Continuous synthesis of glyphosate by dimethyl ester

A technology of dimethyl ester and glyphosate, which is applied in the field of continuous production of glyphosate by dimethyl ester method, can solve the problems of lack of coherence in production, small capacity of a single device, unreasonable energy utilization, etc., and achieves continuous hydrolysis. The effect of reducing the difficulty of recycling and effectively utilizing thermal energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

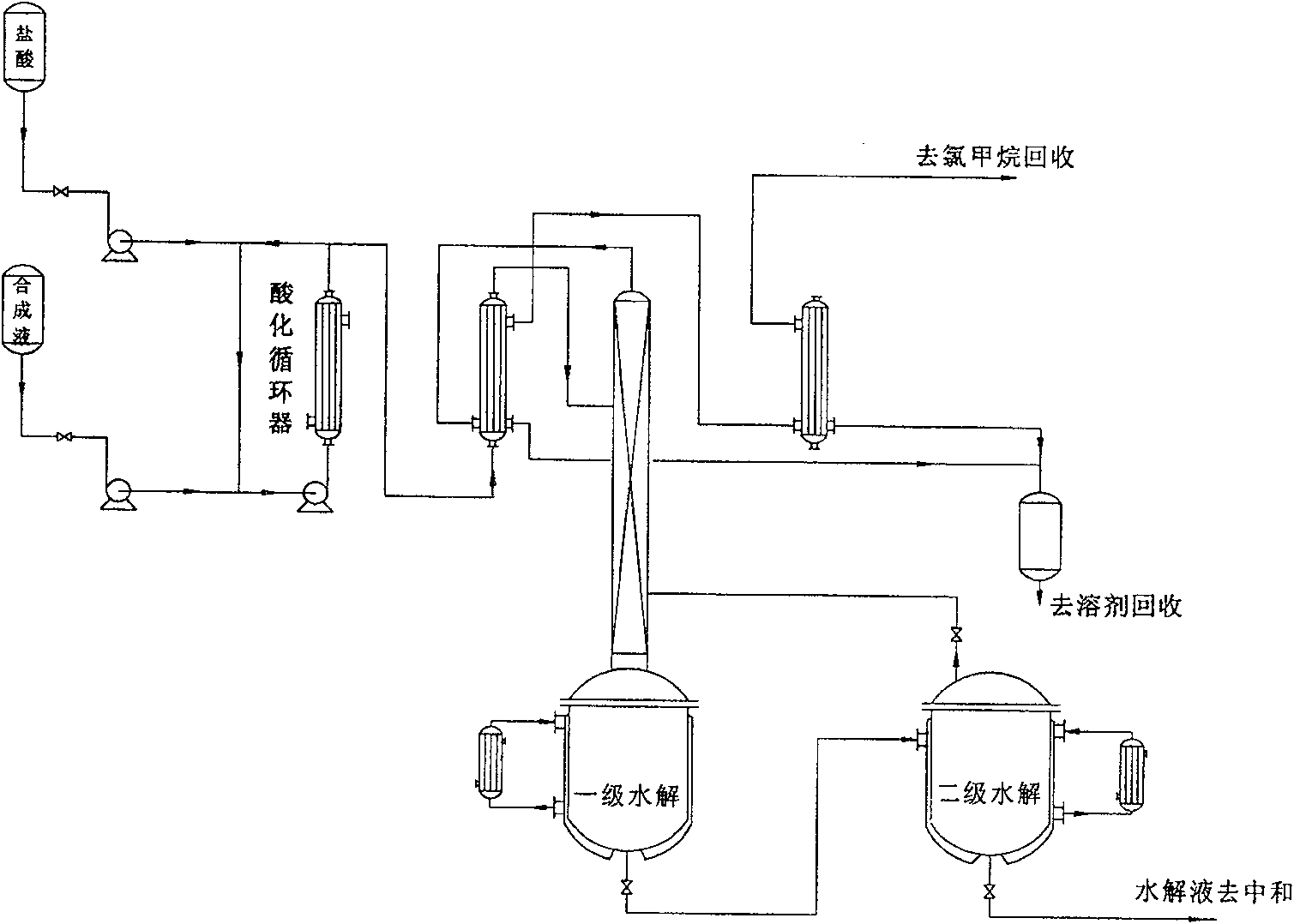

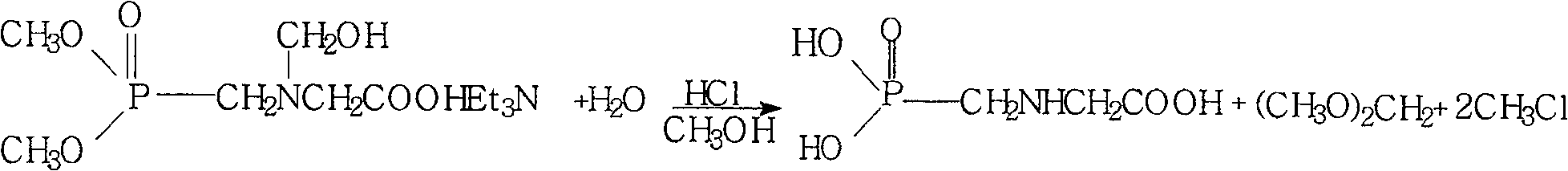

[0049] The mol ratio of synthetic liquid (in terms of glycine) and hydrochloric acid is the acidified synthetic liquid of 1: 3.1, enters the hydrolysis reaction zone with the feed rate of 1.28 tons / h, and the hydrolysis reactor adopts the combination reactor of one tower two stills, will acidify The synthetic liquid is fed continuously from the top of the tower, and the temperature in the tower is controlled at 90-100°C for preliminary hydrolysis. At the same time, the solvent methanol comes out from the top of the tower, and the generated hydrolyzate, unreacted synthetic liquid and intermediate reaction mixture enter continuously from the bottom of the tower. The first-stage tank-type hydrolysis reactor conducts continuous hydrolysis, and the temperature is controlled at 100-110°C, and then continues to enter the second-stage tank-type reactor for hydrolysis, and the temperature is controlled at 124-128°C, and the material is continuously discharged to neutralize and crystalliz...

Embodiment 2

[0051] The mol ratio of synthetic liquid (in terms of glycine) and hydrochloric acid is the acidified synthetic liquid of 1: 3.4, enters the hydrolysis reaction zone with the feed rate of 1.28 tons / h, and the hydrolysis reactor adopts the combined reactor of one tower two stills, will acidify The synthetic liquid is fed continuously from the middle of the tower, and the temperature in the tower is controlled at 90-100°C for preliminary hydrolysis. At the same time, the solvent methanol comes out from the top of the tower, and the generated hydrolyzate, unreacted synthetic liquid and intermediate reaction mixture enter continuously from the bottom of the tower. The first-stage tank-type hydrolysis reactor conducts continuous hydrolysis, and the temperature is controlled at 100-110°C, and then continues to enter the second-stage tank-type reactor for hydrolysis, and the temperature is controlled at 124-128°C, and the material is continuously discharged to neutralize and crystalliz...

Embodiment 3

[0053] The molar ratio of the synthetic solution (in terms of glycine) and hydrochloric acid is pumped into the circulation mixer with a constant flow metering pump in the ratio of 1:3.4, the total flow rate is 1.28 tons / h, and the circulation flow rate is 10 tons / h. After the condenser, enter the hydrolysis combination device (one tower and two kettles) for hydrolysis. The temperature at the top of the tower is controlled at 92°C, the temperature of the first-stage hydrolysis tower is 110°C, and the temperature of the second-stage hydrolysis tower is 120°C. The residence time is 35 minutes, and the hydrolyzate is added with alkali to crystallize for 8 hours to obtain the product glyphosate, and the total yield of glyphosate is 84.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com