Continuous flow closed gas phase high-voltage pulse discharge water treatment device

A high-voltage pulse discharge and water treatment device technology, which is applied in the field of water treatment by ion plasma technology, can solve the problems of poor wastewater treatment effect, difficulty in effectively treating wastewater, and poor treatment effect of lower liquid, so as to meet the requirements of high efficiency and energy saving Wastewater treatment, the structure of the discharge device is simple, and the effect of increasing the concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

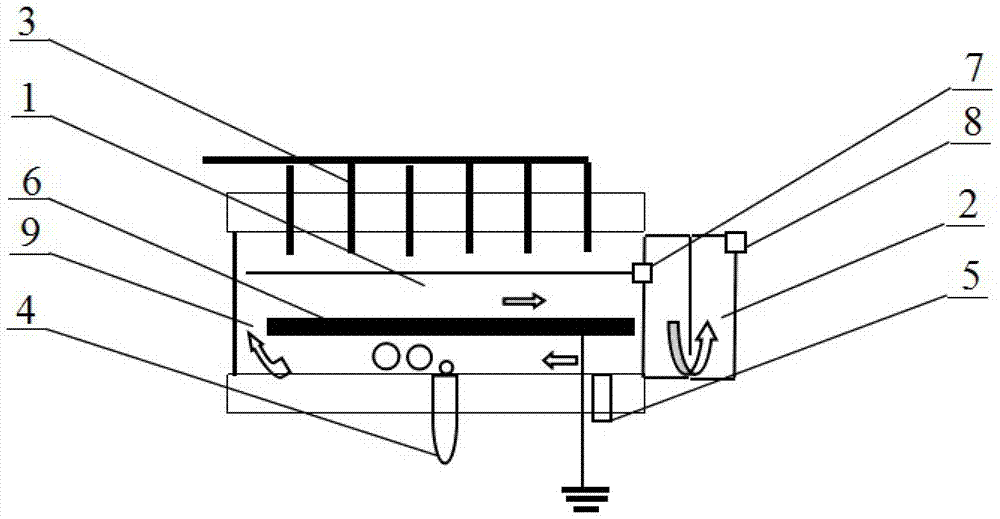

[0020] see figure 1 , a continuous flow closed gas-phase high-voltage pulse discharge water treatment device, mainly composed of a high-voltage pulse discharge reactor 1 and a secondary reactor 2, characterized in that: the high-voltage pulse discharge reactor 1 is a cylindrical airtight container, The upper end of the high-voltage pulse discharge reactor 1 is suspended with several high-voltage electrodes 3 at equal intervals, the lower end is provided with an air inlet 4 and a liquid inlet 5, and a circular flat ground electrode 6 is in the middle; the secondary reactor 2 is a rectangular closed The container, the secondary reactor 2 is provided with a vertical baffle in the middle, and the reaction space is U-shaped. One side of the secondary reactor 2 communicates with the high-voltage pulse discharge reactor 1 through the liquid outlet (a) 7, and the other side passes The liquid outlet (b) 8 communicates with the external container.

[0021] The outer ring surface of the...

Embodiment 2

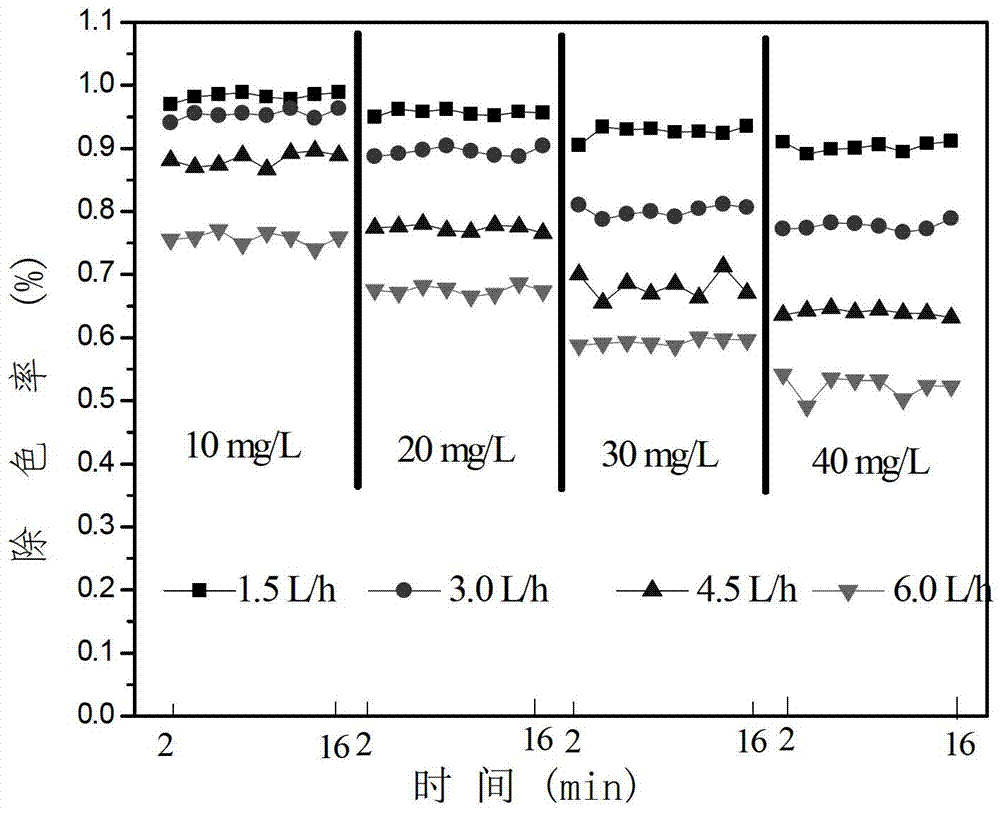

[0026] When utilizing the continuous flow closed gas-phase high-voltage pulse discharge water treatment device of Example 1 of the present invention to carry out high-voltage pulse discharge water treatment, the air inlet of the high-voltage pulse discharge reactor 1 is continuously filled with oxygen, and the gas flow rate is 40L / h, The liquid inlet hole 5 is continuously filled into the waste methylene blue aqueous solution with a concentration range of 10-40 mg / L, and a liquid flow rate of 1.5-6 L / h. The high-voltage electrode 3 is 7 cylindrical needle electrodes, and the distance between the high-voltage electrode 3 and the ground electrode 6 is 25 mm. The waste liquid and oxygen flow into the upper space of the ground electrode 6 through the liquid through hole 9 on one side of the ground electrode 6, and then flow into the plasma area generated by the discharge between the high voltage electrode 3 and the ground electrode 6, and the first degraded waste water reacts throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com