Porous partition spray equipped desulfurization tower

A desulfurization tower and spray layer technology, applied in the field of desulfurization towers, can solve problems such as uneven distribution of gas and liquid, and large resistance in the gas-liquid distribution area of a single tower and double circulation, so as to reduce investment and operating costs, ensure smoothness, reduce The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

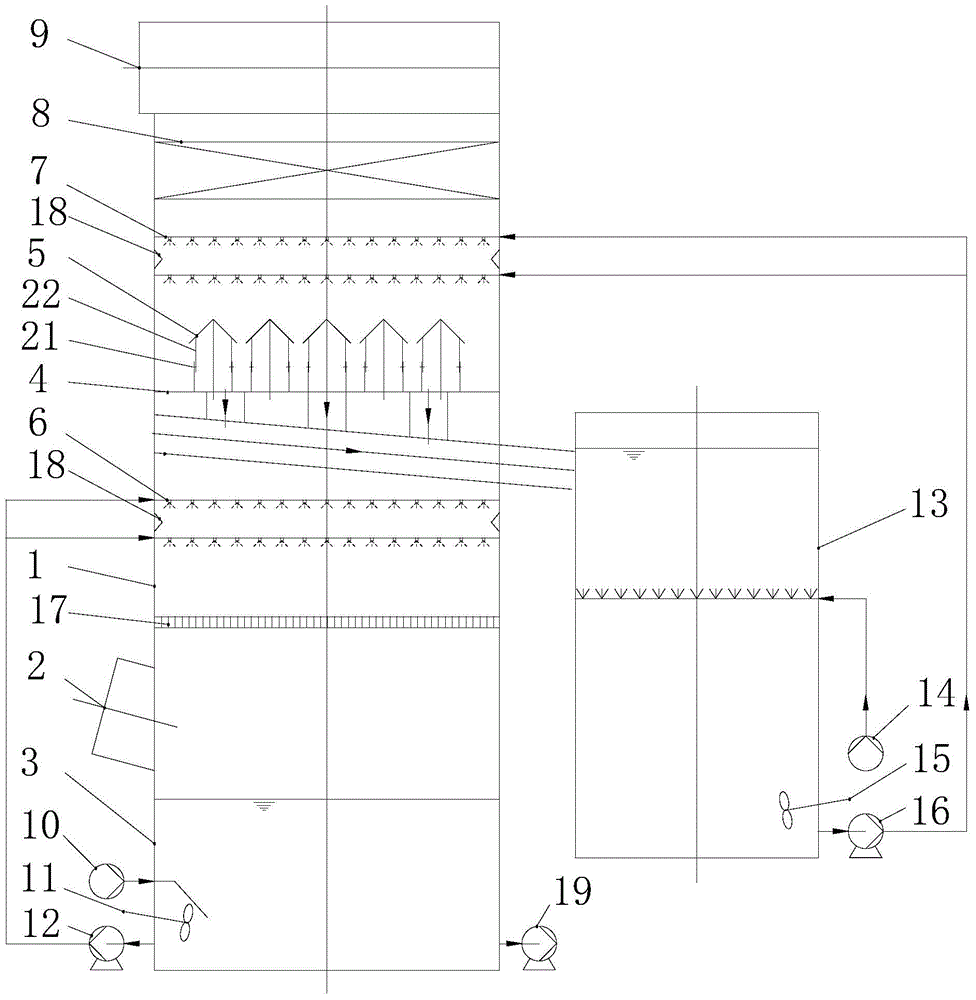

[0015] refer to figure 1 It is an embodiment of a desulfurization tower with porous partition spraying in the present invention. A desulfurization tower with porous partition spraying includes a tower body 1, and a flue gas inlet 2 is opened at the lower part of the tower body 1. There is a flue gas outlet 9 on the top of the tower body 1. The lower part of the tower body 1 is the first-level absorption zone, and the upper part of the tower body 1 is the second-level absorption zone. plate separated;

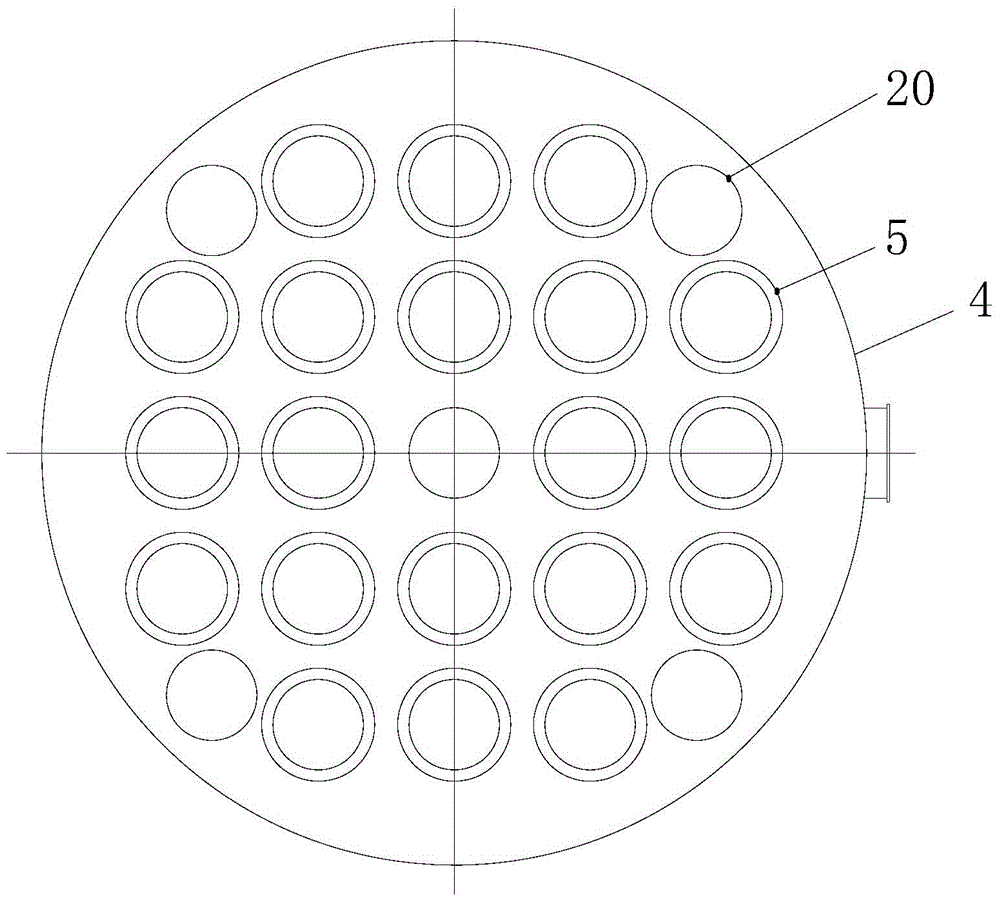

[0016] Such as figure 1 , figure 2 As shown, the porous air flow distribution plate includes a plate body 4, and a liquid leakage hole 20 is opened on the plate body 4, and an upward ventilation column 21 is also provided on the plate body, and each of the ventilation columns 21 is provided with an anti-two The slurry in the primary absorption zone enters the gas caps 5 in the primary absorption zone. The gas caps 5 are conical, and each of the gas caps 5 is fixed on the ven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com