Vibration rammer with horizontal vibration function

A vibratory rammer and functional technology, applied in the field of vibratory rammers, can solve the defects of safety and work efficiency, can not solve the problems of vibratory rammer horizontal clamping, vibration amplitude disorder, etc., and achieve the effect of large effective working range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

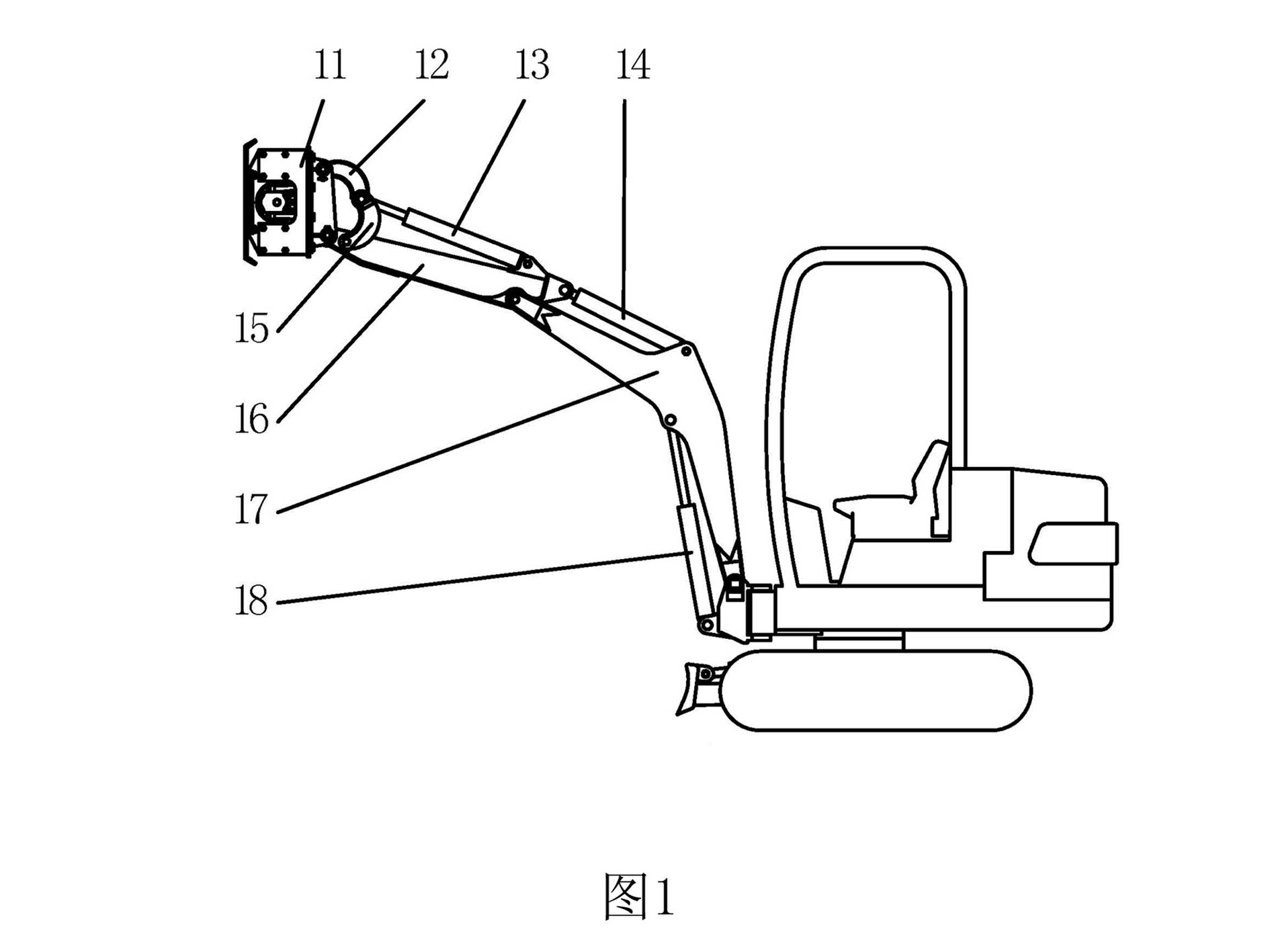

[0017] like figure 1 As shown, the vibration rammer with horizontal vibration function of the present invention includes a hydraulic excavator. The vibrating rammer with horizontal vibration function utilizes the hinge point cylinder 13, arm cylinder 14, and boom cylinder 18 of the hydraulic excavator to control the boom 17 and arm 16 to change the working position, as well as the rocker 15 and connecting rod 12. The technology that the connecting hinge point can change the position achieves the purpose of manipulating and controlling the vertical and horizontal vibration positions of the vibratory rammer with the horizontal vibration function. The above-mentioned accessories of the hydraulic excavator are used as the clamping device of the vibratory rammer with the function of horizontal vibration, so as to achieve the purpose of clamping and manipulating the vibratory rammer with the function of horizontal vibration for vibratory compaction under various conditions.

[0018...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com