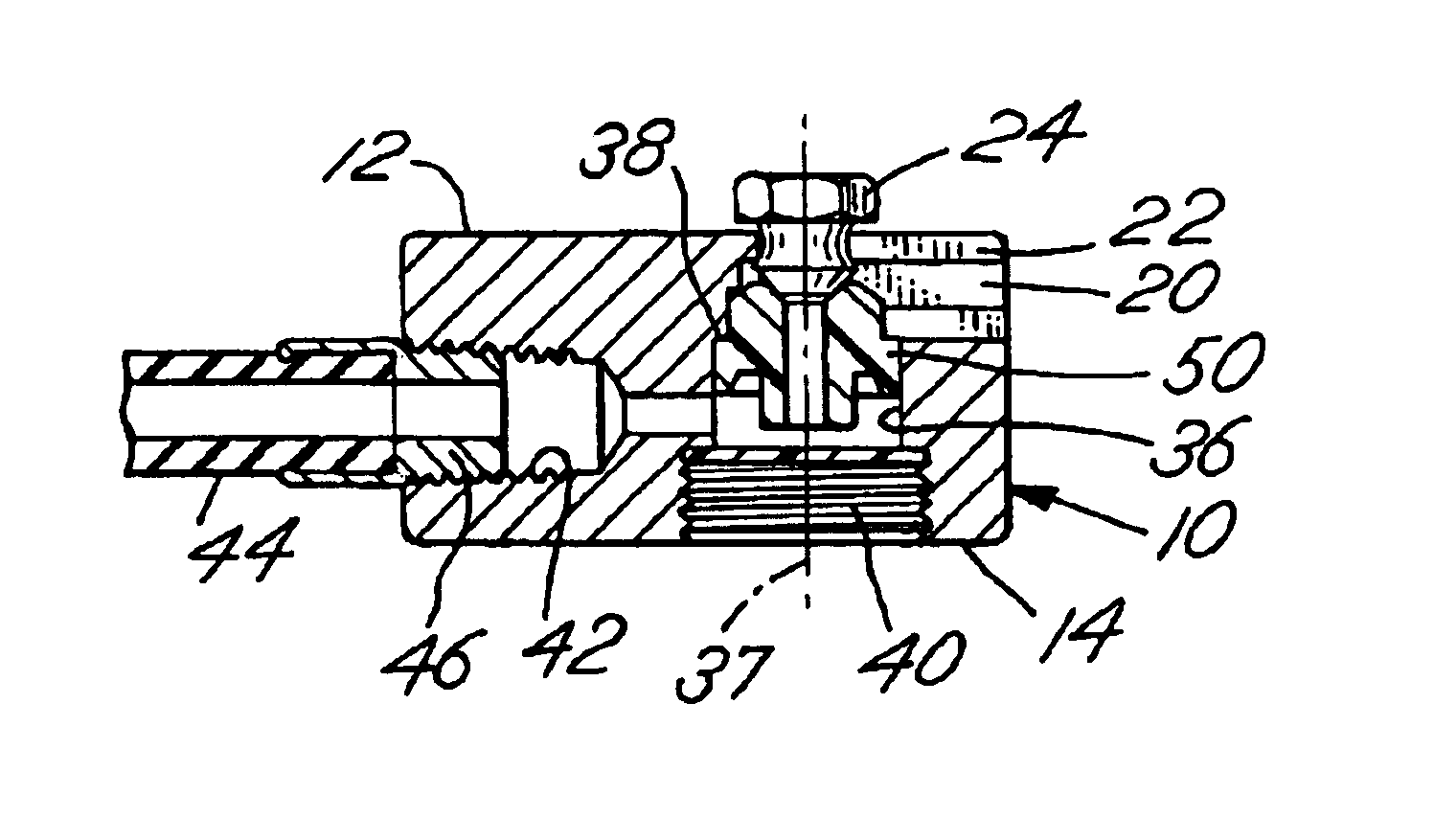

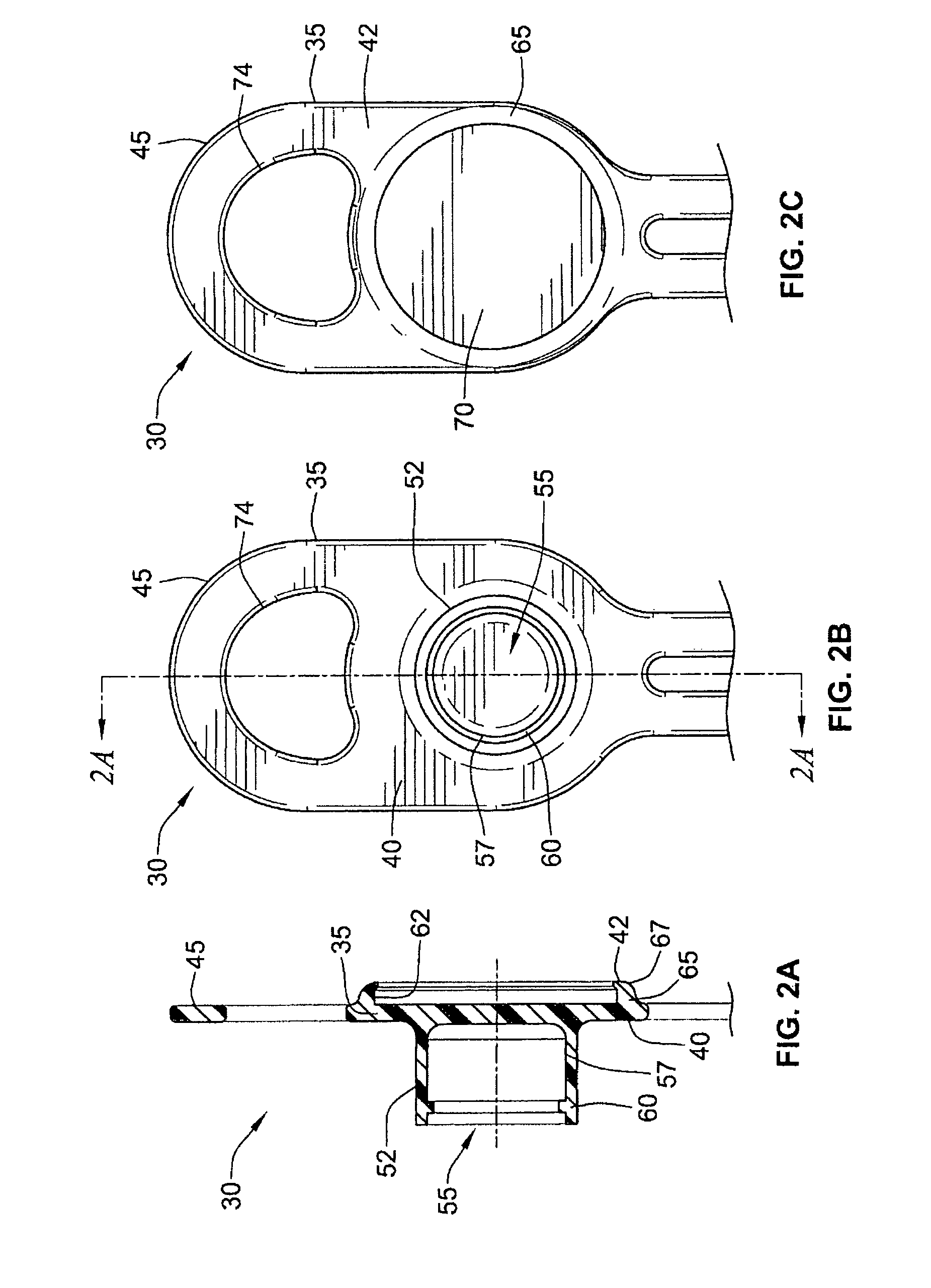

Grease gun coupler

InactiveUS20150115601A1Improve sealingPrecise alignmentManual lubricationJoints with sealing surfacesGrease fittingBall bearing

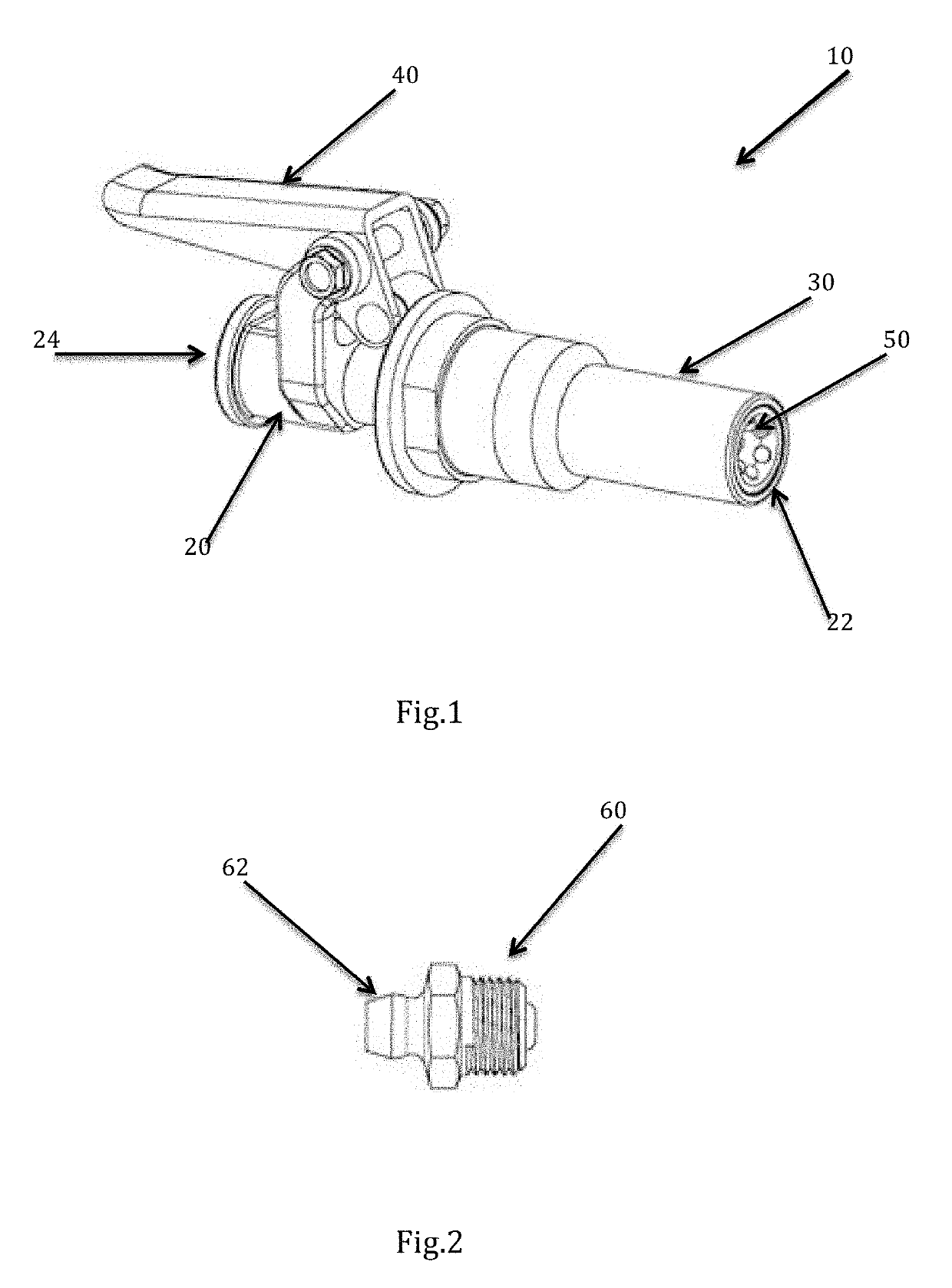

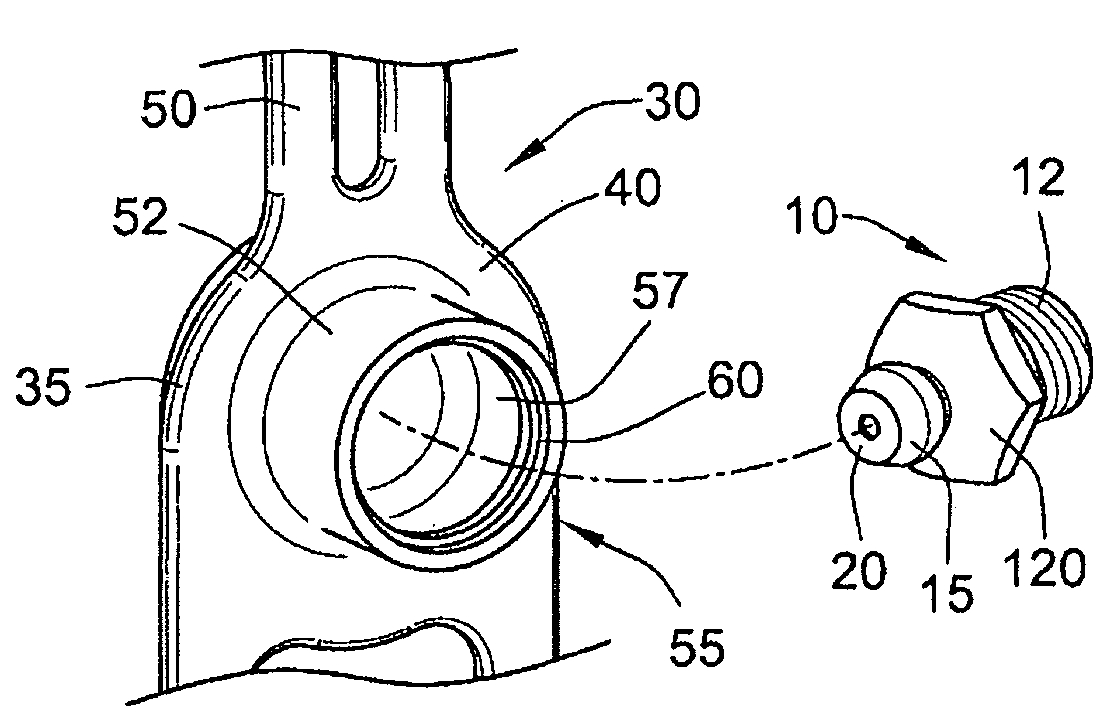

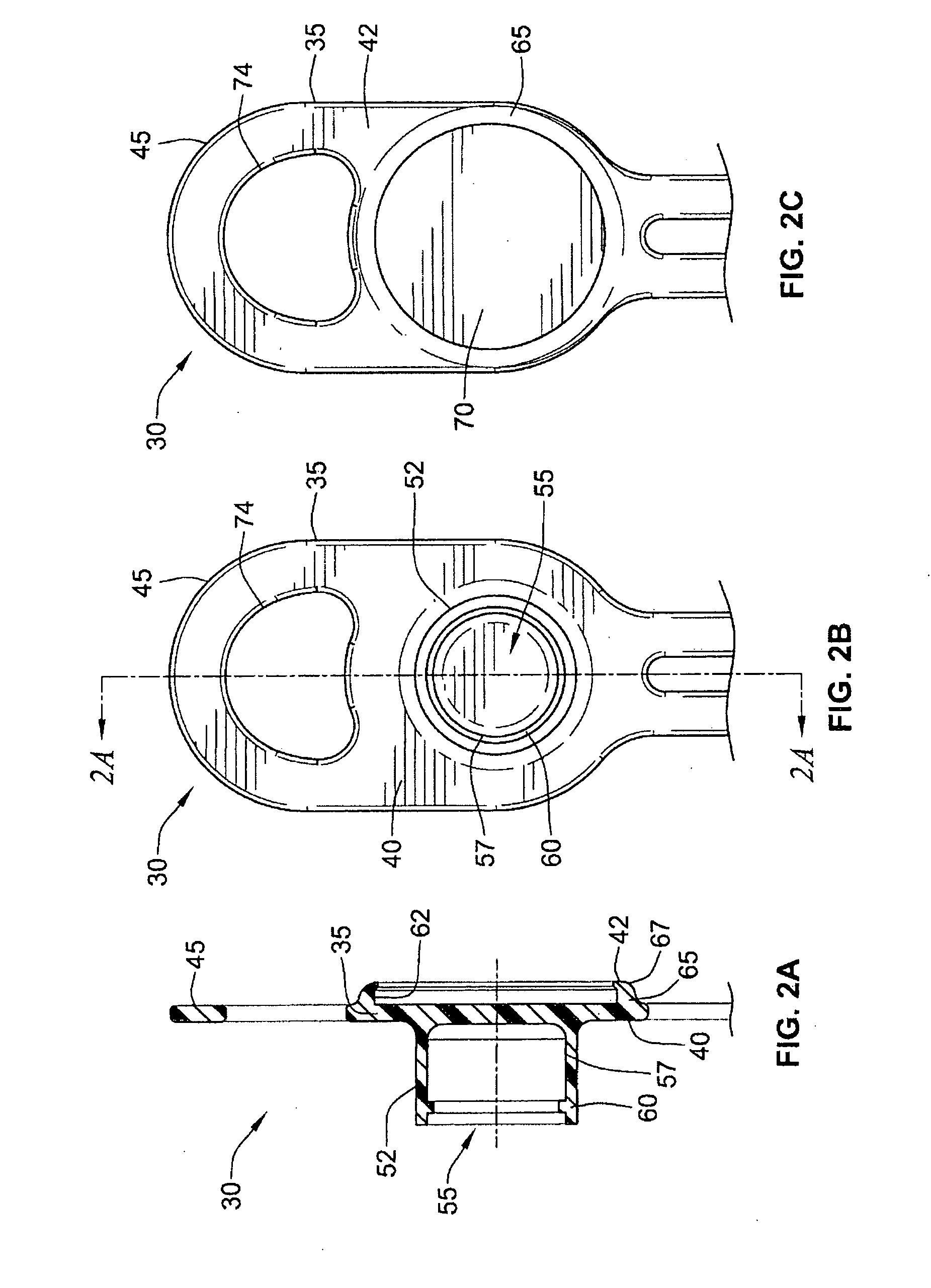

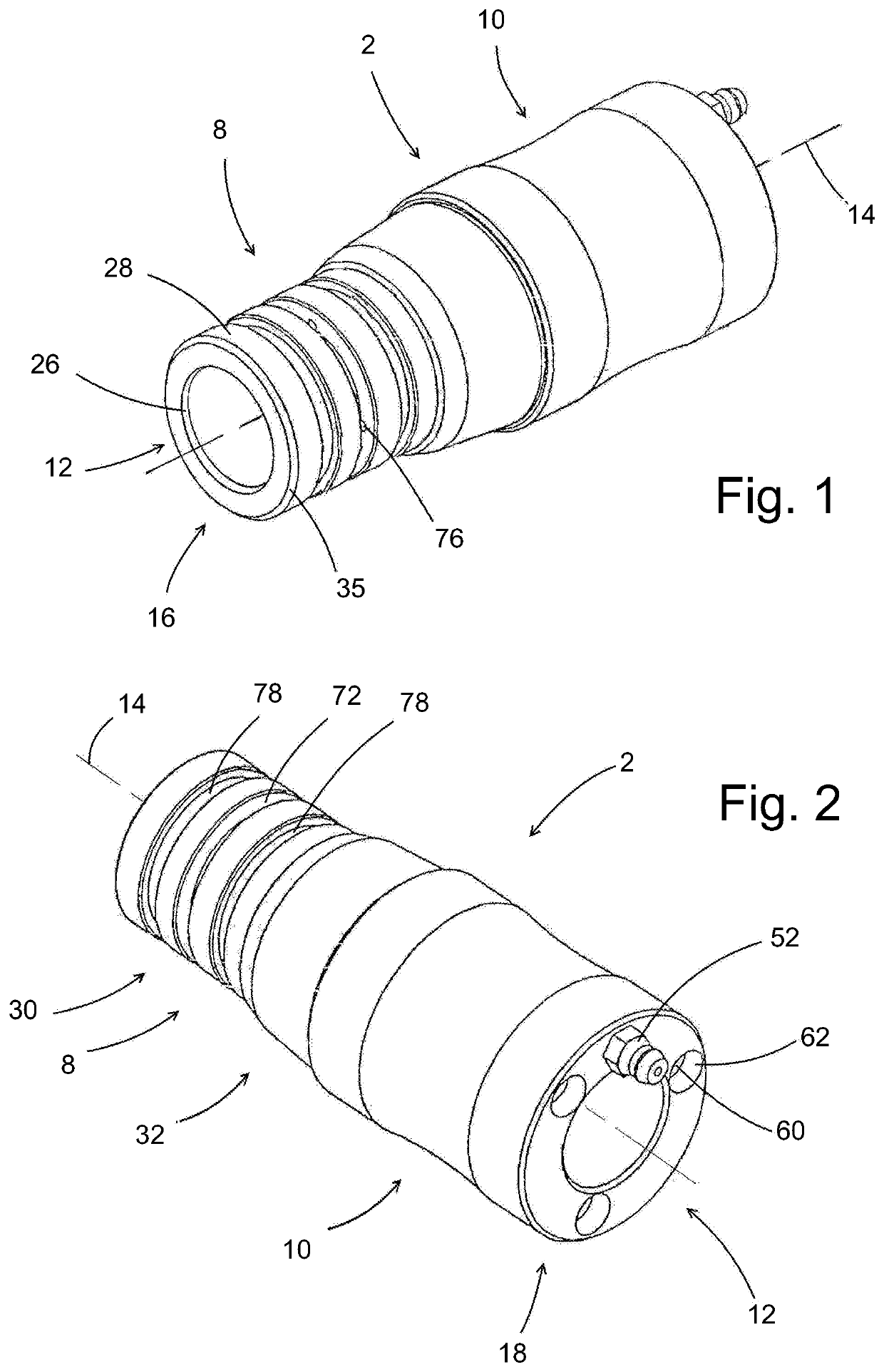

A grease gun coupler for delivering grease from a tube of a grease gun to a grease fitting is provided. Insertion of a grease fitting in the coupler pushes in a piston, allows a bias or an operator to push an outer sleeve towards the grease fitting, which biases the ball bearings inwards, thus securing the grease fitting in the coupler. Retraction of the outer sleeve releases the ball bearings, thus allowing another bias to push back the piston and expel the grease fitting.

Owner:Y&D BROS INNOVATIONS

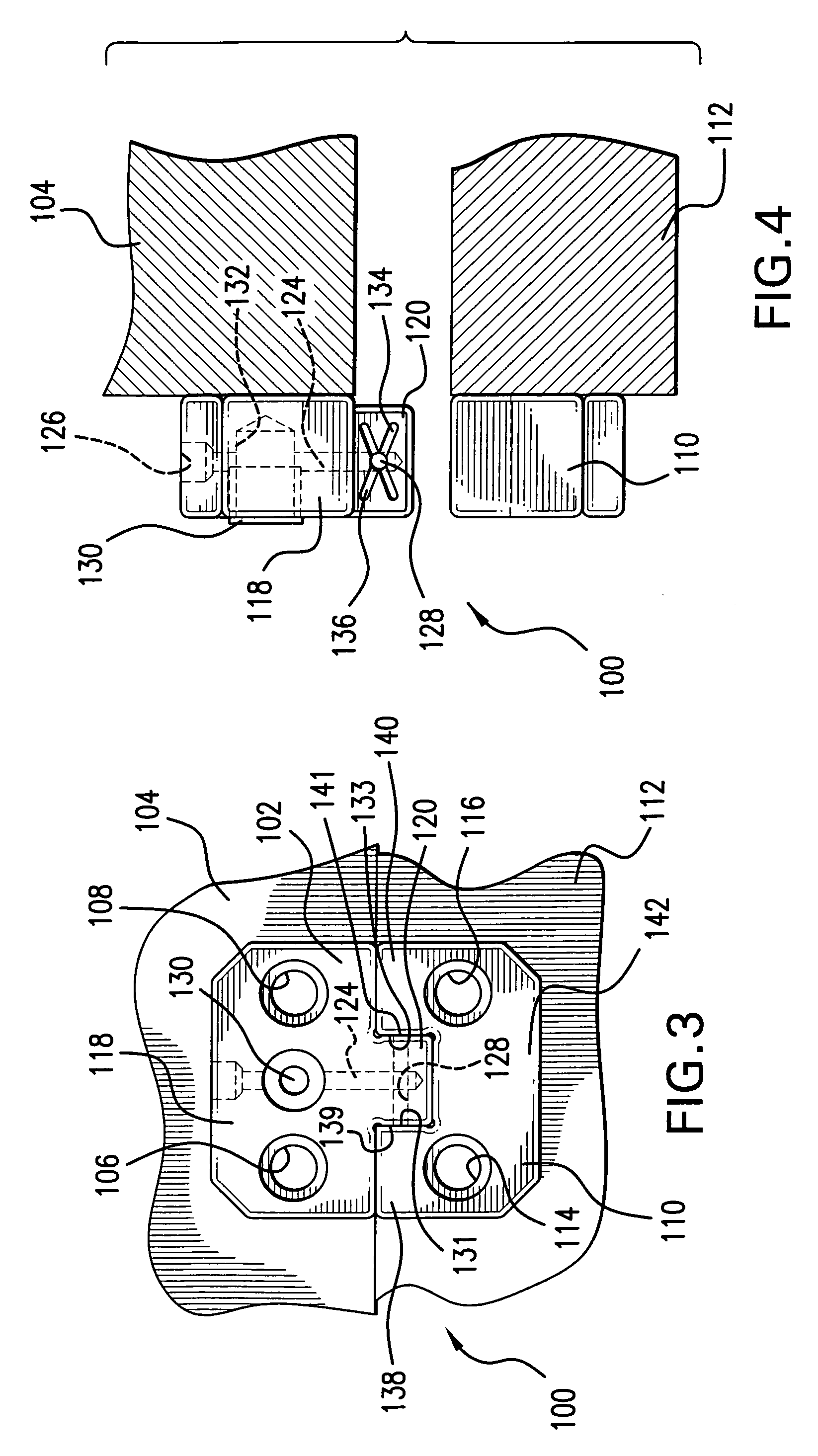

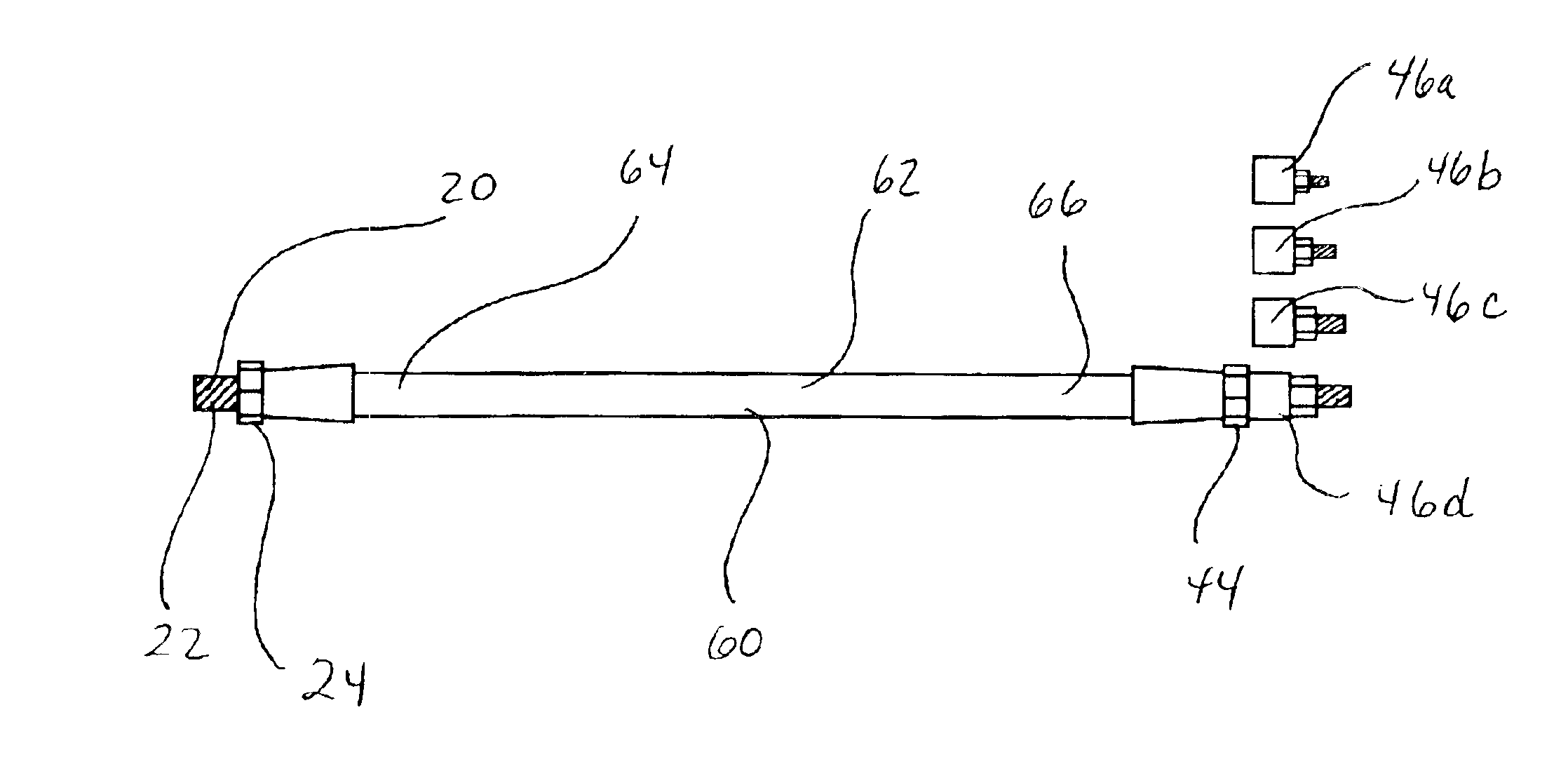

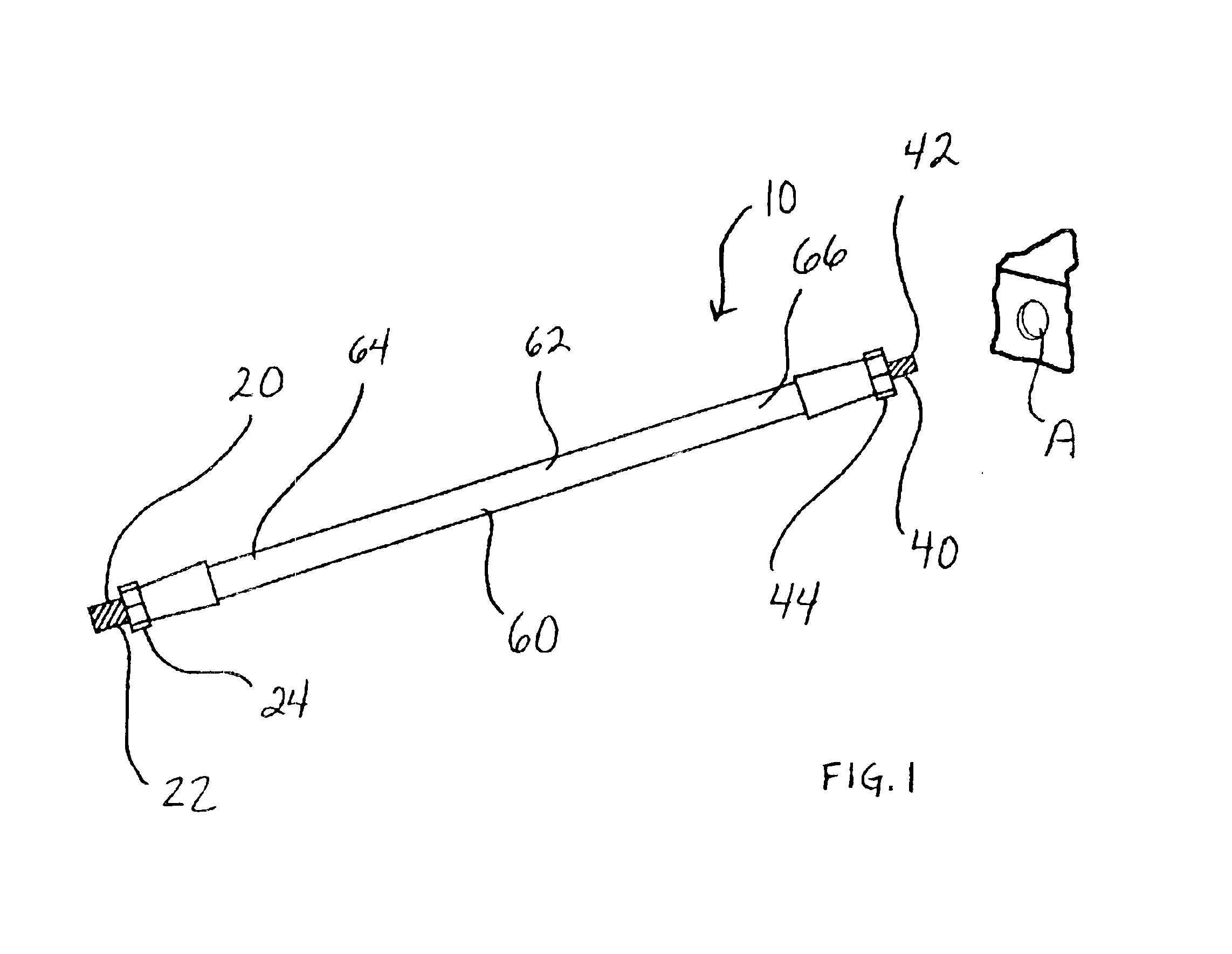

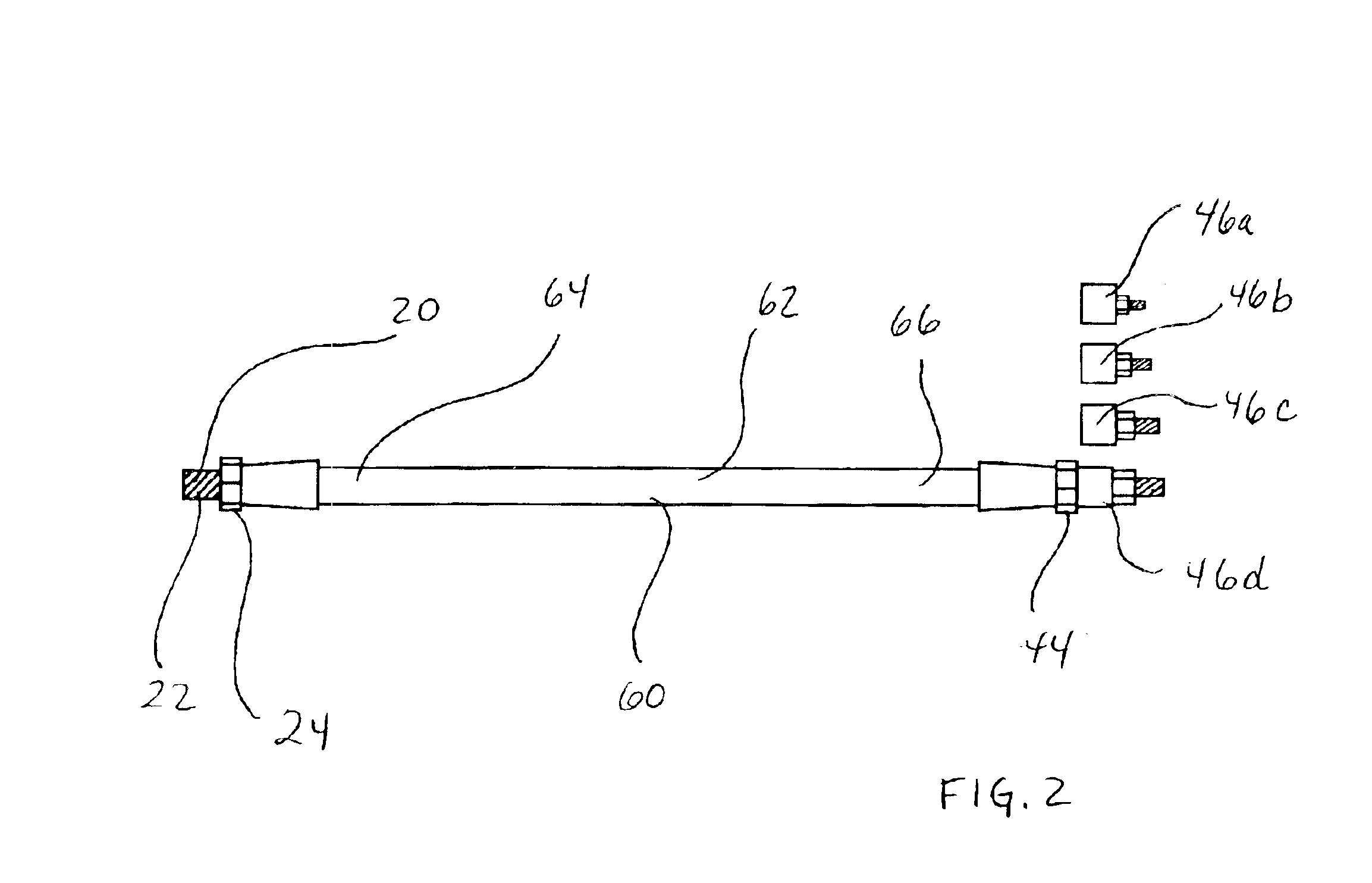

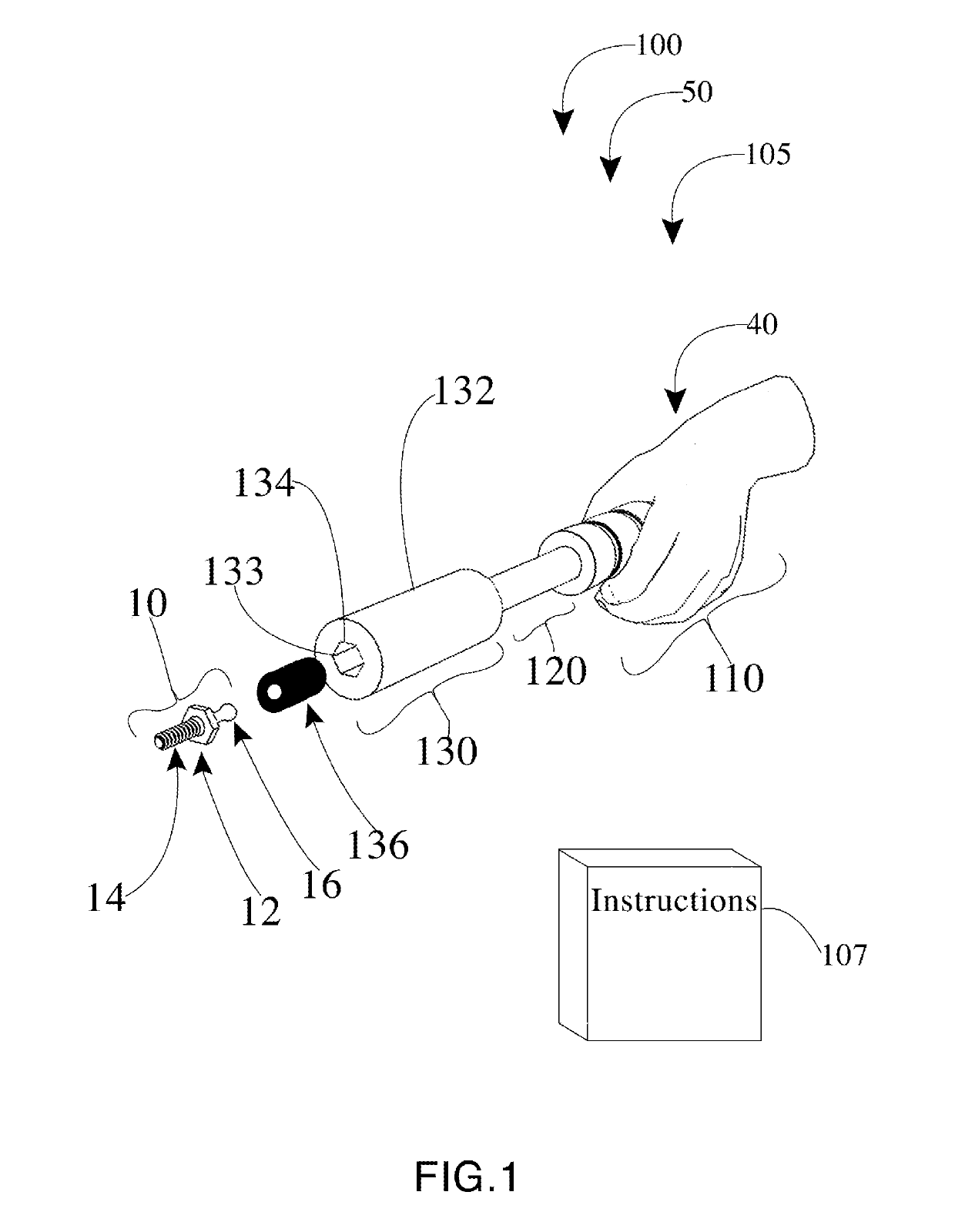

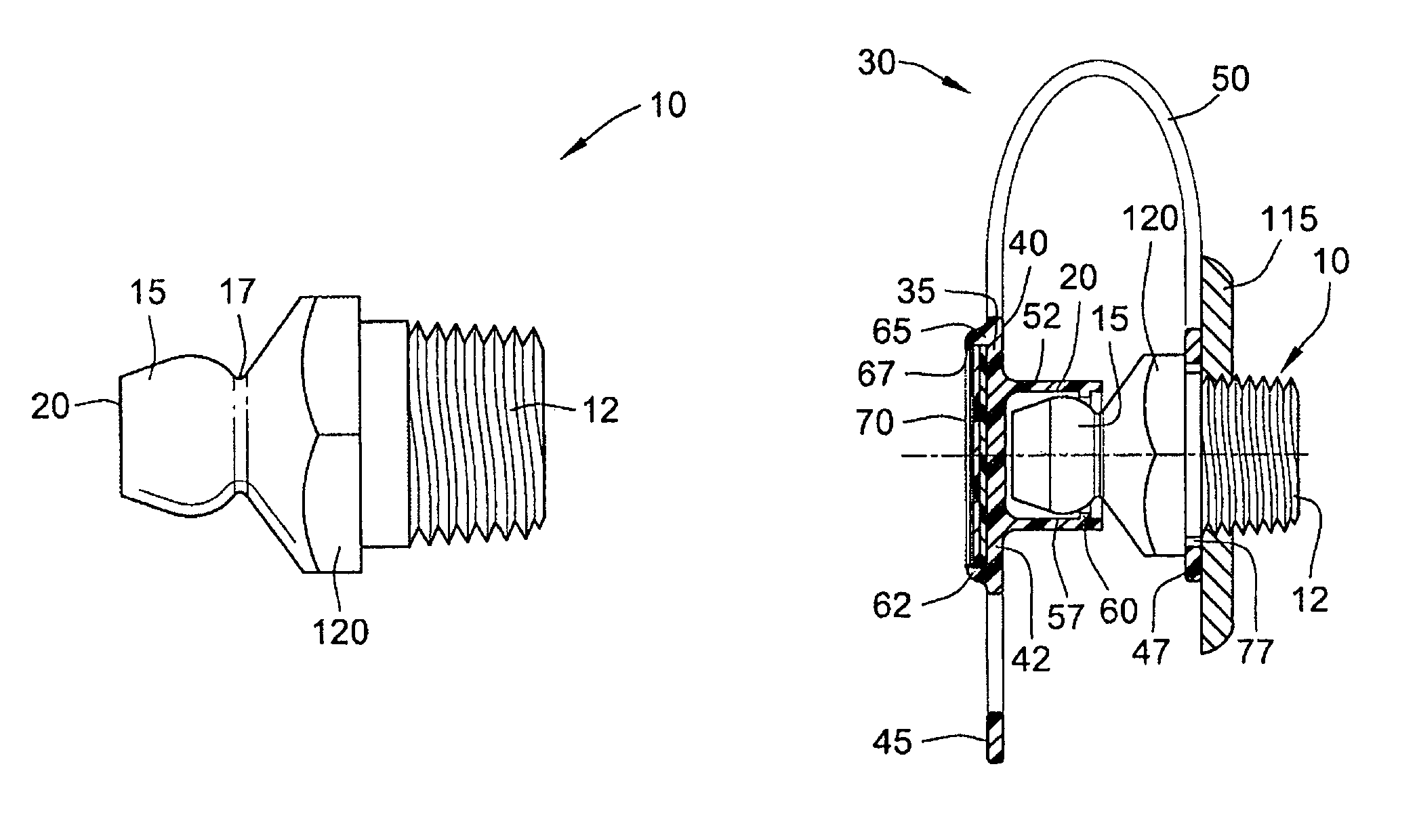

A coupling device

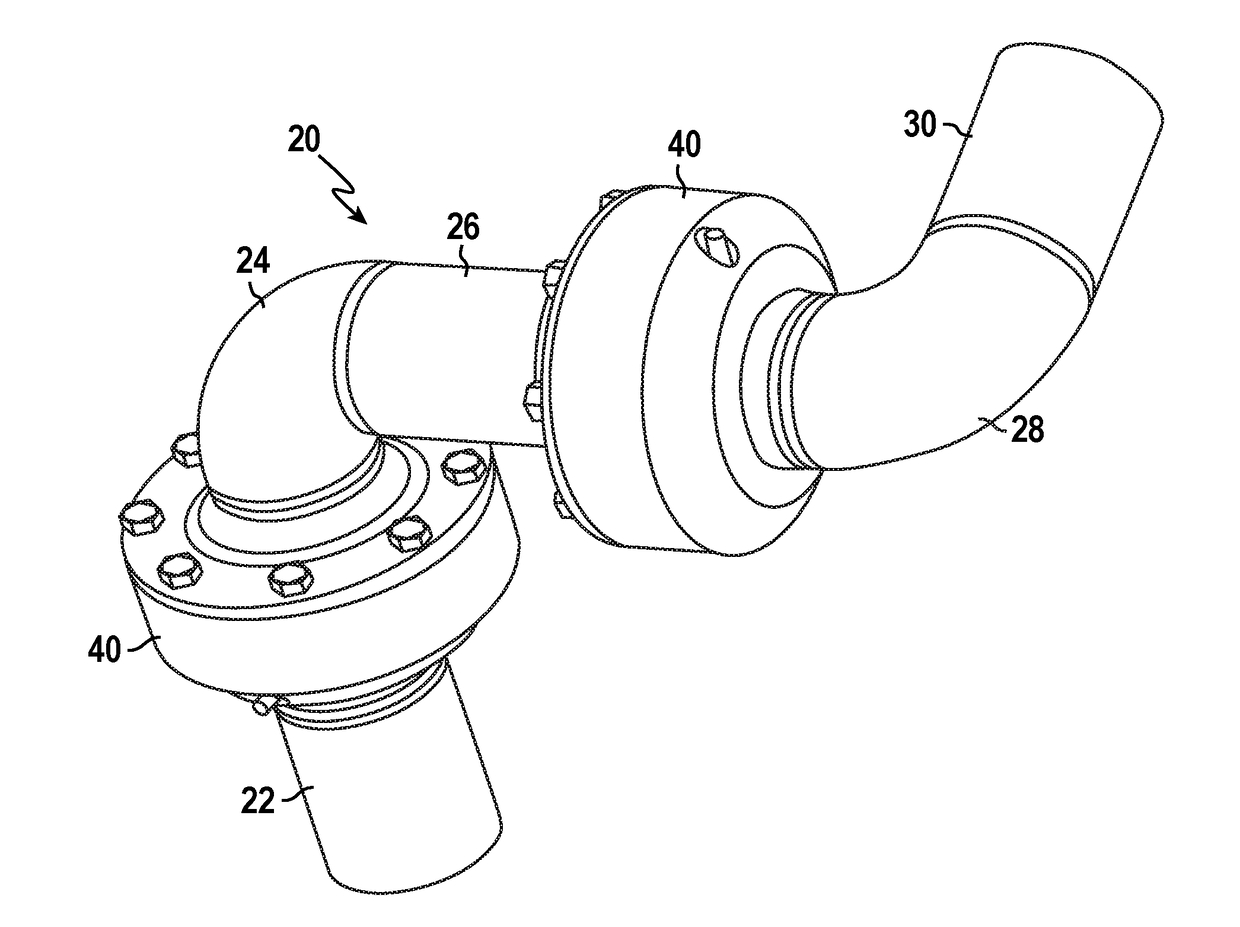

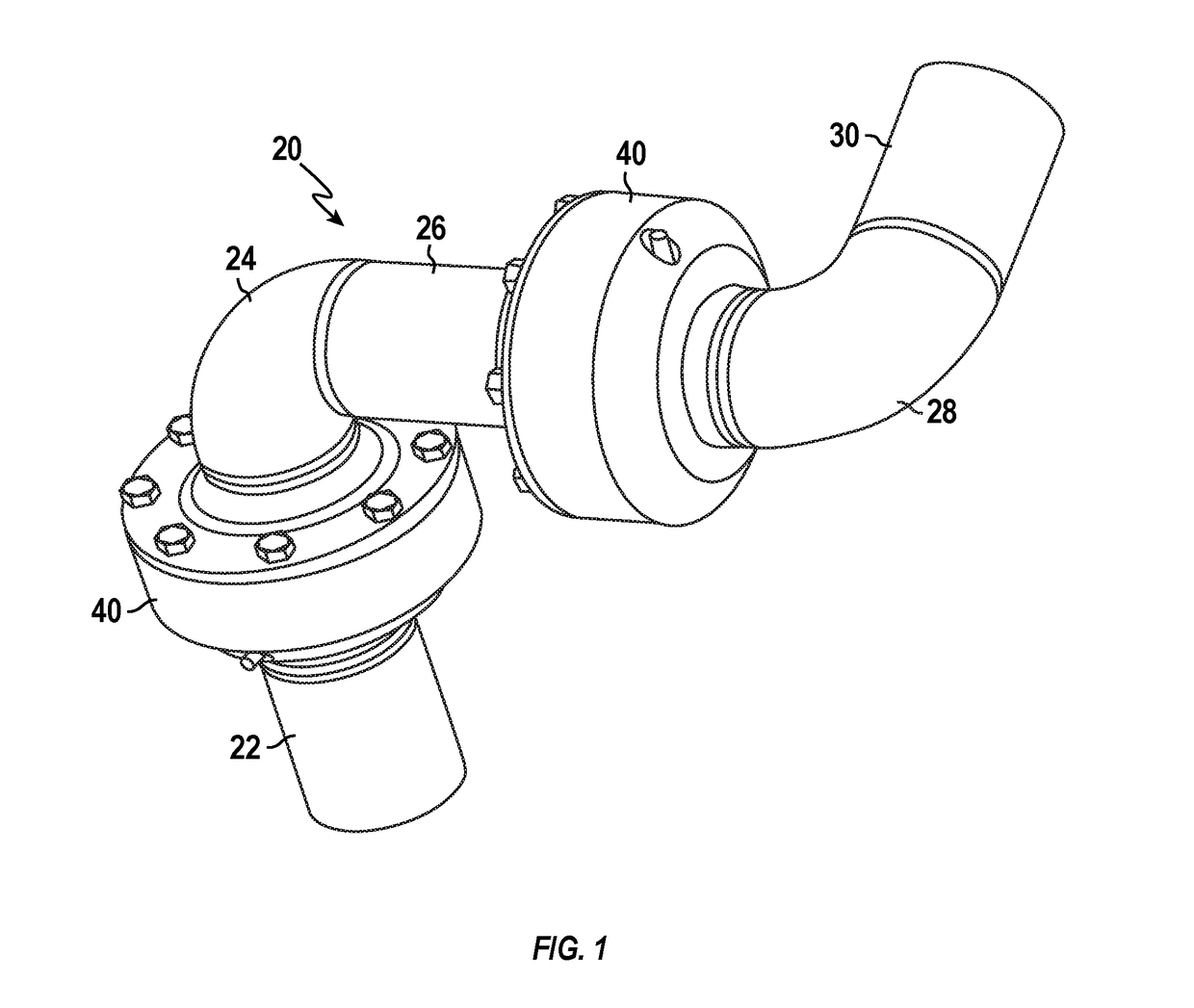

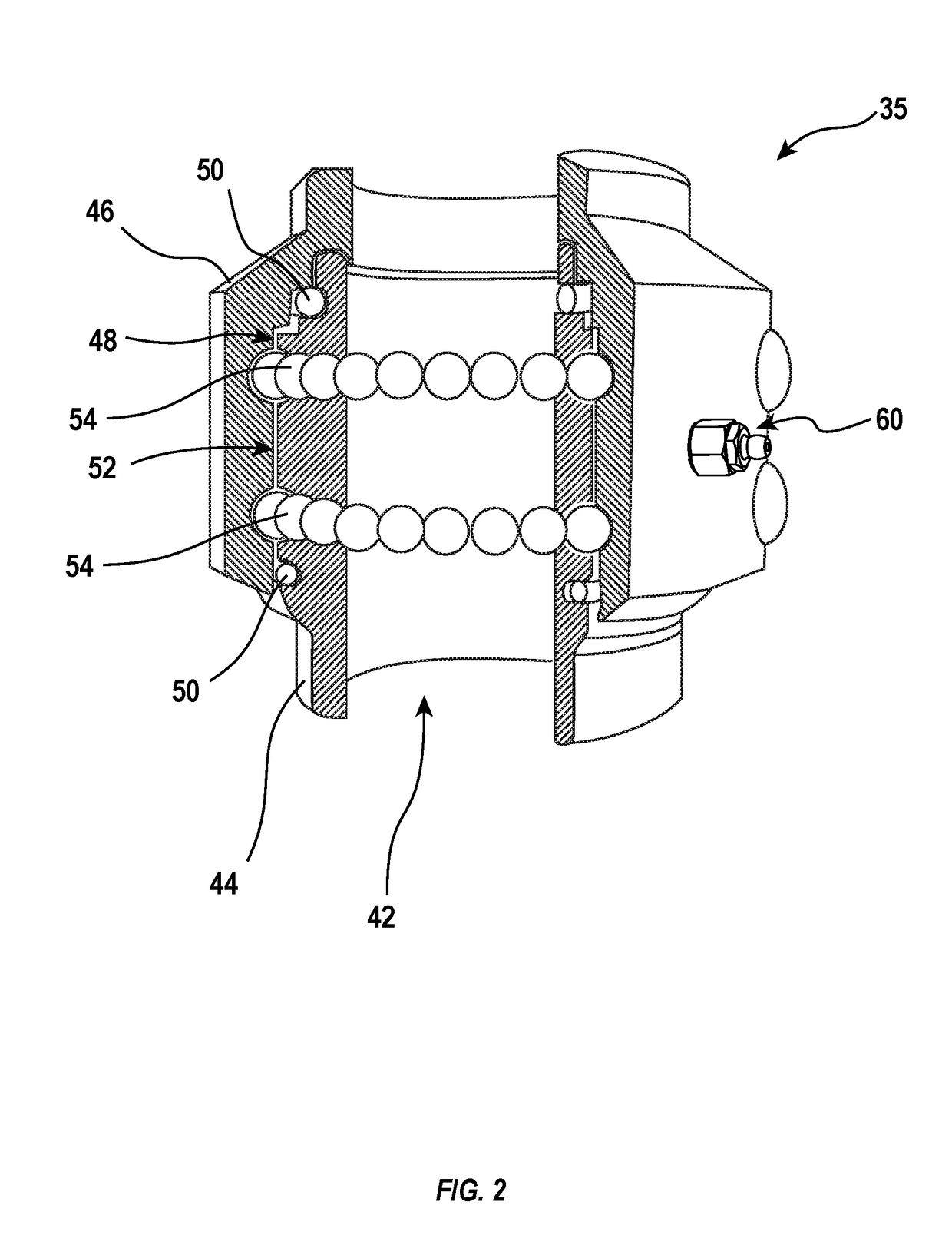

InactiveUS20190120413A1Prevent liquid leakageFacilitates easy disengagementCouplingsConduits/junctionsGrease fittingEngineering

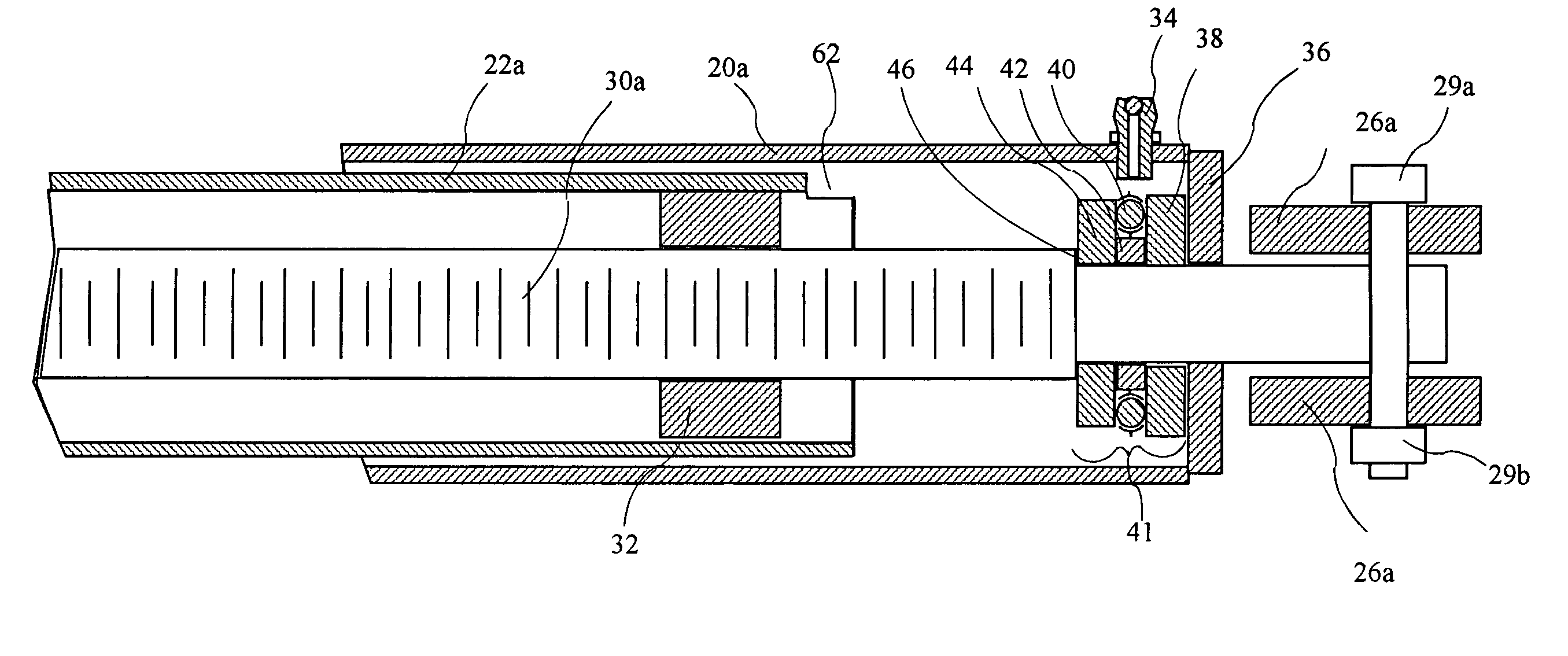

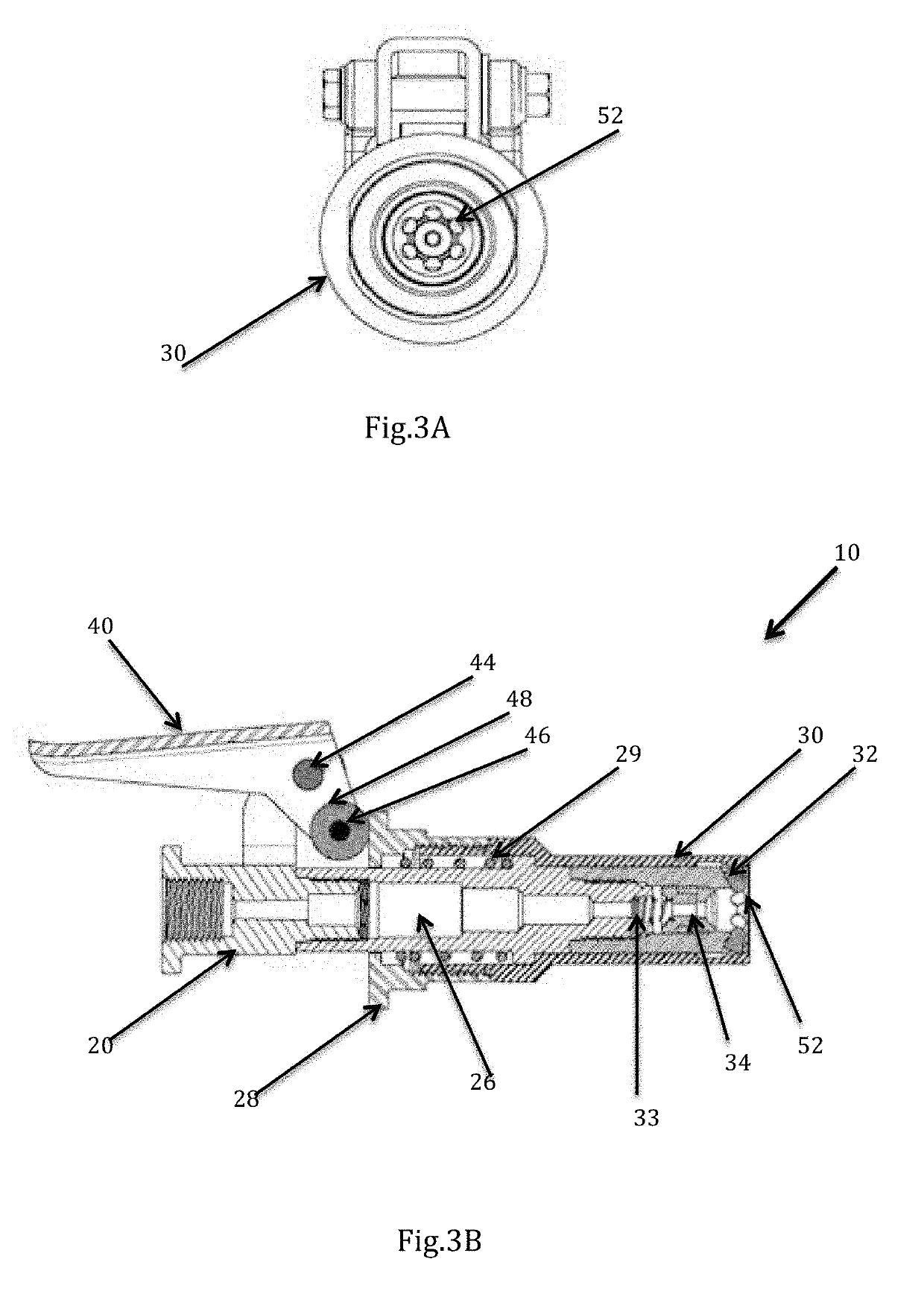

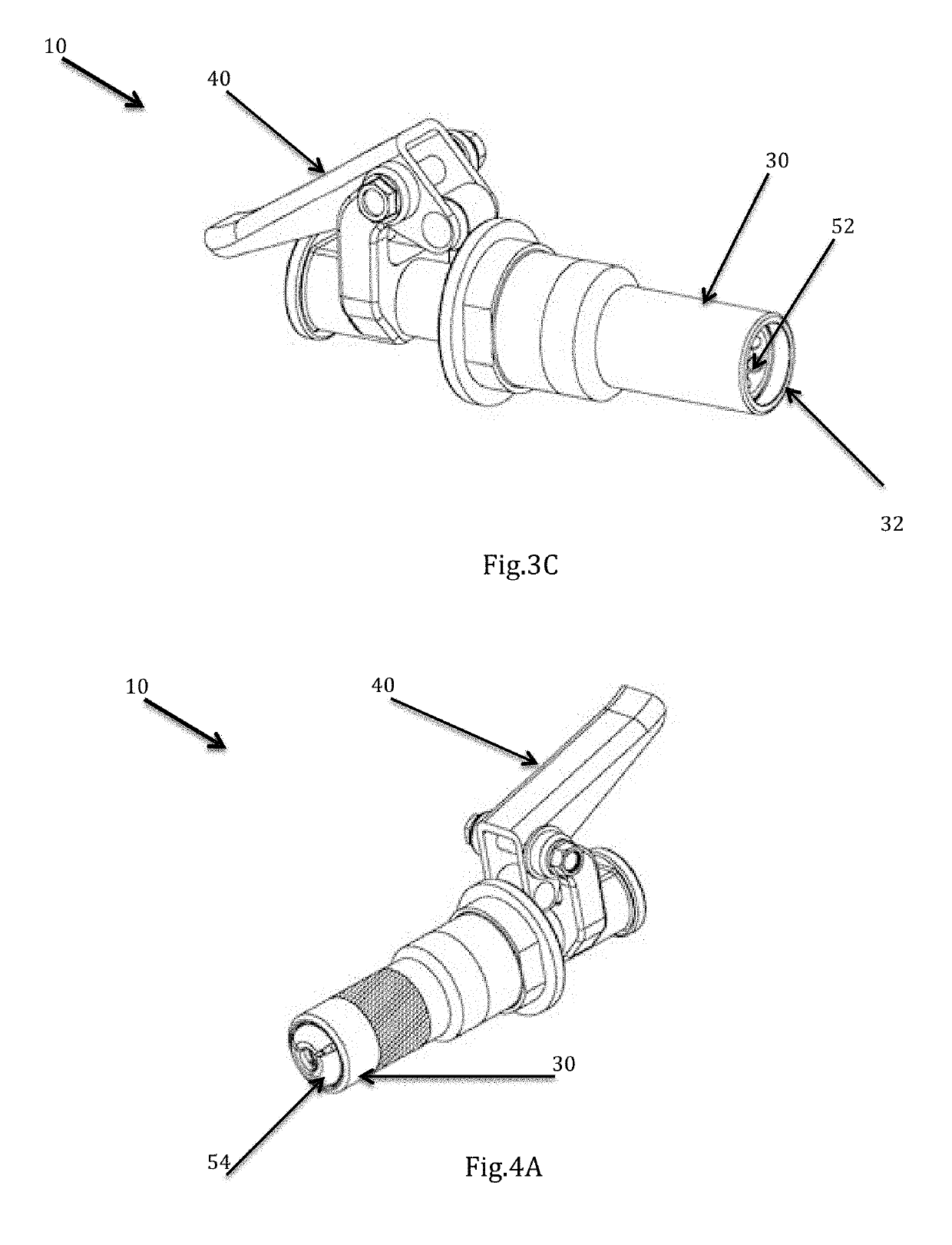

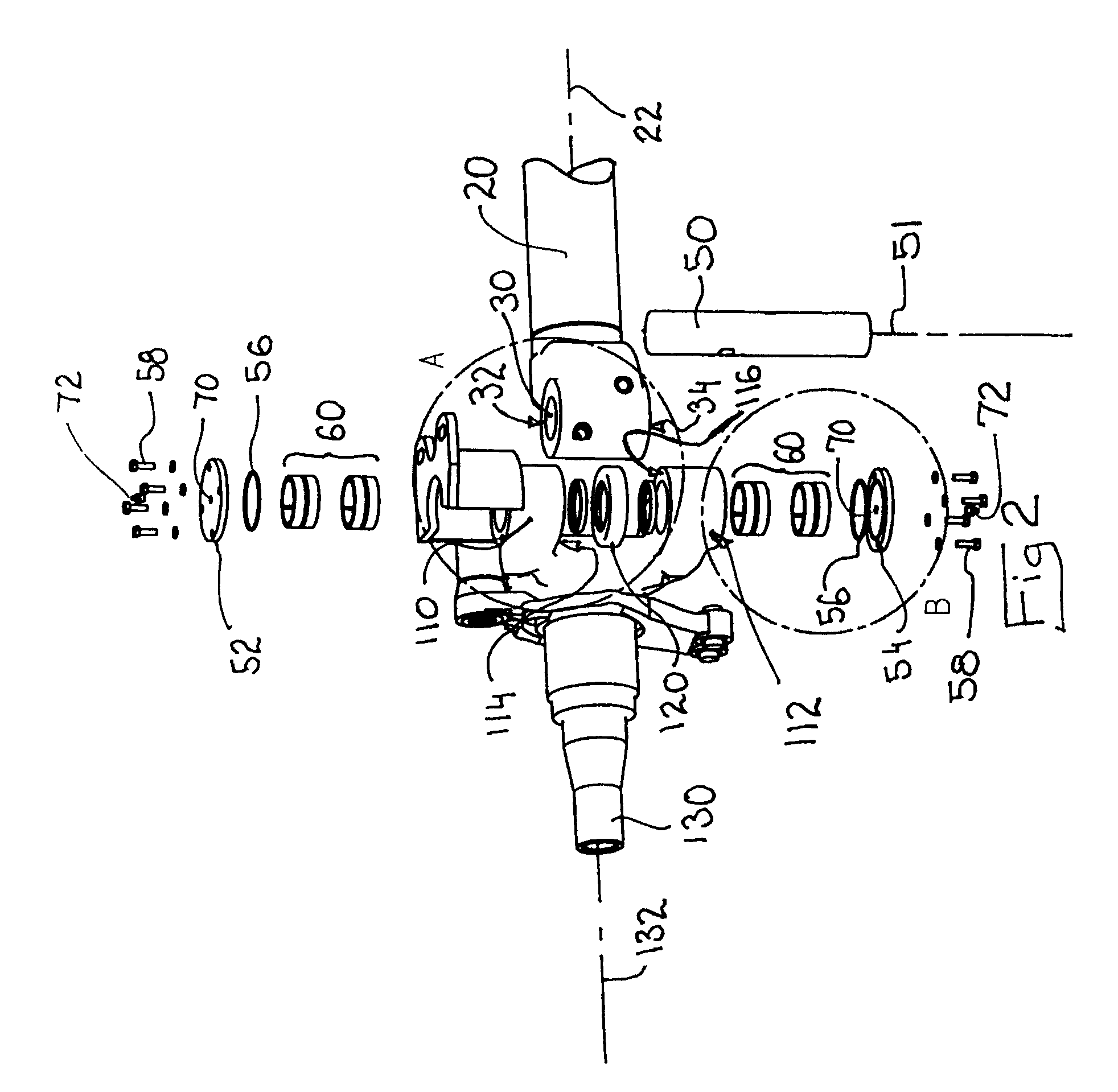

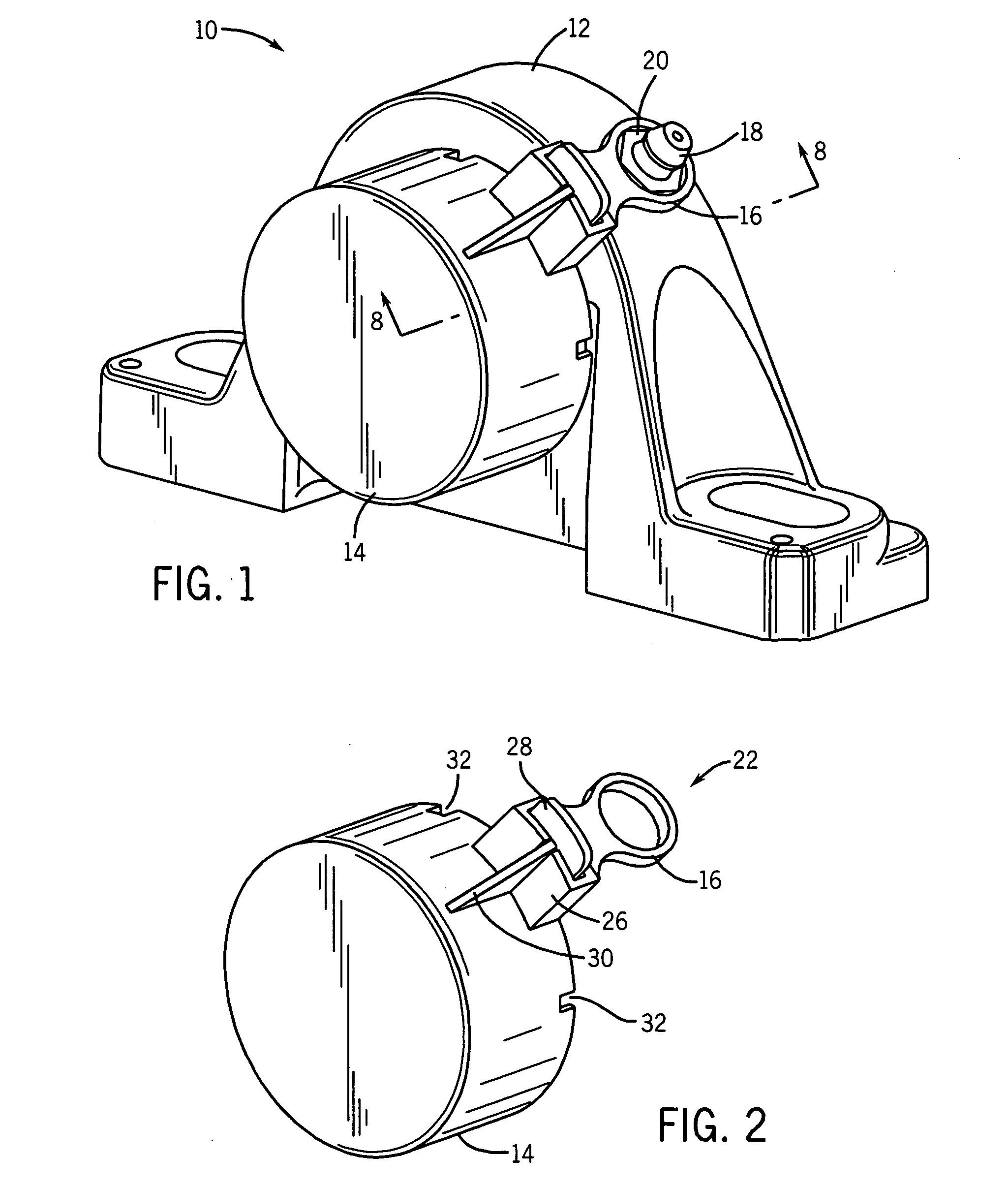

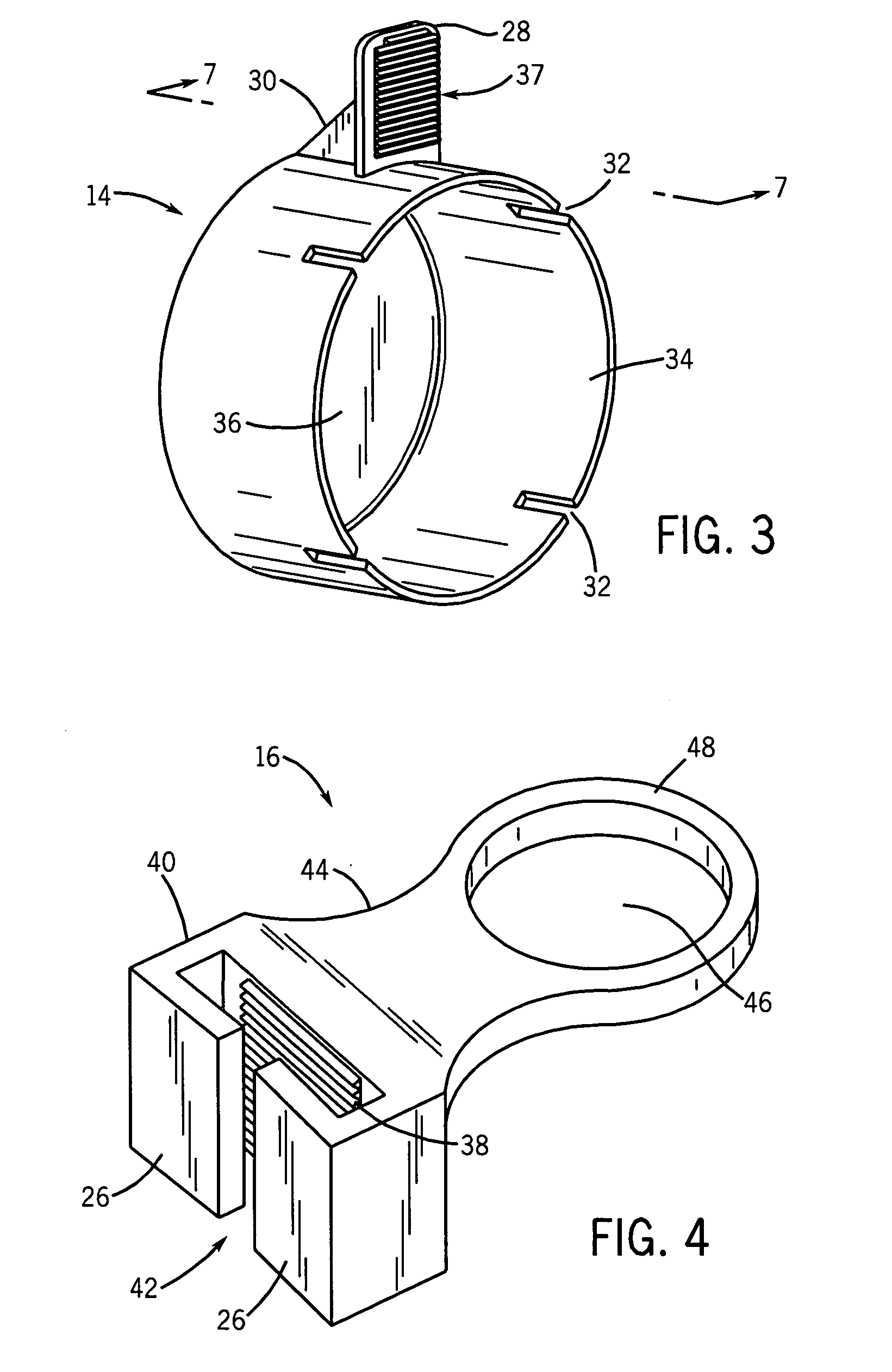

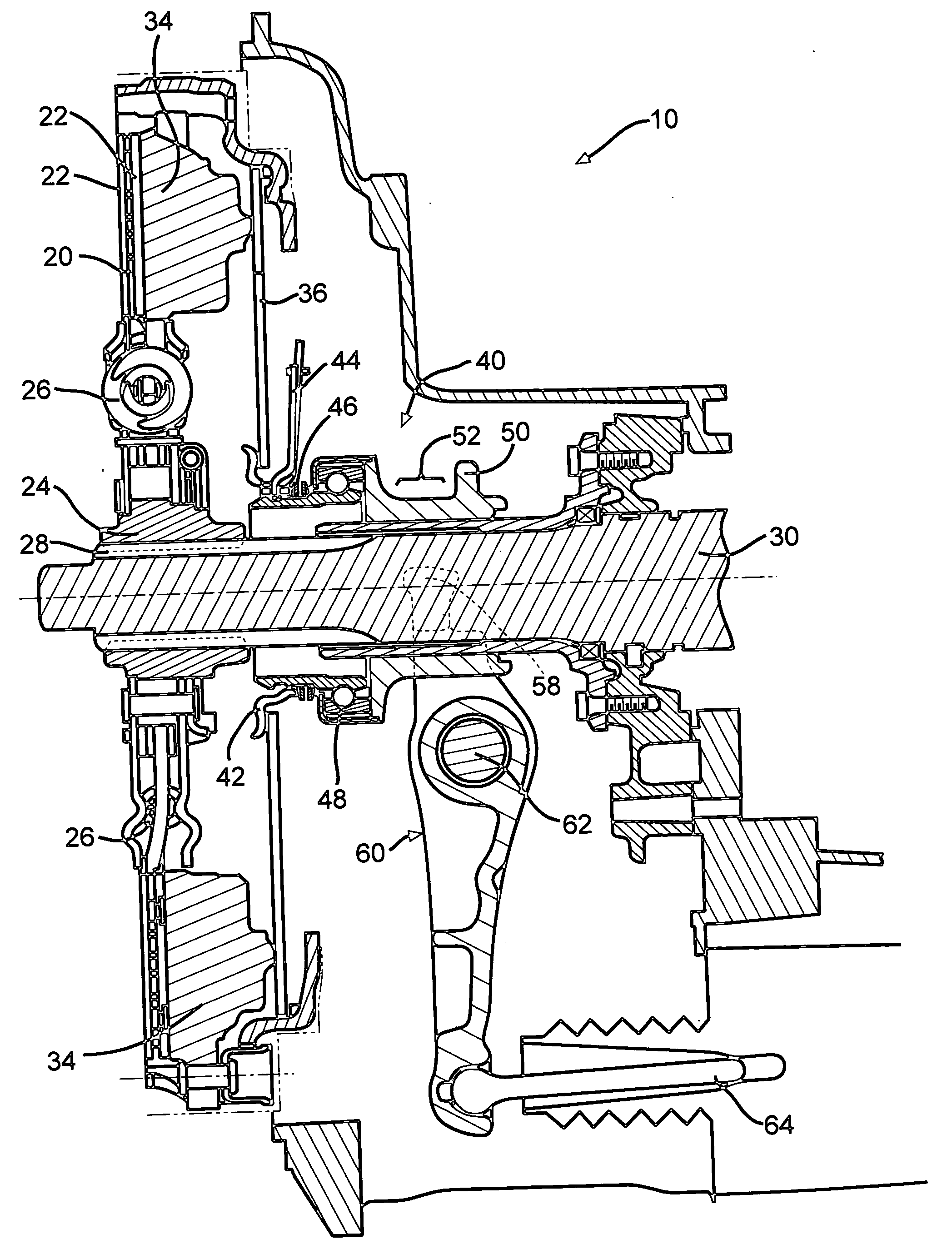

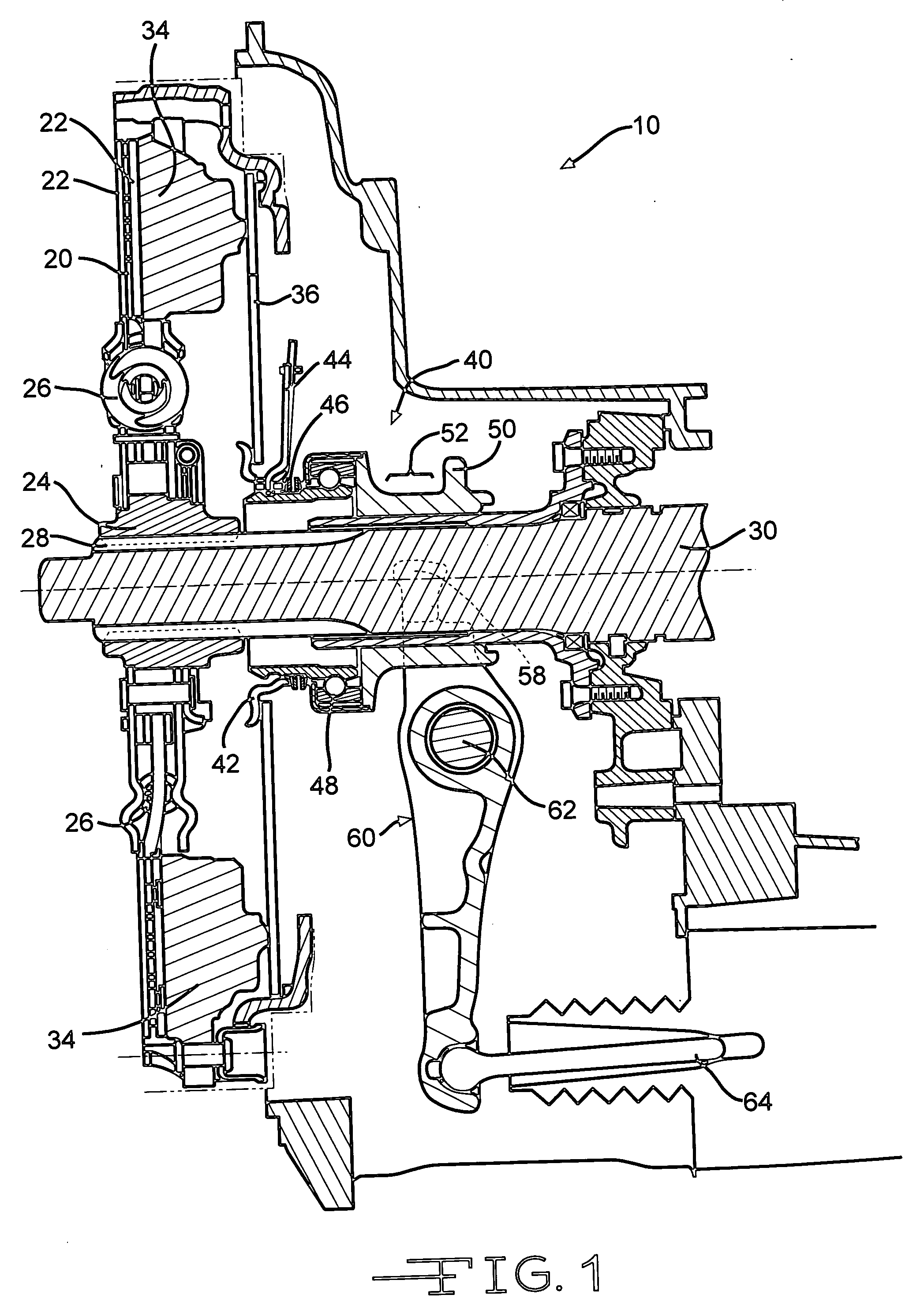

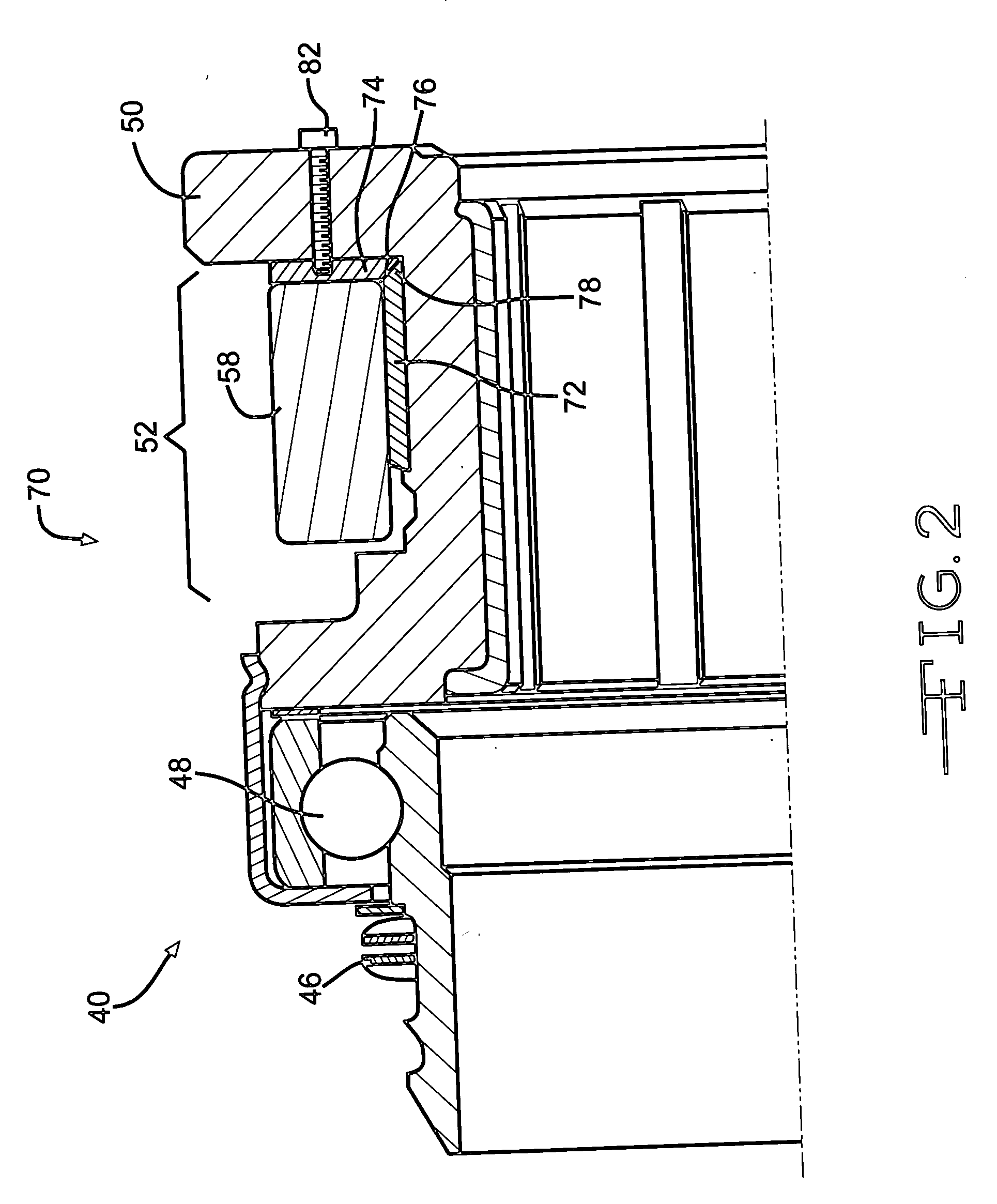

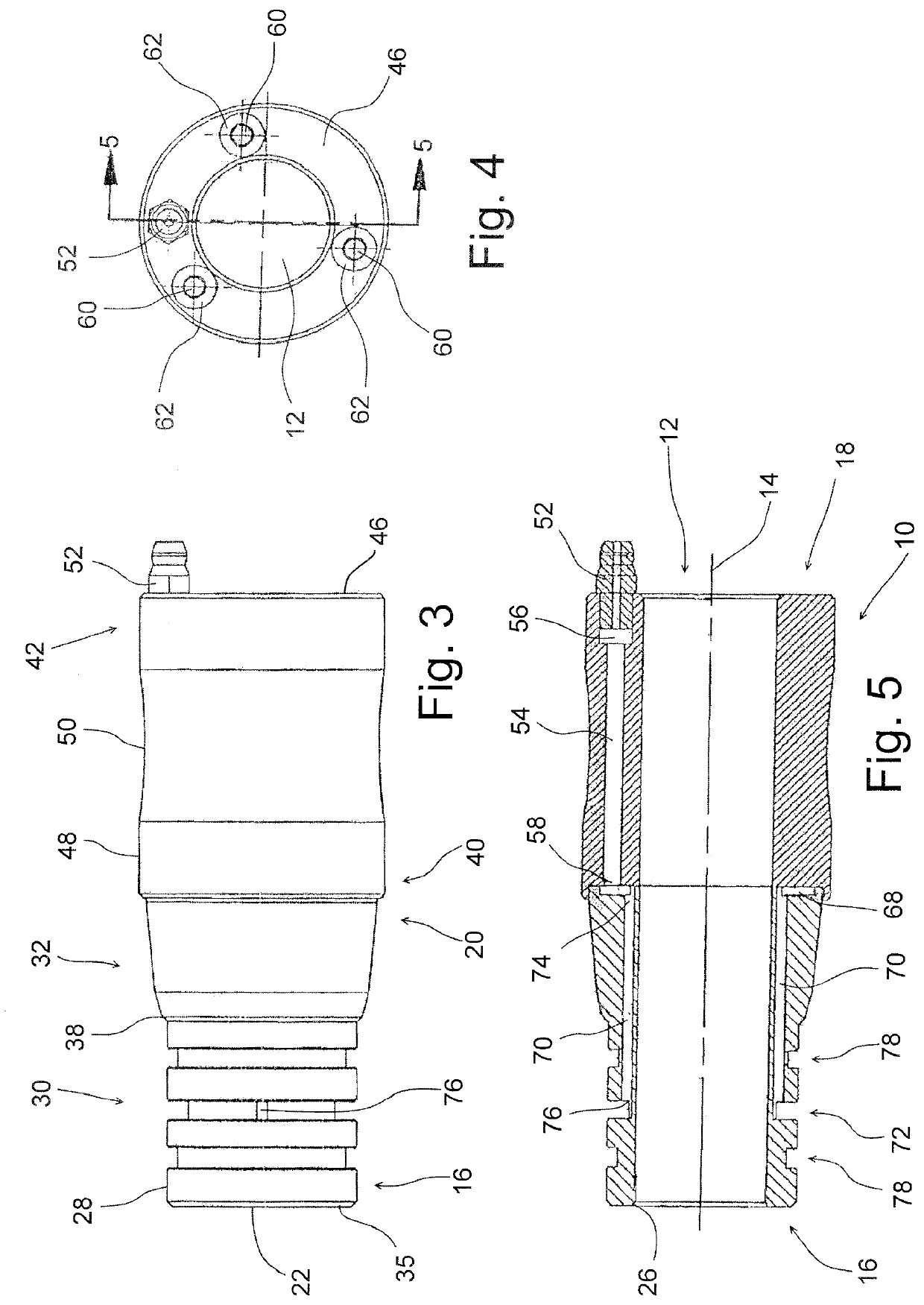

The problem to be solved is to provide a coupling device (10) that provides efficient engaging and disengaging of the nipple (62) with the coupling device (10) and especially that provides quick release of the nipple (62) with the coupling device (10) after flow of grease through it at high velocity and pressure without exerting excessive pressure on the coupling device (10) by the user, and the problem is solved by providing a coupling device (10) as in present invention that includes a lever (40) with a linkage mechanism that has a roller (48), which movably connects the lever (40) to the slider to move the slider axially forward and backward to disengage and engage the clamping unit (50) with the nipple (62) of the grease fitting by releasing and applying pressure exerted by a protrusion (32) structured at the end of the slider (30) opposite to the side facing the lever (40). FIG. 1 is the representative figure.

Owner:GROZ ENG TOOLS P LTD

Swivel joint with electrical conductivity grease fitting

Owner:KNAPPCO CORP

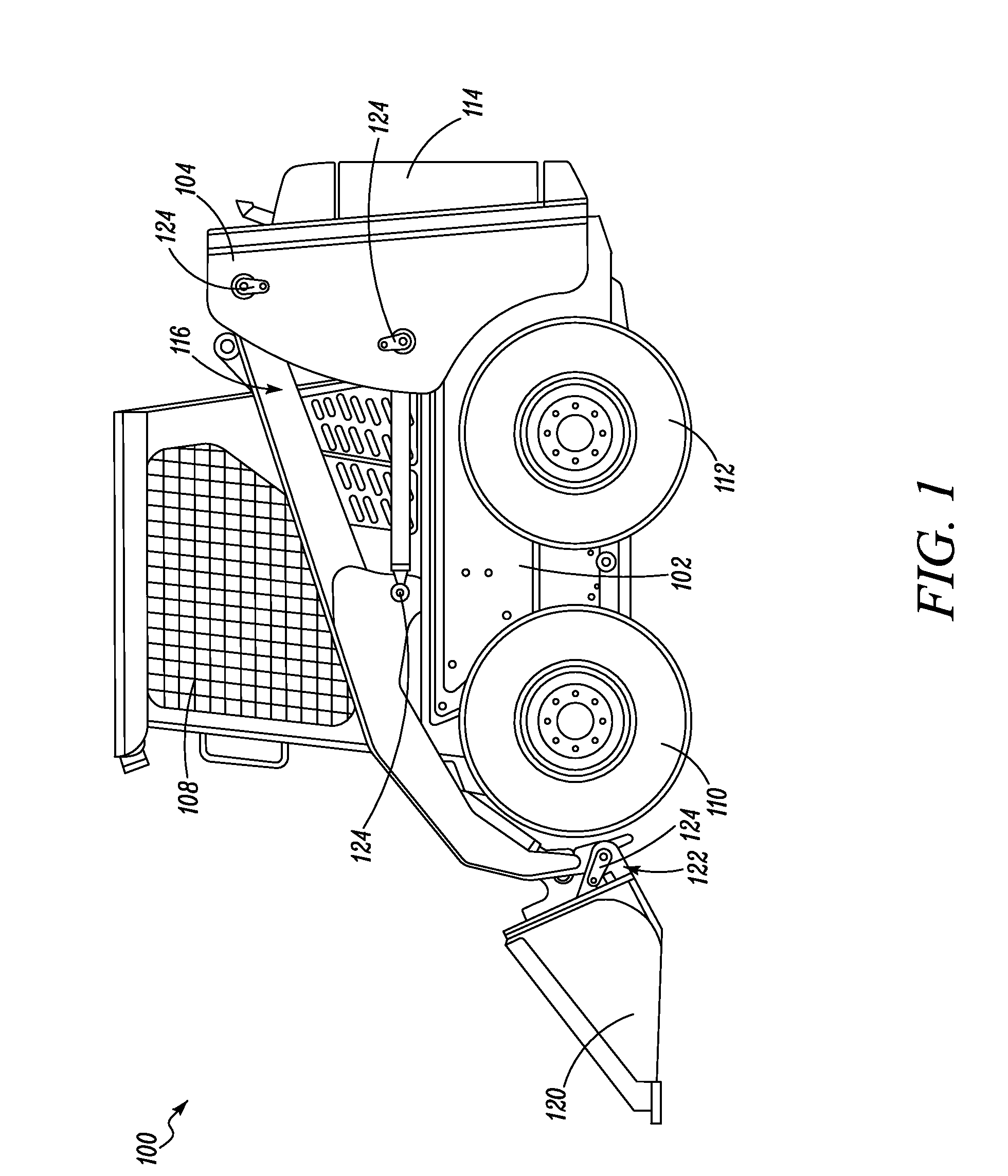

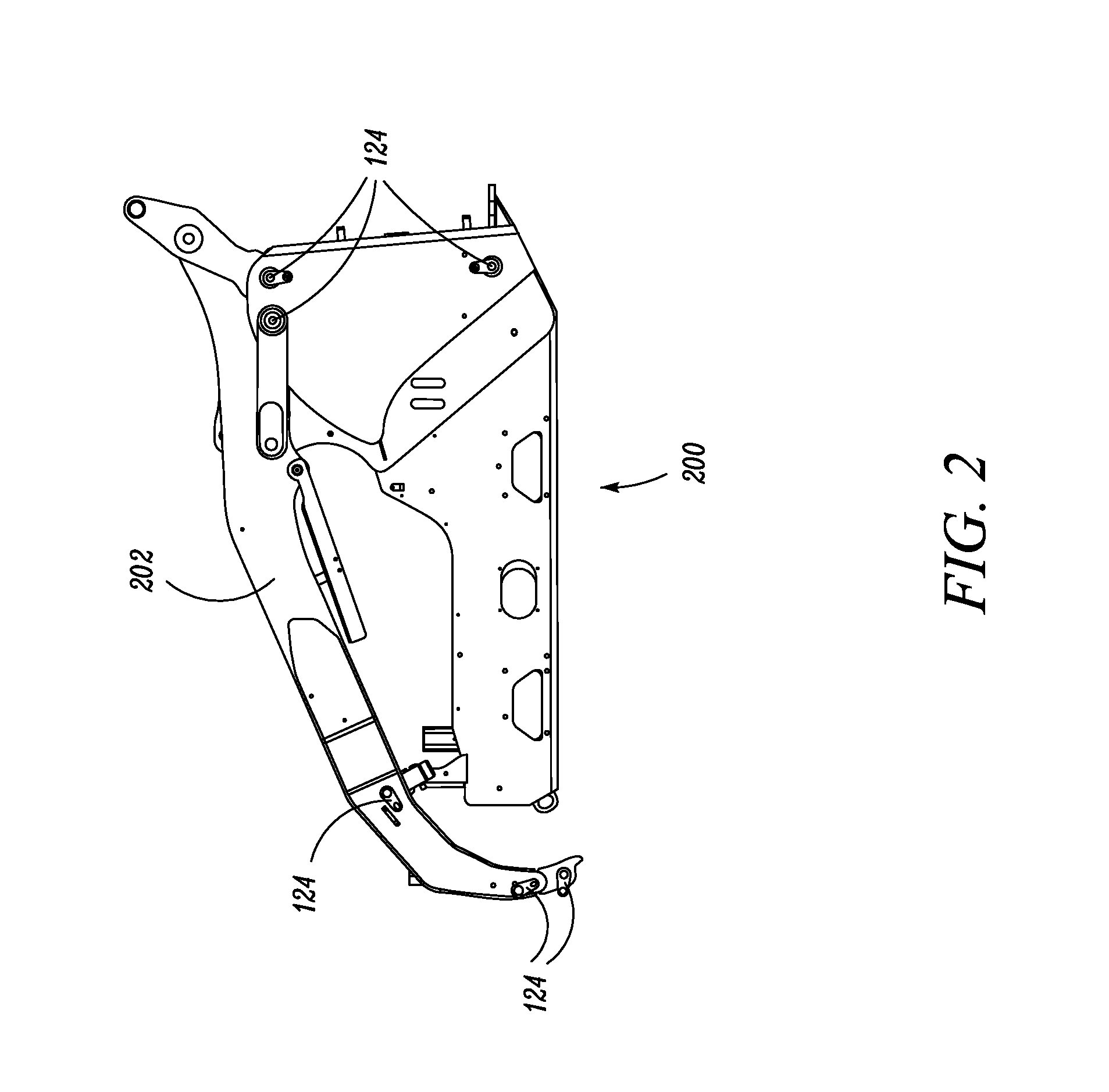

Steer axle assembly

An improved steer axle assembly for a trailer is provided in which a tapered roller thrust bearing extends between each lower kingpin yoke thrust face and each lower kingpin sleeve thrust face to transfer load between the lower yoke sleeve and the kingpin sleeve while allowing the yokes to swivel about the kingpins. Upper and lower needle bearing assemblies extend respectively between the upper and lower yoke sleeves and the kingpins to guide the swivelable movement of the yokes about the kingpins. Upper and lower kingpin caps are secured across the upper and lower yoke sleeves respectively above and below the kingpins to seal the opposite ends of the kingpins within the yoke sleeves. At least one of the upper and lower kingpin caps associated with each kingpin has a grease passage extending therethrough for admitting grease into an interior of the yoke sleeves and a grease fitting releaseably coupleable to a pressurized grease supply and sealingly engaging the grease passage to introduce grease into the grease passage.

Owner:2777216 ONTARIO

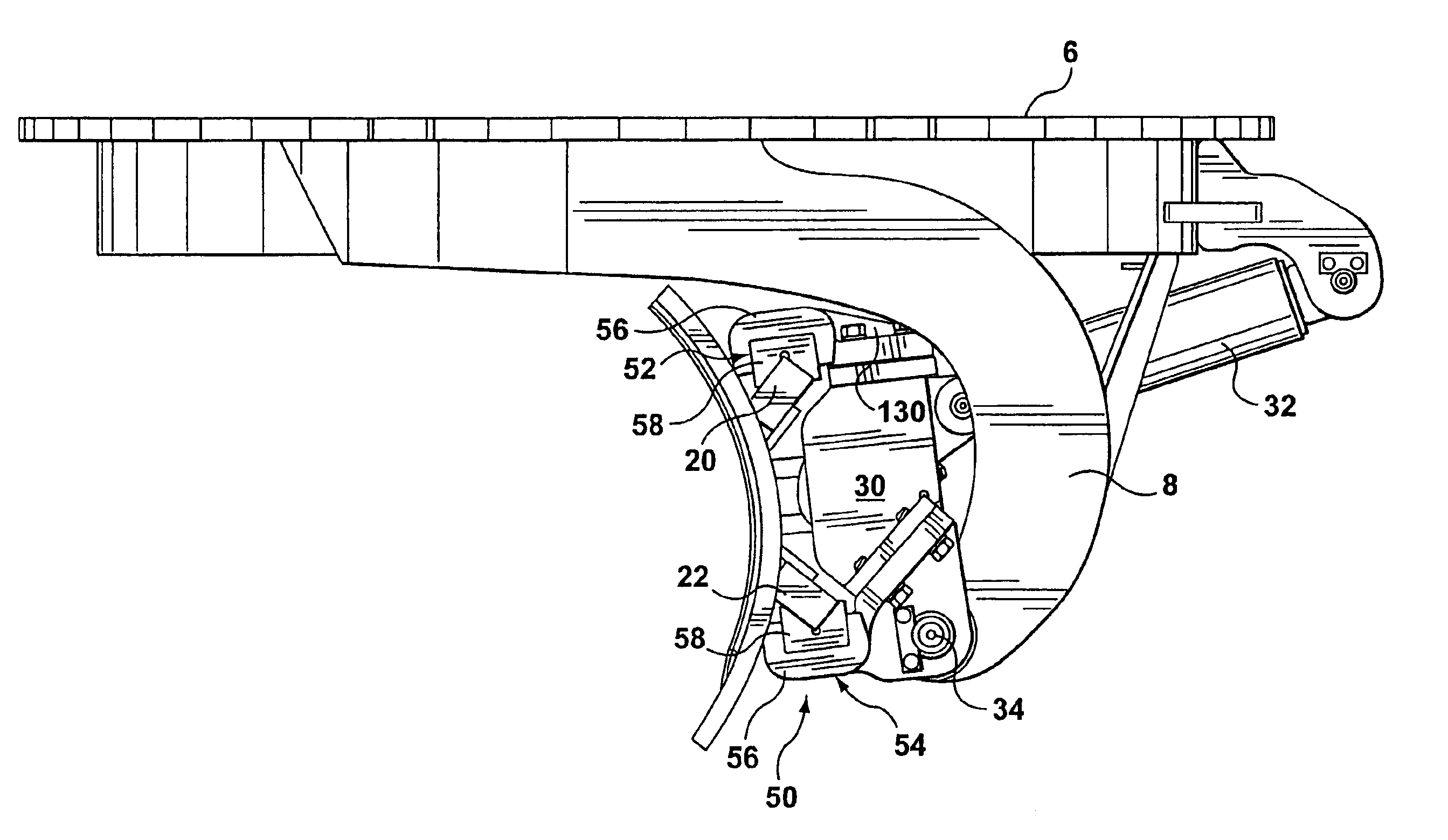

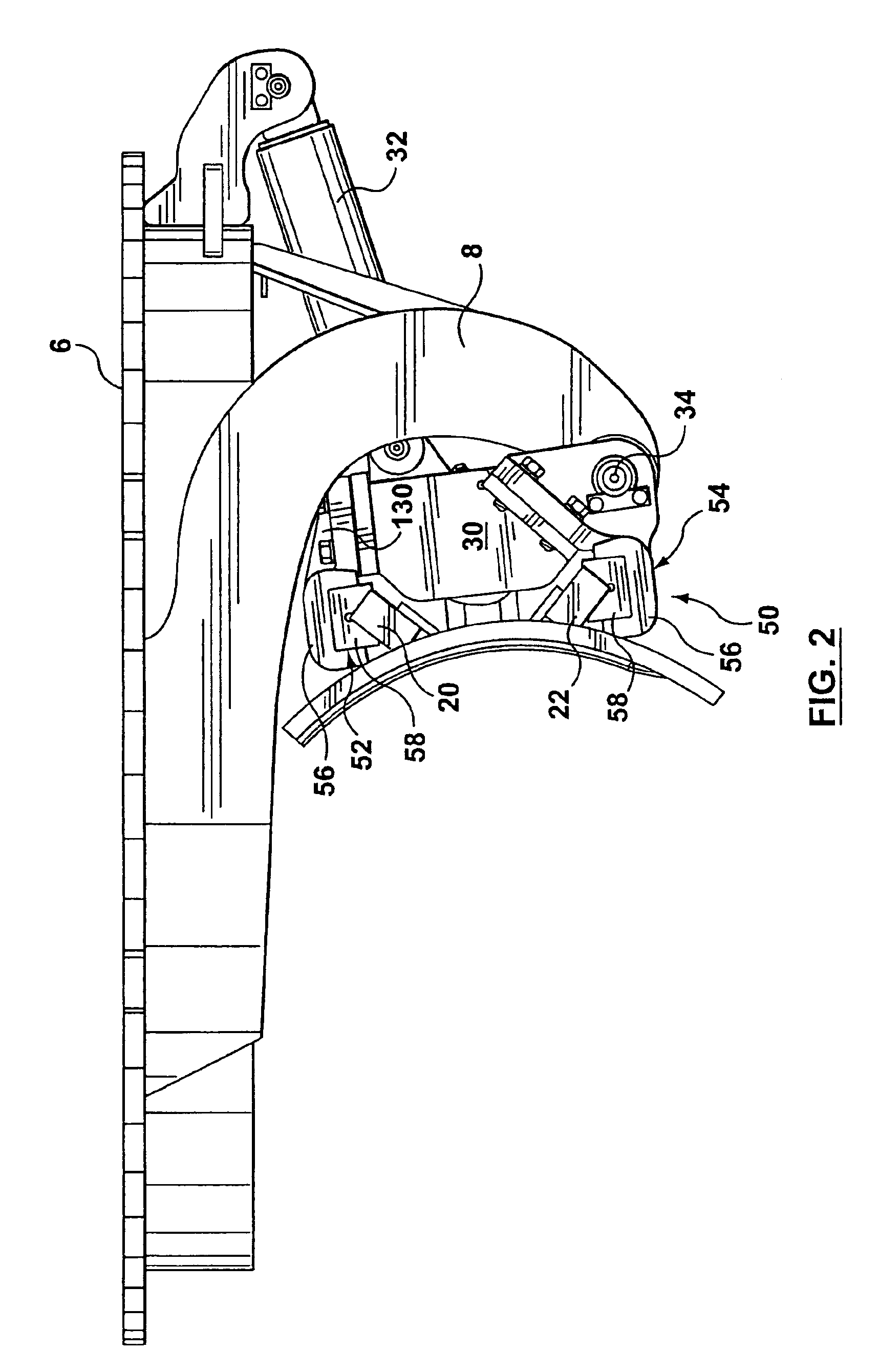

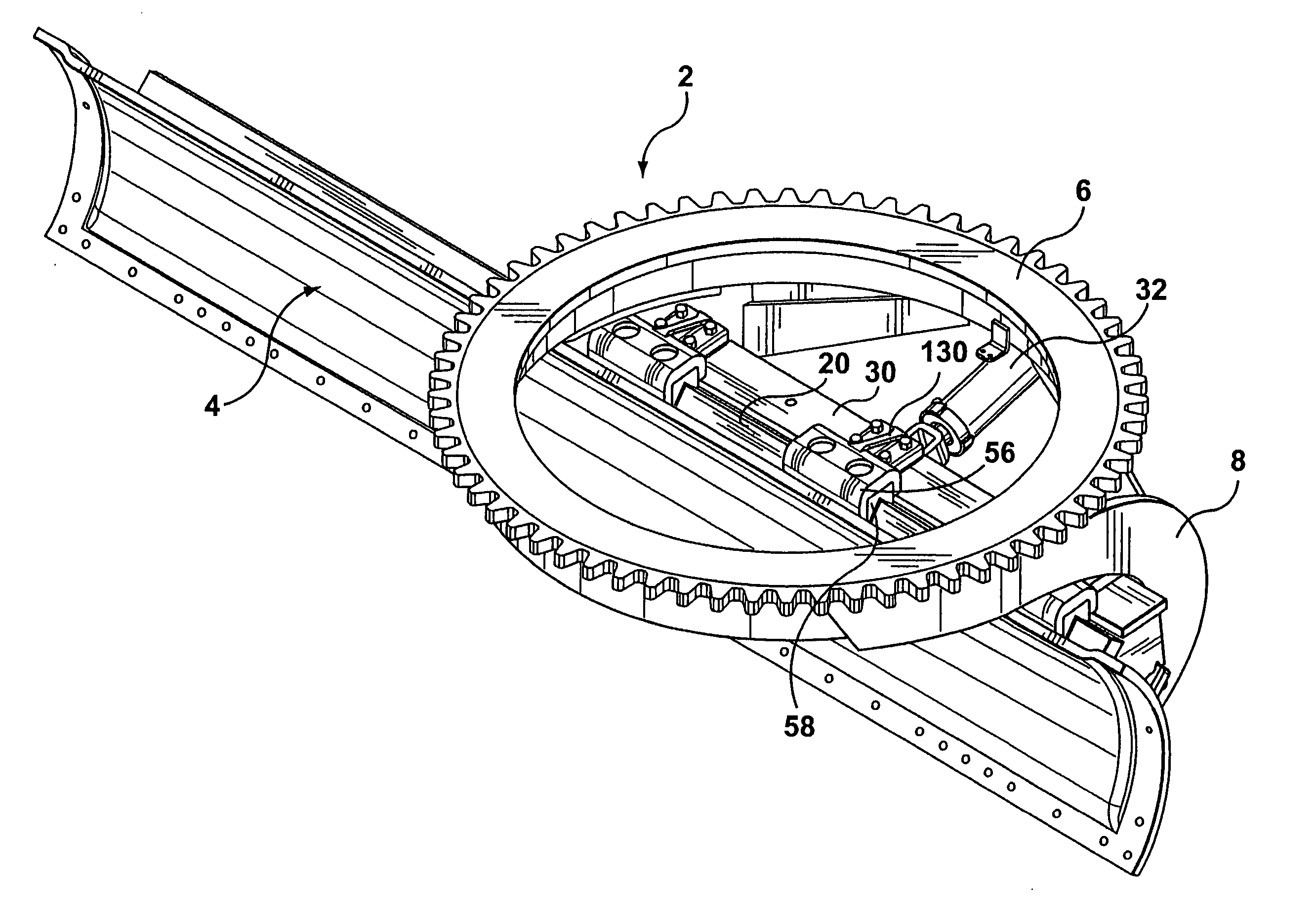

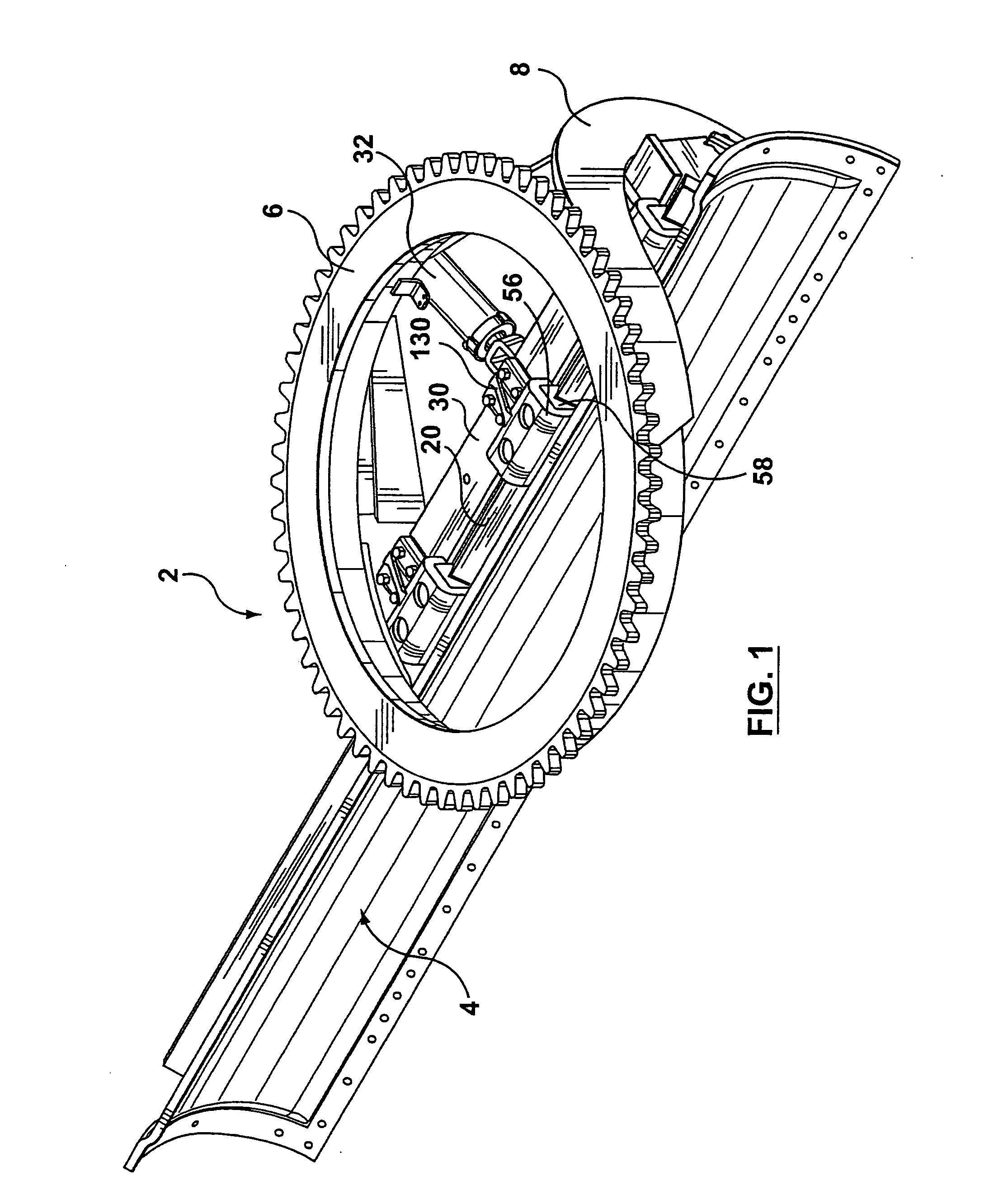

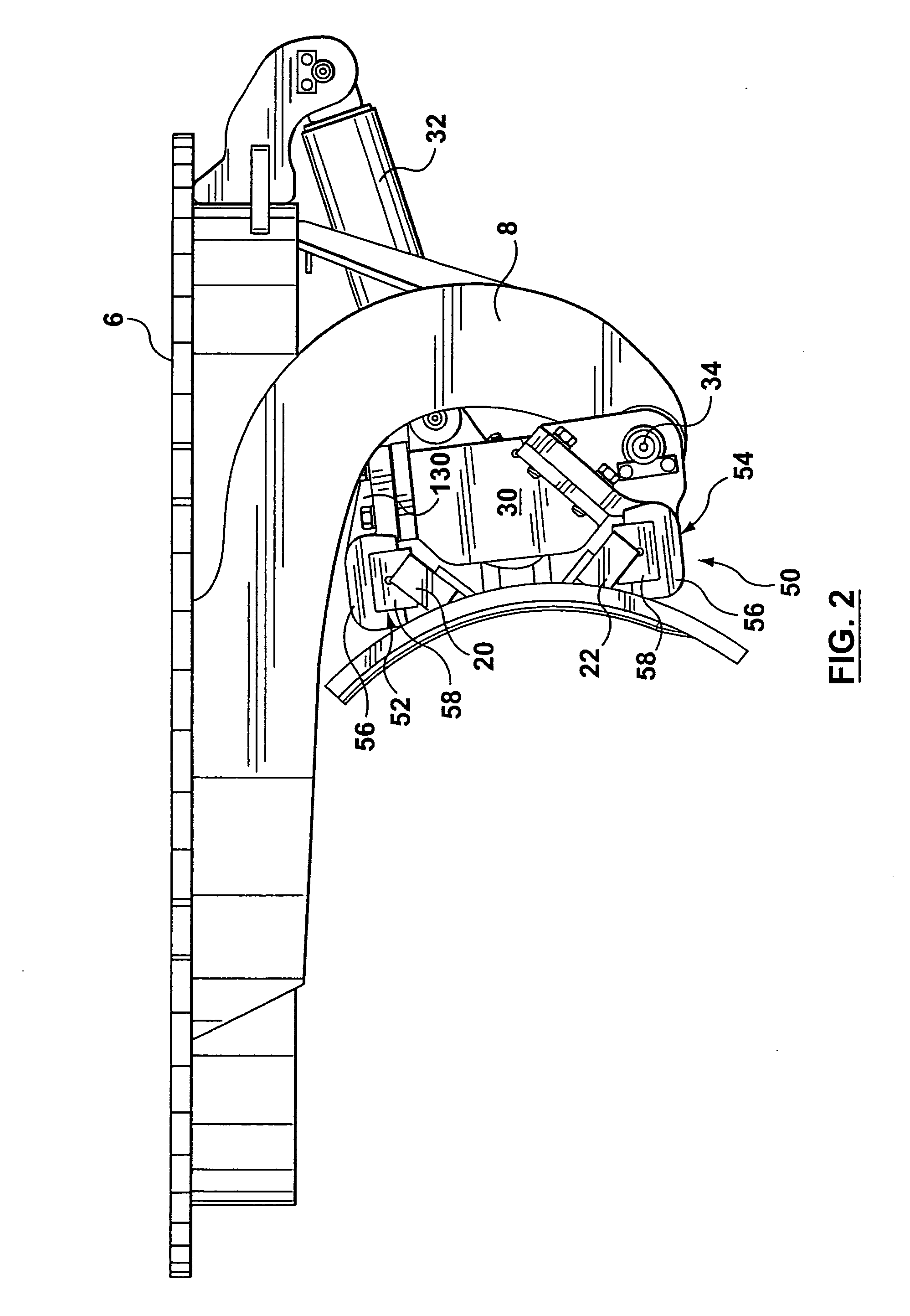

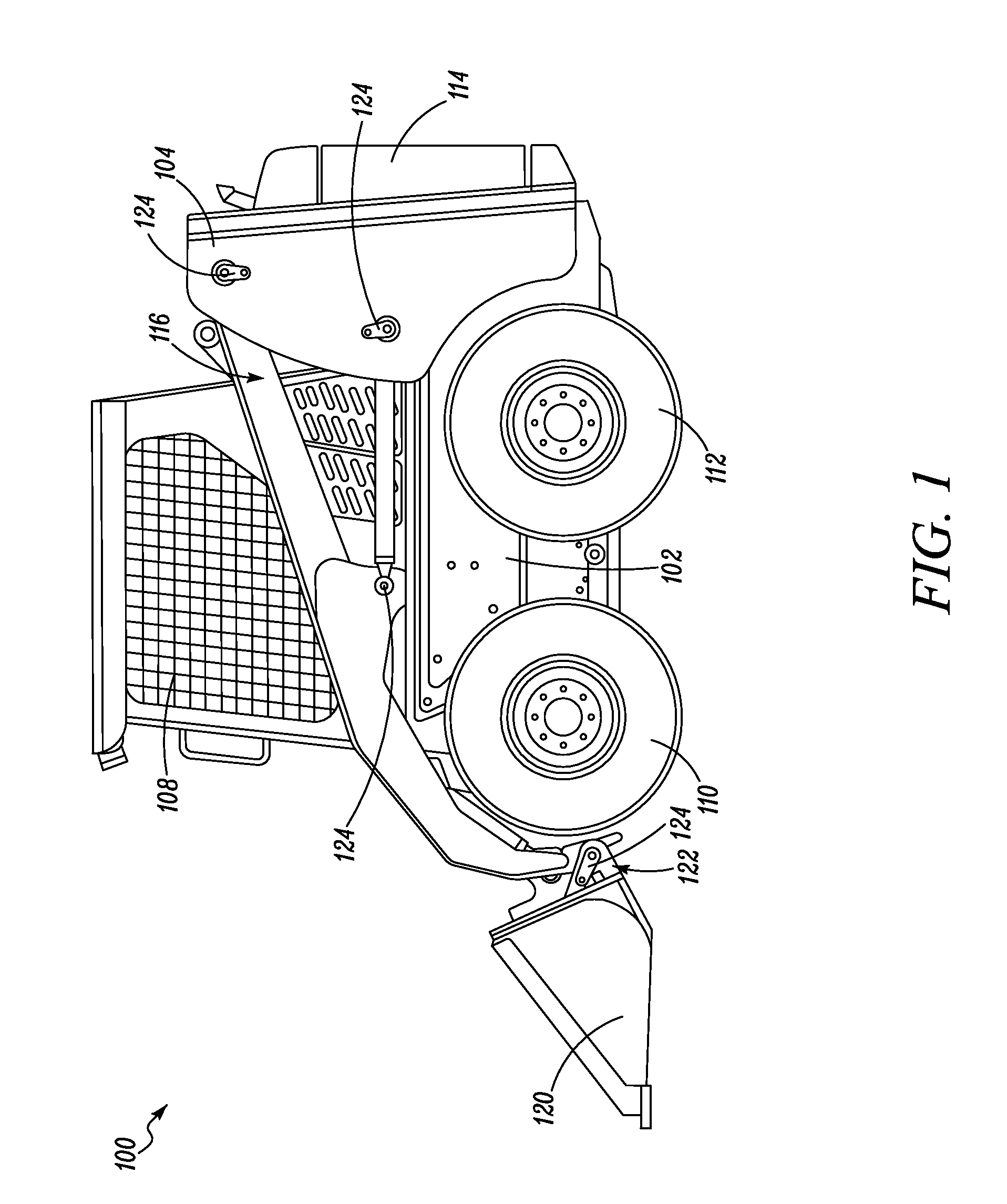

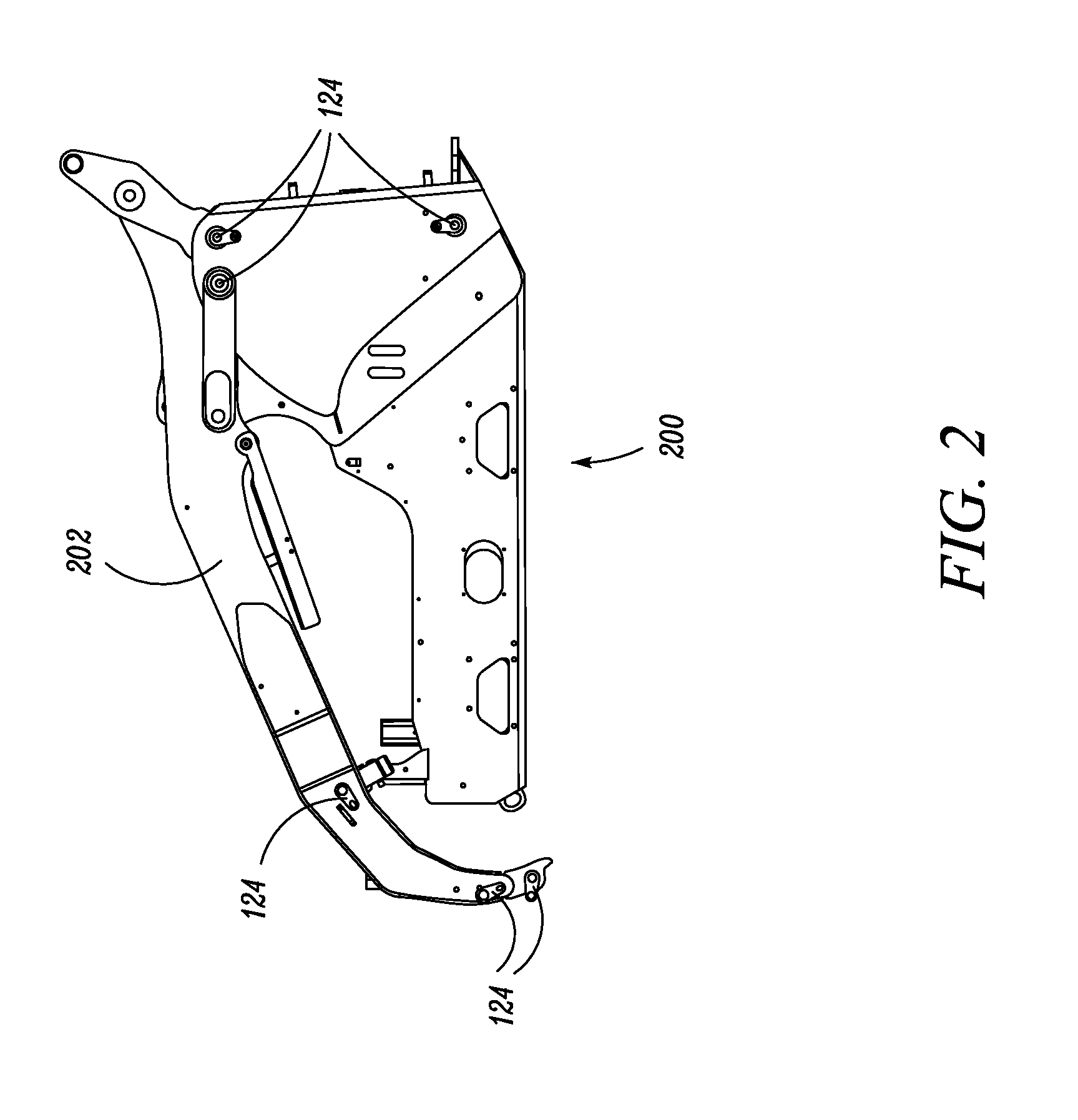

Slide rail adjustment for grader blade

A bearing support arrangement for a grader blade uses short stroke hydraulic cylinders to compensate for wear between slide bearings and slide rails of the grader blade. The cylinders are preferably pressurized by grease and a grease fitting is provided for each cylinder to provide convenient access, to allow service by the operator. Preferably the cylinders are located in a generally closed cavity between the bearing support holder and the slide bearing.

Owner:VOLVO MOTOR GRADERS

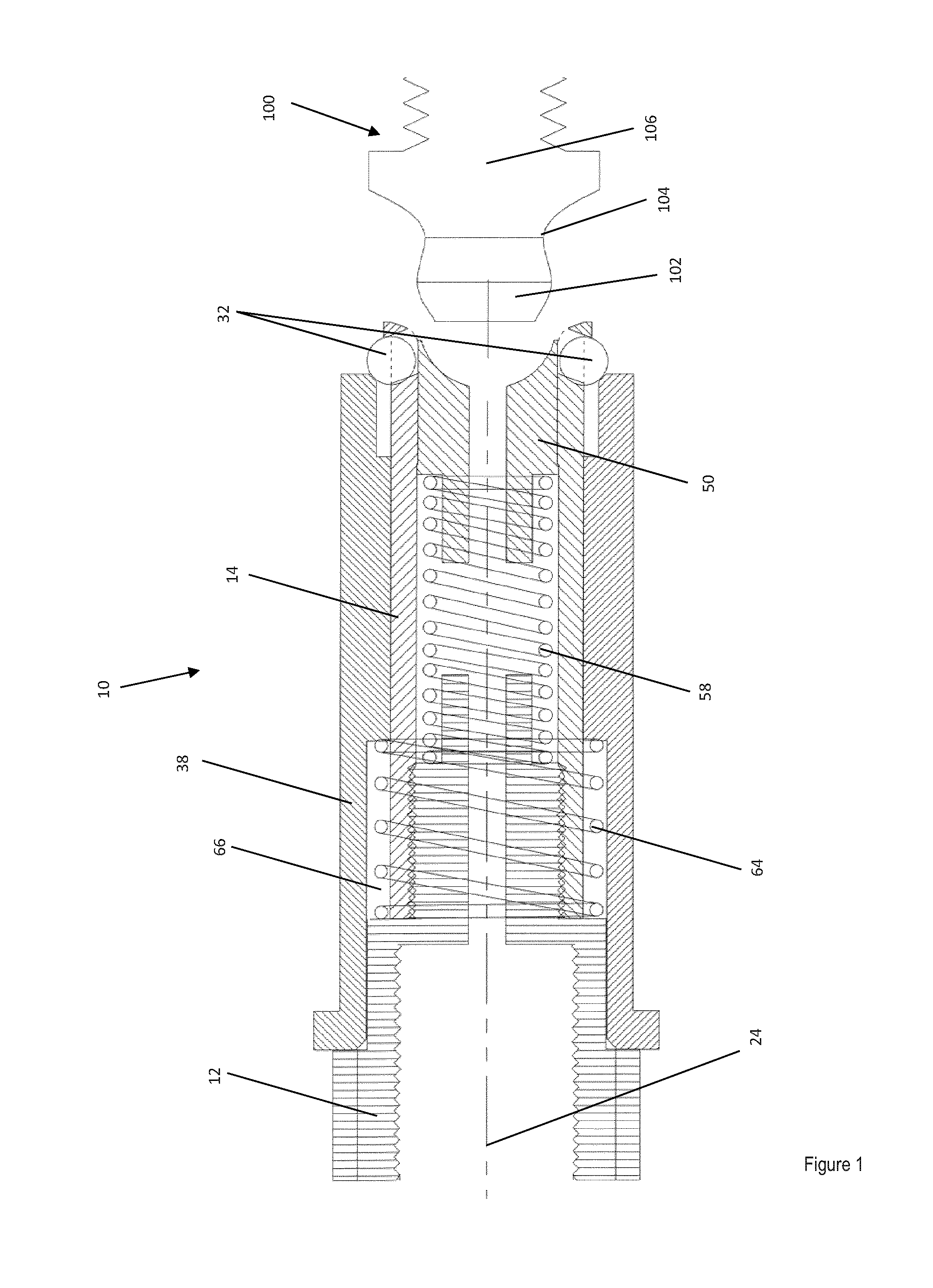

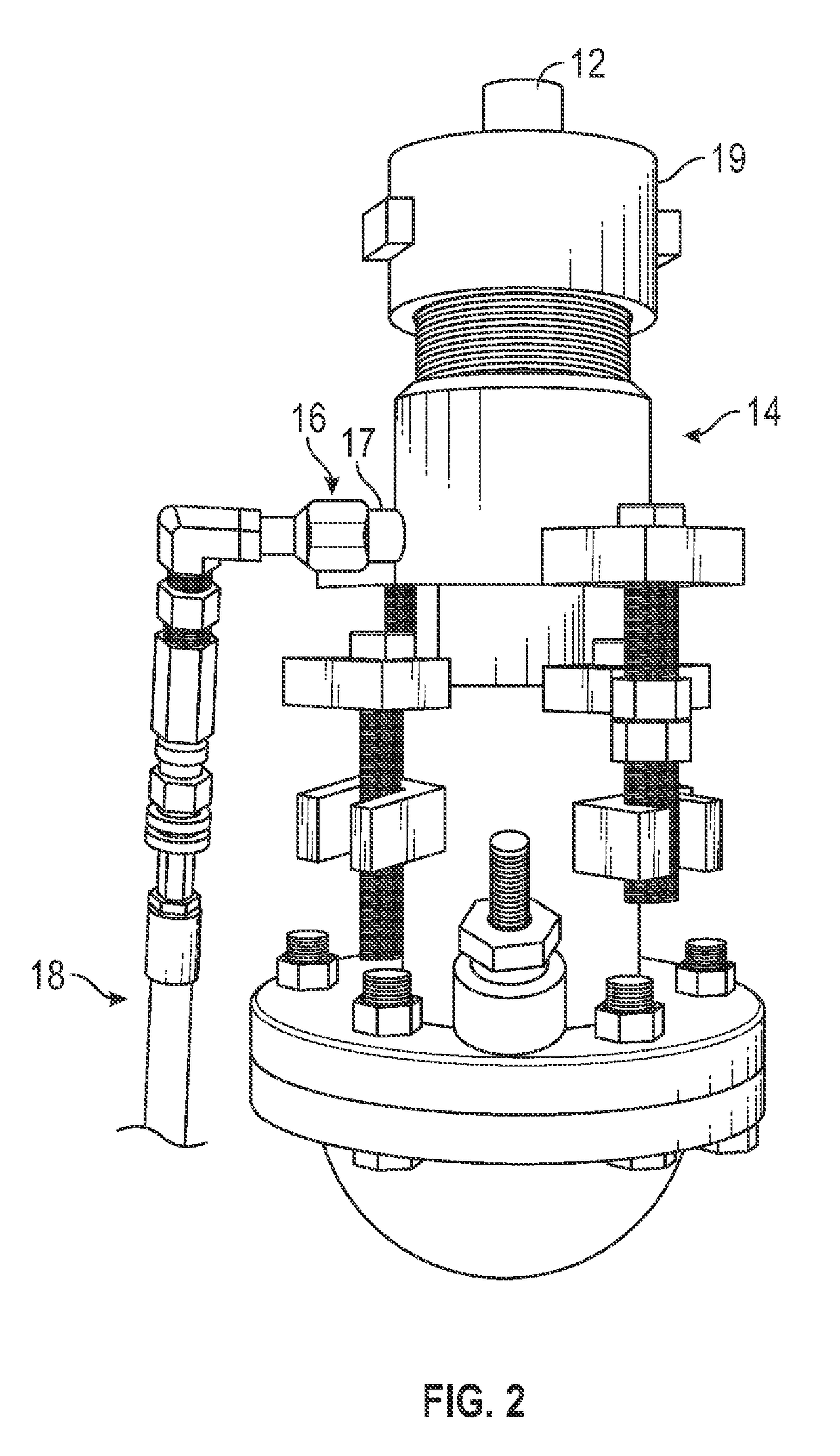

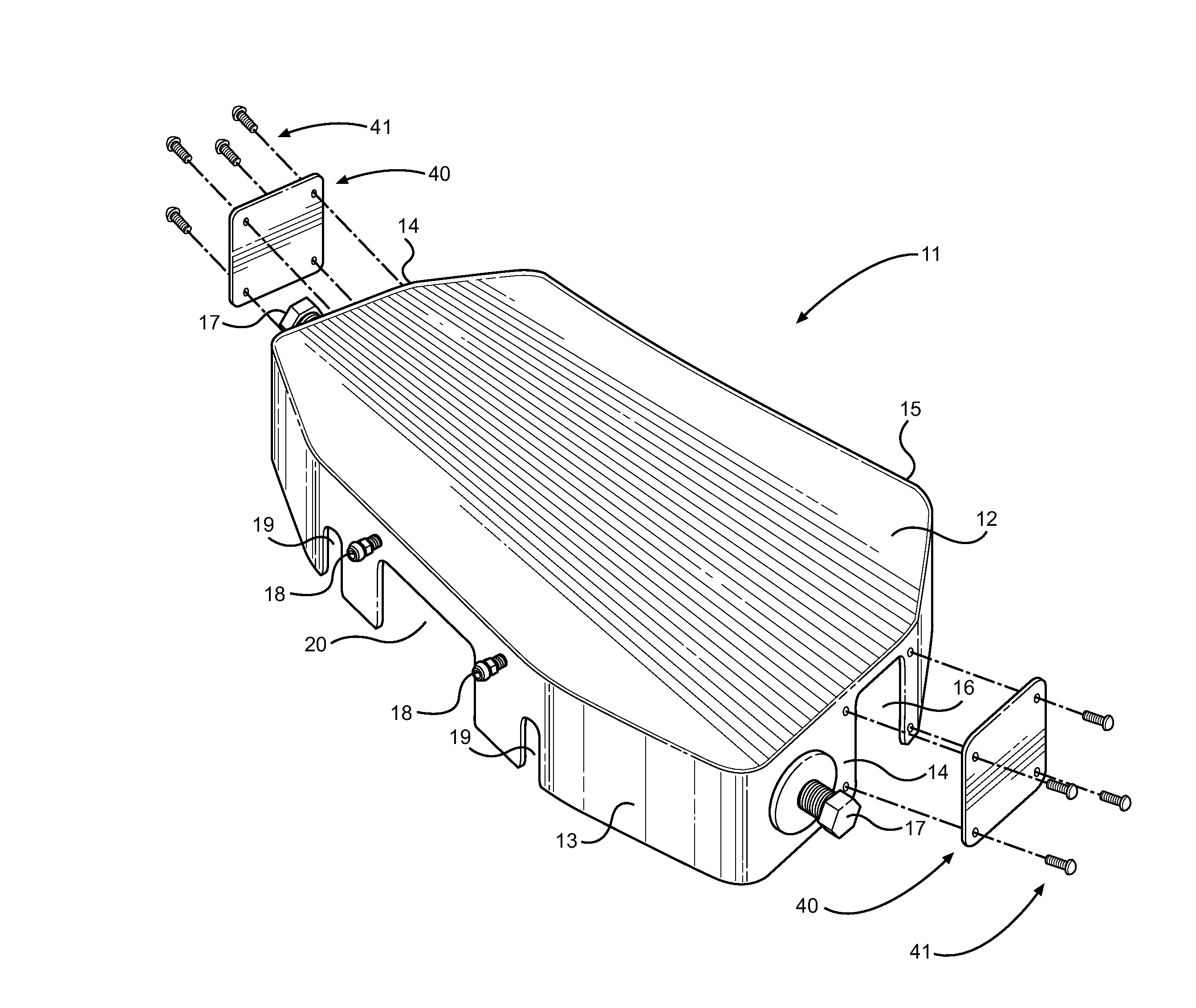

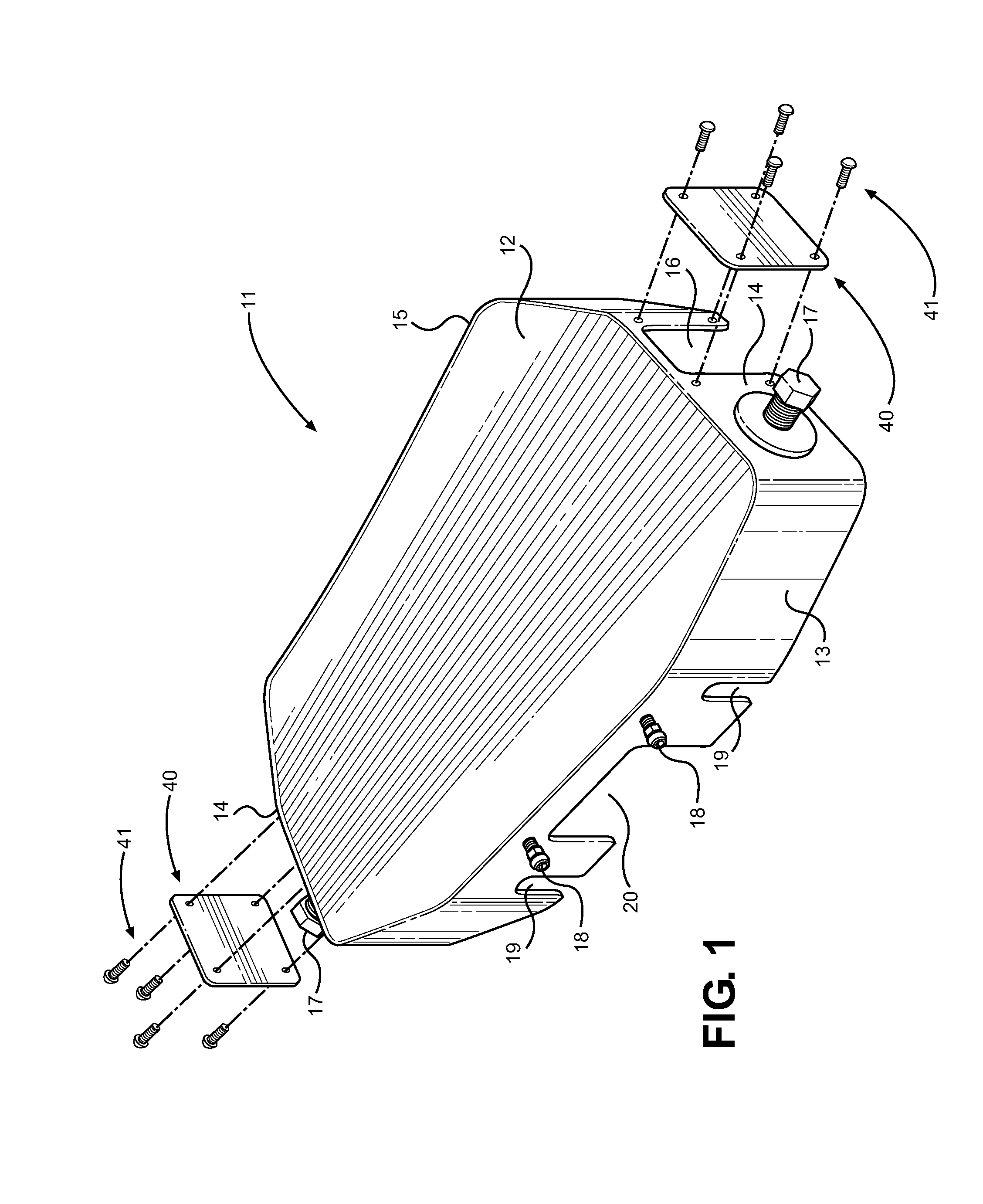

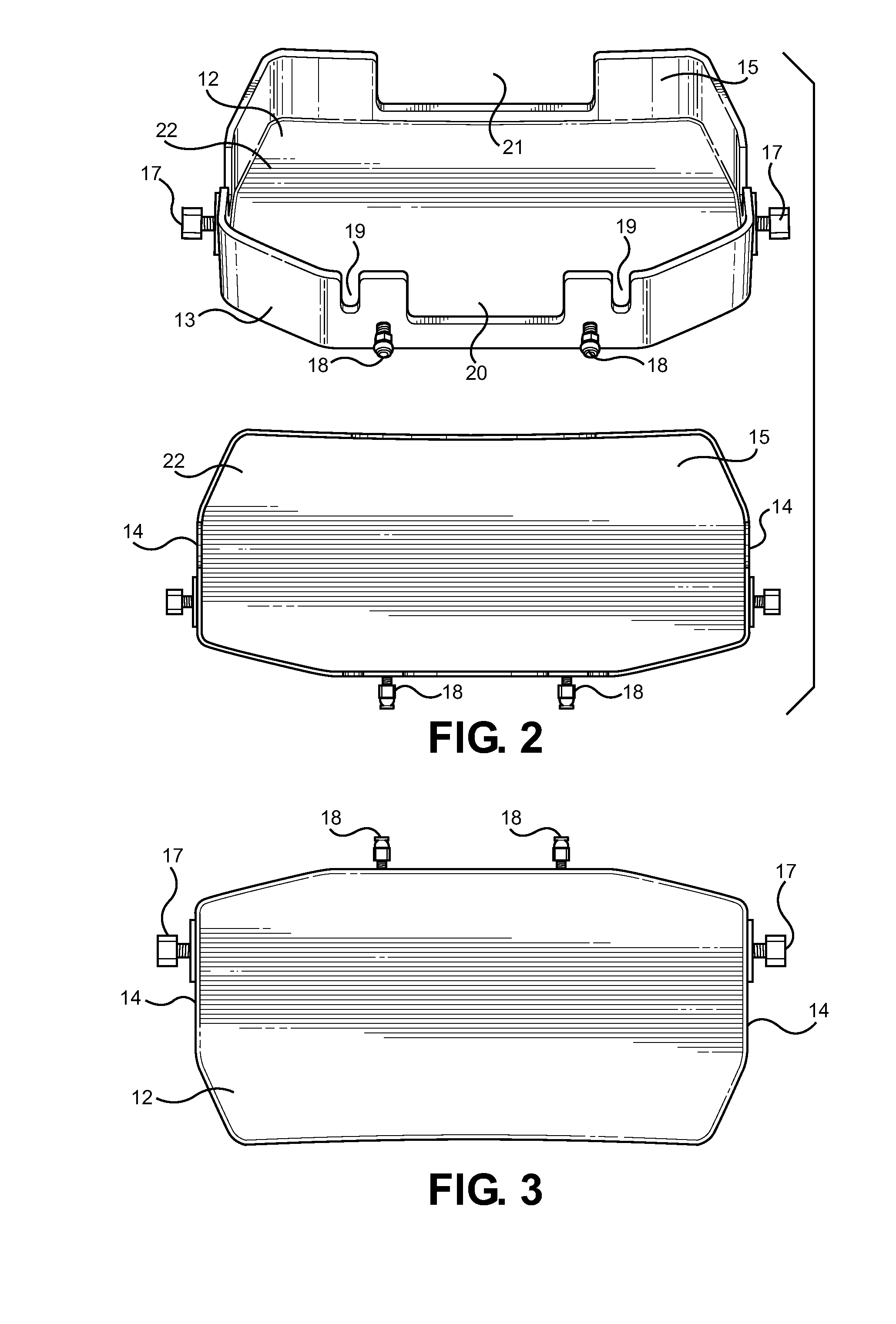

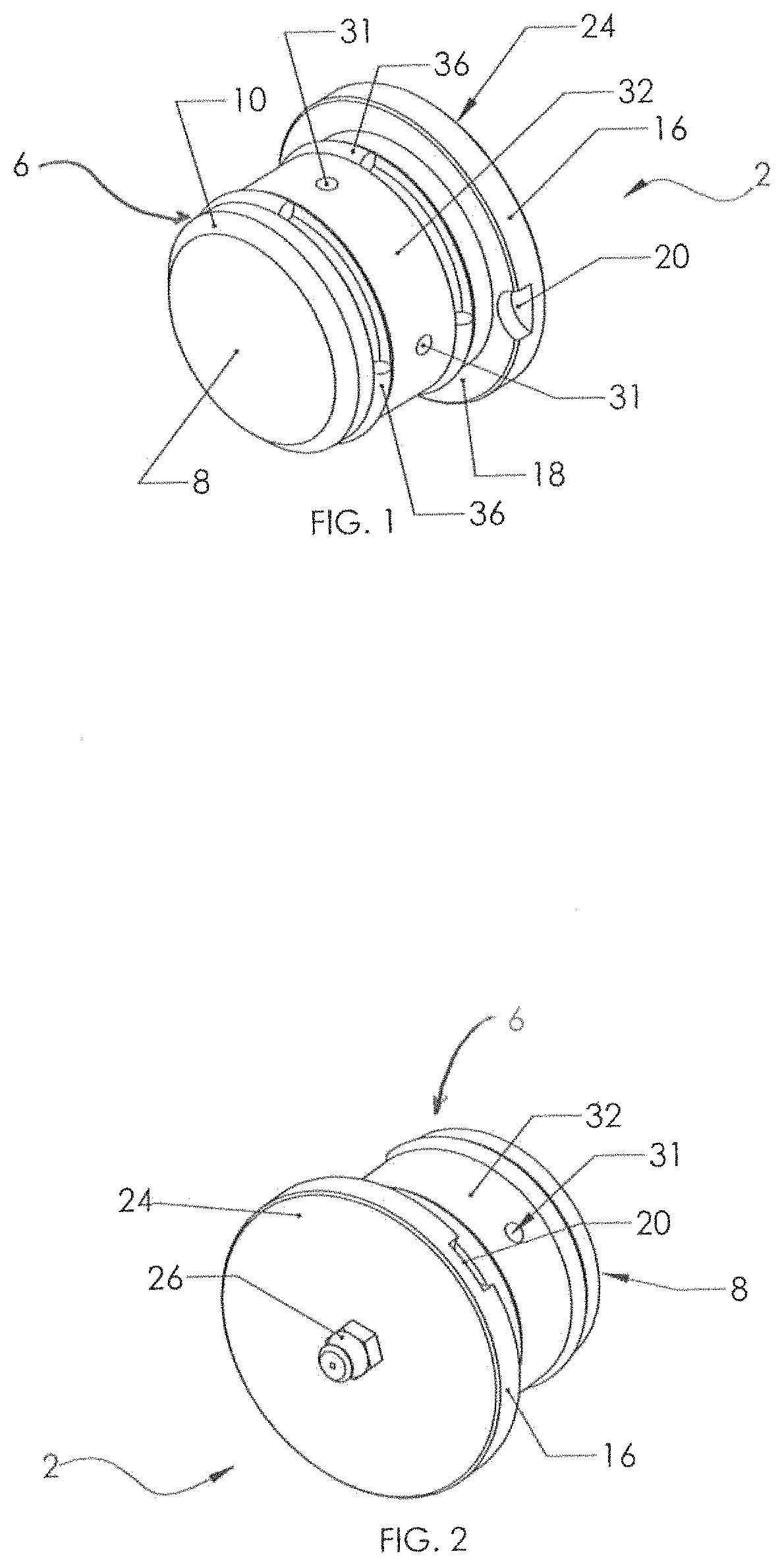

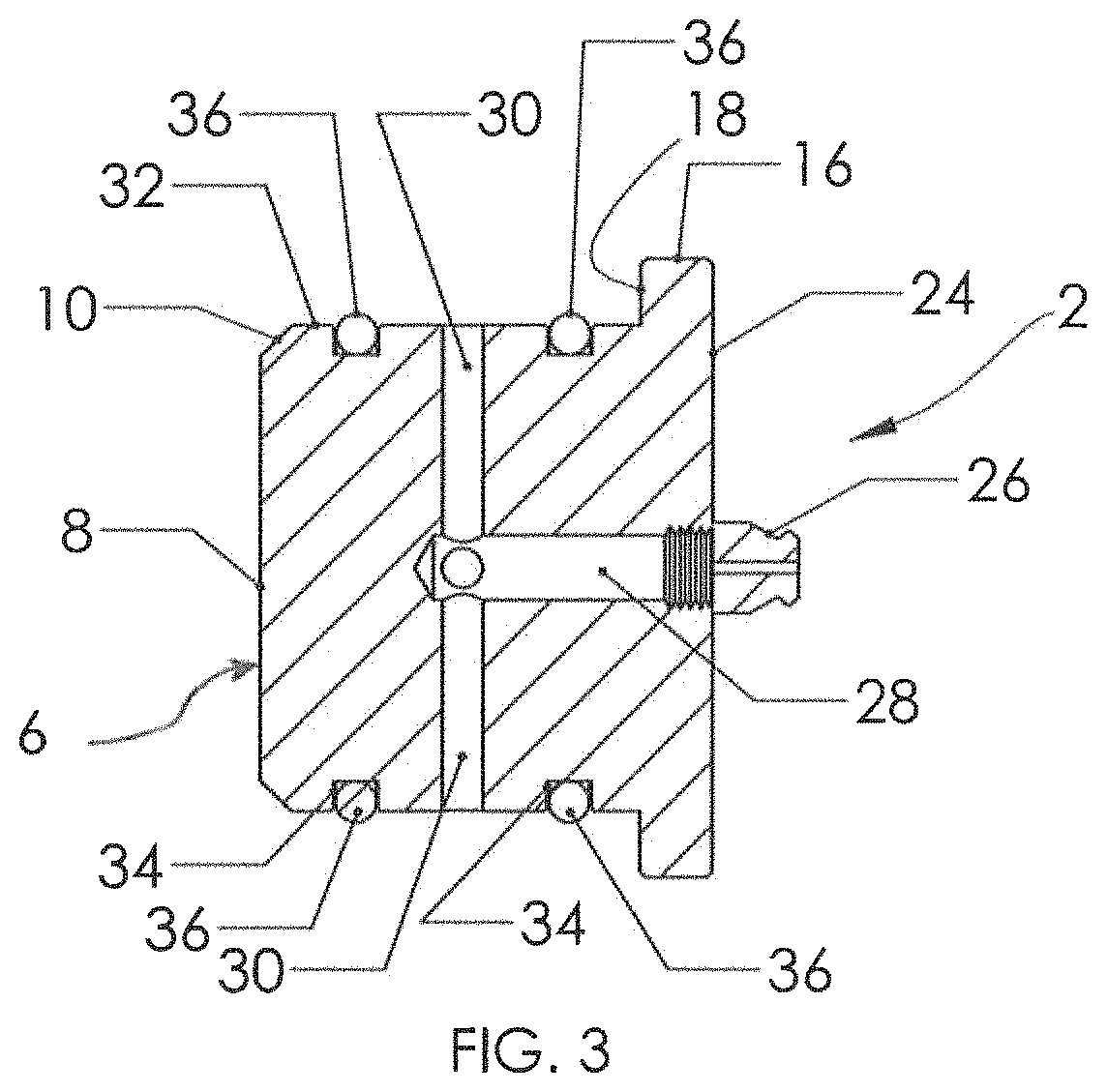

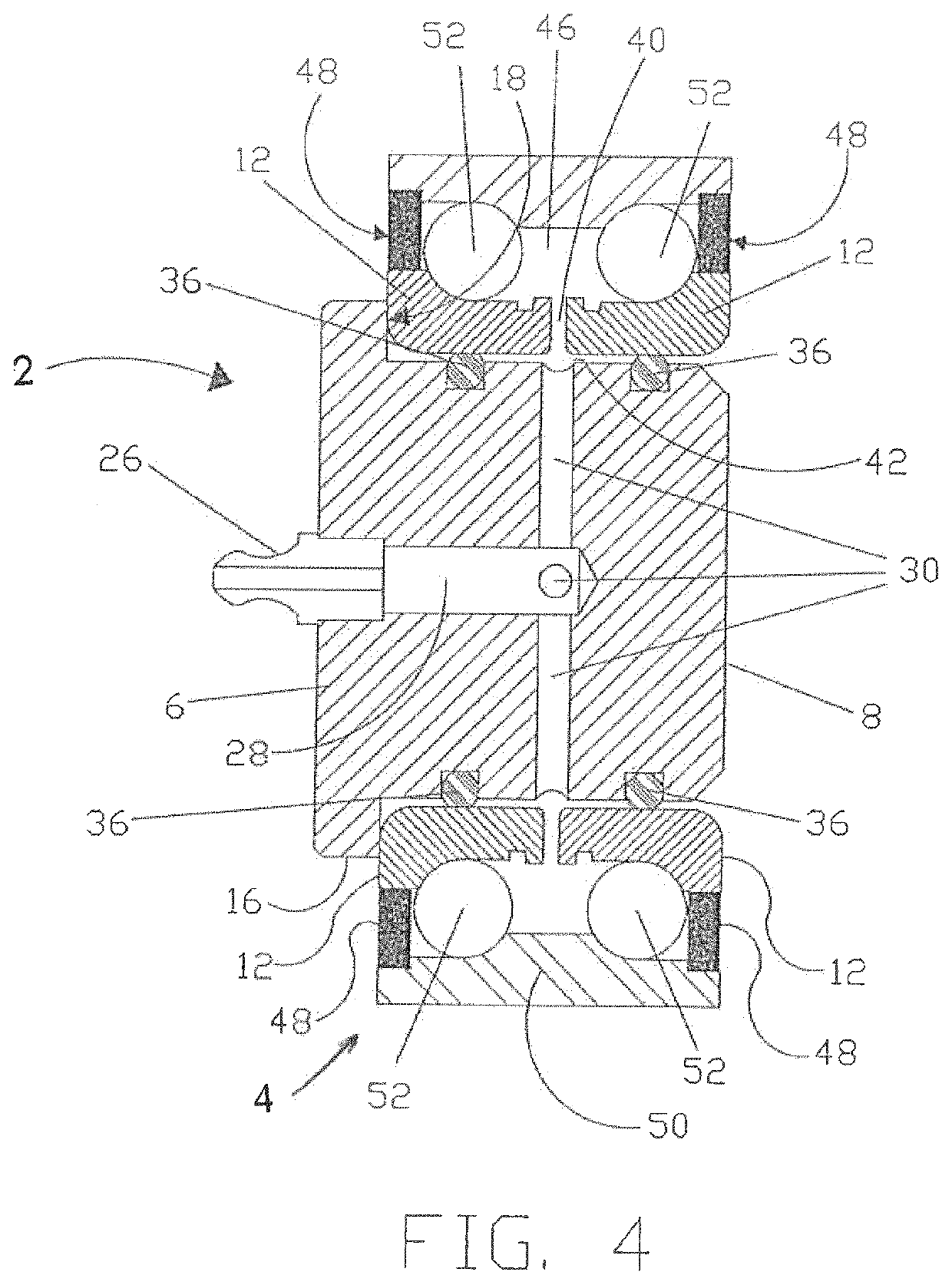

Grease tool for repacking dual angular contact bearing with grease, and method of using same

ActiveUS20170370412A1Easy to disassembleEasy to cleanBearing repair/replacementRolling contact bearingsGrease fittingFlange

A grease tool and method for greasing a dual angular contact bearing where the grease tool is fabricated from a single unitary piece of material. The grease tool comprises a cylindrical hub, a flange supported adjacent only one end of the cylindrical hub, and a grease fitting attached to the grease tool to facilitate a supply of grease thereto. During use, a pair of spaced apart O-rings, accommodated by an exterior surface of the cylindrical hub, form a pair of grease seals with an inwardly facing surface of an inner race of the dual angular contact bearing. A supply passage conveys the supplied grease from the grease fitting to a grease outlet(s) located in an exterior cylindrical surface of the grease tool, between the pair of O-rings, for conveyance of the supplied grease radially to the inner race of the dual angular contact bearing and facilitate repacking thereof.

Owner:PETIT DENIS

Grease gun adaptor device

InactiveUS6902209B2Easy to adaptEffective lubricationOpening closed containersBottle/container closureGrease fittingLandscaping

An improved grease gun adaptor device, wherein cost efficient refills for a standard grease gun can be utilized to lubricate equipment and tools having grease fittings that heretofore have required the purchase of brand specific tubes of grease, wherein a flexible design and cap screw enable easy, single-handed attachment to virtually any location of grease-fitting aperture, and wherein a simple one-piece design enables cost efficient production and utilization thereof. The present invention is particularly suited for, although not limited to, enabling a user to adapt the tip of a standard grease gun to a specified grease fitting to lubricate landscaping equipment and power tools, thereby eliminating the need to purchase a brand specific tube of grease.

Owner:MCINERNEY EDWARD A

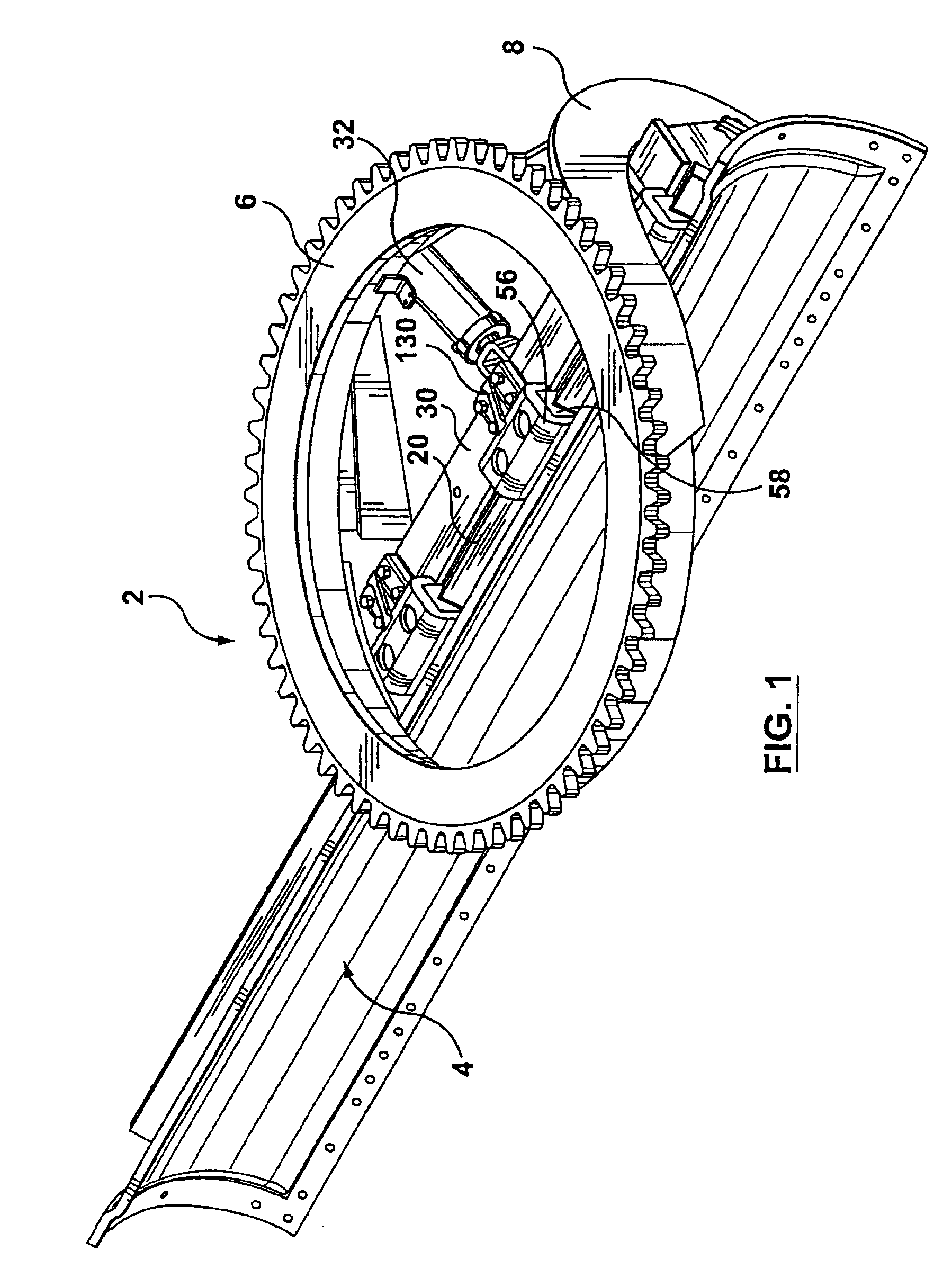

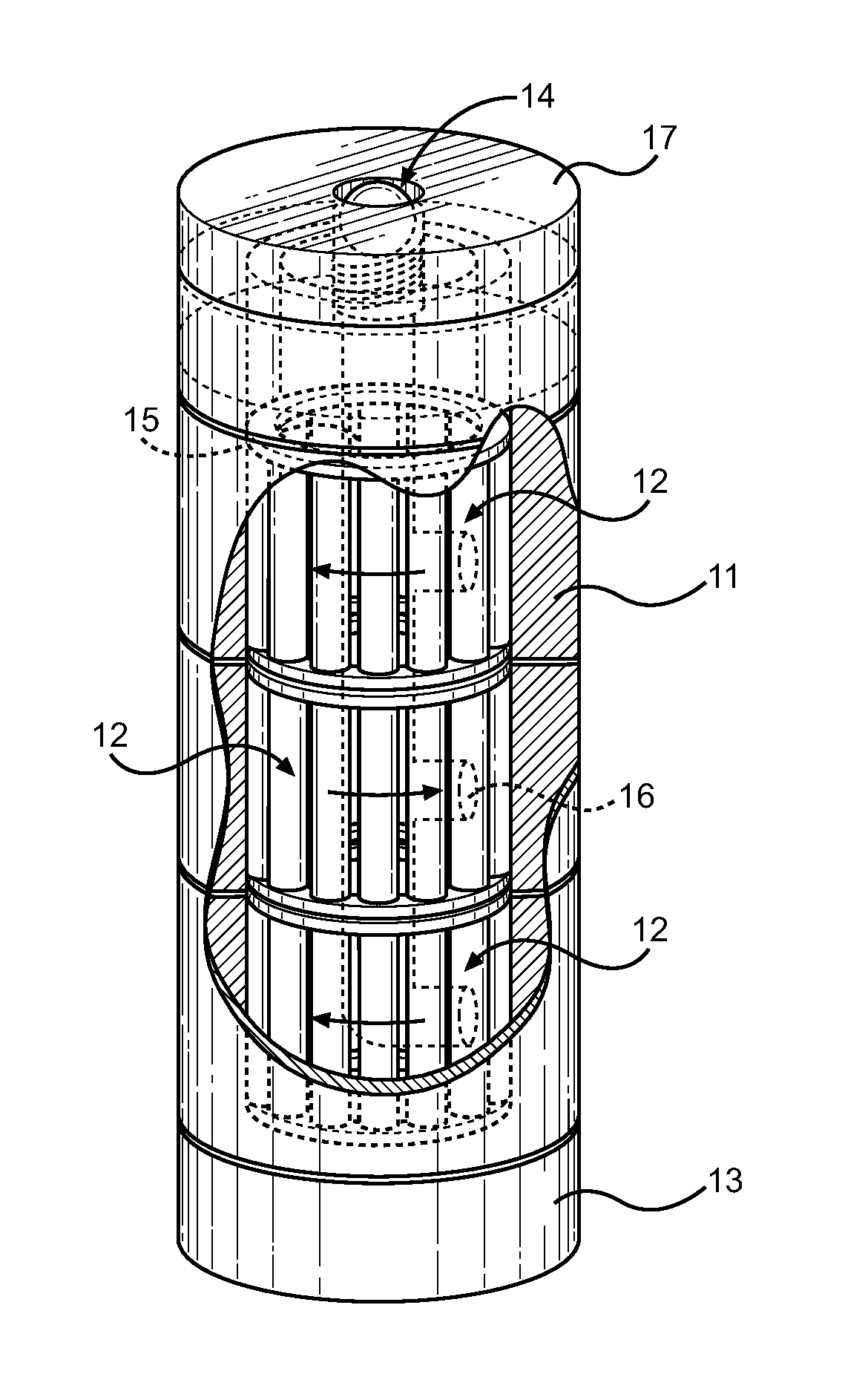

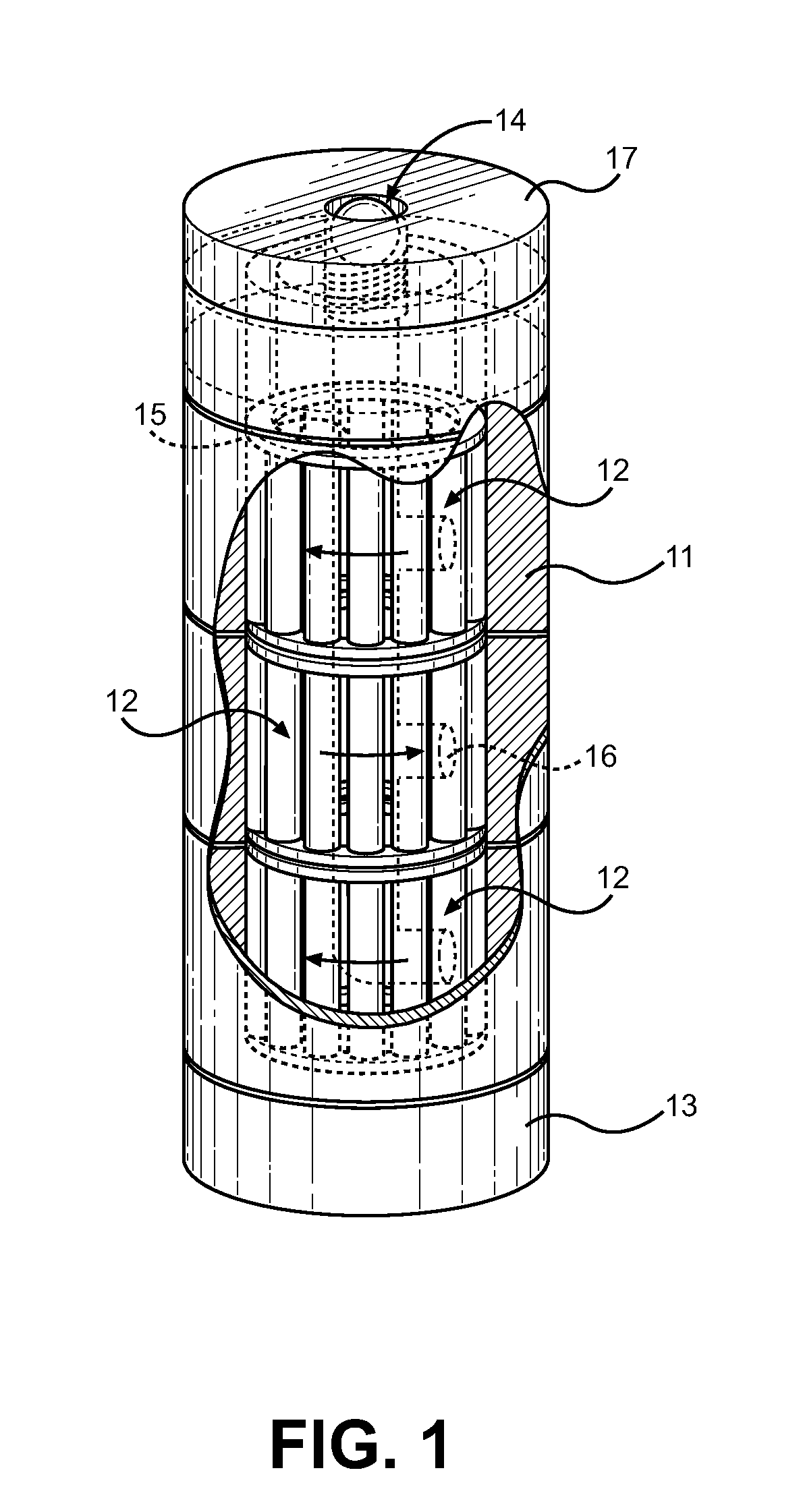

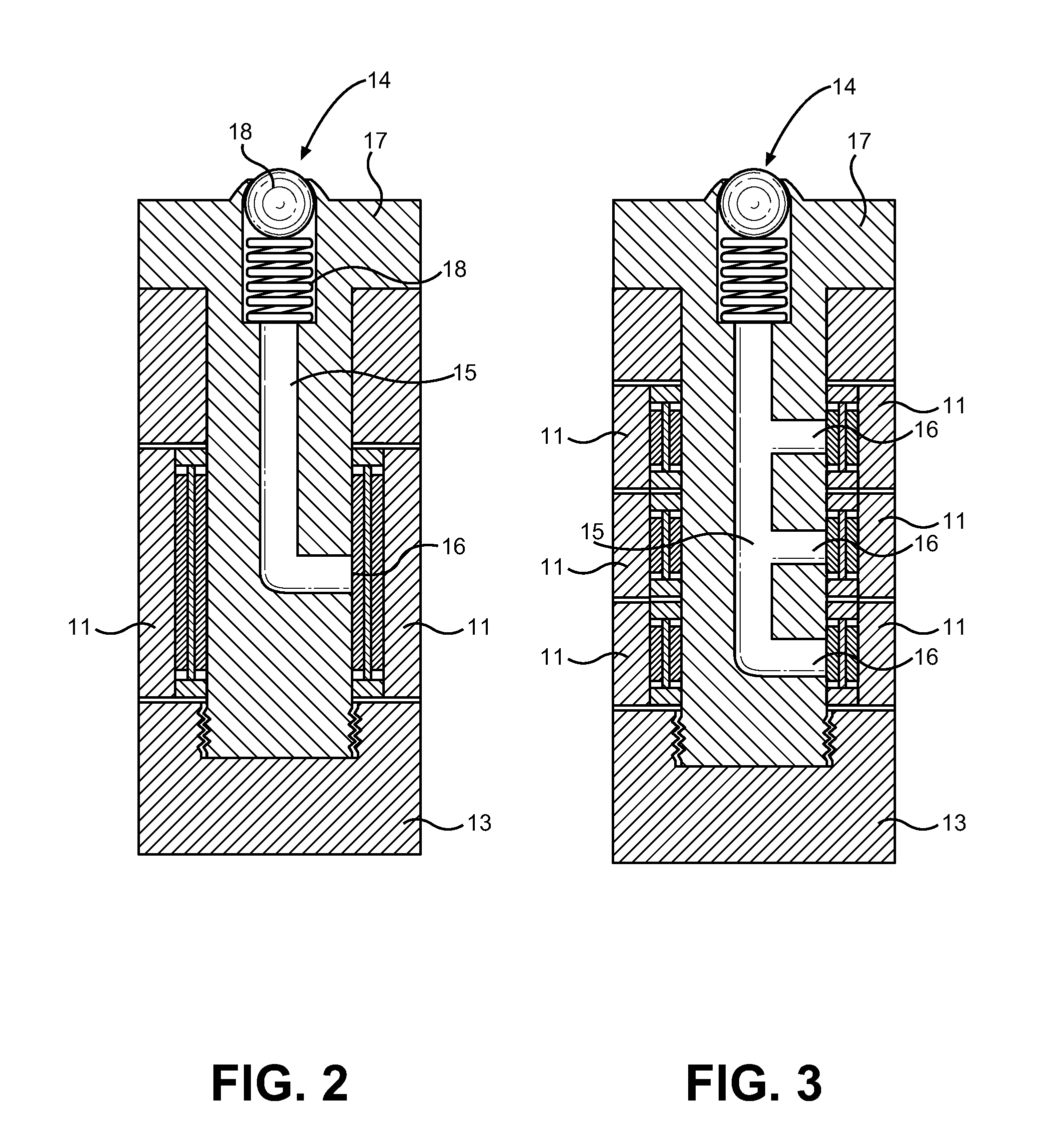

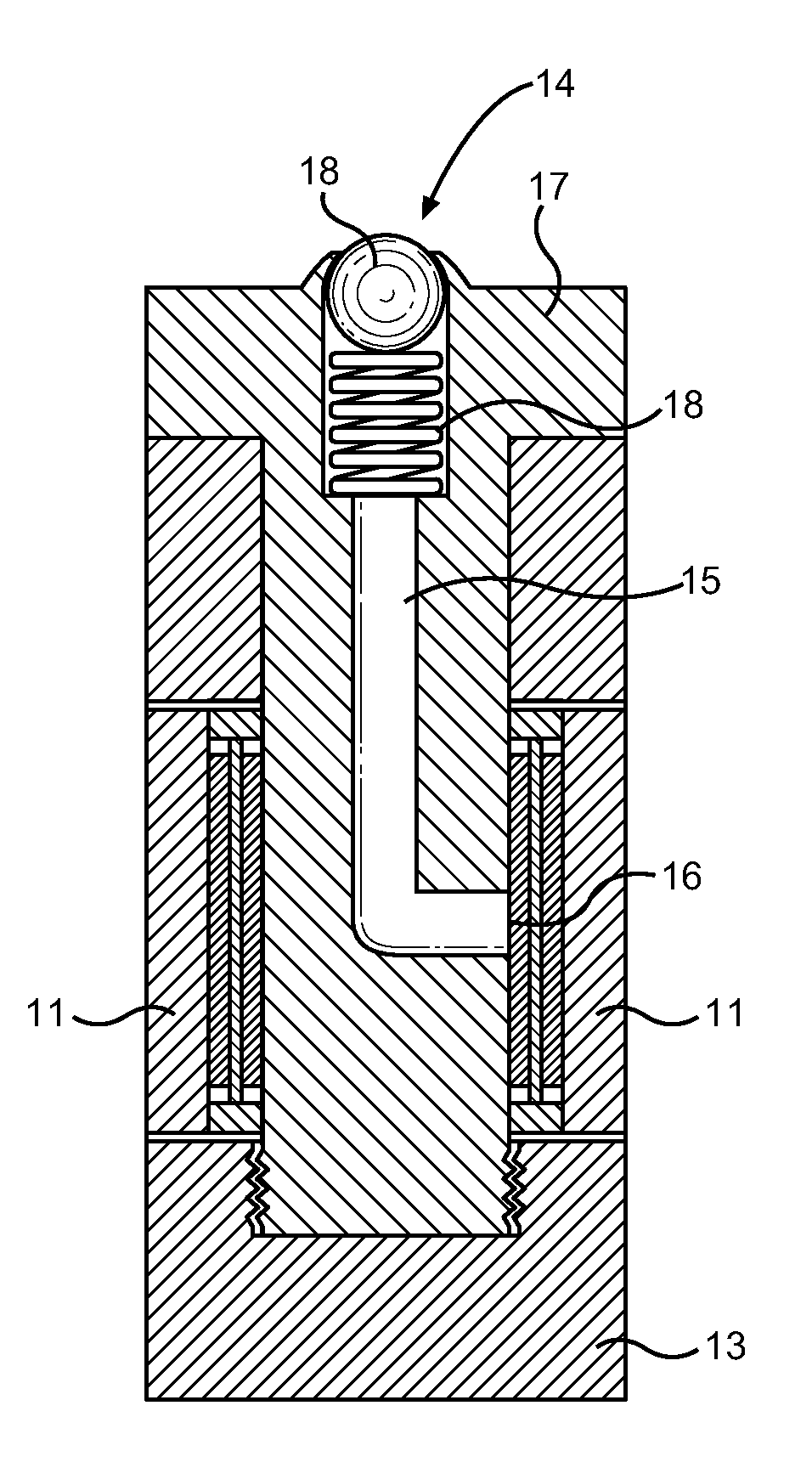

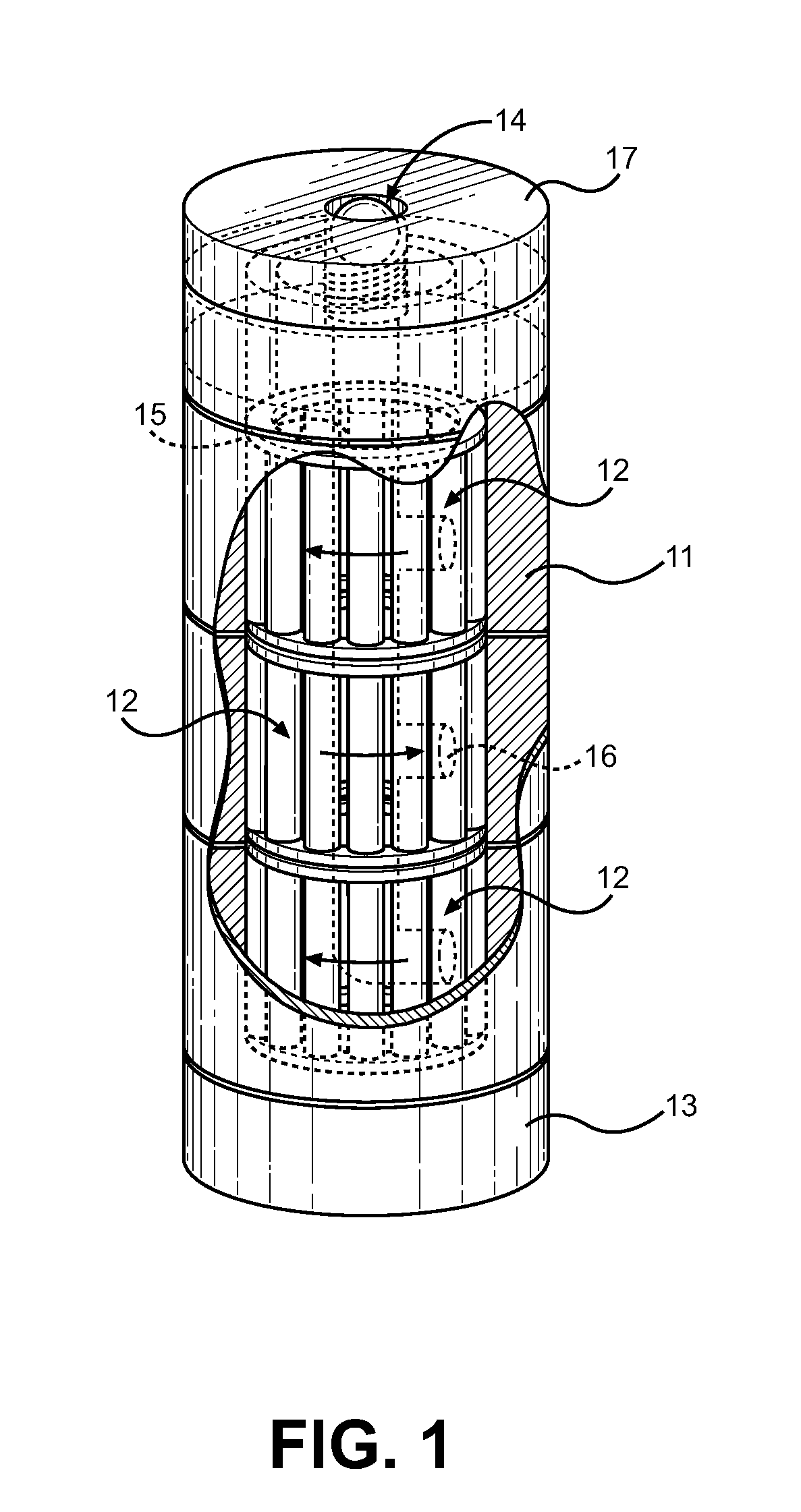

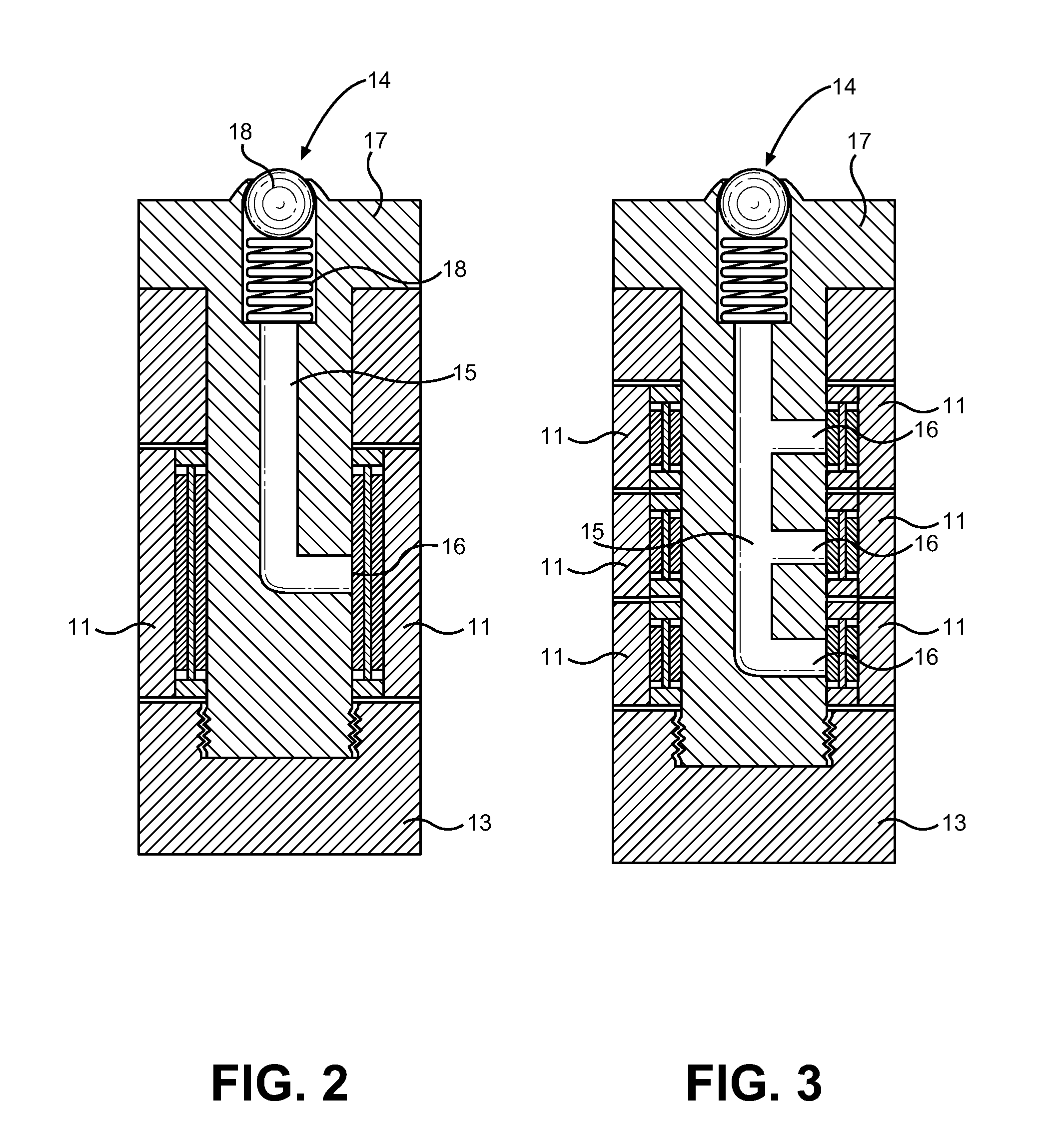

Needle bearing hinge assembly

InactiveUS8561261B2Increase loadReduce wearWing accessoriesBearing componentsFriction reductionNeedle roller bearing

Disclosed is an enclosed needle bearing hinge mechanism having externally rotatable race surfaces, internal needle bearings, an internal pathway for introducing grease into the assembly for improved lubrication, reduced wear and a construction adapted to support large door or latch loads. The assembly comprises a housing having at least one needle bearing in contact with an outer rotating race, stationary or counter-rotating interior races, a central pin shaft and an internal pathway for lubrication to be communicated from a topmost grease fitting to the contact interface between the needle bearing and outer rotating race. One or plurality of needle bearing assemblies and counter-rotating outer races may be present within the assembly, each with an independent grease pathway branch. The pathway comprises a hollow internal conduit that allows lubricant to contact each needle bearing in the assembly, reducing friction and improving longevity of the hinge bearing assembly.

Owner:GIBSON THOMAS

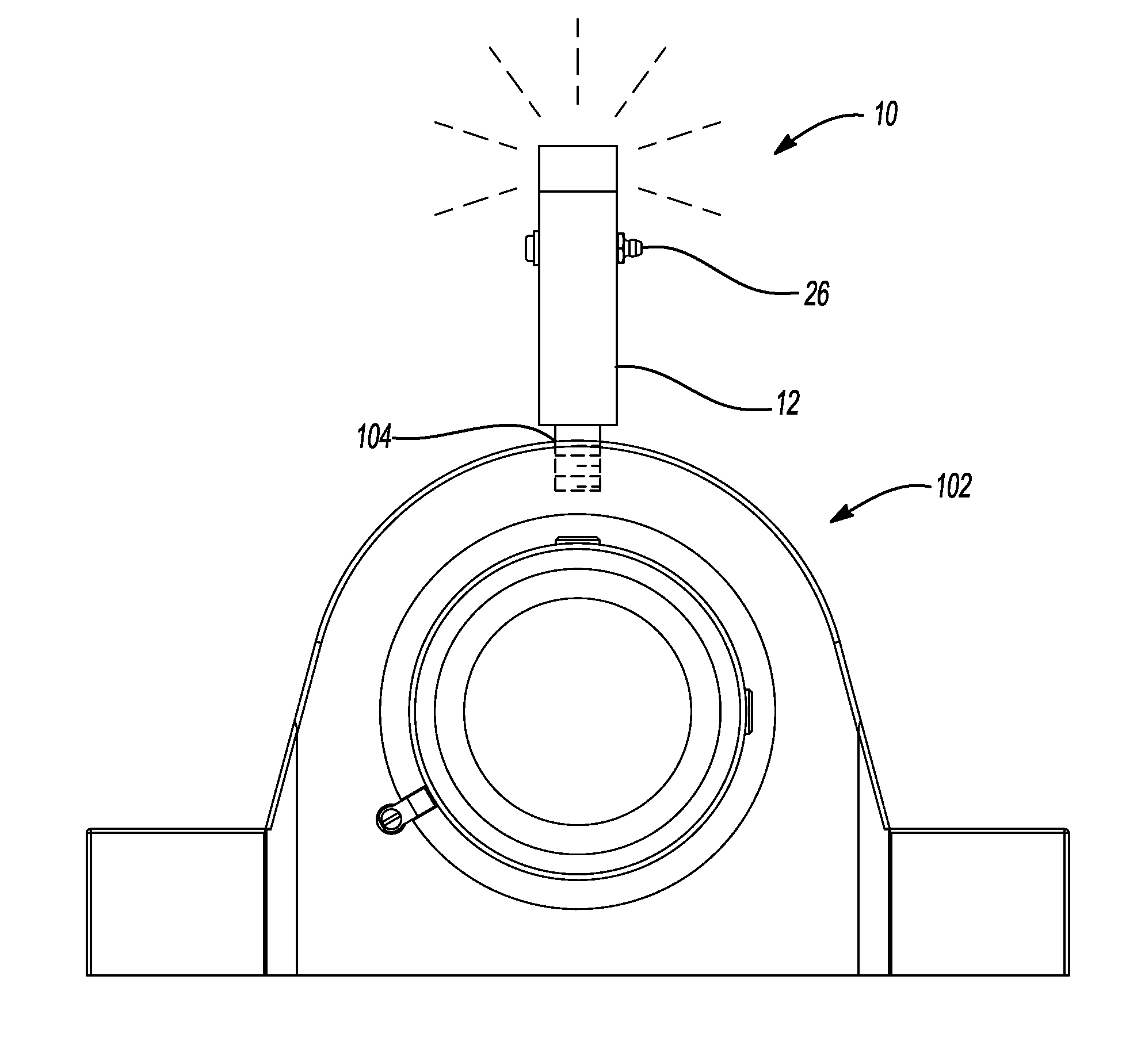

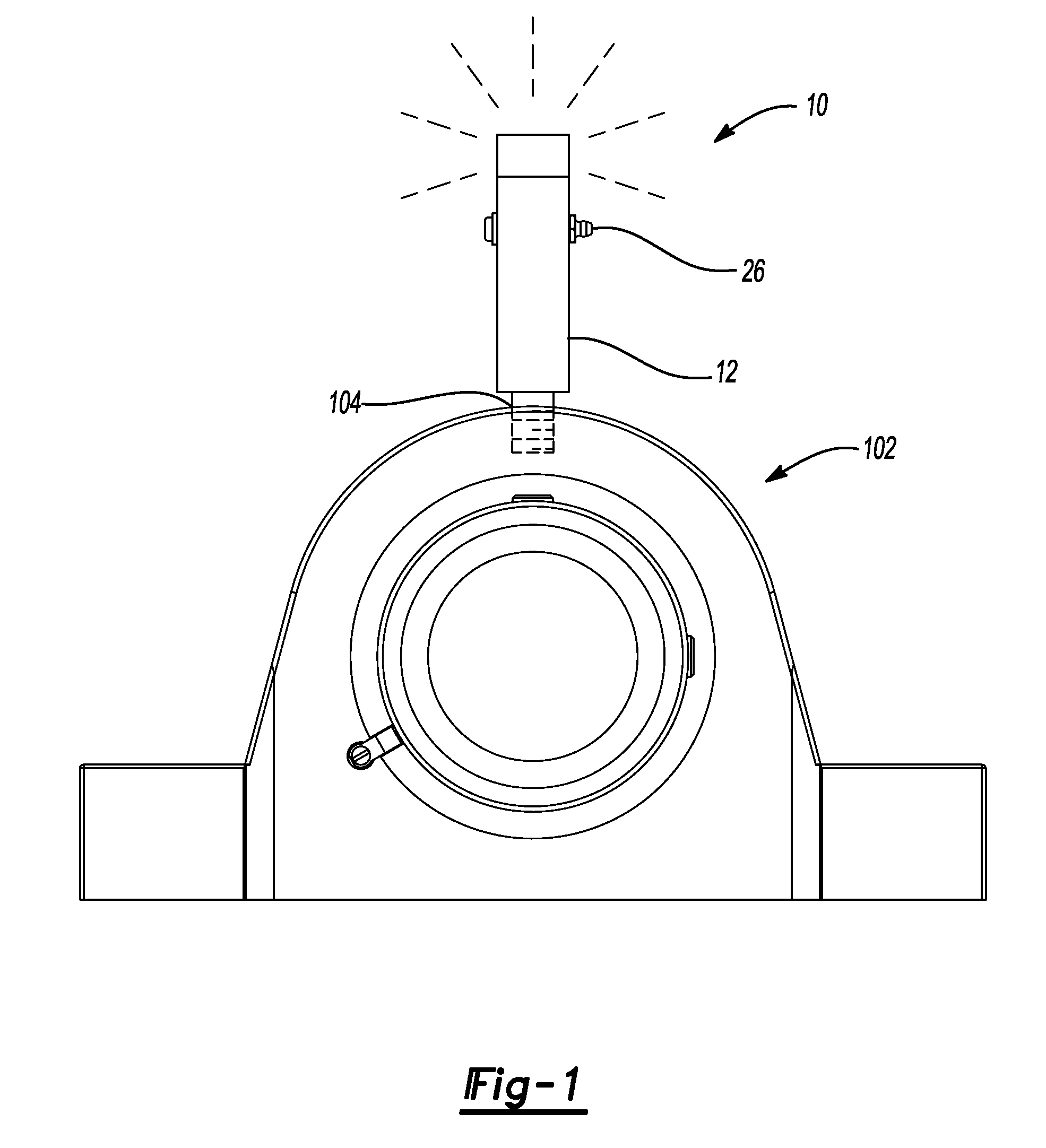

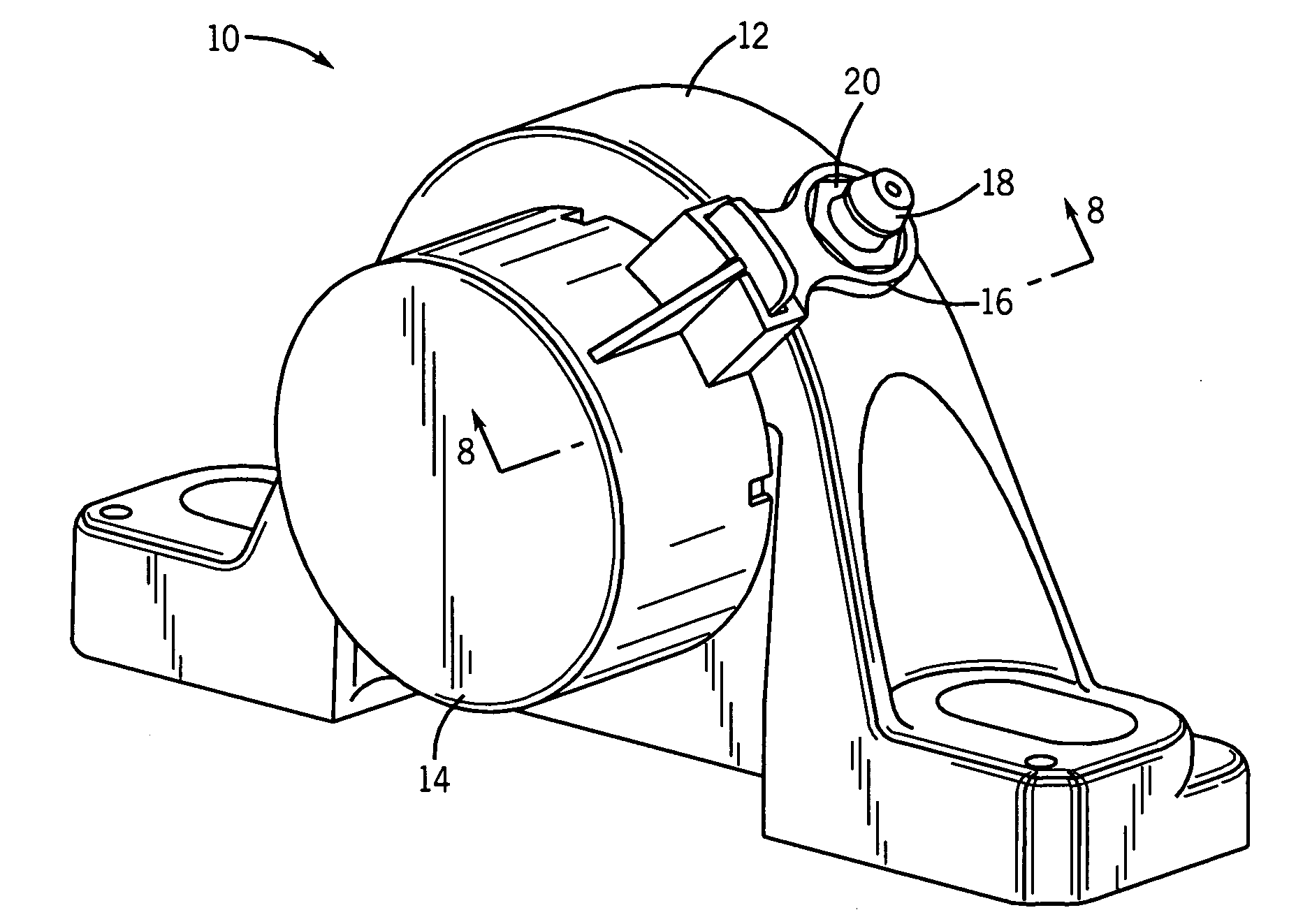

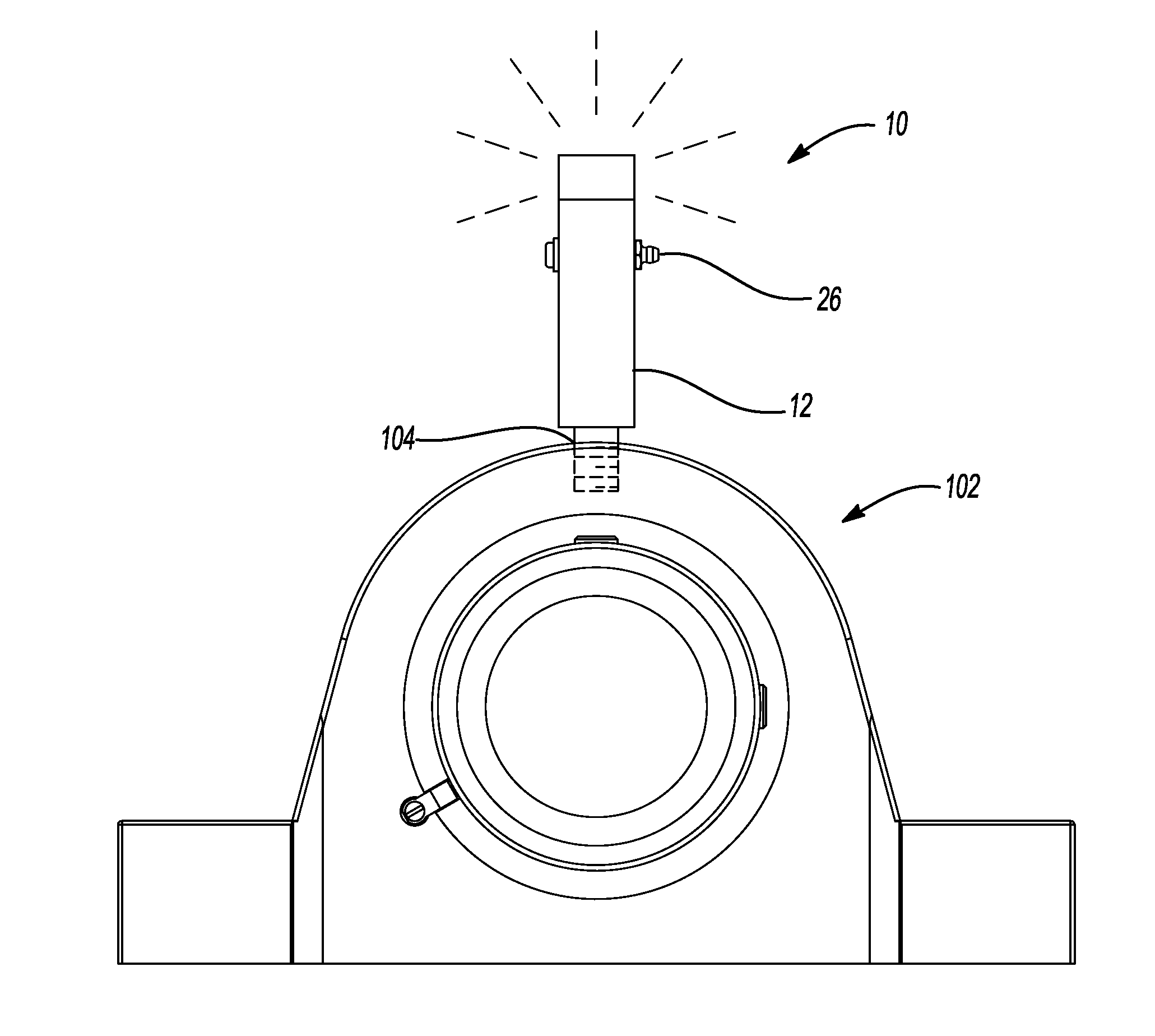

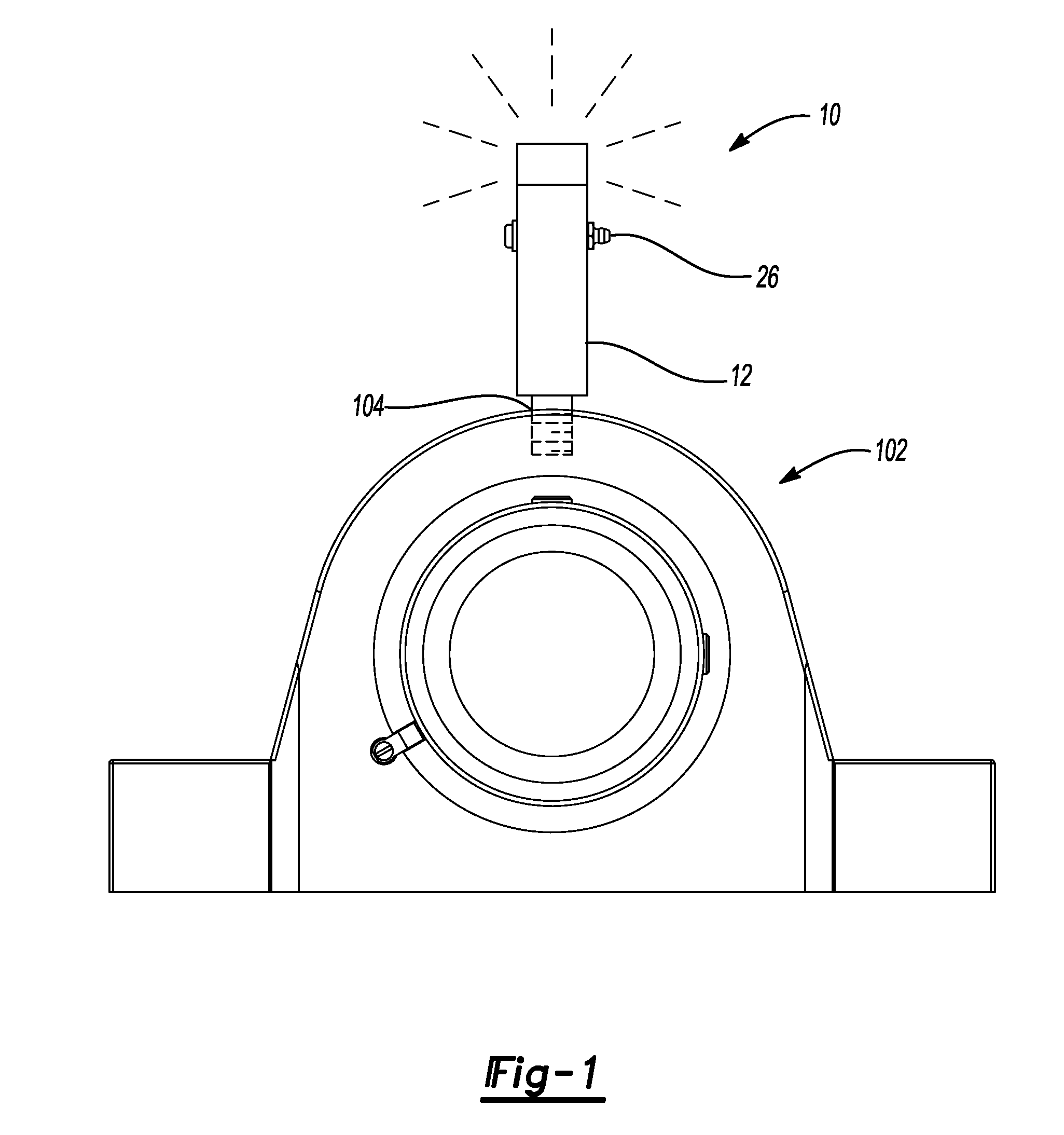

Temperature sensing grease fitting with alarm

ActiveUS9291203B2Prolong lifeLimited lifeBearing assemblyThermometers using material expansion/contactionElectricityGrease fitting

A bearing temperature monitoring system for detecting a temperature of bearing grease within a bearing housing. The bearing temperature monitoring system comprises a housing mountable to the bearing housing, a power source selectively outputting an electrical current, and an electrical circuit. The electrical circuit includes a temperature sensor component electrically coupled to the power source. The temperature sensor component can be responsive to a change in temperature such that the temperature sensor component opens or closes the electrical circuit at a predetermined temperature even in the absence of an applied electrical current. The electrical circuit further includes an alert device electrically coupled to the power source and the temperature sensor component that outputs an alert in response to the temperature sensor component.

Owner:REGAL BELOIT AMERICA

Fitting cover

A lubricant fitting cover for a zerk having a substantially planar body with a first side and a second side, the first side is capable of being removeably secured to the head of a grease fitting, the second side includes an indicator for providing information about the type of lubricant to be injected through the grease fitting.

Owner:WHITMORE MFG LLC

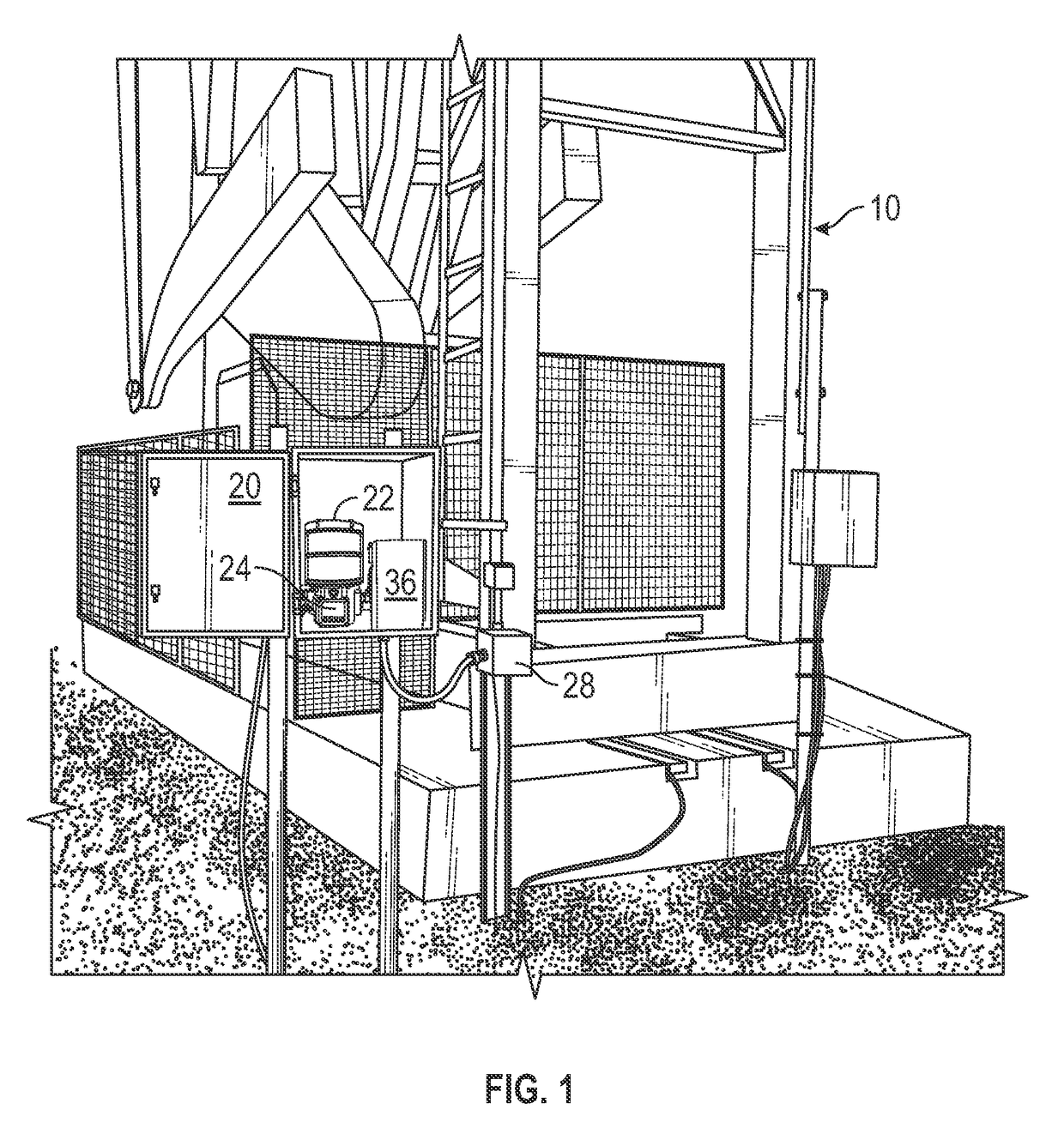

Apparatus for automatically lubricating an oil well sucker rod stuffing box

A stuffing box lubrication system for oilfield pumping units automatically delivers to the stuffing box, at specified time intervals, a precise volume of lubricant. The stuffing box lubrication system has a grease reservoir, a pump, a controller, a high pressure hose and grease fitting, and a stuffing box which receives the grease. In situations where the stuffing box in use is not equipped with a ported inlet for receiving the grease, the present invention may further include a stuffing box adapter, having a ported inlet, where the stuffing box adapter couples with the stuffing box.

Owner:JAMESON SPECIALTIES INC

Bearing end cover

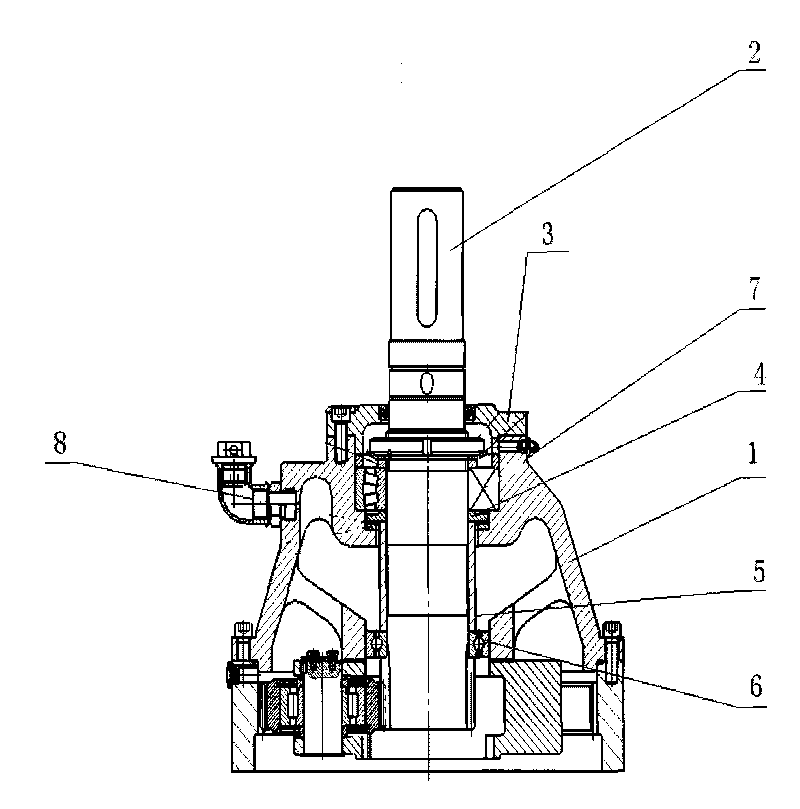

A bearing cover includes a clip securable to a bearing housing and an end cover securable to the clip to cover a central opening of the bearing housing. The clip may be secured to a grease fitting or other structural component attached to the bearing housing. The relative location and engagement of the clip and end cover may be adjusted to accommodate different sizes and configurations of bearing housings.

Owner:BALDOR ELECTRIC COMPANY

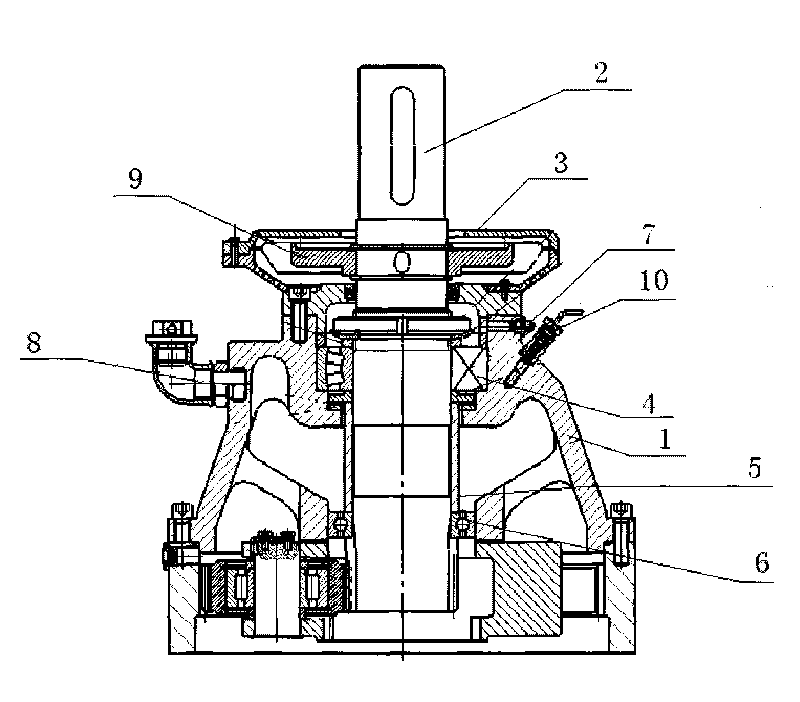

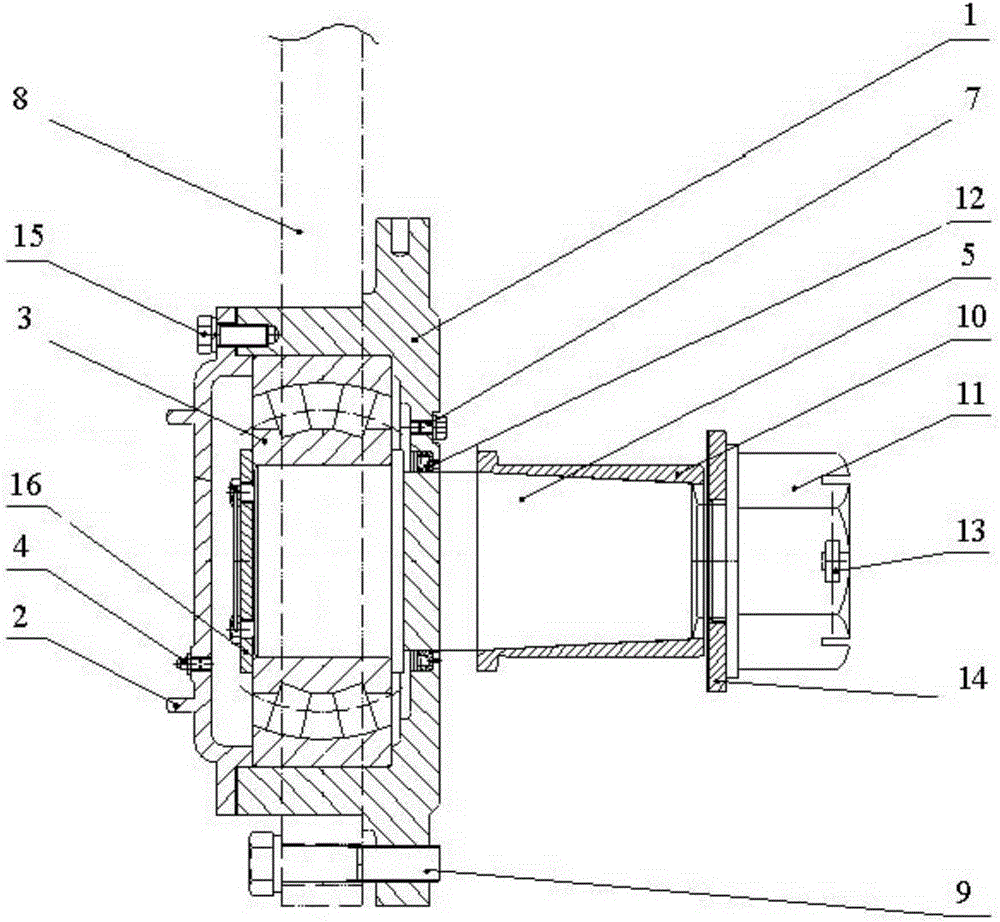

Vertical planetary reducer with temperature control device

InactiveCN101761641AImprove cooling effectNot easy to melt and loseThermometer detailsGear lubrication/coolingTemperature controlGrease fitting

The invention provides a low-cost vertical planetary reducer with a temperature control device. The device consists of a machine body, an input shaft, an input end cover, a self-aligning bearing, an input shaft sleeve, a locating ball bearing, a vent hole, a greasing fitting, a temperature measuring contact, a temperature measuring component, an output data line and a fan. The device is provided with an input shaft heat dissipating device and a temperature monitoring device and can dissipate heat in time to improve the heat dissipating capability of the inside of the reducer. When the temperature measuring component sends alarm signals, the damage on the bearing can be prevented. The reducer has long serve life, improves grease utilization factor, reduces oil dirt and can meet the market requirements completely. The cost performance of the invention is leading at home.

Owner:TIANJIN GENERAL PRINCIPLE MACHINERY NEW TECH

Slide rail adjustment for grader blade

A bearing support arrangement for a grader blade uses short stroke hydraulic cylinders to compensate for wear between slide bearings and slide rails of the grader blade. The cylinders are preferably pressurized by grease and a grease fitting is provided for each cylinder to provide convenient access, to allow service by the operator. Preferably the cylinders are located in a generally closed cavity between the bearing support holder and the slide bearing.

Owner:VOLVO MOTOR GRADERS

Needle Bearing Hinge Assembly

InactiveUS20120291223A1Reduce wearEasy to operateWing accessoriesBearing componentsFriction reductionNeedle roller bearing

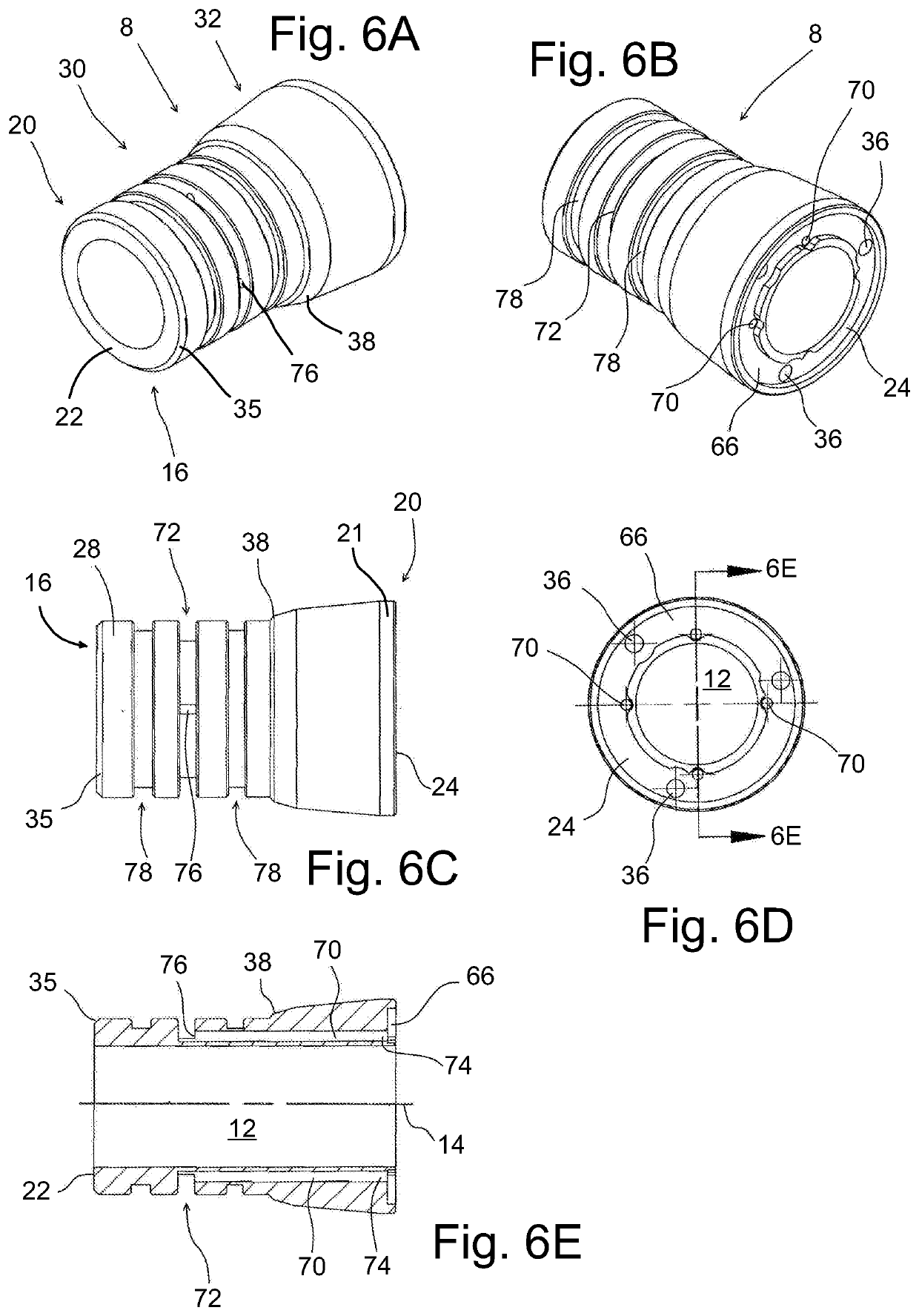

Disclosed is an enclosed needle bearing hinge mechanism having externally rotatable race surfaces, internal needle bearings, an internal pathway for introducing grease into the assembly for improved lubrication, reduced wear and a construction adapted to support large door or latch loads. The assembly comprises a housing having at least one needle bearing in contact with an outer rotating race, stationary or counter-rotating interior races, a central pin shaft and an internal pathway for lubrication to be communicated from a topmost grease fitting to the contact interface between the needle bearing and outer rotating race. One or plurality of needle bearing assemblies and counter-rotating outer races may be present within the assembly, each with an independent grease pathway branch. The pathway comprises a hollow internal conduit that allows lubricant to contact each needle bearing in the assembly, reducing friction and improving longevity of the hinge bearing assembly.

Owner:GIBSON THOMAS

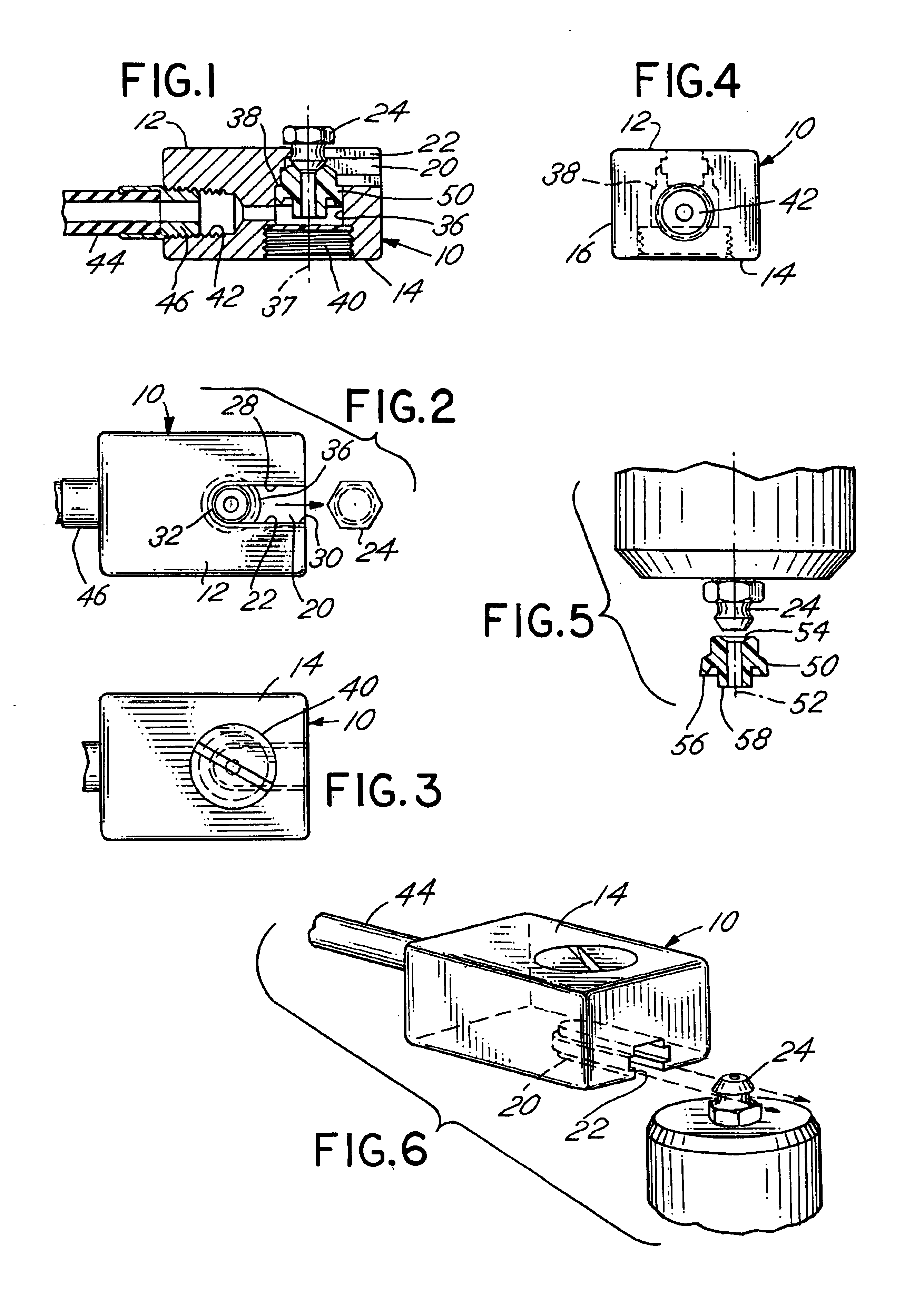

Grease fitting coupler

InactiveUS6920961B2Improve sealingJoints with sealing surfacesMachines/enginesGrease fittingEngineering

A grease fitting coupler device includes a body member with a slot on one side for engagement with a fitting and a series of passages through the body member connected with a lubrication source. A slidable valve member within the body member is pressurized against the fitting to seal the coupler device while lubricating fluid is passed therethrough.

Owner:LISLE CORPORATION

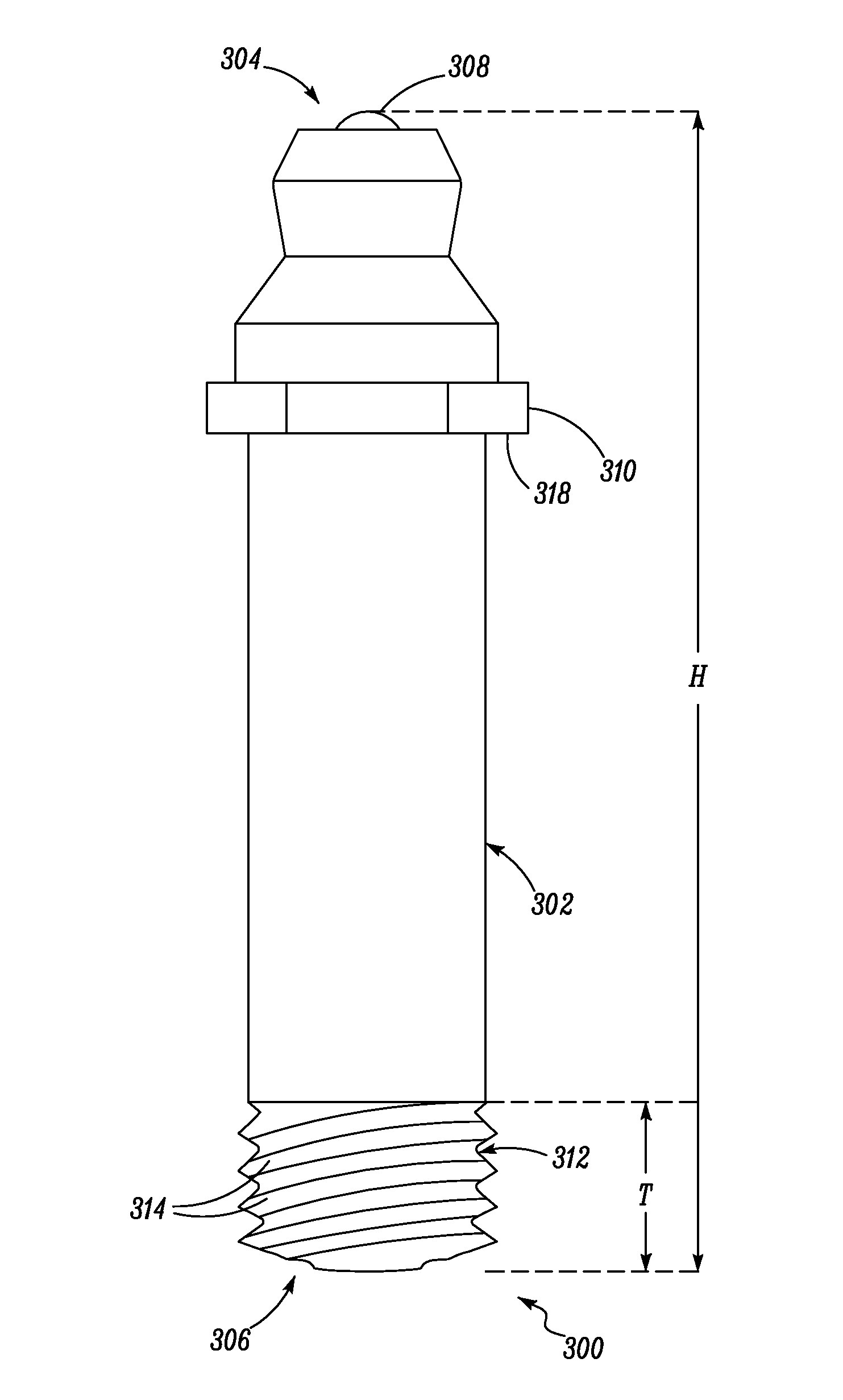

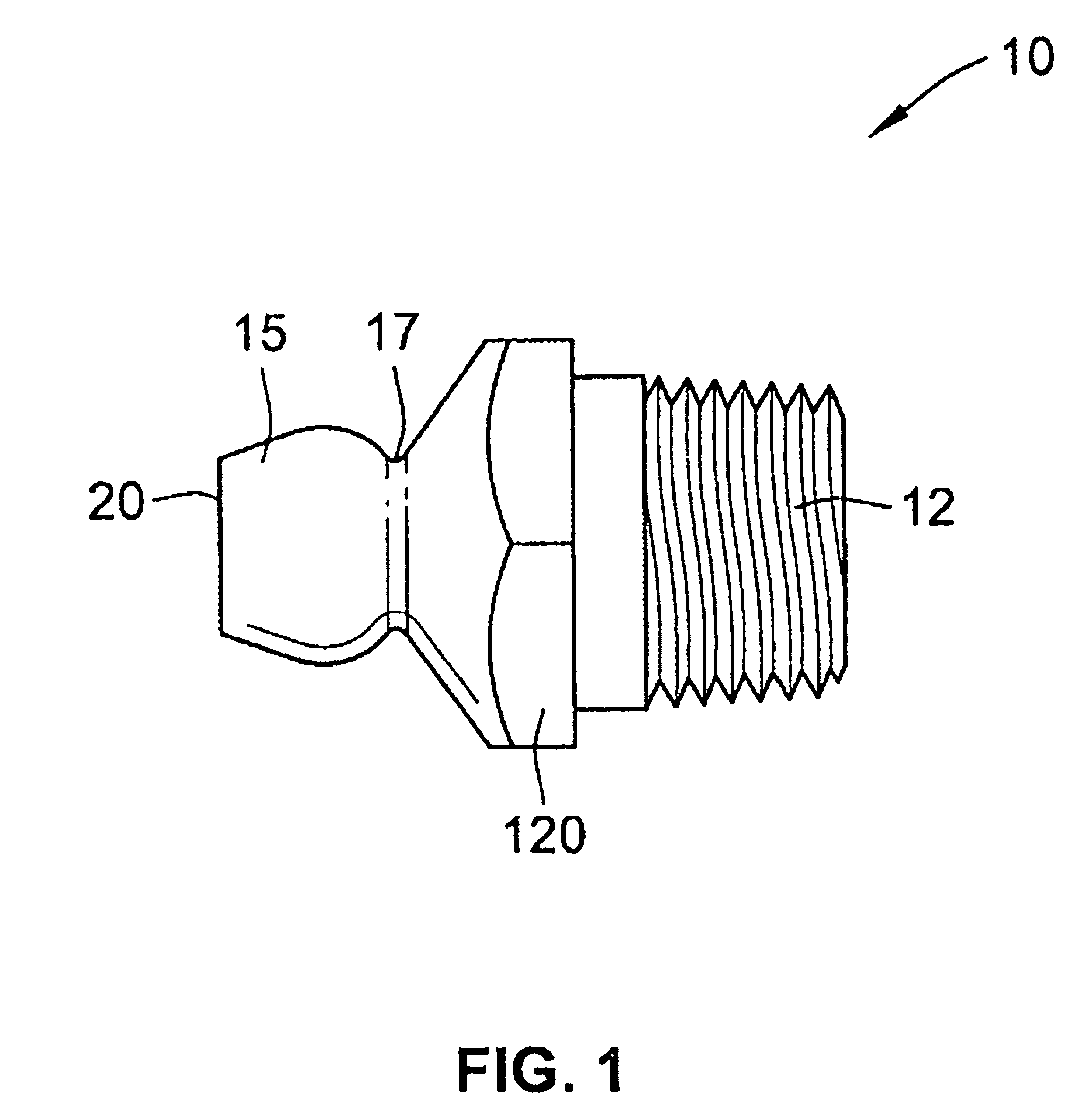

Grease fitting

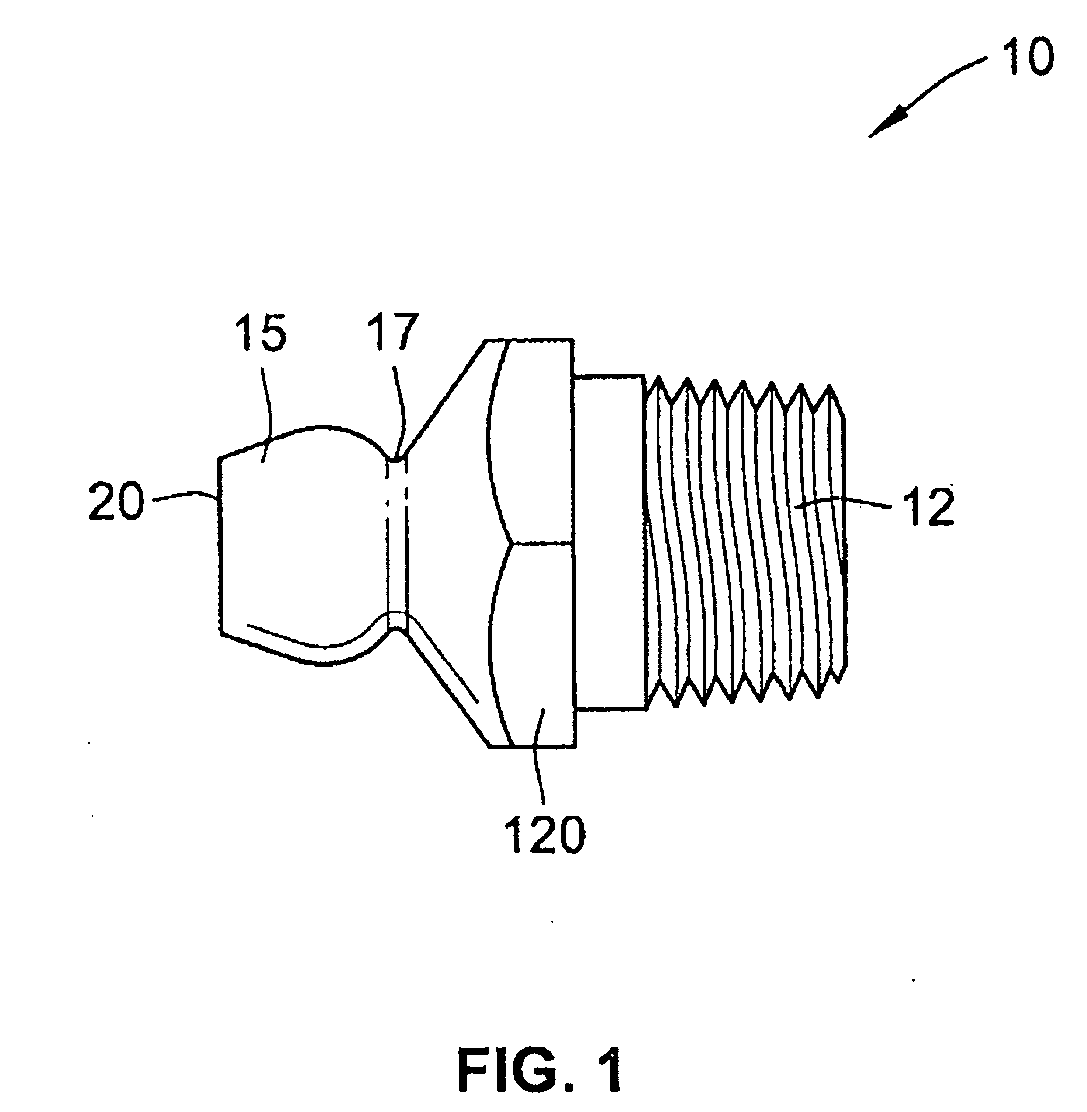

A grease fitting is disclosed. The grease fitting has an outer shell. The outer shell encloses an internal cavity. The outer shell includes a ball check, a hexagonal portion, and a thread blank. The ball check is located at a first end of the outer shell. The ball check is configured to receive grease. The thread blank is located at a second end of the outer shell. The thread blank includes hardened lead threads configured to form threads in an untapped hole. In an embodiment, the grease fitting may include a thread guide extending from the thread blank.

Owner:CATEPILLAR SARL

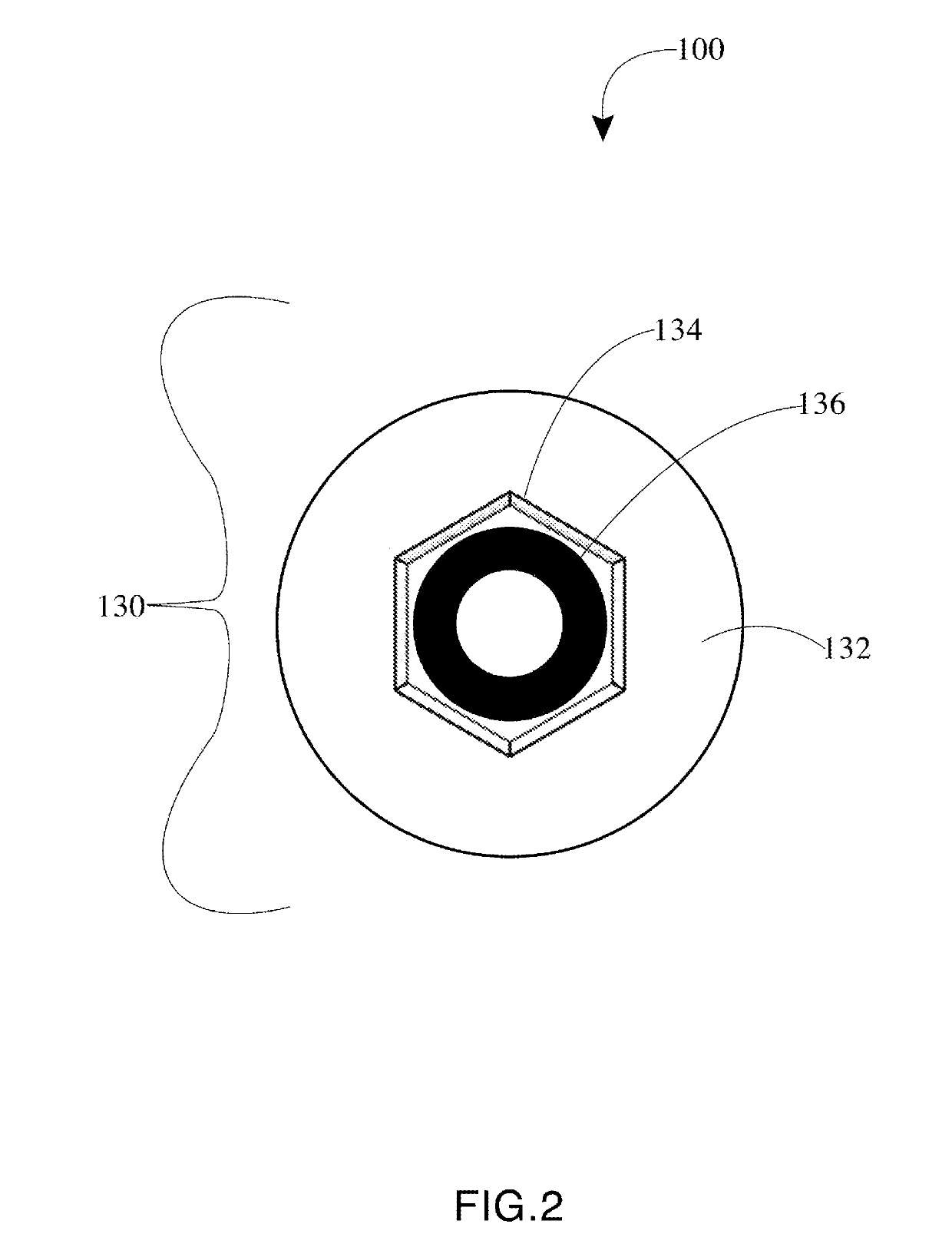

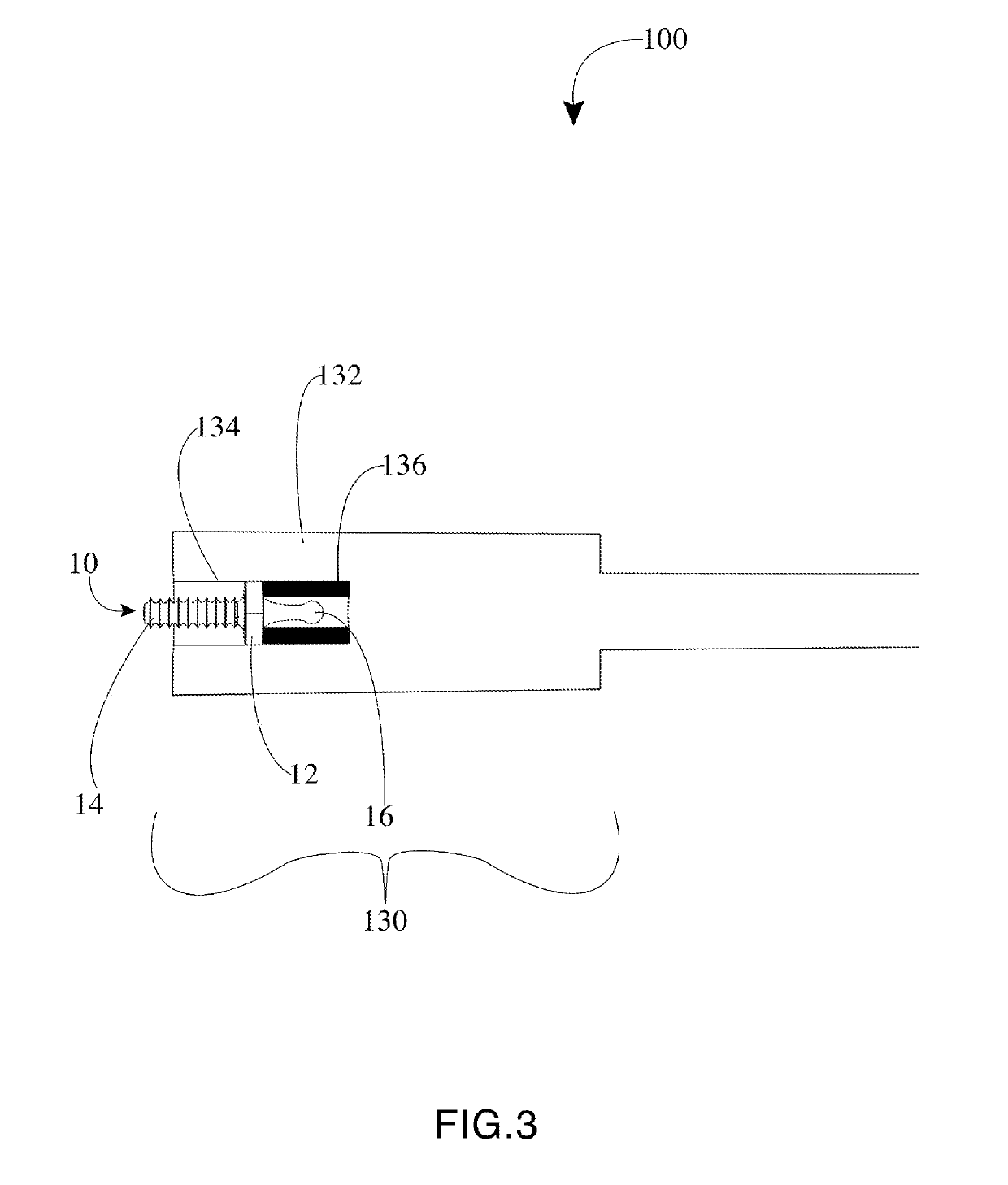

Grease-fitting installation tool and method

A grease-fitting installation tool is disclosed herein. The grease-fitting installation tool may include a hand-tool useful for installing and uninstalling a grease-fitting that has a hexagonal-collar, a threaded-shank, and a nipple, i.e., a Zerk fitting. The hand-tool may have a first tool-head and a second tool-head, each able to receive and manipulate a grease-fitting. The first and second tool-heads may be attached end to end, being joined in the center of a hand-tool by a couple. The couple may have a wrench interface allowing the hand-tool to be engaged by a wrench or other tool. Each tool-head may include a hollow-socket having a socket-aperture and six internal contact-surfaces which are hexagonally arranged. The tool-head may also include a deformable, cylindrical gripping member disposed within the hollow-socket for retaining the grease-fitting when the grease-fitting is inserted into the gripping member.

Owner:BLANCHETTE ROY JOSEPH

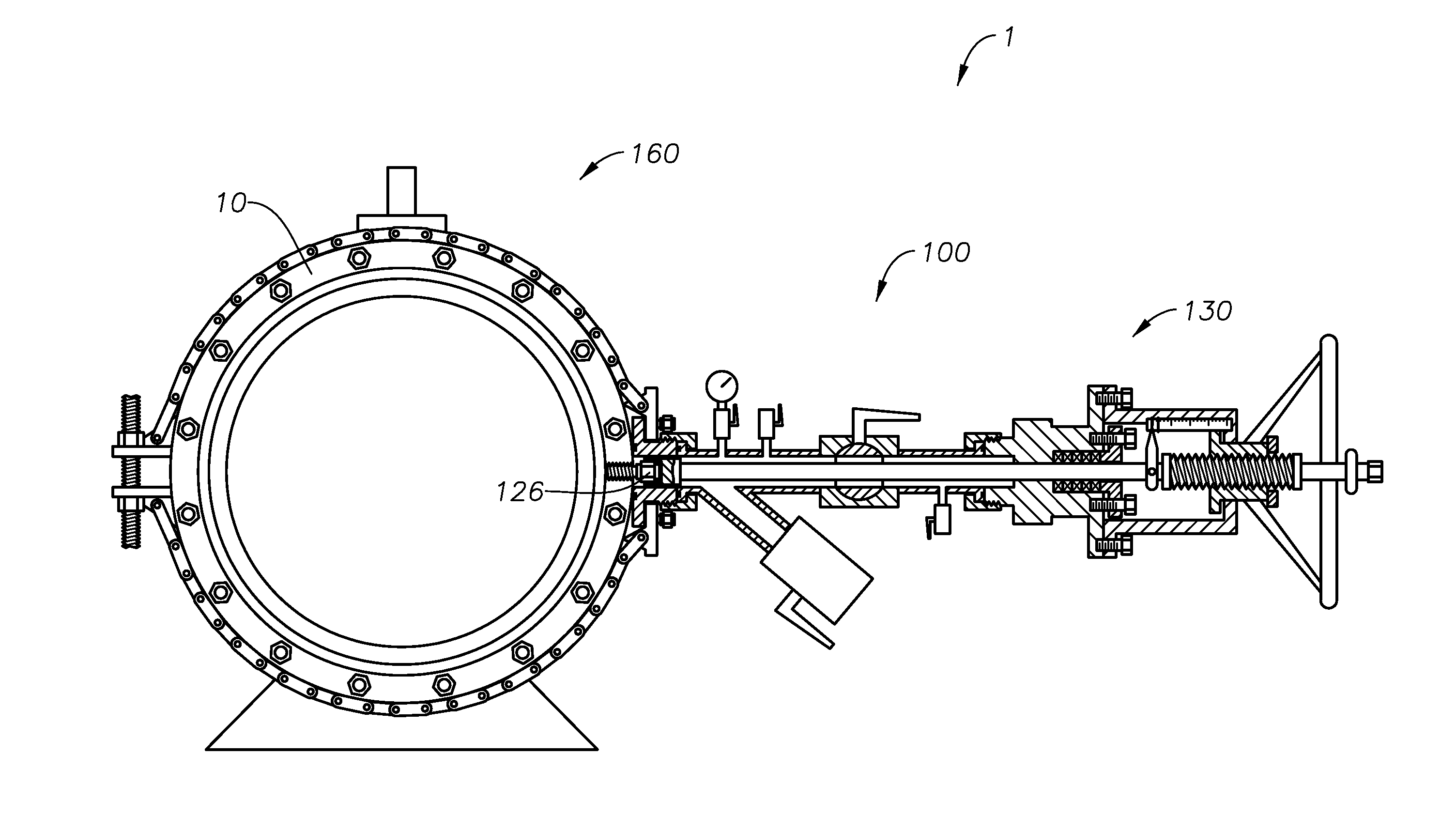

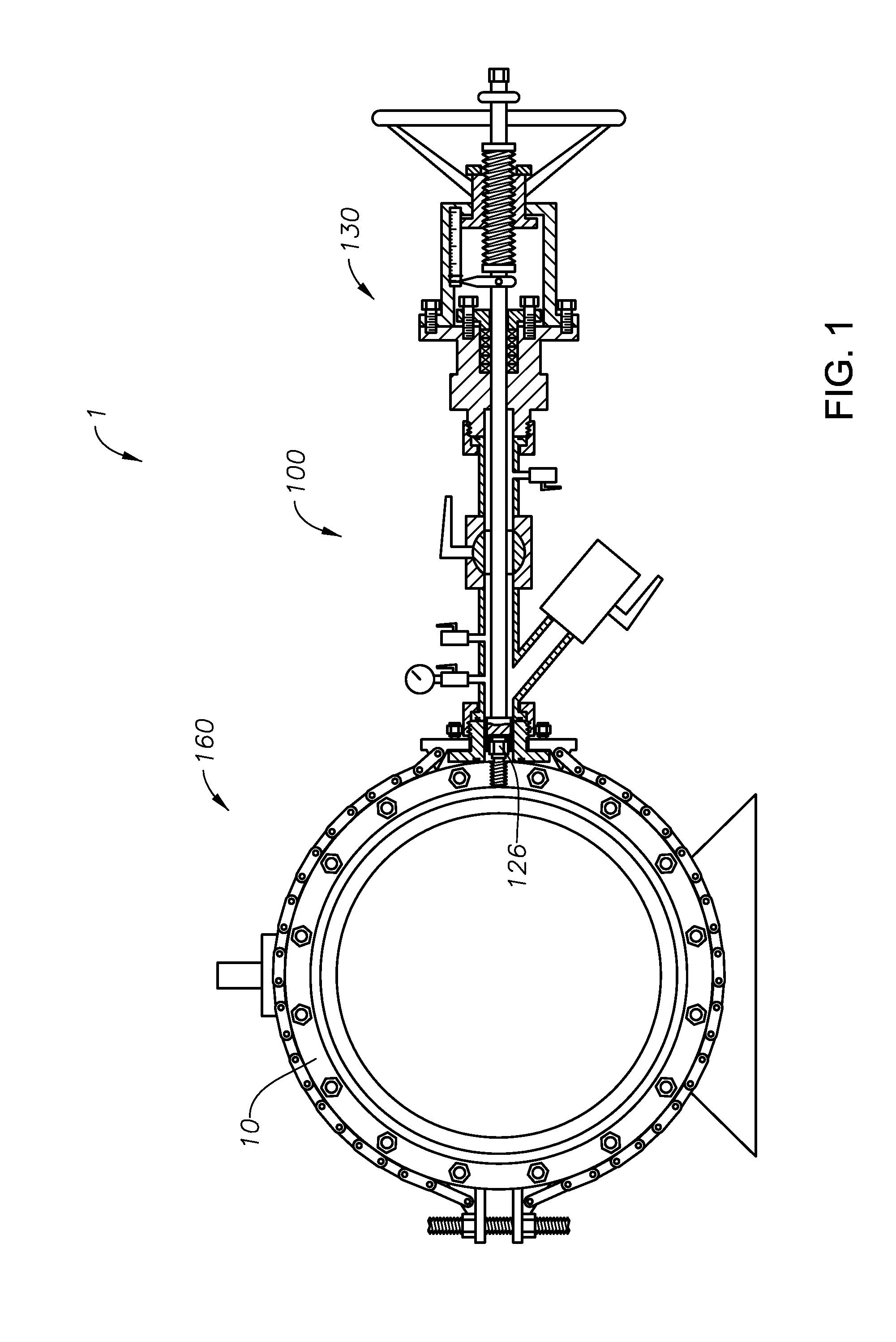

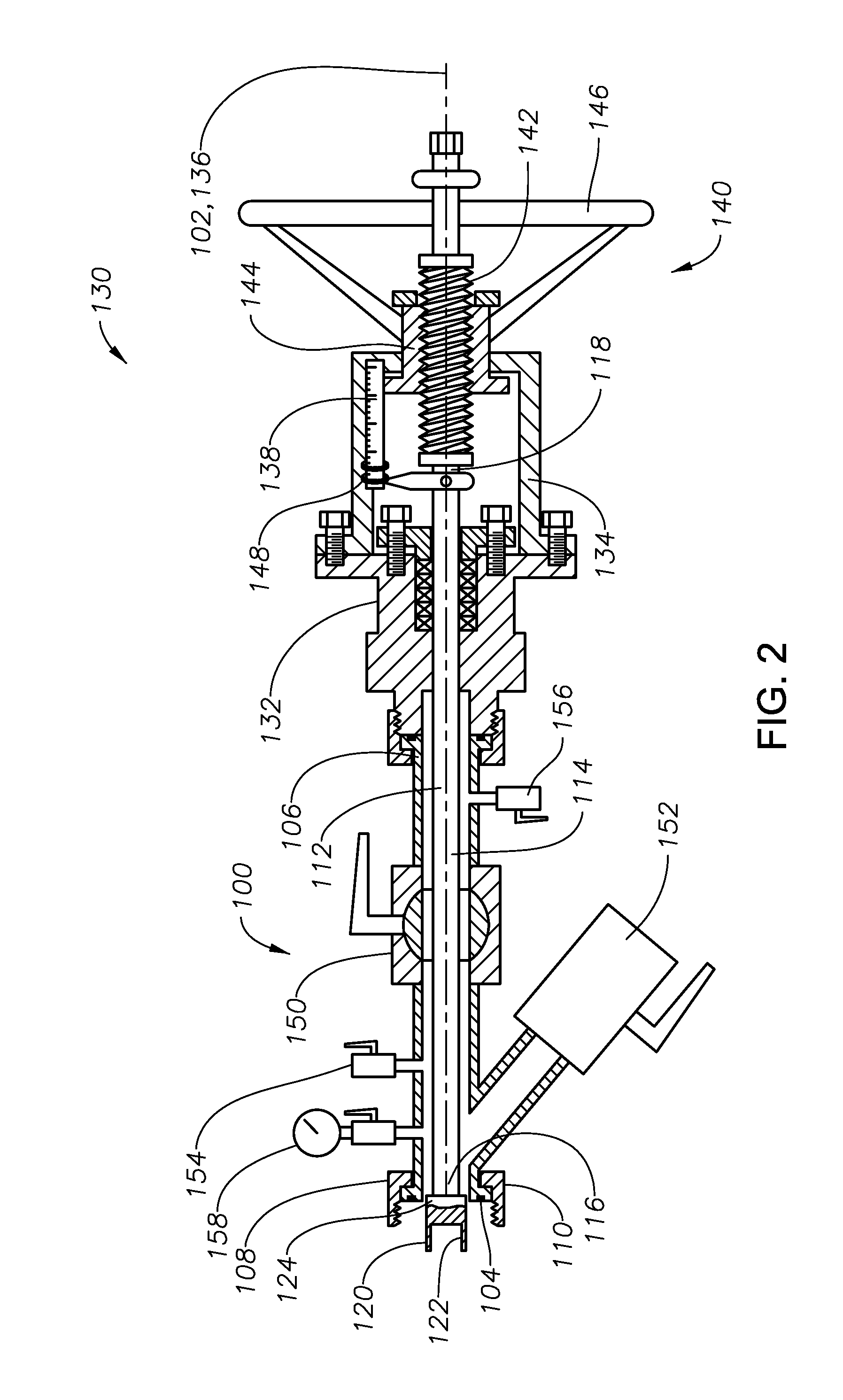

High pressure grease fitting tool for online replacement

A grease fitting replacement tool includes a housing, a shaft, an adaptive socket, a loosening device, loosening device includes a packed coupling, a stem housing, and a stem drive system, the stem drive system includes a stem, a threaded mount, and an actuator, a main valve, a fall-out trap, a pressure port valve, a vent valve, a pressure gauge, and a temporary mounting system. A method of using a grease fitting replacement tool to replace a grease fitting of a piece of equipment while the piece of equipment remains in operation.

Owner:SAUDI ARABIAN OIL CO

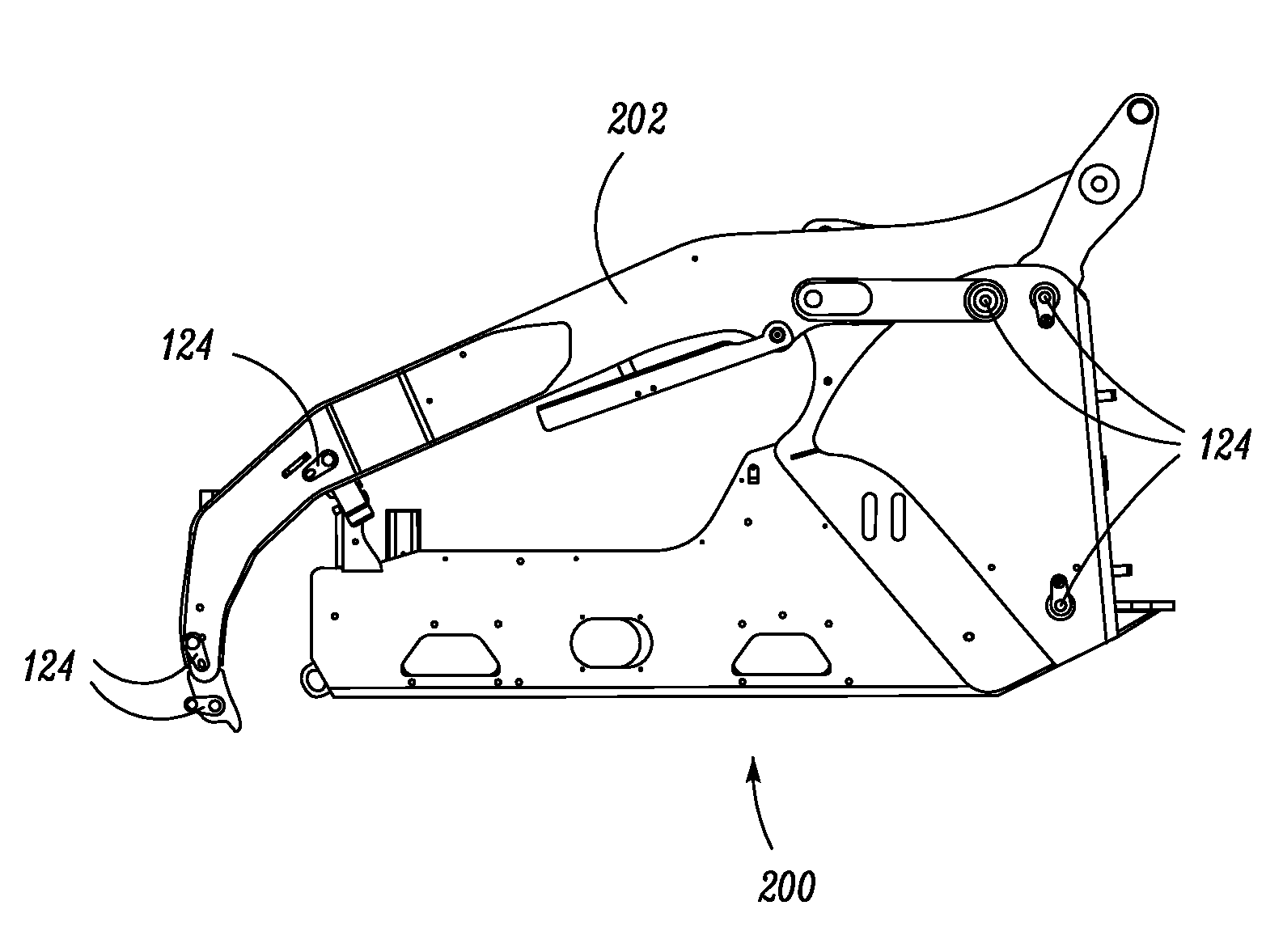

Linkage pin assembly

A linkage pin assembly is disclosed. The linkage pin assembly includes a grease fitting, a linkage pin, and a coupling. The grease fitting includes an outer shell. The outer shell encloses an internal cavity. The outer shell includes a thread blank having at a second end of the outer shell. The thread blank includes hardened lead threads. The hardened lead threads are induction hardened to at least RKW C 53. The linkage pin has an untapped hole. The coupling is between the grease fitting and the linkage pin. The coupling is formed when the hardened lead threads of the grease fitting create corresponding threads in the untapped hole of the linkage pin when the grease fitting is inserted into the linkage pin.

Owner:CATEPILLAR SARL

Fitting cover

A lubricant fitting cover for a zerk having a substantially planar body with a first side and a second side, the first side is capable of being removeably secured to the head of a grease fitting, the second side includes an indicator for providing information about the type of lubricant to be injected through the grease fitting.

Owner:WHITMORE MFG LLC

Fifth Wheel Locking Mechanism Cover

InactiveUS20130175787A1Facilitates coverageSecure structureTowing devicesGrease fittingLocking mechanism

A tractor trailer fifth wheel cover is disclosed forming an enclosure over the fifth wheel locking mechanism along the underside of the fifth wheel bearing plate. The cover comprises an upper surface and upstanding sidewalls having a plurality of penetrations therethrough. The cover forms an open interior to accept the fifth wheel kingpin locking mechanism therein and prevents dirt and debris from interfering with the mechanism operation over periods of environmental exposure. The pull handle of the locking mechanism routes through an aperture along the cover sidewall, while the design of the cover is such that it forms an enclosure supported within the underside structure of the bearing plate. The device is fastenably secured to the bearing plate structure and over the locking mechanism, while grease fittings allow lubrication of the locking mechanism assembly therewithin. The cover remains installed during deployment of the fifth wheel without interfering with normal operation.

Owner:LHEUREUX DAVID +1

Motor vehicle clutch linkage lubrication

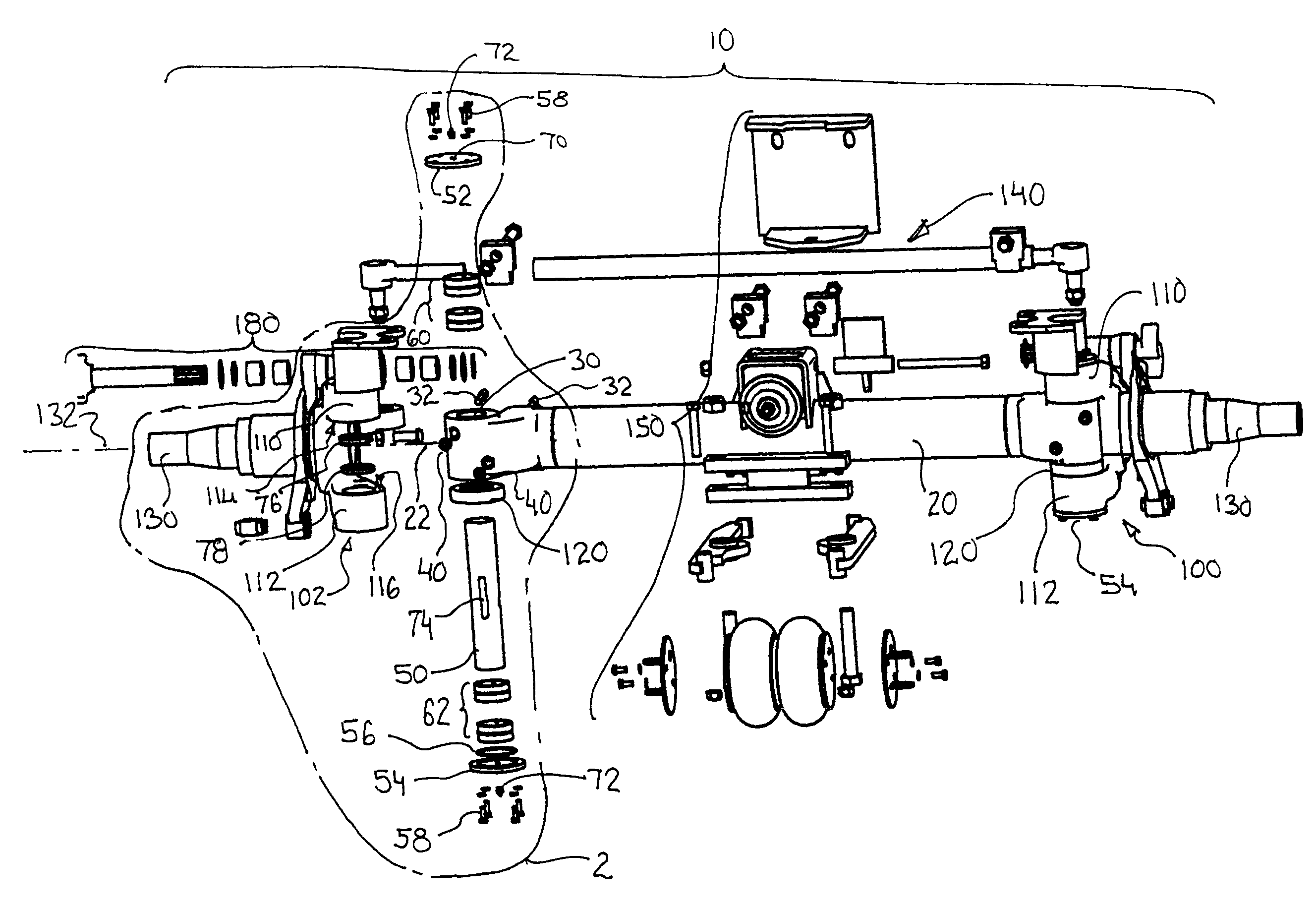

Several distinct motor vehicle clutch fork and release bearing lubrication arrangements which may be utilized singly or in various combinations include: oil impregnated inserts, self-lubricating pockets, single or multiple central grease fittings in communication with passageways that provide grease to contact and bearing surfaces and sealed boots filled with lubricant which cover a portion of ends of the release fork.

Owner:ZF FRIEDRICHSHAFEN AG

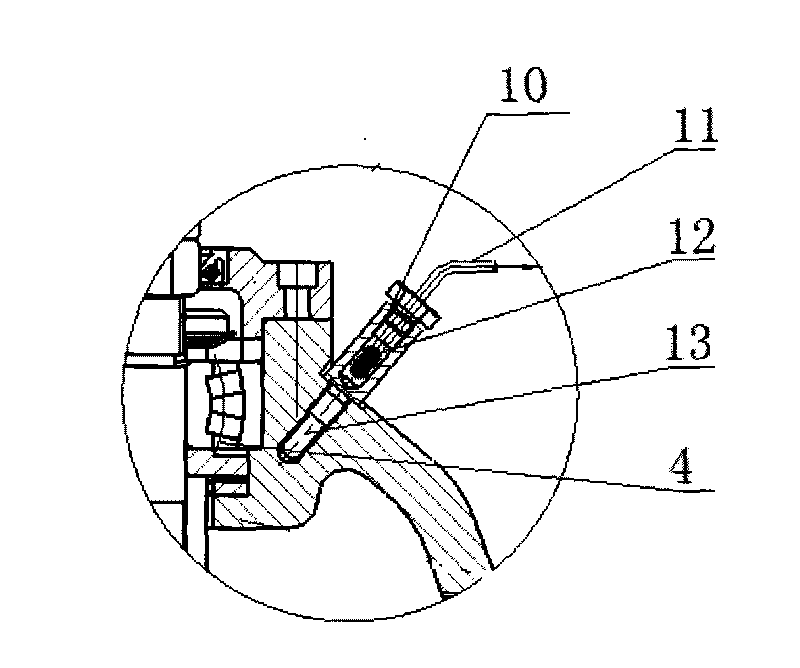

Crank connecting structure of pumping unit

InactiveCN105240506AReasonable structural designFully lubricatedConnecting rod bearingsGear lubrication/coolingGrease fittingEngineering

The invention relates to a crank connecting structure of a pumping unit. The crank connecting structure comprises a bearing box, a bearing cover, a self-aligning roller bearing, a crank pin shaft, a connecting rod, a grease fitting and a screw plug. The bearing box comprises an open box body with a hollow cavity. The bearing cover is used for sealing an opening of the bearing box. The self-aligning roller bearing is arranged in the bearing box. The crank pin shaft penetrates into the bearing box and is in shaft connection with the self-aligning roller bearing. The connecting rod penetrates the bearing box, is perpendicular to the crank pin shaft and is in rotary connection with the self-aligning roller bearing and the crank pin shaft at the same time. The grease fitting is arranged on the bearing cover and used for injecting lubricating grease into the bearing box. The screw plug is arranged on the side, opposite to the grease fitting, of the bearing box and used for discharging redundant lubricating grease injected into the bearing box by the grease fitting. The defects in the prior art are overcome, lubricating grease is fully utilized, it is guaranteed that a left bearing cavity and a right bearing cavity are filled with lubricating grease, full bearing lubricating is achieved, high safety and reliability are achieved, and use is convenient.

Owner:DERUI PETROLEUM EQUIP QINGDAO

Temperature sensing grease fitting with alarm

ActiveUS20140266741A1Easy to determinePreventative maintenanceRolling contact bearingsBearing assemblyElectricityGrease fitting

A bearing temperature monitoring system for detecting a temperature of bearing grease within a bearing housing. The bearing temperature monitoring system comprises a housing mountable to the bearing housing, a power source selectively outputting an electrical current, and an electrical circuit. The electrical circuit includes a temperature sensor component electrically coupled to the power source. The temperature sensor component can be responsive to a change in temperature such that the temperature sensor component opens or closes the electrical circuit at a predetermined temperature even in the absence of an applied electrical current. The electrical circuit further includes an alert device electrically coupled to the power source and the temperature sensor component that outputs an alert in response to the temperature sensor component.

Owner:REGAL BELOIT AMERICA

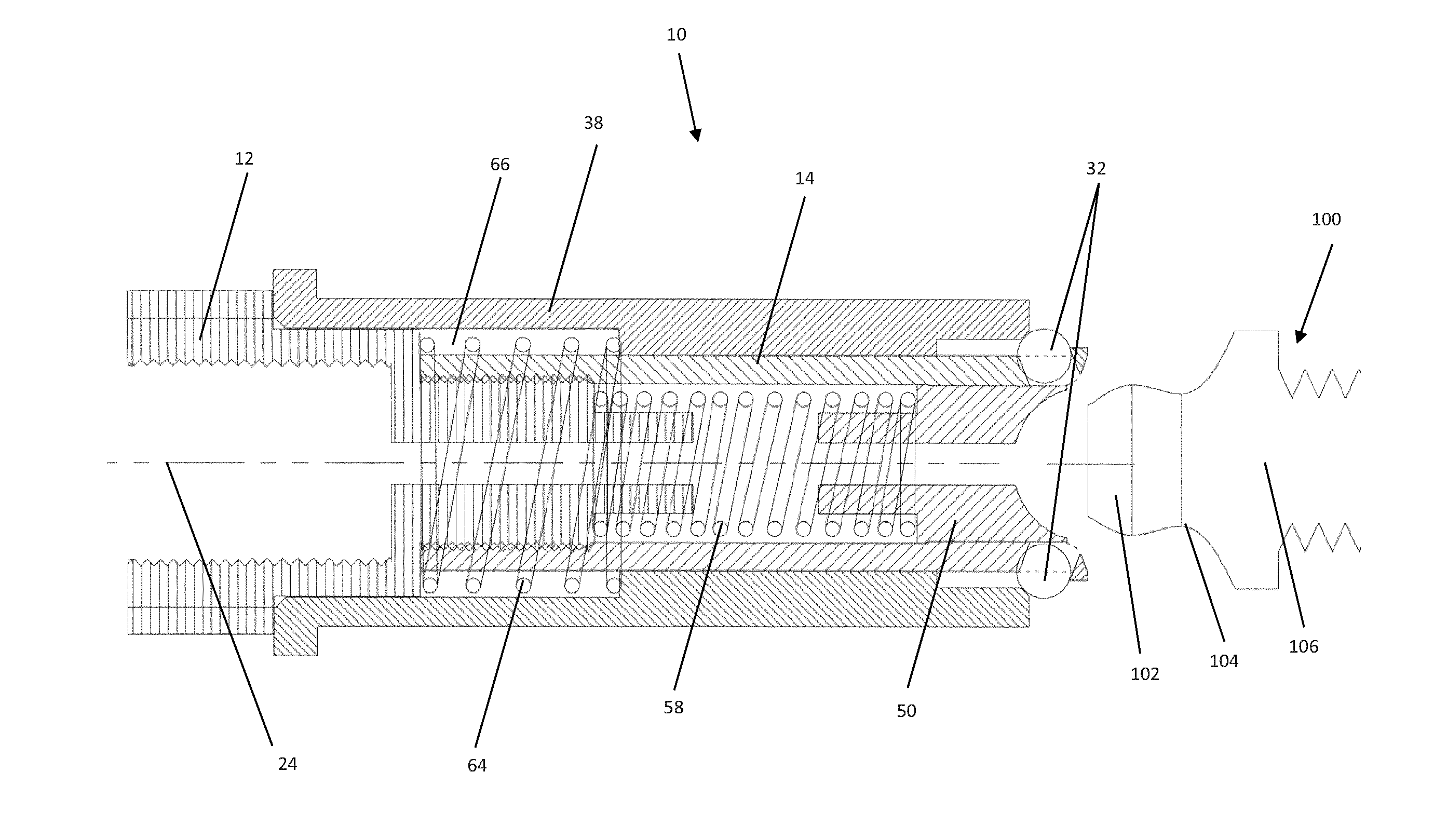

Over an axle grease tool for repacking wheel bearing with grease, and method of using same

ActiveUS20200080687A1Low costMinimize timeLubricant transferBearing componentsGrease fittingMechanical engineering

A grease tool and method for greasing a wheel bearing where the grease tool includes a handle and manifold. The handle and manifold define a central passage that extends through the grease tool. A supply channel is formed radially between the central passage and an exterior surface of the grease tool and extends axially through the handle to an annular supply recess formed in the manifold. A grease fitting attached to the grease tool to facilitate a supply of grease through the supply channel and the supply recess to an inwardly facing surface of the wheel bearing. The central passage in the grease tool facilitating sliding the grease tool over an axle that extends through the wheel bearing and positioning of the grease tool within the wheel bearing evenly repacking of the bearing in a position over the axle.

Owner:PETIT DENIS

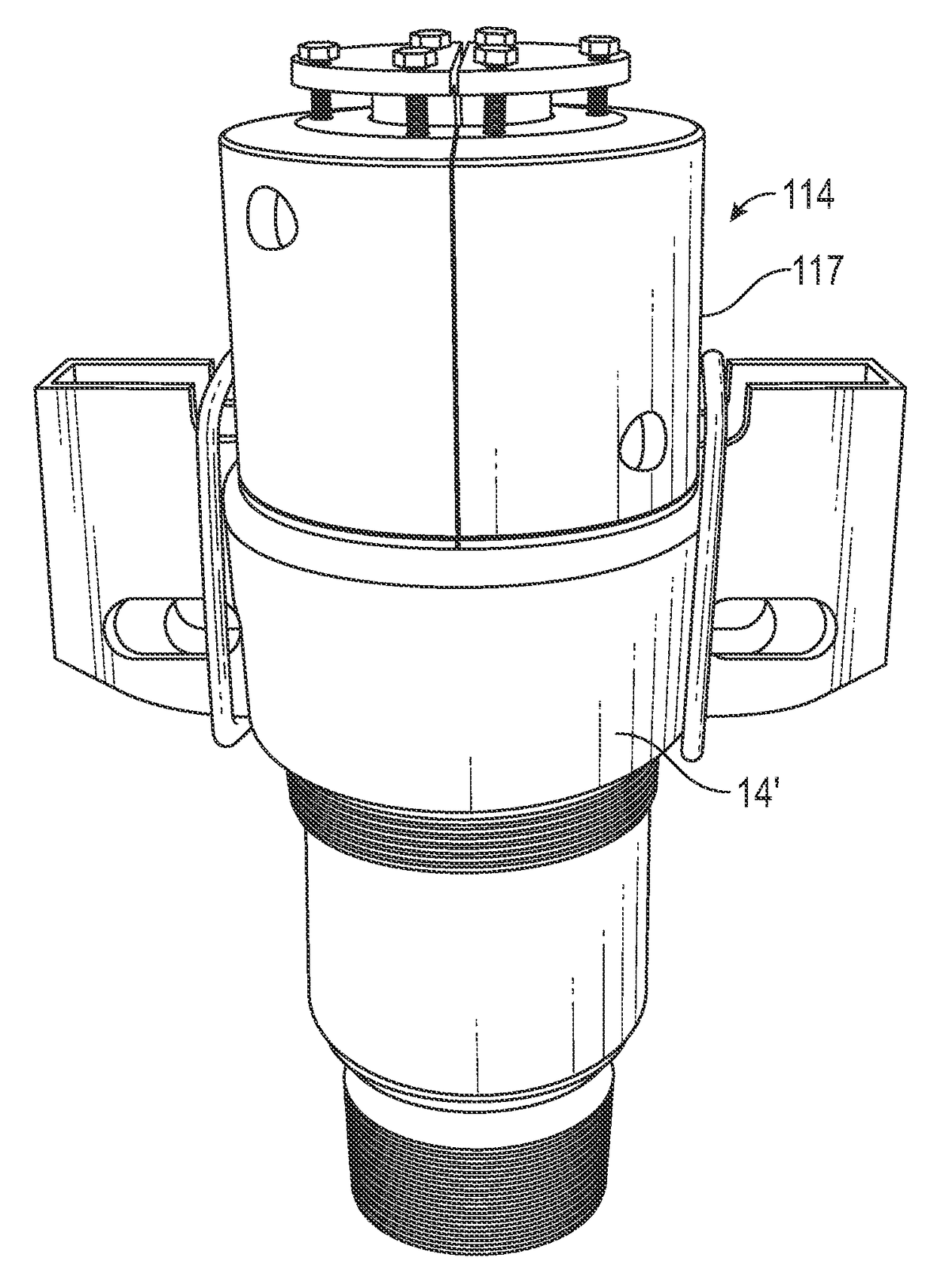

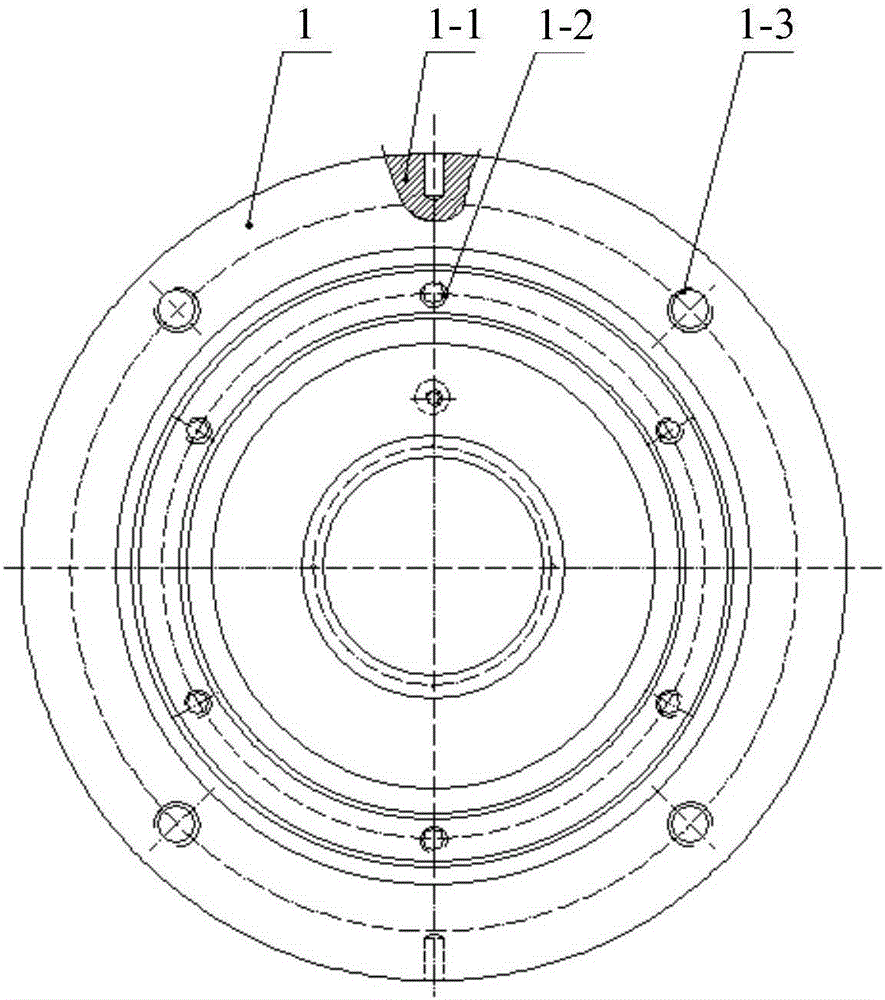

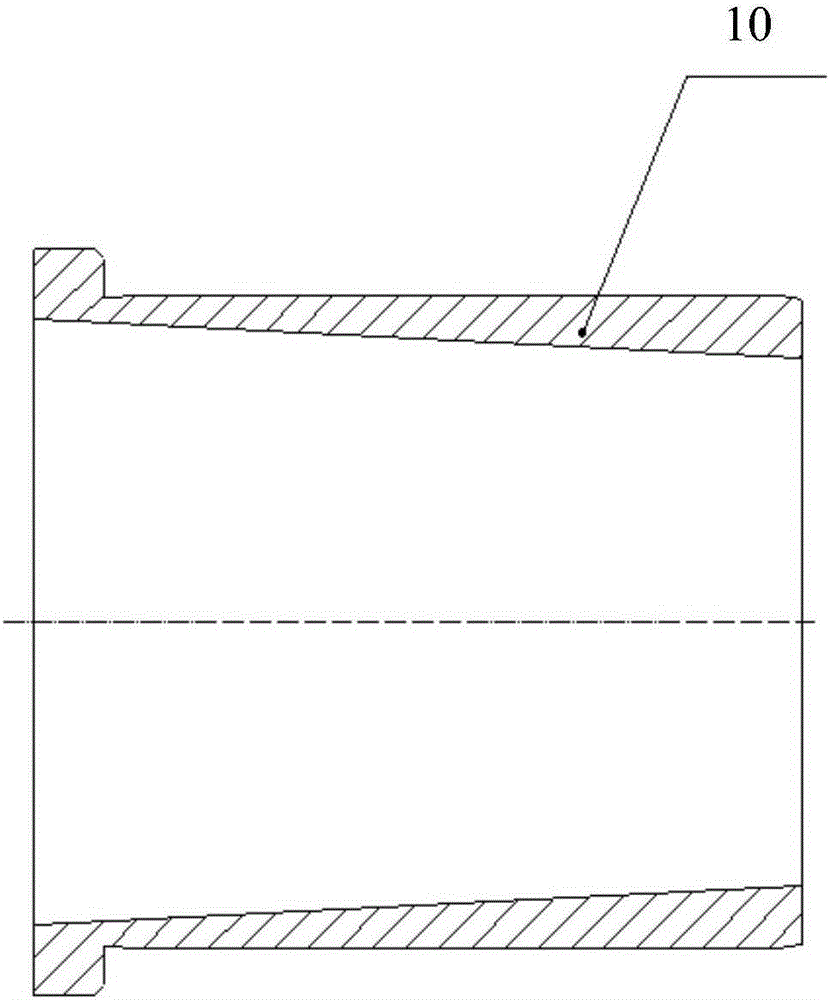

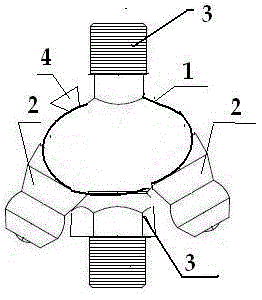

Novel multi-port acute-angle grease fitting structure with control valve

The invention relates to a novel multi-port acute-angle grease fitting structure with a control valve. The novel multi-port acute-angle grease fitting structure comprises a circular cavity, upper connecting structures and longitudinal connecting structures. The circular cavity is arranged between the upper connecting structures and the longitudinal connecting structures. The upper connecting structures and the longitudinal connecting structures are internally provided with cavities. The circular cavity and the connecting structures are integrated. The upper connecting structures are arranged on the upper portion. The longitudinal connecting structures are longitudinally arranged. The axial direction of each of the upper connecting structure and the longitudinal connecting structure form an acute angle which is larger than 0 degree and smaller than 90 degrees. Sealing openings are formed at the tails of the upper connecting structures. The control valve is formed on the circular cavity.

Owner:QINGDAO GUANDA TRADE

Grease tool for repacking dual angular contact bearing with grease, and method of using same

ActiveUS10670184B2Easy to disassembleIncrease supplyRolling contact bearingsLubricant transferGrease fittingEngineering

A grease tool and method for greasing a dual angular contact bearing where the grease tool is fabricated from a single unitary piece of material. The grease tool comprises a cylindrical hub, a flange supported adjacent only one end of the cylindrical hub, and a grease fitting attached to the grease tool to facilitate a supply of grease thereto. During use, a pair of spaced apart O-rings, accommodated by an exterior surface of the cylindrical hub, form a pair of grease seals with an inwardly facing surface of an inner race of the dual angular contact bearing. A supply passage conveys the supplied grease from the grease fitting to a grease outlet(s) located in an exterior cylindrical surface of the grease tool, between the pair of O-rings, for conveyance of the supplied grease radially to the inner race of the dual angular contact bearing and facilitate repacking thereof.

Owner:PETIT DENIS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com