Vertical planetary reducer with temperature control device

A planetary reducer and temperature control device technology, which is applied in the direction of measuring devices, thermometer parts, thermometers, etc., can solve the problems of damaged vertical planetary reducer, poor heat dissipation effect, and rapid temperature rise of the input shaft, etc., to improve Heat dissipation ability, not easy to melt and lose, and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

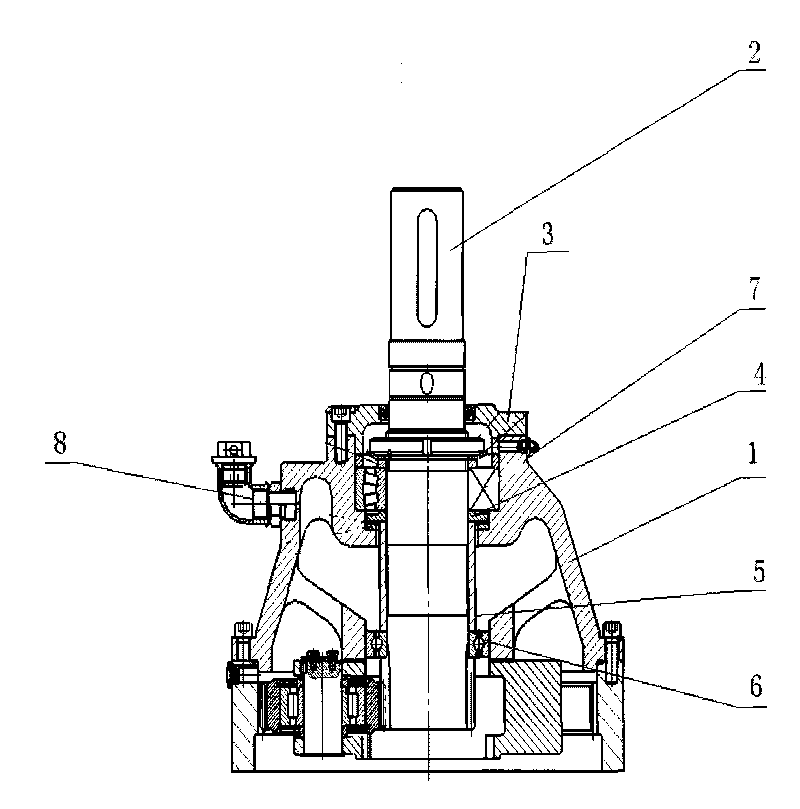

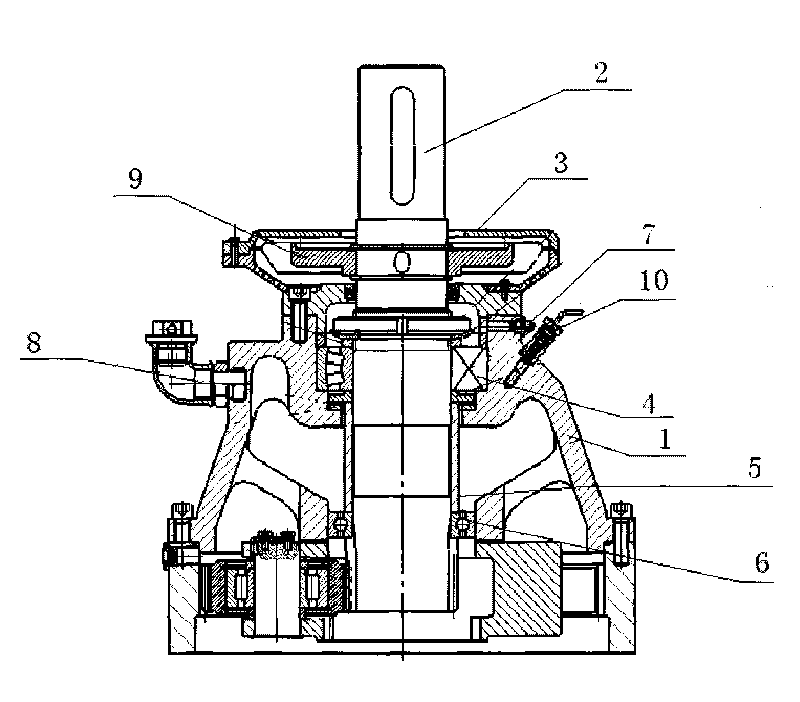

[0029] figure 2 It is a schematic diagram of the overall structure of the vertical planetary reducer with temperature control device of the present invention, as shown in the figure:

[0030] A vertical planetary reducer with a temperature control device, the temperature control device is composed of an input shaft cooling device and a temperature monitoring device 10, wherein the input shaft cooling device is composed of a fan 9, an air vent 7 and a grease nozzle 8 .

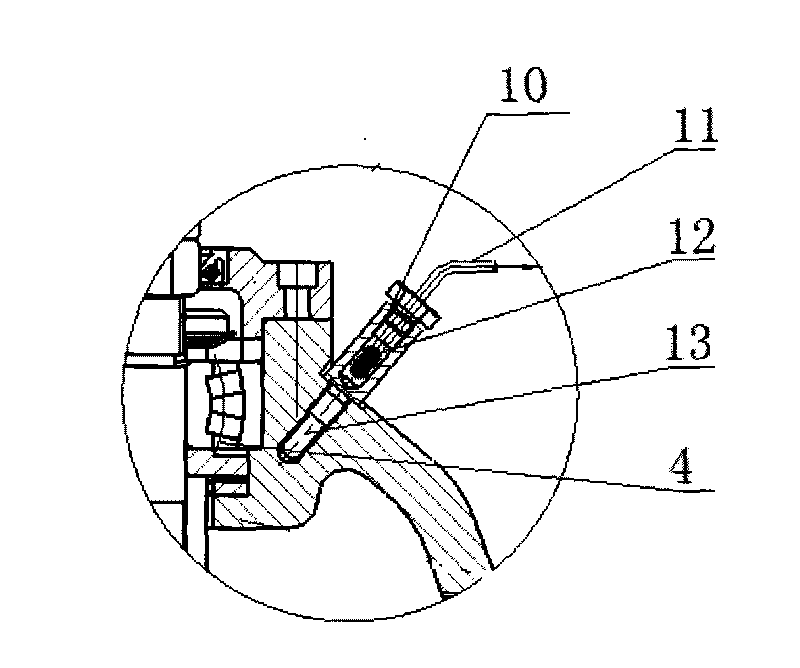

[0031] image 3 It is a schematic structural diagram of the temperature monitoring device of the vertical planetary reducer with a temperature control device in the present invention, as shown in the figure:

[0032] The temperature monitoring device 10 is composed of a temperature measuring contact 13 , a temperature measuring element 12 and an output data line 11 connected in sequence.

[0033] combined with figure 2 , 3 , the technical solution of the present invention is described in detail as follow...

Embodiment 2

[0038] The fan 9 installed can adopt a kind of fan of self-contained drive motor, and this fan comprises motor and fan blade, and wherein motor comprises housing, stator, rotor and motor shaft; Fan blade is fixed on the motor shaft, drives fan 9 and input Axis 2 realizes synchronous rotation.

[0039] When working, the fan 9 can be independently driven and controlled by its built-in motor, and can be started and rotated synchronously with the input shaft 2 on the input shaft 2 .

[0040] Practice has proved that a vertical planetary reducer with a temperature control device in the present invention has the following advantages:

[0041] 1. Equipped with an input shaft cooling device; the structure of the input end cover is improved, and a fan is installed in the input end cover to ventilate and dissipate heat in time, which improves the internal heat dissipation capacity of the reducer, makes the grease difficult to melt and lose, and the bearing can always be fully lubricated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com