Automatic additive-feeding device and method and washing machine

A technology of automatic feeding and additives, applied in other washing machines, washing devices, textiles and papermaking, etc., can solve problems such as clogging, inability of additives to dissolve in time, and difficulty in cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

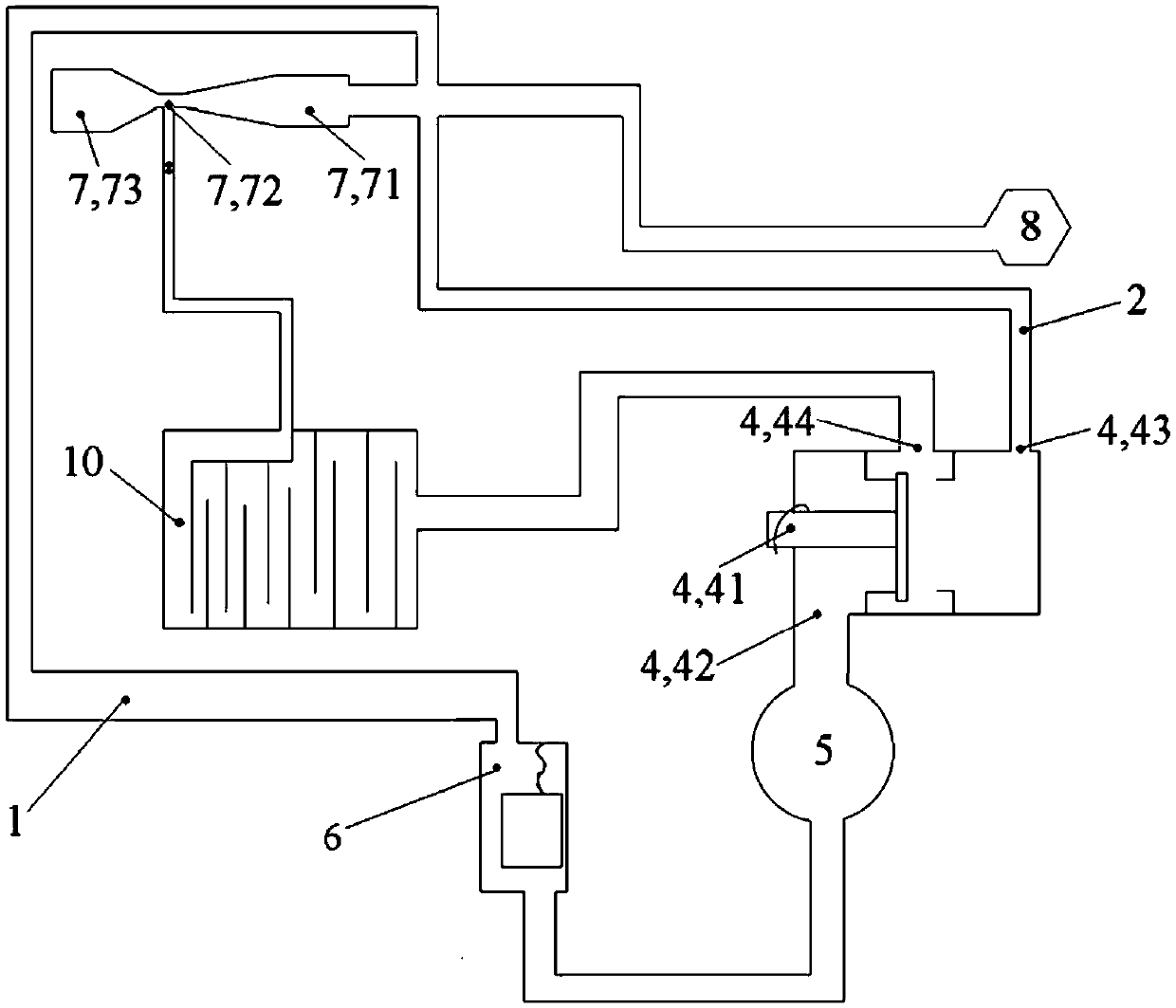

Embodiment 1

[0050] In this example, if figure 1 As shown, there is provided an additive automatic dosing device, including a Venturi tube 7 connected to the water outlet 8, a pipeline is connected between the diffuser section 71 of the Venturi tube 7 and the water outlet 8, and a branching device is provided on the pipeline. There are flushing flow channel 1 and cleaning flow channel 2, flushing flow channel 1 is connected with additive liquid storage box 5 through water valve 6, additive liquid storage box 5 is connected with connection flow channel 3 through reversing valve 4, cleaning flow channel 2 is connected with all The above reversing valve 4 is directly connected, and the reversing valve 4 is connected with the suction port 72 of the Venturi tube 7, so that the flushing water flow and the cleaning water flow are respectively returned to the Venturi tube 7 through the reversing valve 4, and the water flow containing the additive is transported to outlet 8.

[0051] In this embod...

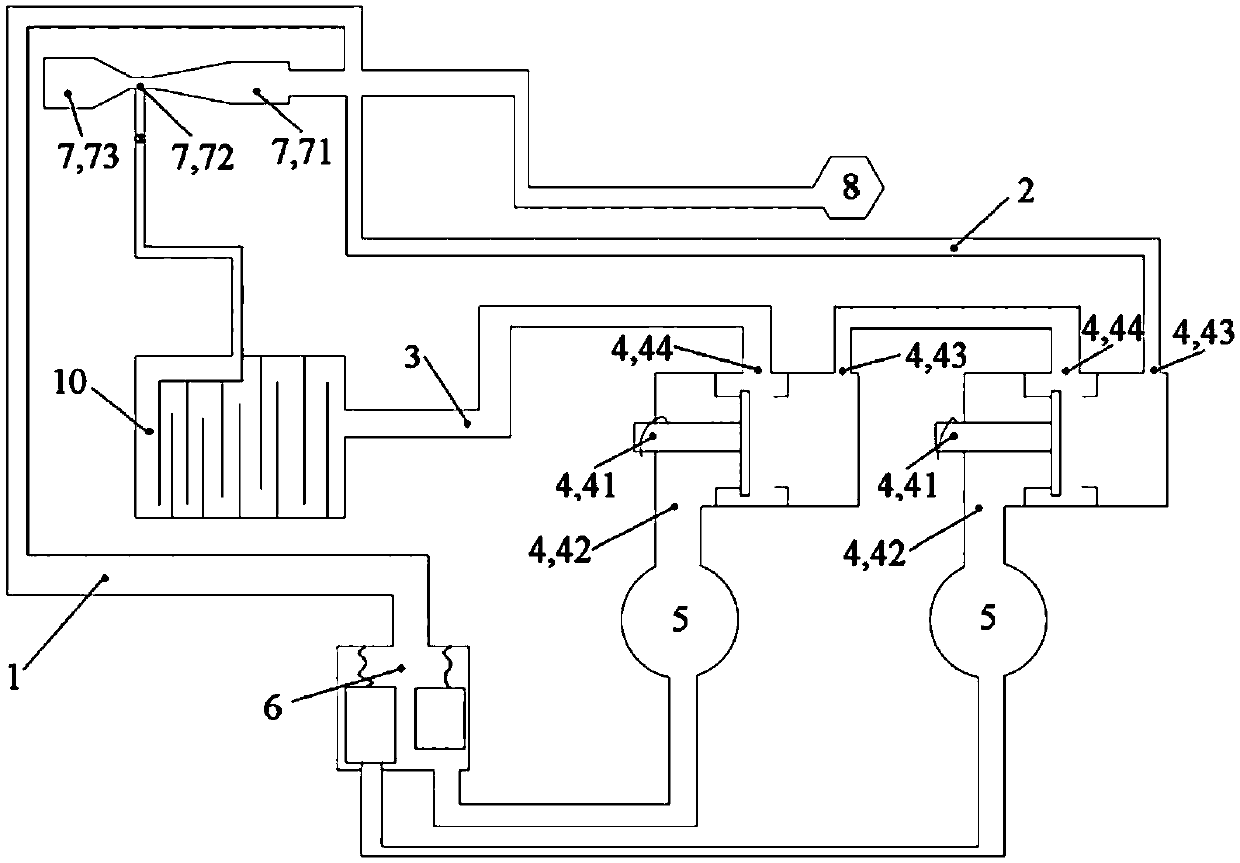

Embodiment 2

[0061] In this example, if figure 2 , as shown in 4 and 5, the present invention provides an additive automatic dosing device, including a Venturi tube 7 connected to the water outlet 8, and a pipeline is connected between the diffusion section 71 of the Venturi tube 7 and the water outlet 8, The pipeline is divided with a flushing channel 1 and a cleaning channel 2, the flushing channel 1 is connected to the reversing valve 4 through the additive liquid storage box 5, the cleaning channel 2 is directly connected to the reversing valve 4, and the reversing The valve 4 is connected to the suction port 72 of the Venturi tube 7 , so that the flushing water flow and the cleaning water flow respectively pass through the reversing valve 4 and flow back to the Venturi tube 7 , and the water flow with dissolved additives is delivered to the water outlet 8 .

[0062] In this embodiment, the suction structure is connected to the water supply structure, and the water outlet end of the s...

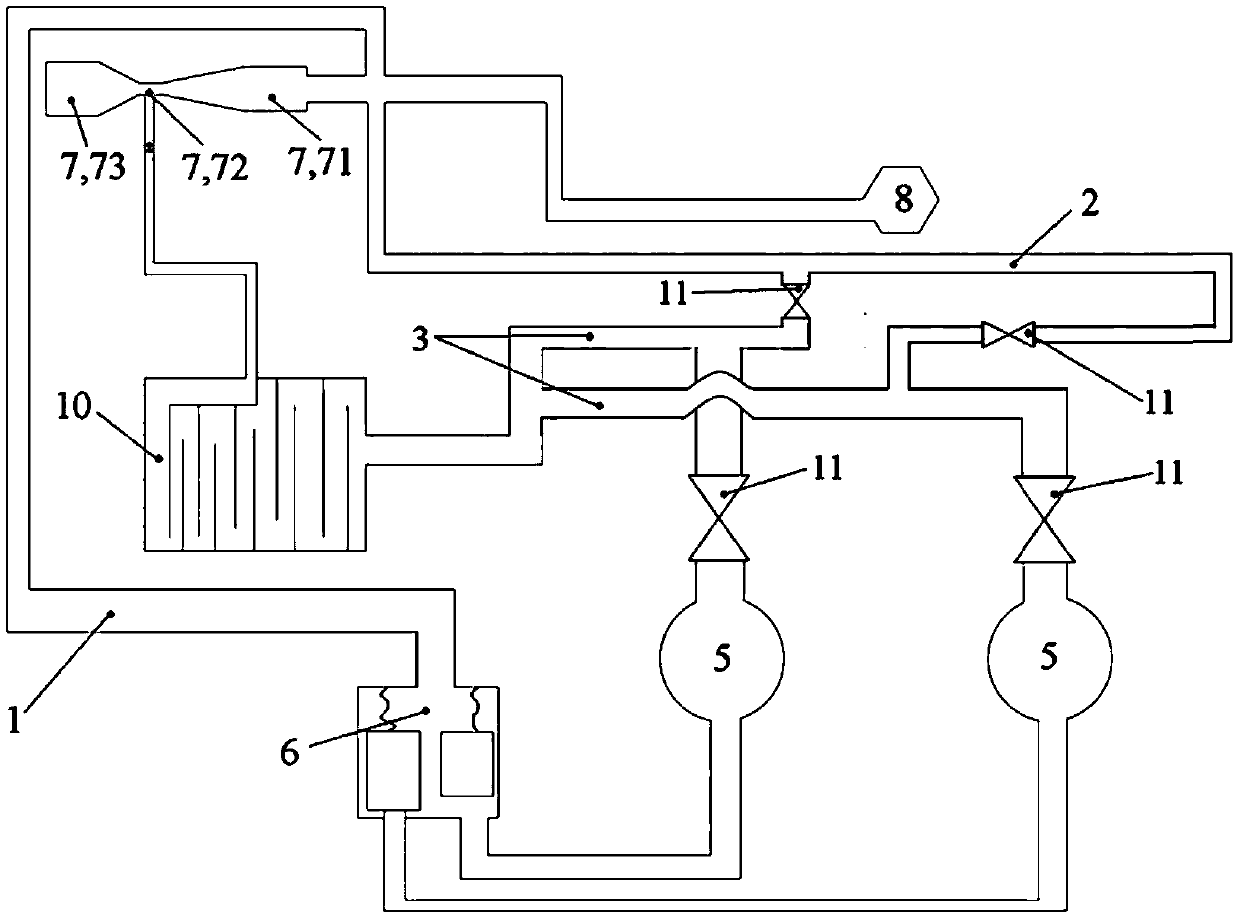

Embodiment 3

[0078] In this example, if image 3 As shown, one end of the flushing channel 1 is connected to the water supply channel downstream of the suction structure, and the other end is connected to the suction port of the suction structure through the liquid storage box 5. Pressure, the flushing water introduced from the flushing channel 1 in the liquid storage box 5 is returned to the water supply channel through the action of the suction structure.

[0079]In this embodiment, the suction structure is connected to the water supply structure, and the water outlet end of the suction structure branches out of the flushing channel 1 on the pipeline connected to the water outlet 8 . In the existing dispensing device, negative pressure vacuum is often used to directly suck the lotion into the waterway, and since the lotion is mostly viscous liquid, it will cause residual hardening in the liquid storage box if it is not used for a long time. To solve this problem, In the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com