Novel multi-port acute-angle grease fitting structure with control valve

A technology for controlling valves and grease nipples, applied in the field of manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

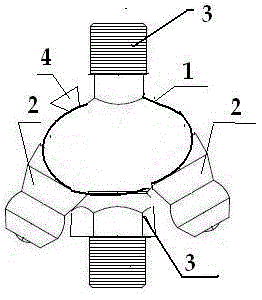

[0010] see figure 1 As shown, the present invention includes a circular cavity 1, two upper connecting structures 2 and two longitudinal connecting structures 3, the circular cavity is located in the middle of the upper connecting structure and the longitudinal connecting structure, and the upper connecting structure and the longitudinal connecting structure The inside of the connection structure is provided with a cavity, a circular cavity, two upper connection structures and a longitudinal connection structure integrated structure, the upper connection structure is located above, the longitudinal connection structure is in a longitudinal state, the upper connection structure and the longitudinal connection structure The connection structures form acute angles along their respective axial directions, and the angle range is less than 90 degrees and greater than 0 degrees. There is a sealing port at the end of the upper connection structure and a control valve in the circular c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com