Ultrahigh molecular weight polyethylene injection moulding machine

An injection molding machine and ultra-high molecular weight technology, applied in the field of plastic injection molding machines, can solve problems such as poor fluidity, and achieve the effect of increasing the effective coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

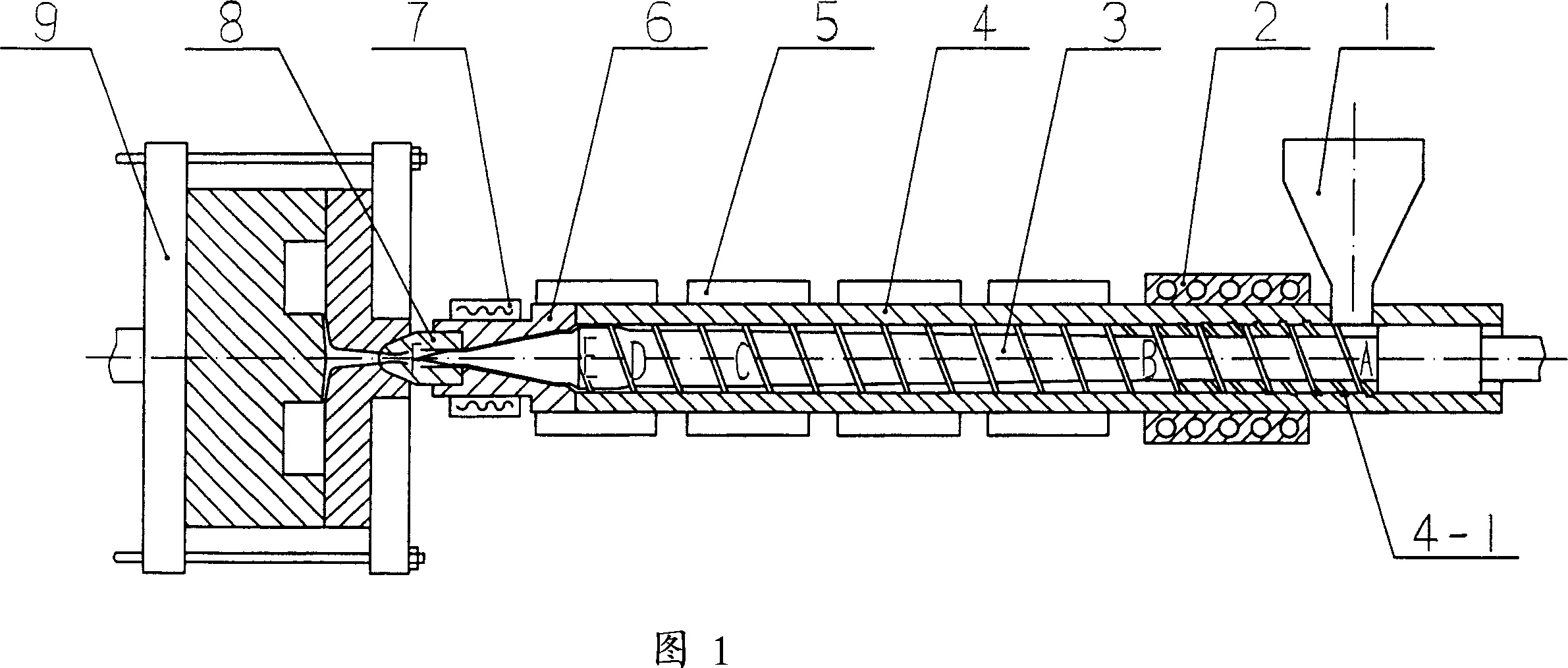

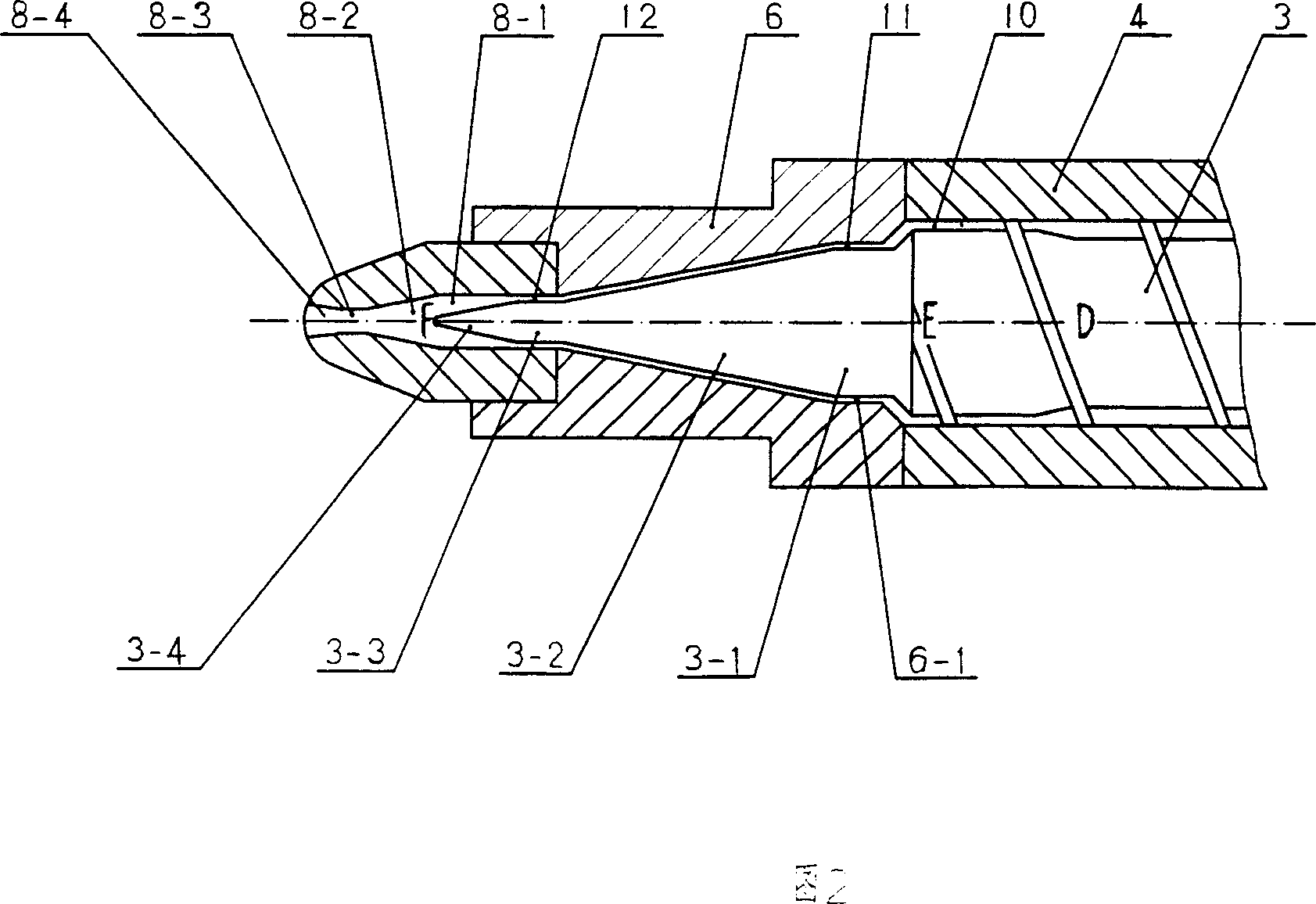

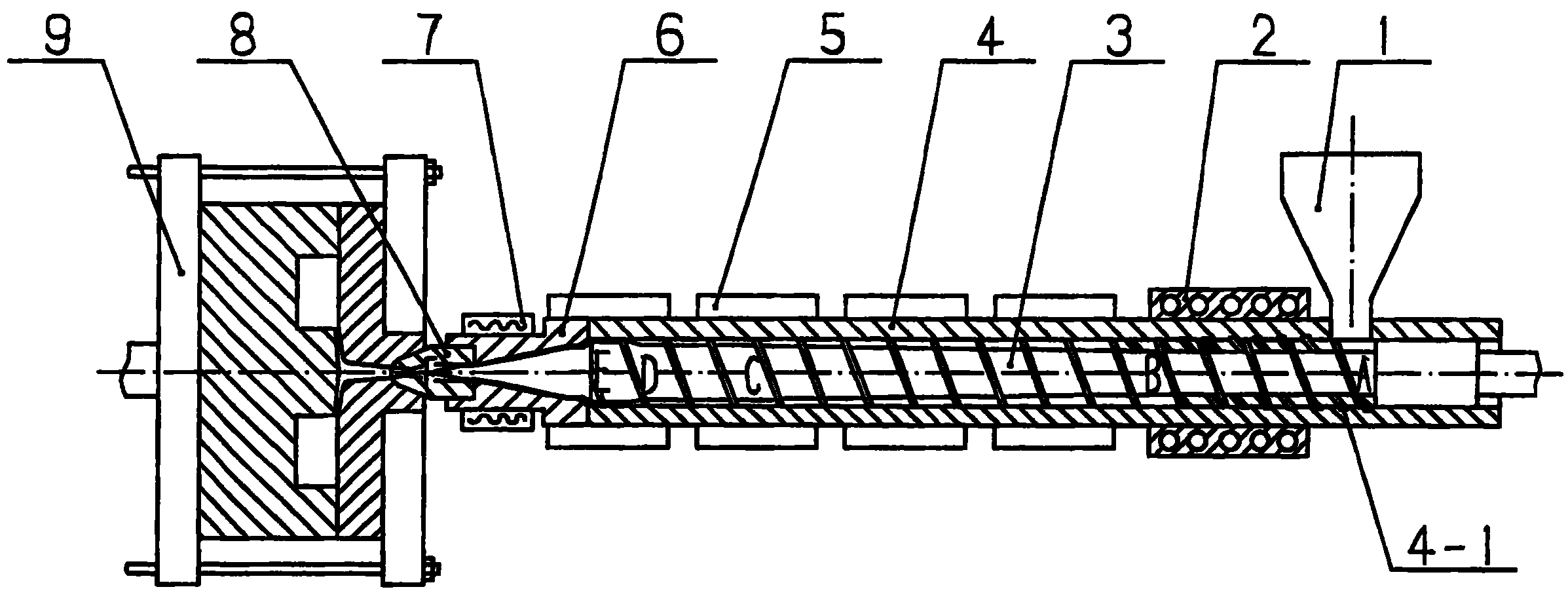

[0028] The theoretical injection volume implemented according to the present invention is 327cm 3 A plastic injection molding machine with a screw diameter of 45mm, a groove depth of the first homogenization section of 2.8mm, a compression ratio of 1.93, a screw groove depth of 2.4mm in the second homogenization section, and a compression ratio of 2.25mm; The cone angle of the first-stage cone and the second-stage cone is 20°, the thickness of the gap between the nozzle check zone and the precursor check zone is 0.3mm, the gap width is 32mm, the nozzle hole diameter is 1.8mm, and the screw pitch is 32mm.

[0029] The injection molding molds are common structure tensile test sample molds, impact test sample molds and wear test sample molds, and the mold heating temperature is 87°C. The ultra-high molecular weight polyethylene raw material is a powdery resin with a viscosity-average molecular weight of 2.7 million. Add a small amount of additives and mix evenly with a high-speed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com