Patents

Literature

32results about How to "Avoid clogging accidents" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

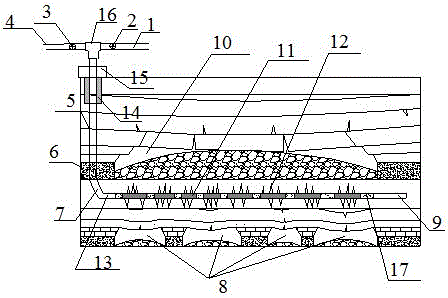

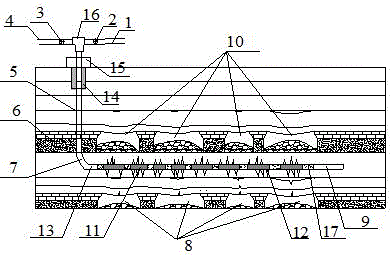

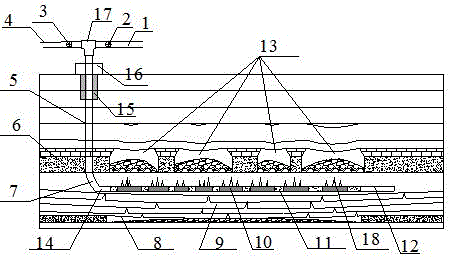

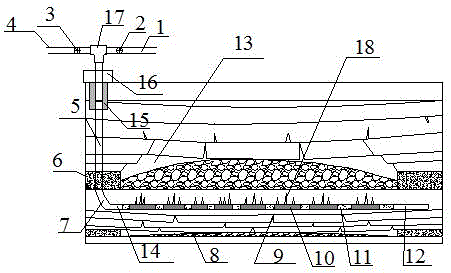

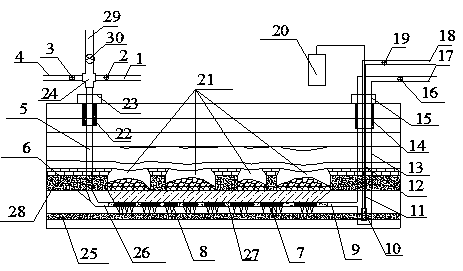

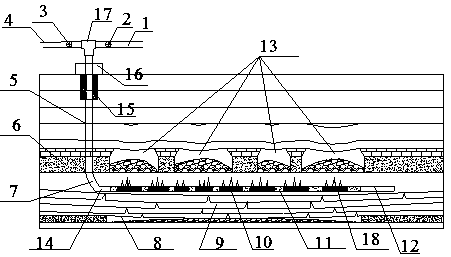

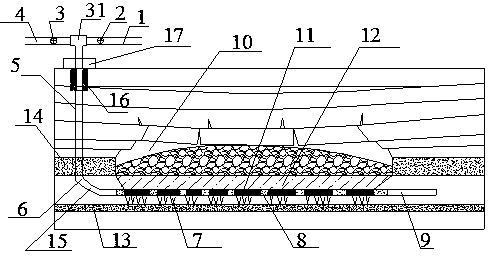

Method of synergetic extraction of coal bed gas of tool post type mined area and lower coal bed

ActiveCN106089290AAvoid recyclingAvoid collapse accidentsFluid removalDrainageEnvironmental engineeringCoal

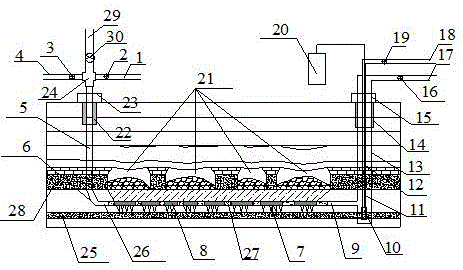

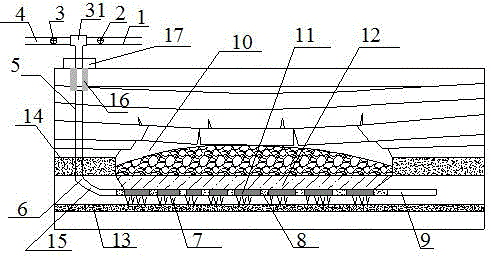

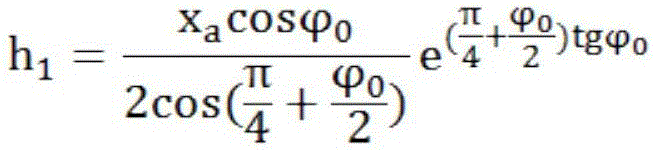

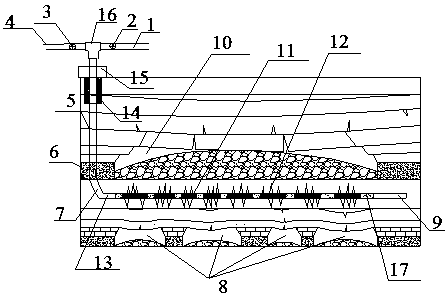

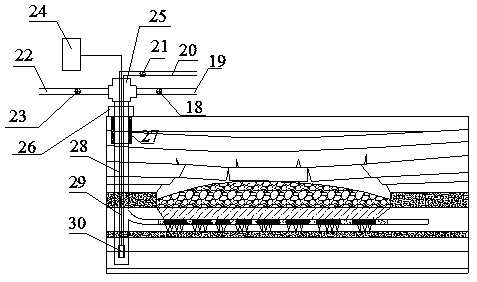

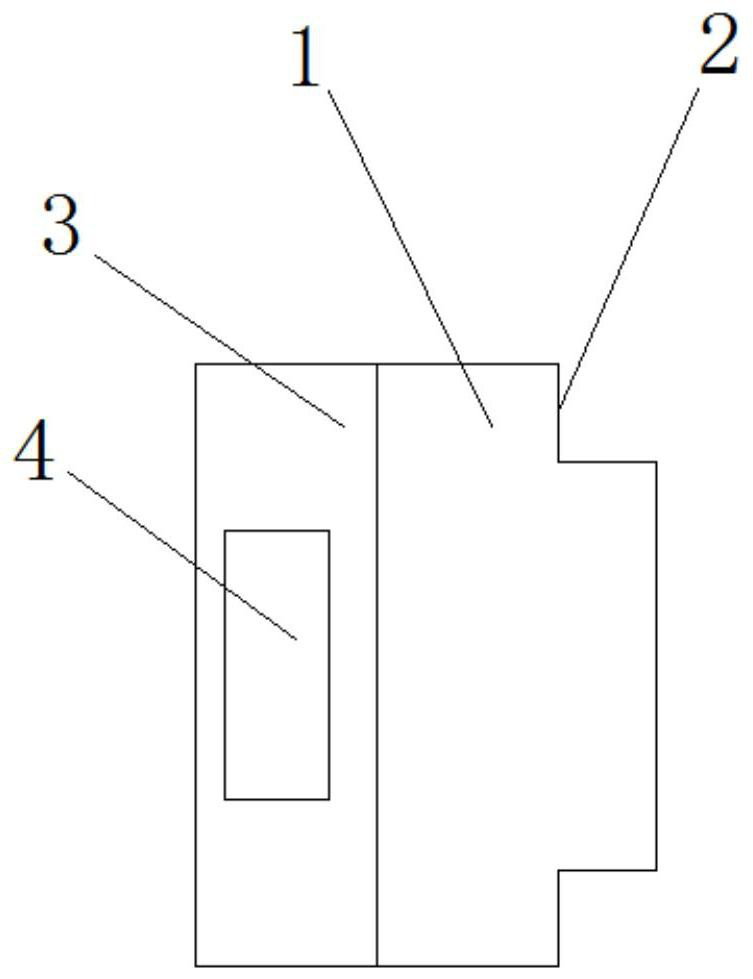

The invention discloses a method of synergetic extraction of coal bed gas of a tool post type mined area and a lower coal bed. The method comprises the steps that firstly, a mine is surveyed; after the floor failure depth is determined, a horizontal well is constructed; the coal bed gas of the mined area is extracted; when the extraction amount of the coal bed gas during unit time is decreased to 20-40% of Q1, the extraction pressure is decreased circularly so that coal bed gas extraction can be continued; when the extraction amount is decreased to 10-18% of Q1, supercritical CO2 is injected for displacement; when the extraction mount is decreased below 20% of Q1 again, oriented fracturing is conducted, a vertical discharge well is arranged on the other side of the horizontal well, and discharging equipment is arranged for conducting coal bed gas extraction; and when the extraction amount of the coal bed gas is decreased below 20% of Q2, the supercritical CO2 is used for displacement again, and extraction is stopped till the extraction amount is decreased to 10% of Q2. By the adoption of the method, coal bed gas resources close to a thin coal seam is extracted along with the coal bed gas in the tool post type mined area, and recovery of gas resources in abandoned still coal seams is achieved.

Owner:TAIYUAN UNIV OF TECH

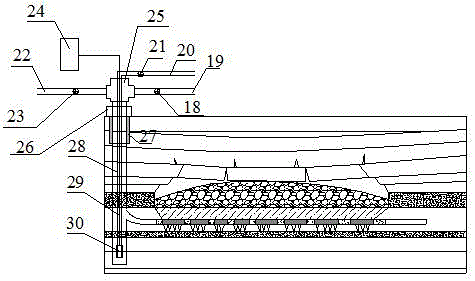

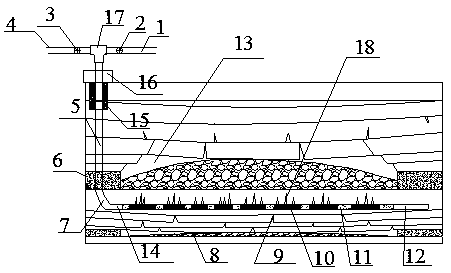

Method for synergetic extraction of coal bed gas in caving type gob area and lower coal bed

ActiveCN106089291ASolution areaSolution rangeConstructionsFluid removalEnvironmental engineeringCoal

The invention discloses a method for synergetic extraction of coal bed gas in a caving type gob area and a lower coal bed. The method comprises the steps that firstly, a mine is explored, a horizontal well is constructed from the ground to a base plate of the gob area, carbon dioxide is compressed into the well for cleaning, and coal bed gas extraction is carried out; when the extraction amount of coal bed gas in unit time drops to 20%-40% of Qi, running and stopping circulate, the extraction pressure is reduced, and the re-extraction process is carried out again; when the extraction amount drops to be below 20% of Qi, carbon dioxide is injected for replacement, and extraction is carried out again; when the extraction amount drops to be below 20% of Q1 again, the horizontal well and a coal and rock strata of the lower coal bed are subjected to fracture, and coal bed gas discharge and extraction are carried out; when the extraction amount drops to be below 20% of Q2, supercritical carbon dioxide replacement is carried out; and when the extraction amount drops to 10% of Q2 through extraction, extraction is stopped. By means of the method, synergetic extraction of coal bed gas in the carving type gob area and coal bed gas near a low coal seam is achieved, cost is reduced, and the coal bed gas resource is extracted to the greatest extent.

Owner:TAIYUAN UNIV OF TECH

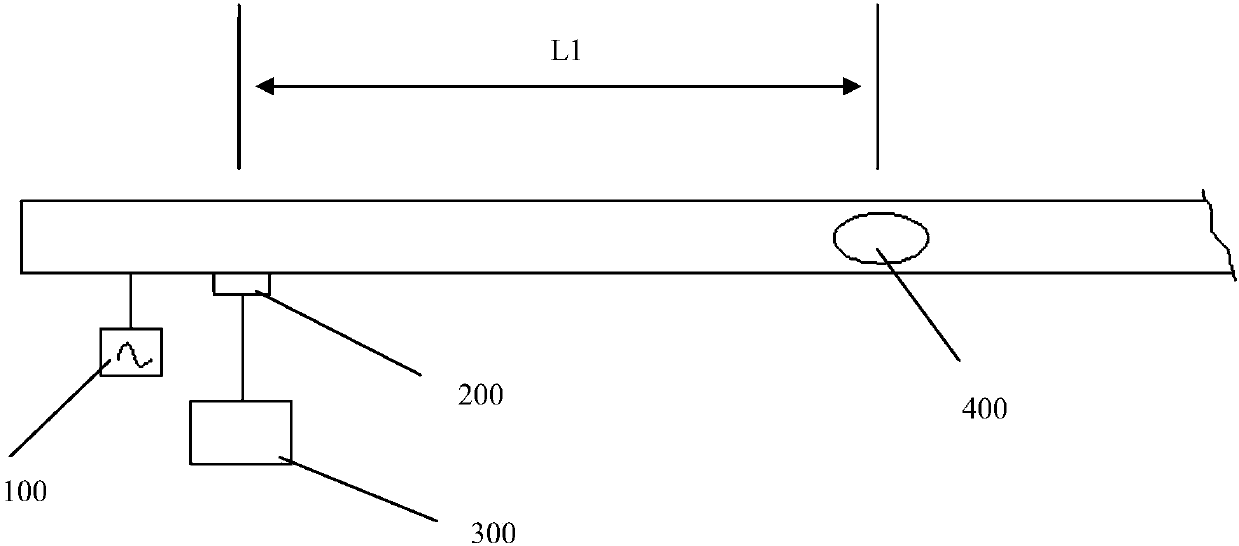

Detecting system and method for incompletely-blocked position of pipeline

InactiveCN107830412AAvoid clogging accidentsGuaranteed safe operationPipeline systemsWavelet transform analysisEngineering

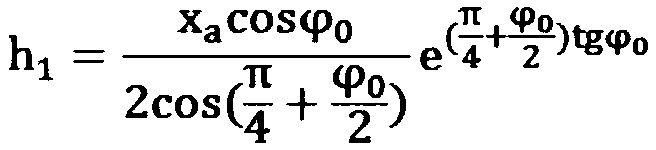

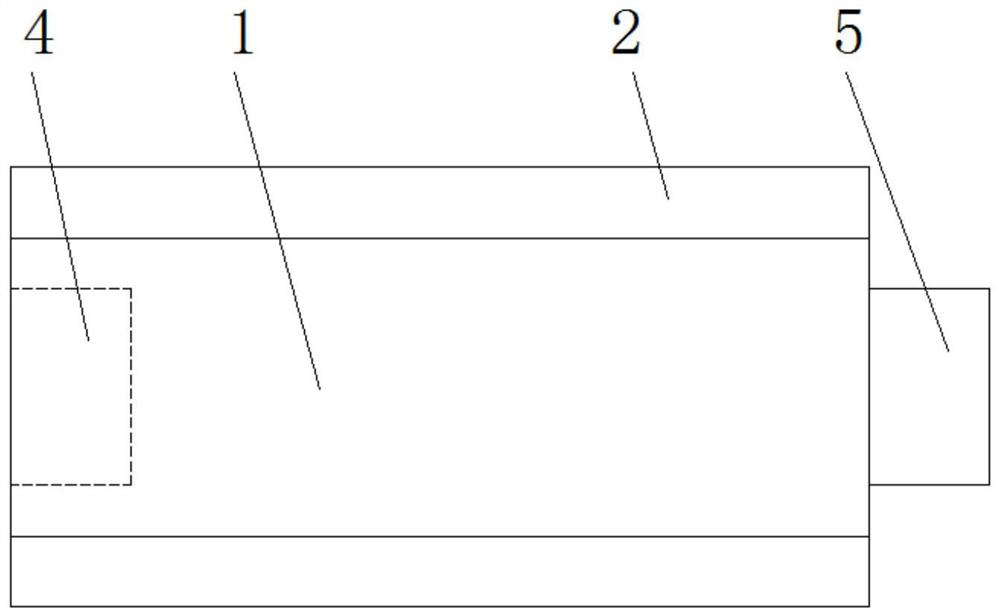

The invention provides a detecting system for an incompletely-blocked position of a pipeline. The detecting system comprises a pressure wave pulse transmitting device, a pressure sensor and a sensor data collecting system connected with the pressure sensor. The pressure wave pulse transmitting device generates pressure wave pulse signals so that the pressure wave pulse signals can be transmitted in the pipeline through media in the pipeline. The pressure sensor senses the pressure wave pulses signals, transmitted by the media in the pipeline, in the pipeline and outputs the pressure wave pulsesignals to the sensor data collecting system. The invention further provides a detecting method for the incompletely-blocked position of the pipeline. Wavelet transform is adopted for analyzing datacollected by the sensor data collecting system, and the incompletely-blocked position of the pipeline is calculated. By means of the detecting system and method for the incompletely-blocked position of the pipeline, the blocked position of a blockage can be effectively detected in the incompletely-blocked initial stage of the pipeline, measures are taken in time, and safety running of the pipelineis ensured.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

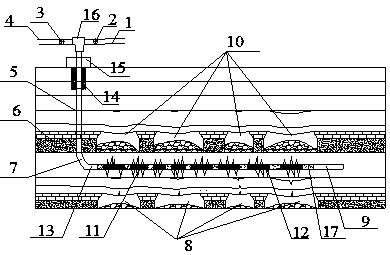

Extraction method for coal bed gas in composite old mined-out area formed through lower tool post method

The invention discloses an extraction method for coal bed gas in a composite old mined-out area formed through a lower tool post method. The method comprises the steps that a horizontal well is constructed at a middle rock layer between an upper old mined-out area and a lower old mined-out area, extraction is carried out, and the coal bed gas extraction amount within the unit time is recorded as Q1; when the extraction amount is decreased to be below 10-20% of Q1, fracturing is carried out for extraction again, and the coil bed gas extraction amount is recorded as Q2; when the extraction amount is decreased to be below 10-20% of Q2, fracturing is carried out again, and the extraction amount is recorded as Q3; when the extraction amount is decreased again to be 10-20% of Q3, carbon dioxide displacement is carried out; then, extraction is carried out again and not stopped until the extraction amount is decreased to 6 m<3> / min. By means of the method, the problems that only a ground vertical well drilling method is adopted for extracting the old mined-out area in the prior art, the effect contact area of an extraction drilling well and an old mined-out area storage layer is small, and the extraction range is limited are solved; sources near the upper old mined-out area coal bed layer are extracted together with lower old mined-out coal bed gas, and the cost is saved.

Owner:TAIYUAN UNIV OF TECH

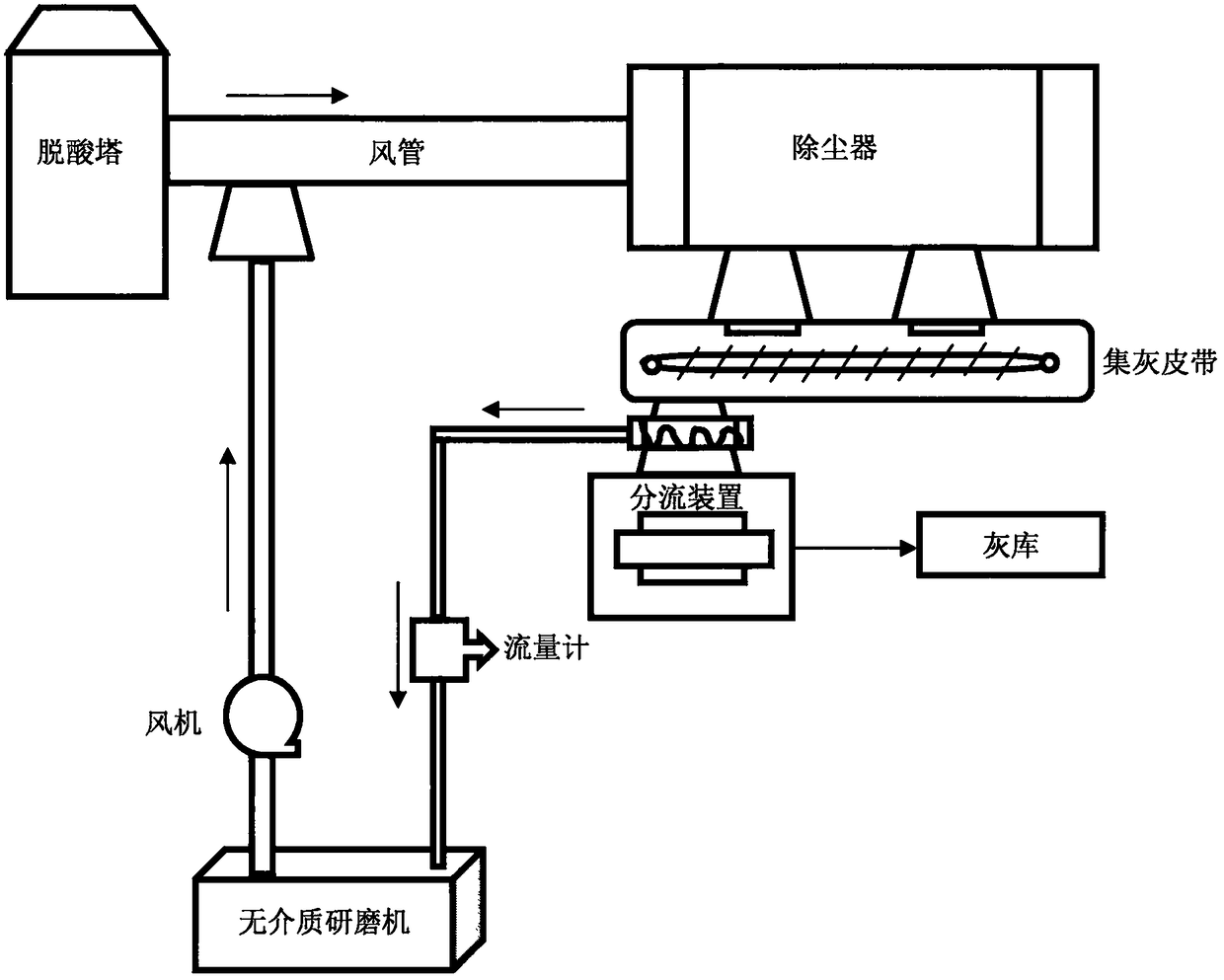

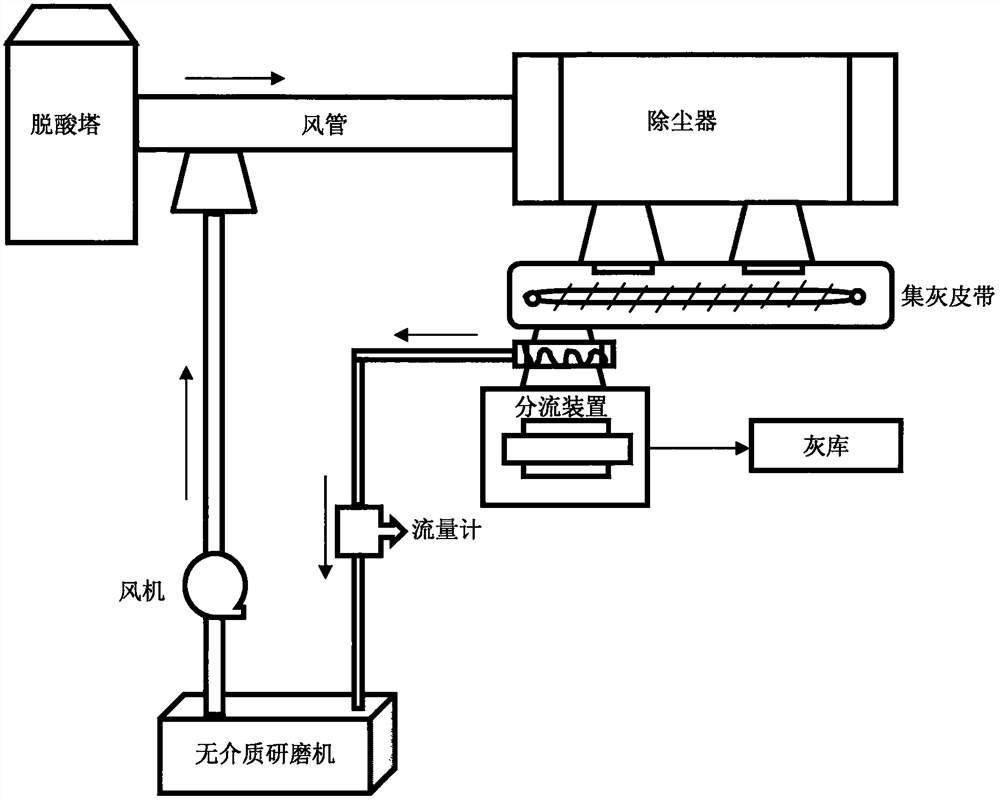

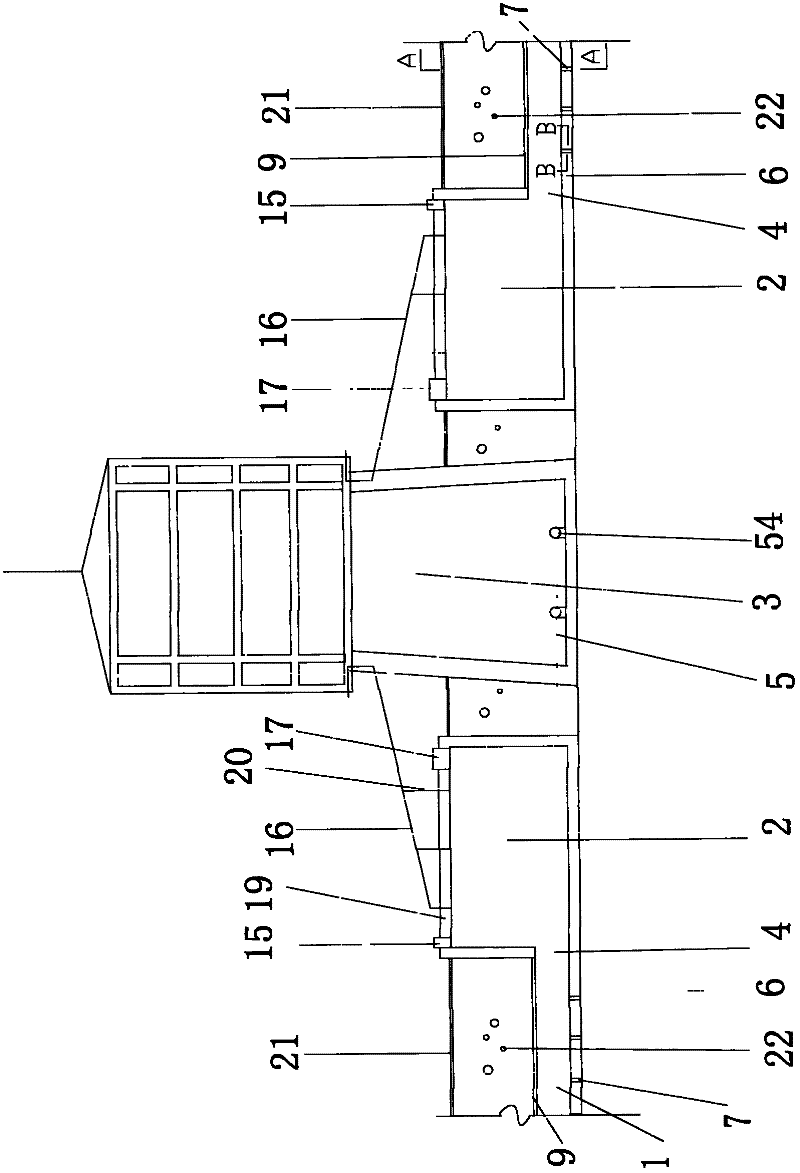

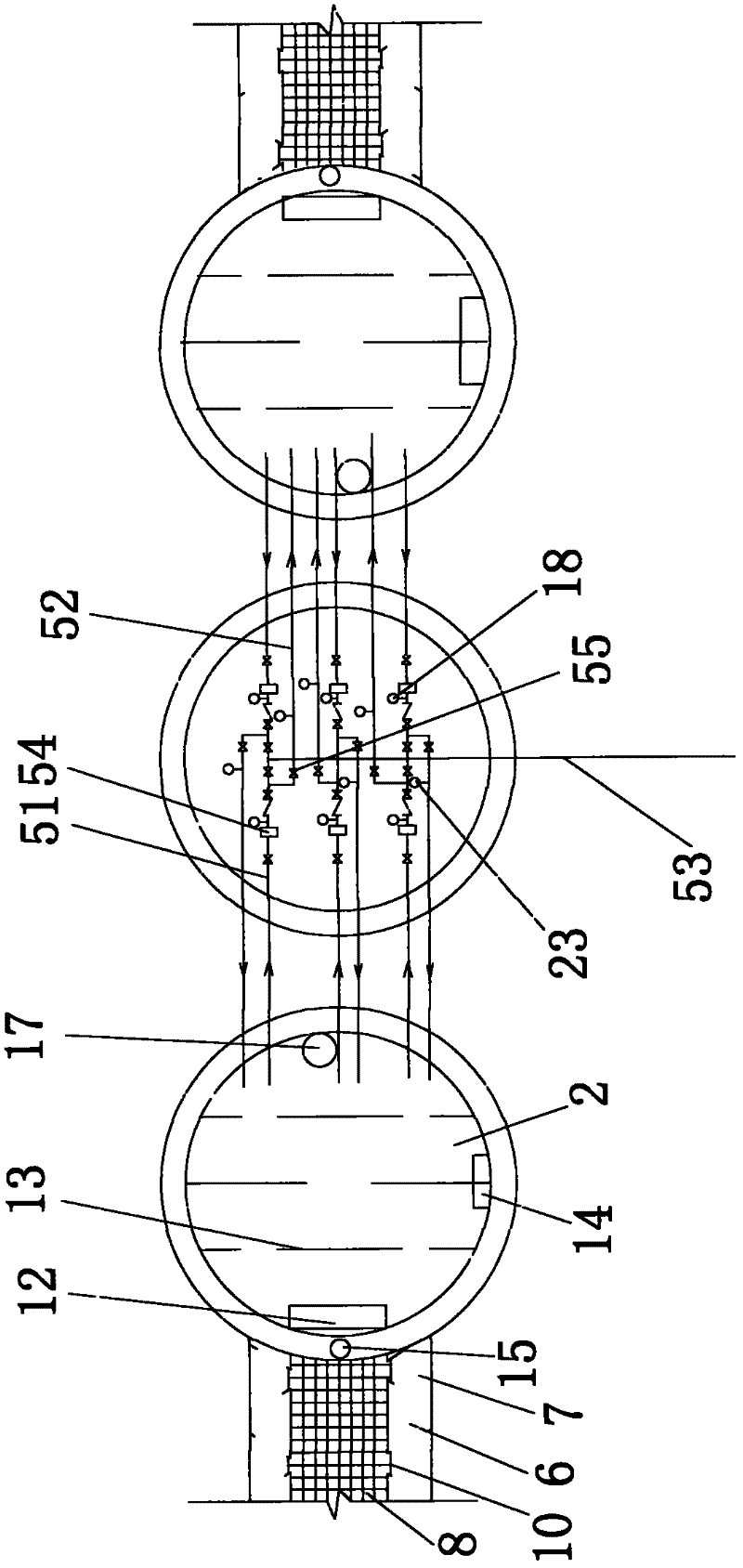

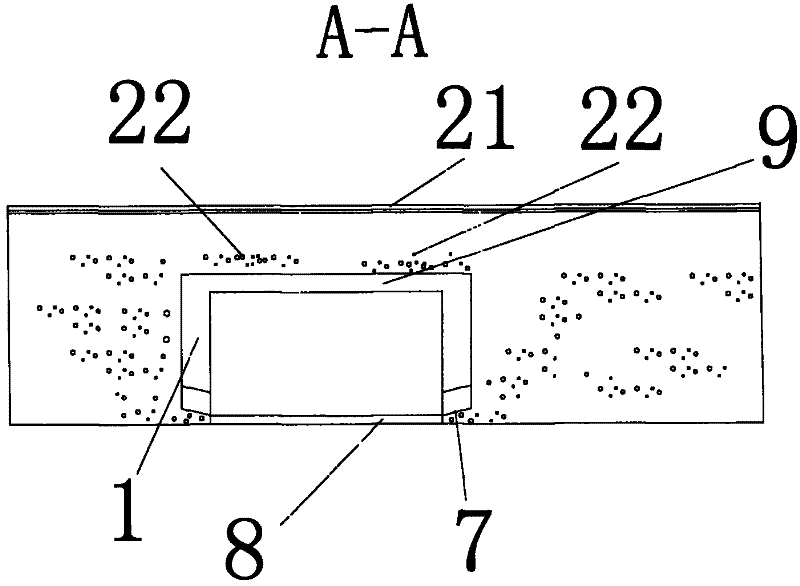

Household waste incineration fly ash cyclic utilization method

ActiveCN108273825AFlexible control of the amount of fly ashContinuous industrial productionSolid waste disposalTransportation and packagingPrillPhosphate

The invention relates to a household waste incineration fly ash cyclic utilization method. A flow distributing device is installed at the lower end of a dust remover of a waste incineration smoke treatment system and controls the amount of fly ash circularly entering a non-medium grinding machine, and therefore the phenomenon that since the fly ash agglomerates at a grinding medium or adheres to the inner wall of the grinding machine, the grinding effect is influenced is avoided. After the fly ash is smashed in a grinding bin, a high-pressure centrifugal fan brings the grinded powder materialsinto a powder selecting machine, fine powder meeting the fineness requirement enters a circulatory system along with airflow, and coarse particle materials incapable of meeting the fineness requirement return to the grinding bin to continue to be grinded. It is guaranteed that the particle sizes of the grinded fine powder are uniform and kept within a certain range, unreacted calcium hydroxide isfully exposed, the specific surface area of the fly ash is increased, the utilization rate of the calcium hydroxide in the fly ash can be improved to be 80% or over, and continuous industrial production can be achieved. Meanwhile, phosphate is fed into the non-medium grinding machine so as to pre-stabilize heavy metal and reduce the application amount of follow-up deacidification agents, and thephosphate also has the grinding assistance function. A strong oxidant is added and achieves the desulfurization and denitration function and the function of promoting dioxin to decompose.

Owner:TIANJIN YIMING ENVIRONMENTAL TECH CO LTD

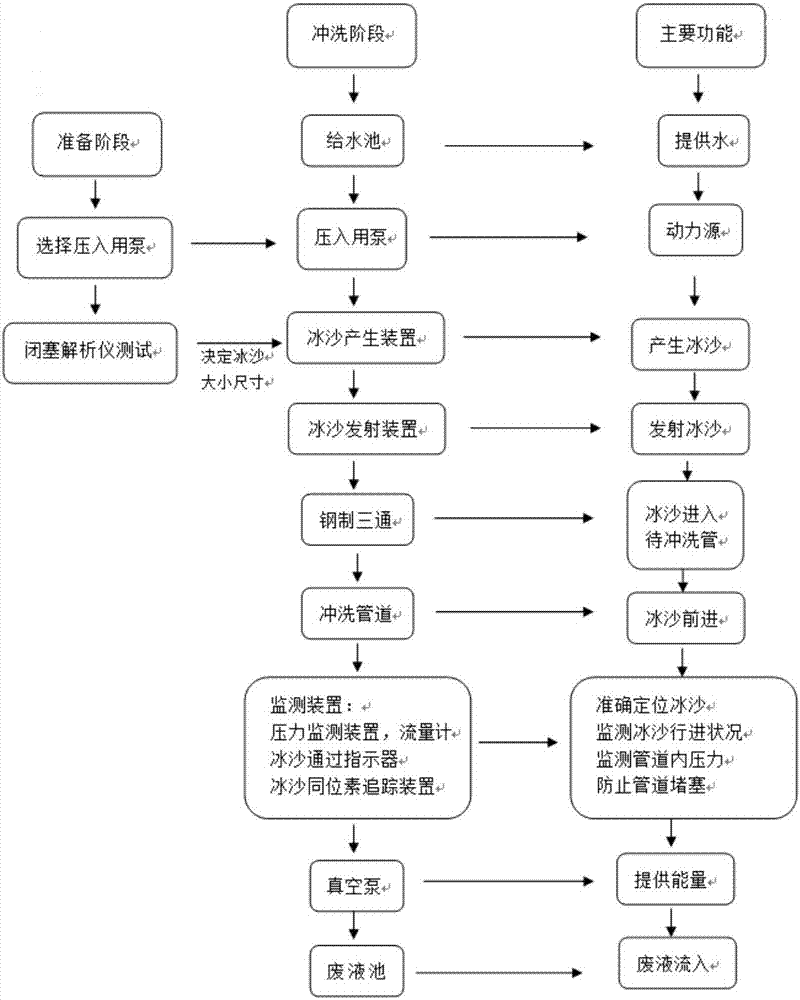

Pipeline ice sand flushing device and flushing method

InactiveCN107335663ANo pollution in the processPrecise positioningHollow article cleaningWater qualityEngineering

The invention discloses a pipeline ice sand flushing device and a pipeline ice sand flushing method. The pipeline ice sand flushing device consists of ice sand jetting equipment, an ice sand producer, a press-in pump, a water feeding basin, a valve, a pushing medium, ice sand monitoring equipment and the like. Facilities used in the pipeline ice sand flushing method comprise the pipeline ice sand flushing device and a series of auxiliary devices: a blockage analyzer, a pressure monitoring device, a flowmeter, an ice sand isotope tracking device and an ice sand passing indicator. The pipeline ice sand flushing device and the pipeline ice sand flushing method have the following advantages that the application range is wide, and no pollution and no corrosion are caused in a use process; in a pipeline flushing process, the position of ice sand can be accurately located, a state during ice sand moving can be mastered, and an ice sand blockage accident can be found and prevented; and the problems that an existing pipeline flushing device is poor in flushing effect, leads to pollution to water and an environment and cannot accurately locate the position of the ice sand due to insufficient pipeline friction or improper selection of a flushing medium are solved.

Owner:HARBIN INST OF TECH

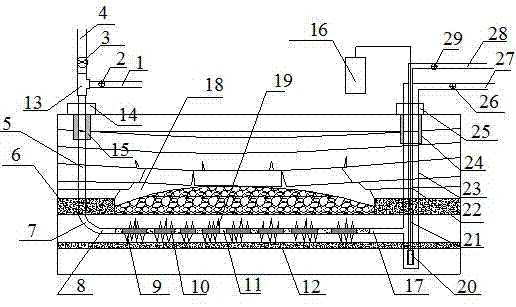

Extraction method for mining formed composite goaf coalbed methane through lower caving method

The invention discloses an extraction method for mining formed composite old mined-out area coalbed methane through a lower caving method. The method includes the steps that coalbed methane extraction is conducted by constructing a horizontal well at the position 1-5 meters above a lower goaf fissure zone; when the extraction amount of the coalbed methane is dropped to 10-20% of Q, segmented crushing is conducted, extraction is conducted on the goaf coalbed methane again, and when the extraction amount of the coalbed methane is dropped to 10-20% of Q again, supercritical carbon dioxide is injected to drive and replace the coalbed methane; extraction is conducted again till the extraction amount is dropped to 6 m<3> / min, and extraction is stopped. By means of the method, the problems that when a ground vertical drilling well is separately used to conduct extraction on a goaf originally, the effective contact area between the extraction drilling well and a goaf reservoir is small, and the extraction range is limited are solved; while the coalbed methane of the goaf on the lower layer is extracted, the coalbed methane resource close to the upper portion of the goaf is also extracted, and cost is saved; meanwhile, the horizontal well is located in the rock stratum, and therefore shaft collapse and blocking of the drilling well in a coal seam are avoided.

Owner:TAIYUAN UNIV OF TECH

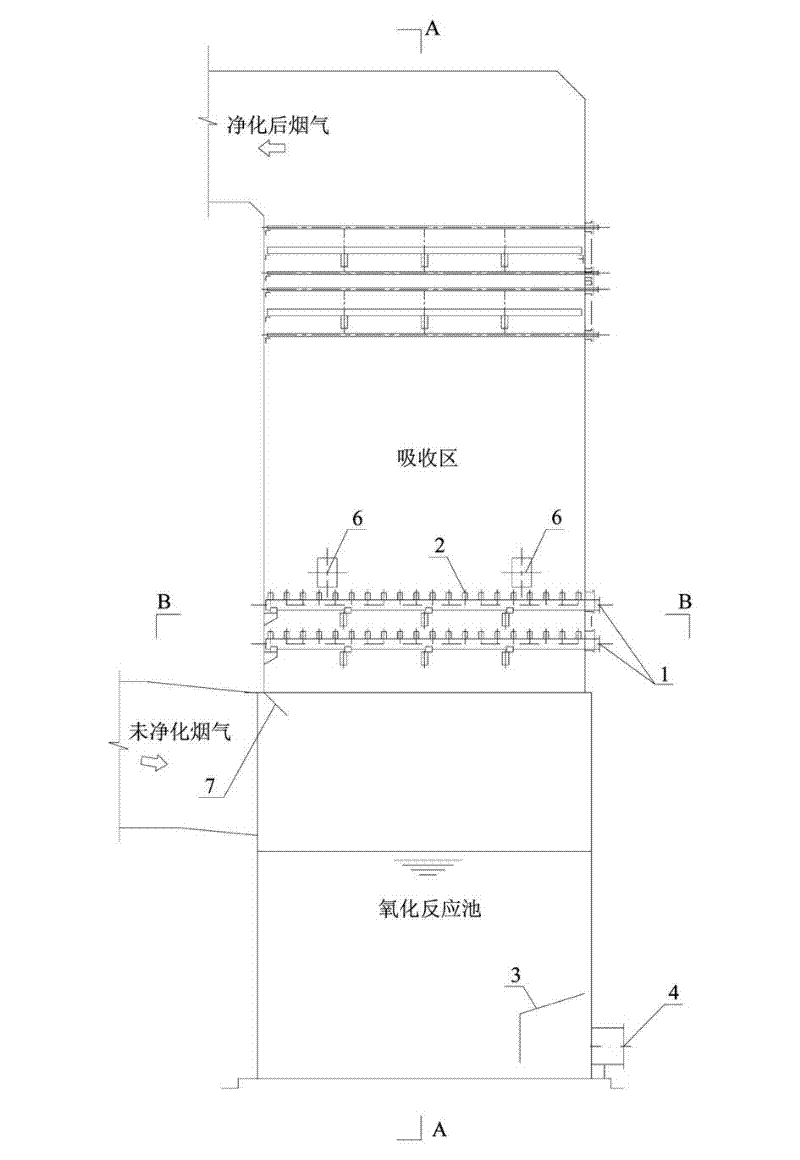

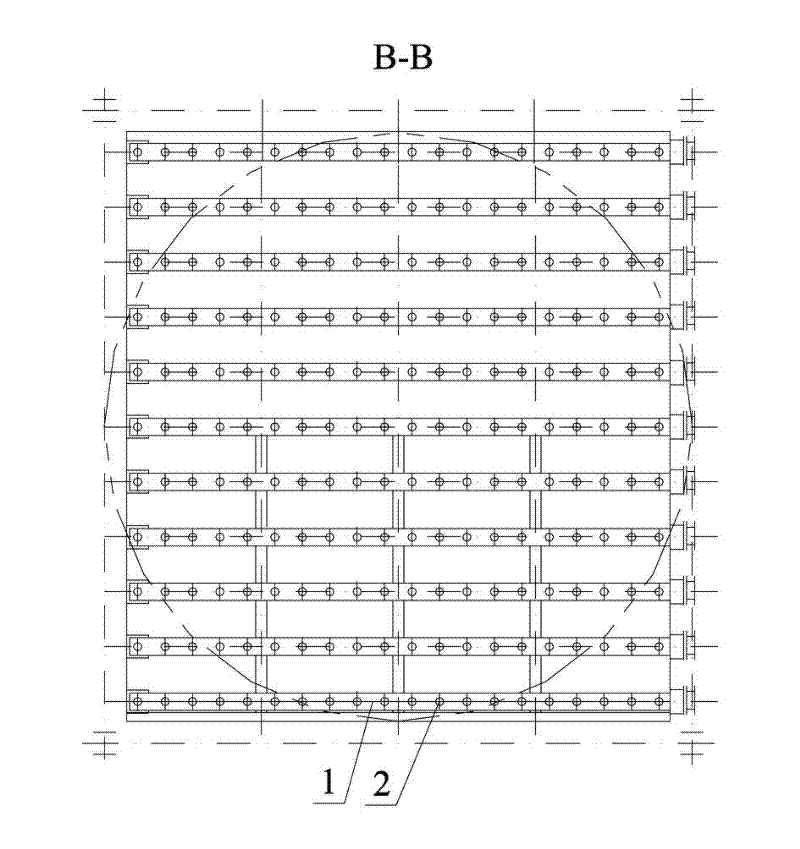

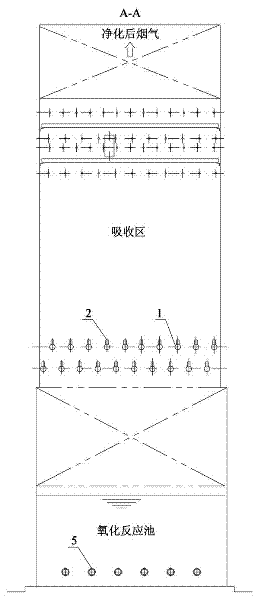

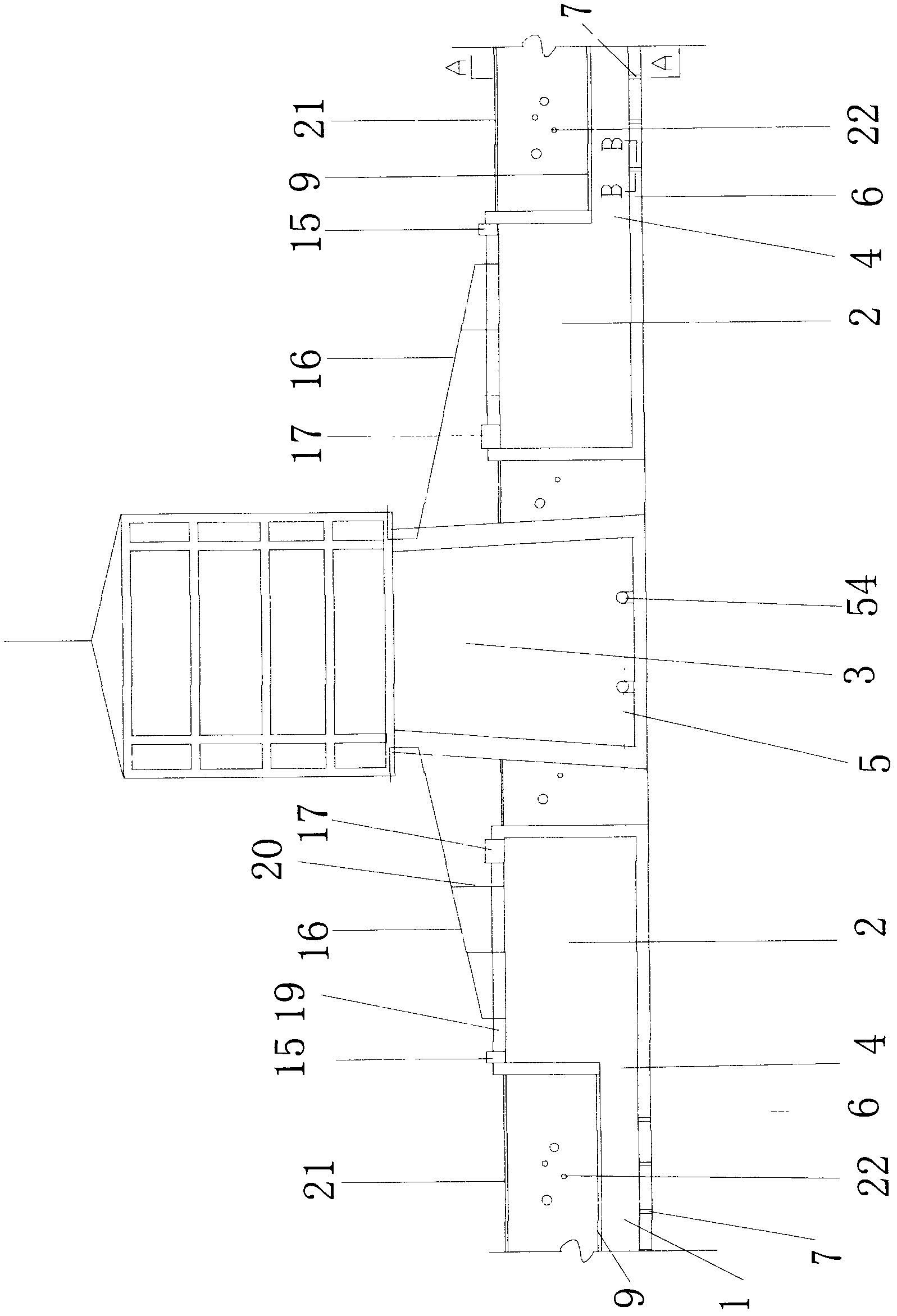

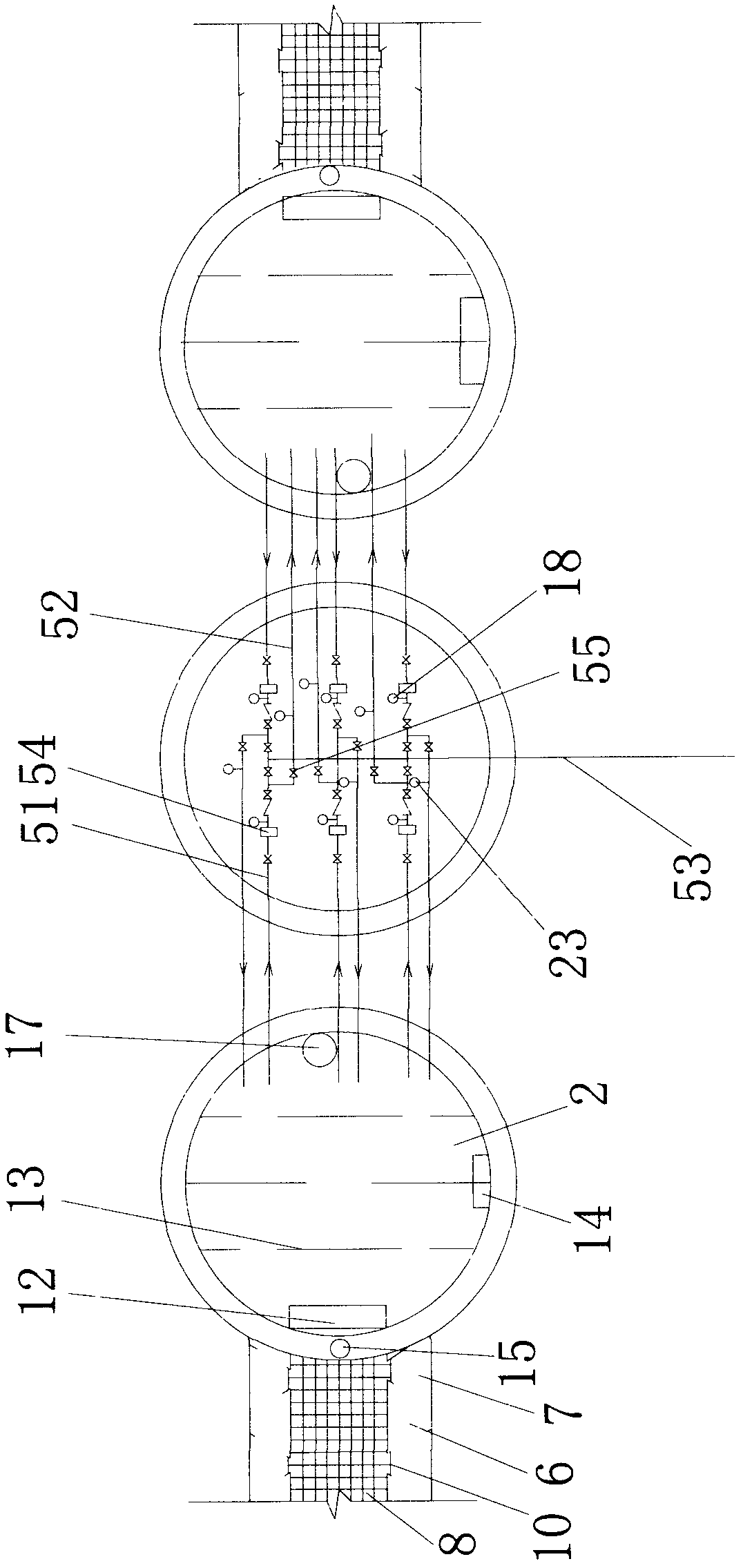

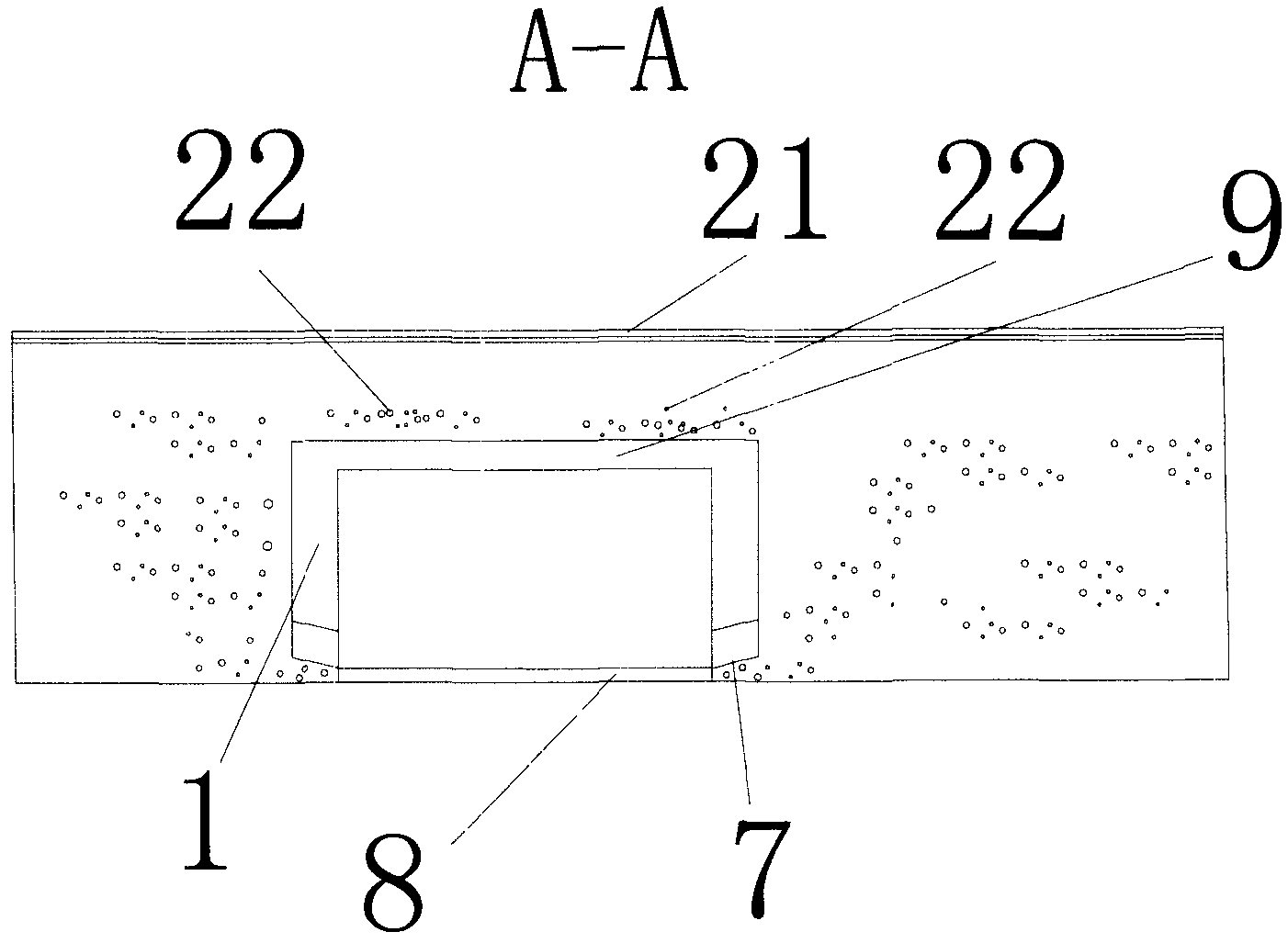

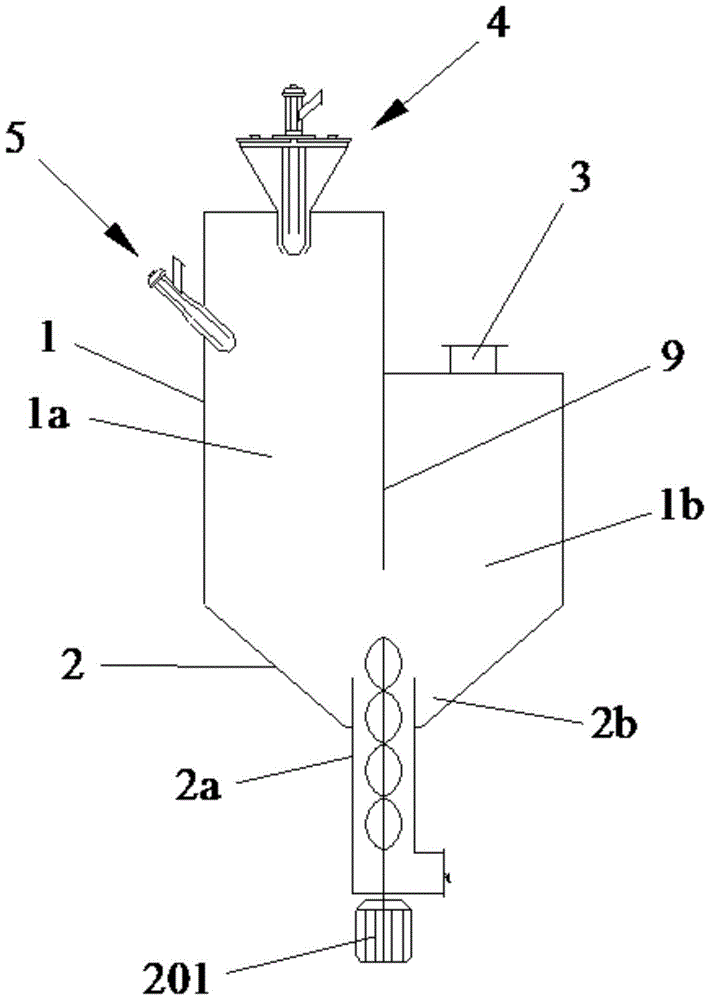

Absorption tower for wet flue gas desulfurization

InactiveCN102225308AImprove oxidation efficiencyPromote crystallizationUsing liquid separation agentSlurryEngineering

The invention relates to an absorption tower for wet flue gas desulfurization. A limestone-gypsum wet flue gas desulfurization process is adopted in the absorption tower. The absorption tower comprises an oxidizing reaction tank and an absorbing area, wherein a circular oxidizing reaction tank is arranged under the absorption tower; a square absorbing area is arranged above the absorption tower; a slurry spraying pipe and a nozzle connected to the slurry spraying pipe are arranged on the lower part of the absorbing area; the slurry spraying pipe is a concentric reducer pipe; the slurry spraying pipe is connected to the nozzle by a flange; a mounting angle of the nozzle which is connected to the slurry spraying pipe is vertical upwards; the oxidizing reaction tank of the absorption tower is connected to the side wall of the absorbing area in the manner of square inscribed circle or square circumscribed circle; the slurry spraying pipe and a nozzle overhauling manhole door are arranged on a steel wall of the absorption tower in the absorbing area; and a ceramic lining oxidation air pipe which is connected to the bottom of the oxidizing reaction tank is mounted by being inclined for 15-20 degrees in the manner of being high in external port and low in internal port. The absorption tower for wet flue gas desulfurization is simply and conveniently maintained, thereby efficiently lowering the maintenance cost.

Owner:SINOFINN NEW ENERGY INVESTMENT +1

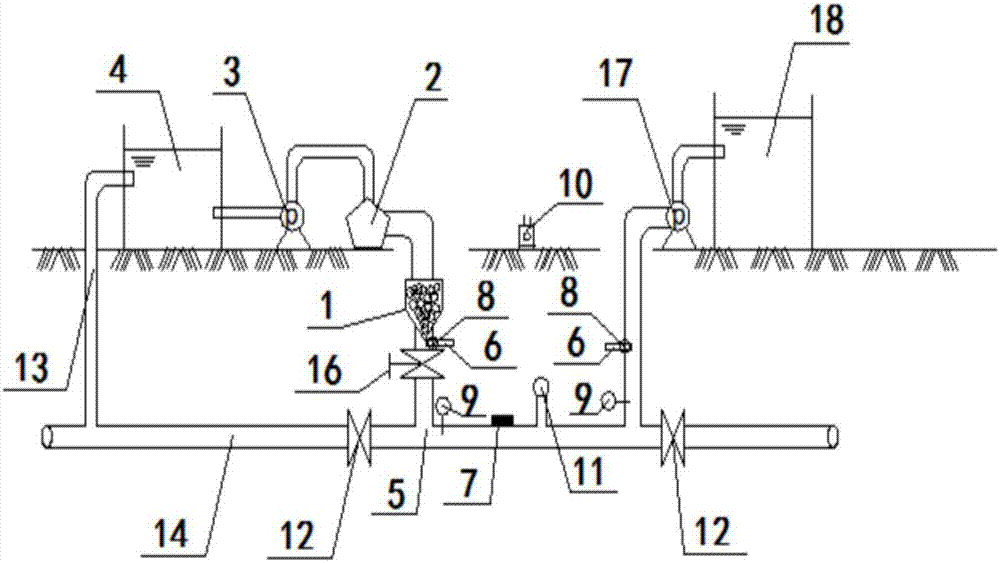

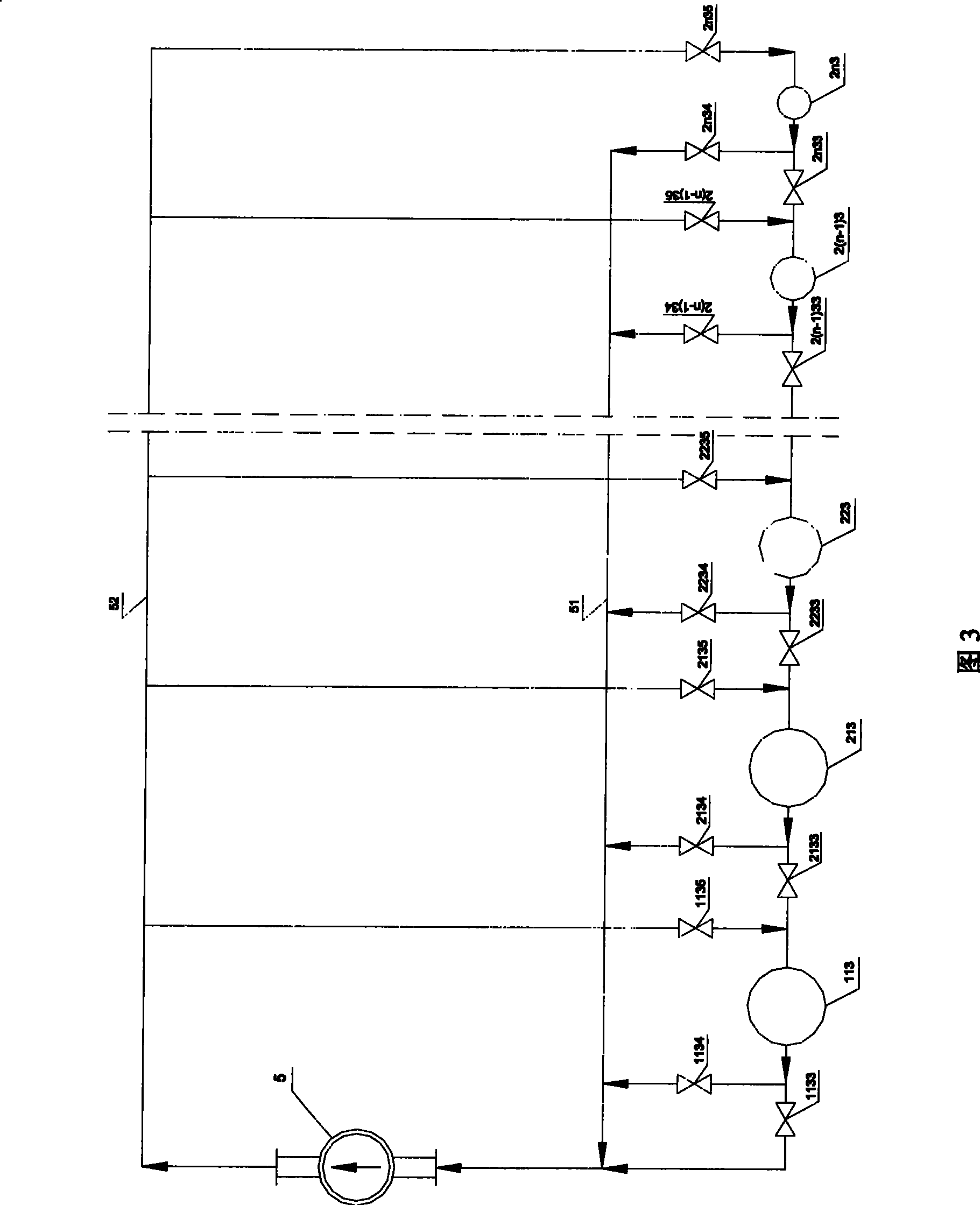

Novel backwashing water intake system for water purification building

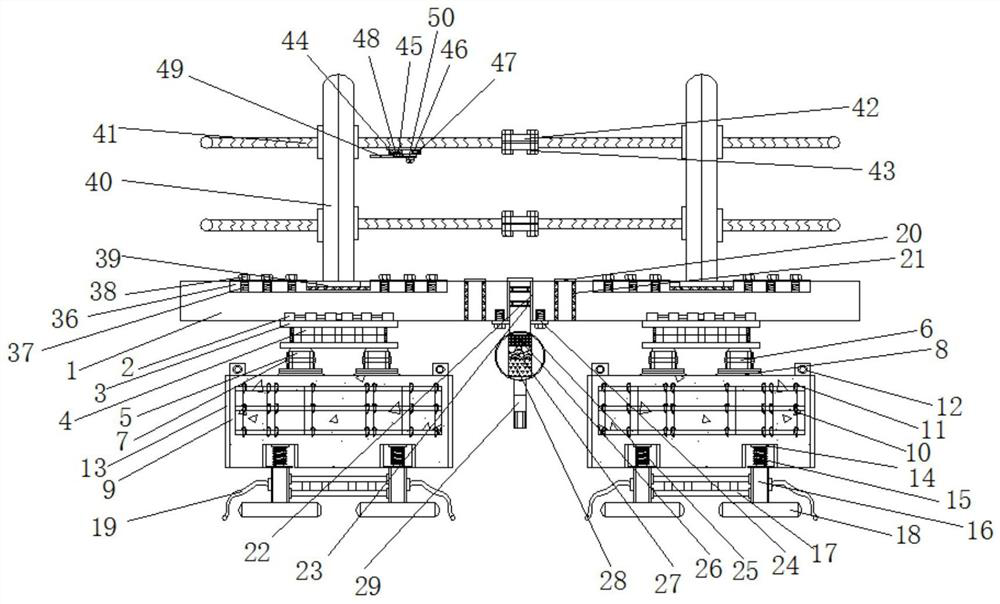

InactiveCN102146694ALow costLarge backwash water flowMultistage water/sewage treatmentDrinking water installationInfiltration galleryWater flow

The invention discloses a novel backwashing water intake system for a water purification building. The system comprises an infiltration gallery, a clean water tank and the water purification building directly arranged in a river, wherein the infiltration gallery is communicated with the clean water tank through a bottom through hole; the clean water tank is communicated with the bottom of the water purification building through a pipeline; infiltration gallery bell mouth bases are symmetrically arranged at the bottoms of both sides of the infiltration gallery and are provided with bell mouths; the bell mouths are arranged obliquely downwards from the outside to the inside of the infiltration gallery; the pipeline comprises a water inlet pipe, a backwashing pipe and a water outlet pipe; the water outlet pipe is arranged on the water purification building; a horizontal centrifugal pump is arranged at the bottom of the water purification building; the water inlet pipe is arranged on the horizontal centrifugal pump; one end of the water inlet pipe is communicated with the clean water tank, and the other end of the water inlet pipe is communicated with the water outlet pipe; the backwashing pipe is arranged on the water inlet pipe; and one end of the backwashing pipe is communicated with another clean water tank. The water intake system has the characteristics of high backwashing water flow, high water pressure, capabilities of ensuring the engineering quality and the backwashing effect, saving materials and lowering the construction cost and difficulty in blocking.

Owner:浙江净水楼建设投资有限公司

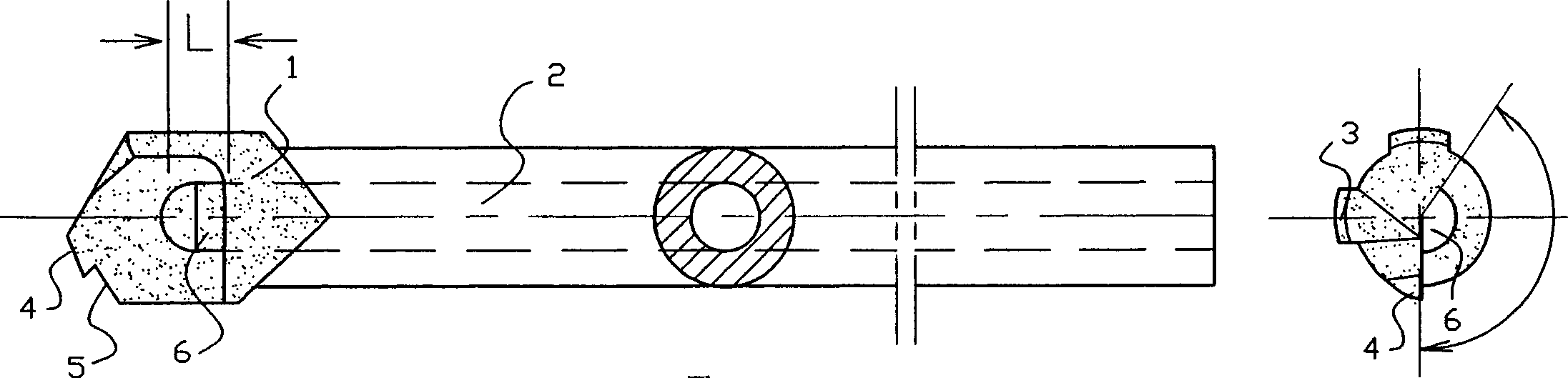

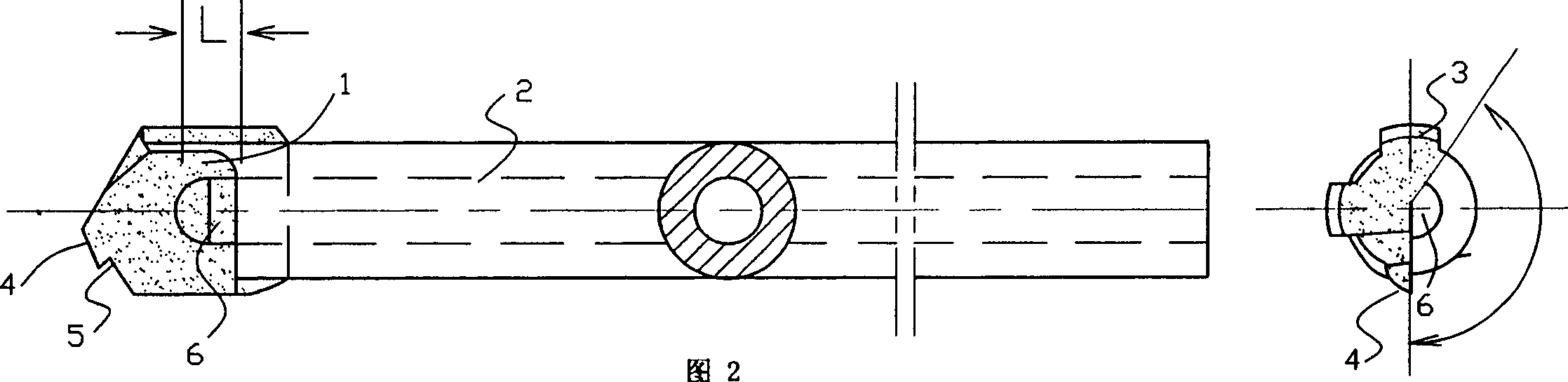

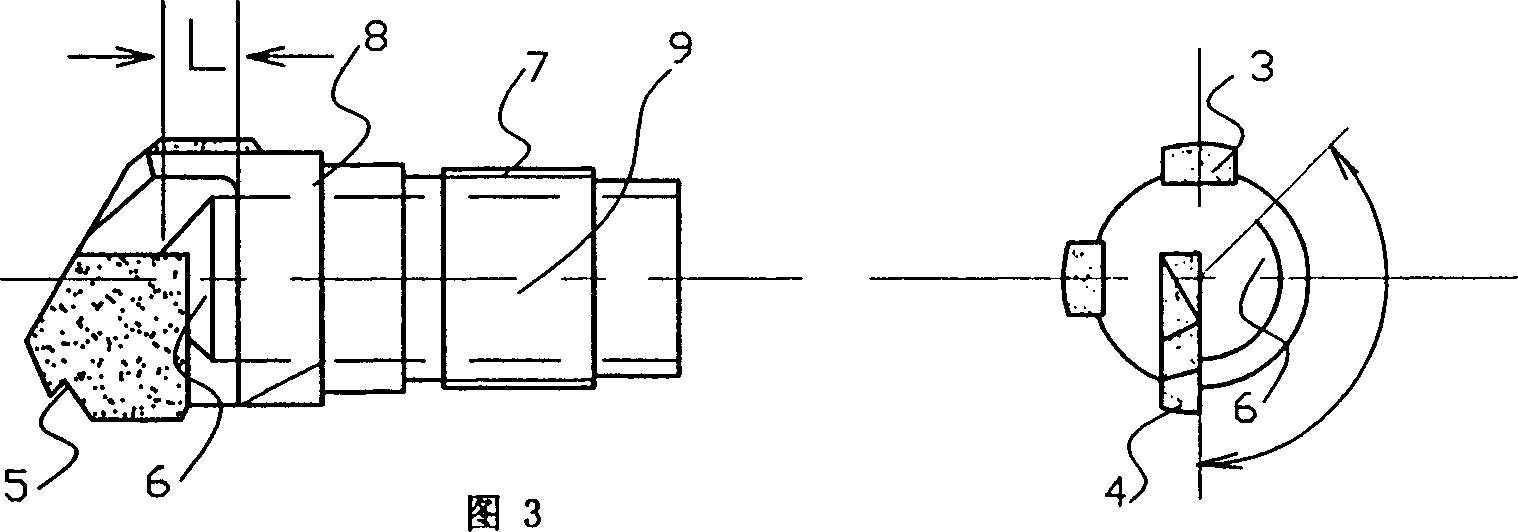

Ejection drill with internal drill chip discharge and single drill chip discharging port

InactiveCN1393313AEasy accessEasy to excludeTransportation and packagingTrepanning drillsSingle chipDrill bit

An ejection drill with internal discharge of drilling chip and a single chip-discharging outlet features that its drill bit has two guide ridges, a cutting edge and a single chip-discharge outlet, and the said cutting edge has no chip breaker, so simplifying the machining technology of drill bit. Its advantages are long service life and low cost.

Owner:王峻

Primary wastewater treatment device

InactiveCN106219818AAvoid clogging accidentsReduce volumeTreatment involving filtrationMultistage water/sewage treatmentTreatment qualitySuspension substance

The invention discloses a primary wastewater treatment device. The primary wastewater treatment device comprises a treatment tank, and a movable retaining plate is connected in an inner cavity of the treatment tank and partitions the inner cavity of the treatment tank into two independent chambers including a sedimentation chamber and a filter chamber from right to left. A rotary-cut stirring mechanism is connected in the sedimentation chamber, an impurity purification mechanism is movably connected in the filter chamber, and a base plate is arranged at the bottom of the treatment tank. By the primary wastewater treatment device, triple wastewater purification treatment including rotary-cut stirring, coagulating sedimentation and impurity filtration can be realized; cutters and brushes are completely used for rotary cutting of wastewater and rotary brushing and stirring of impurities, and accordingly the wastewater and flocculating agents can be mixed thoroughly to reduce harmful substances and suspended solids in the wastewater, and primary wastewater treatment quality is greatly improved.

Owner:姜元超

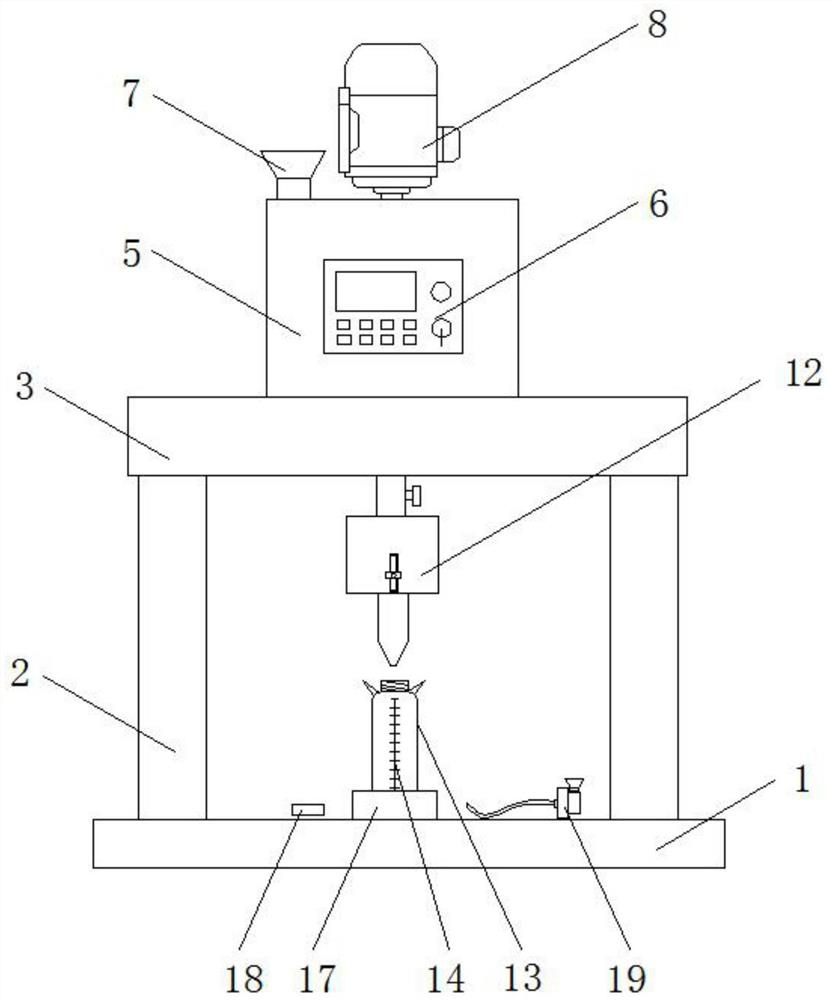

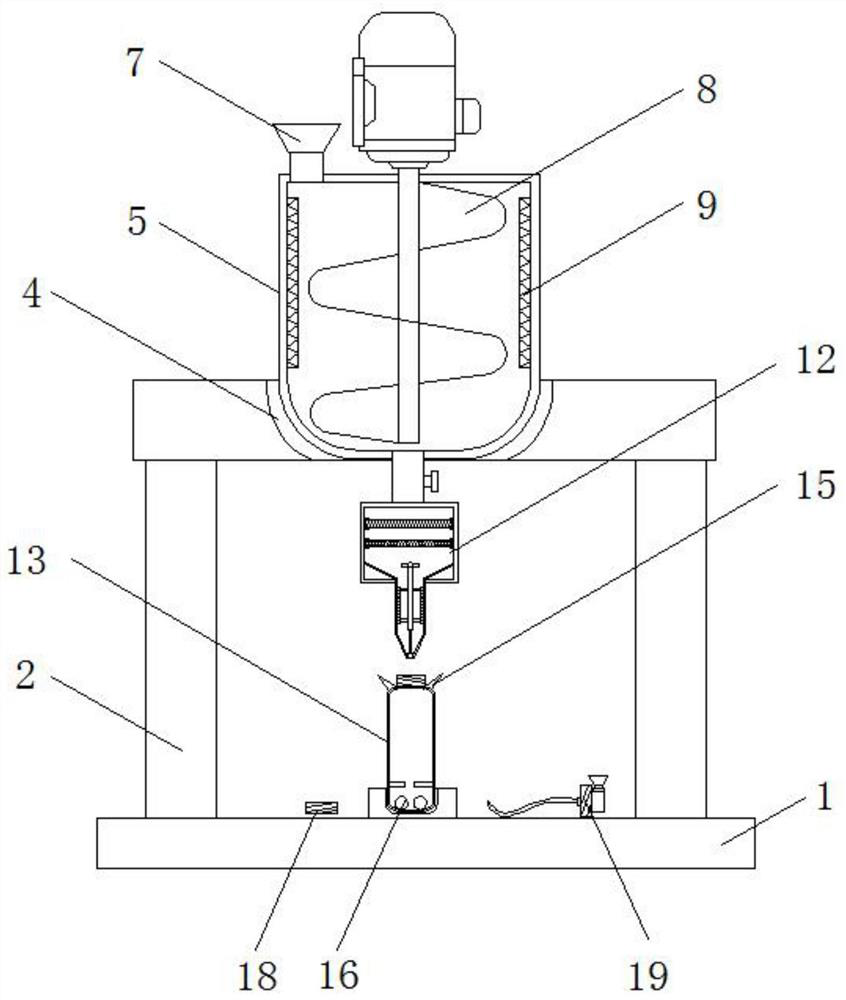

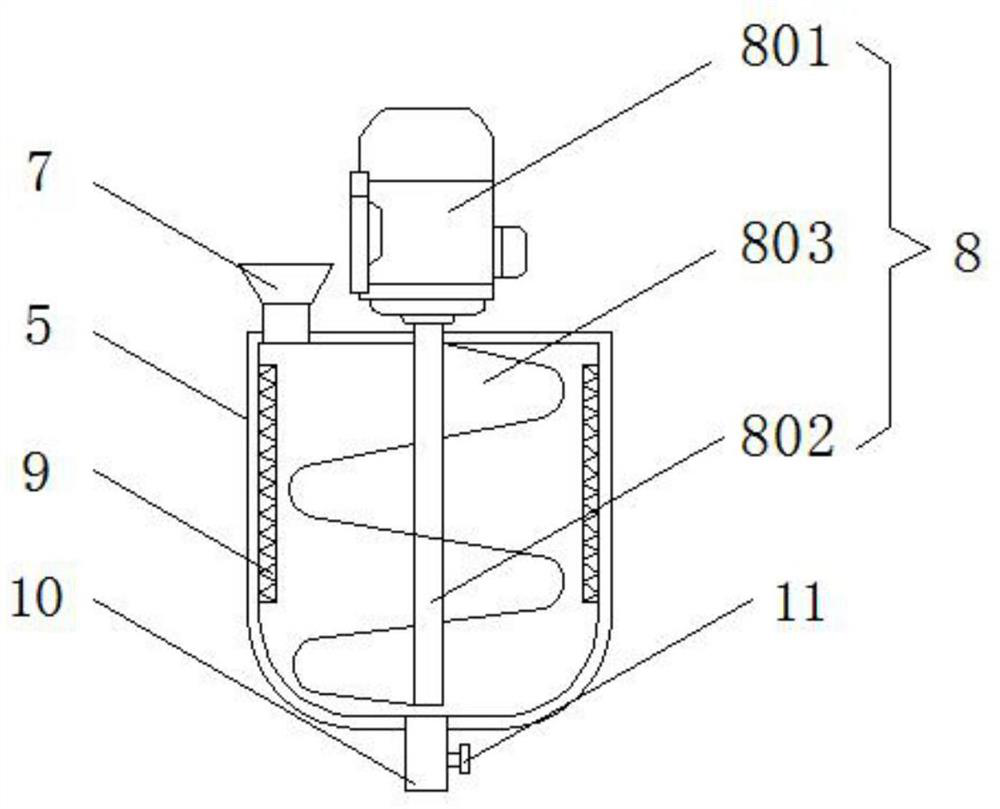

Material tank for processing of cable sheath

The invention discloses a material tank for processing of a cable sheath. The material tank comprises a base body. A protection box and a material conveying table are sequentially arranged at the top of the base body from left to right. A material stirring tank and a noise elimination box are sequentially arranged at the top of the material conveying table from left to right. The inner walls of the material stirring tank are provided with convex rods. The outer surface of a main shaft of an inner cavity of the material stirring tank is connected with a stirring assembly. According to the material tank, the material stirring effect and stirring efficiency are improved, and material particles are finer; by means of pushing force of continuous advancing of a rotary blade, materials can be further stirred and guided out fast; and the size of the material particles is reduced, meanwhile, the blockage accident can be avoided when the materials are guided out, and therefore the material tank is beneficial to improving the material stirring effect and efficiency.

Owner:CHANGZHOU TUOYUAN CABLE ASSEMBLY

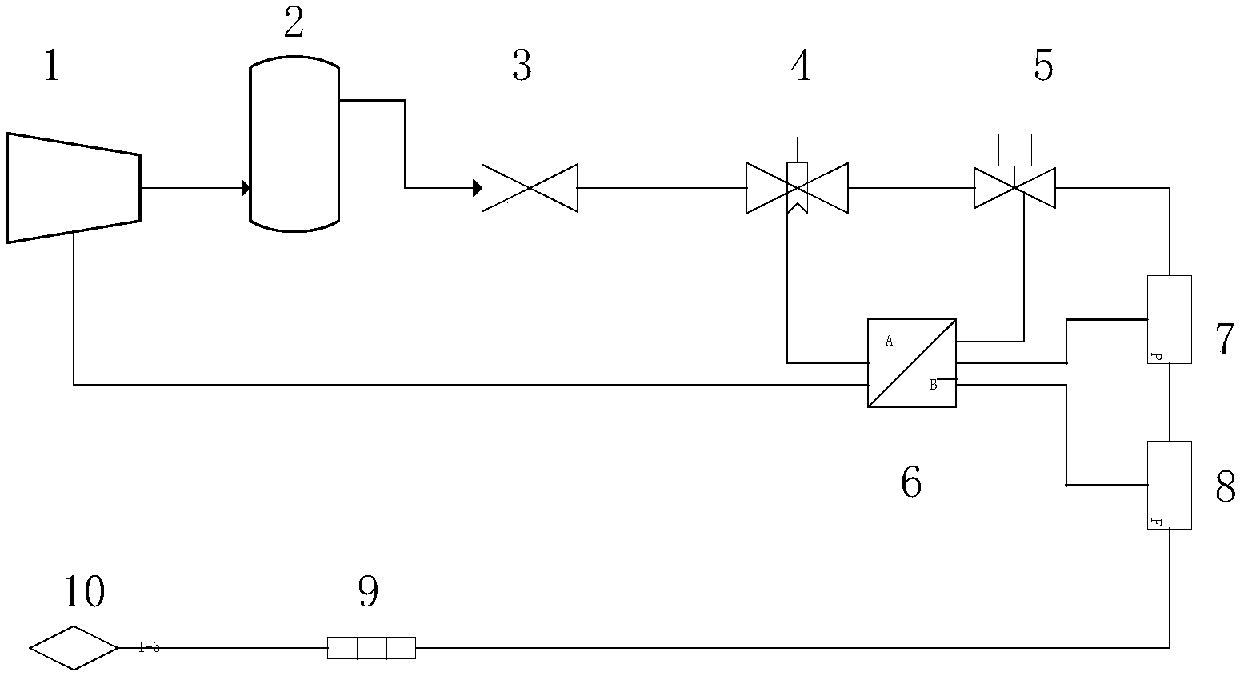

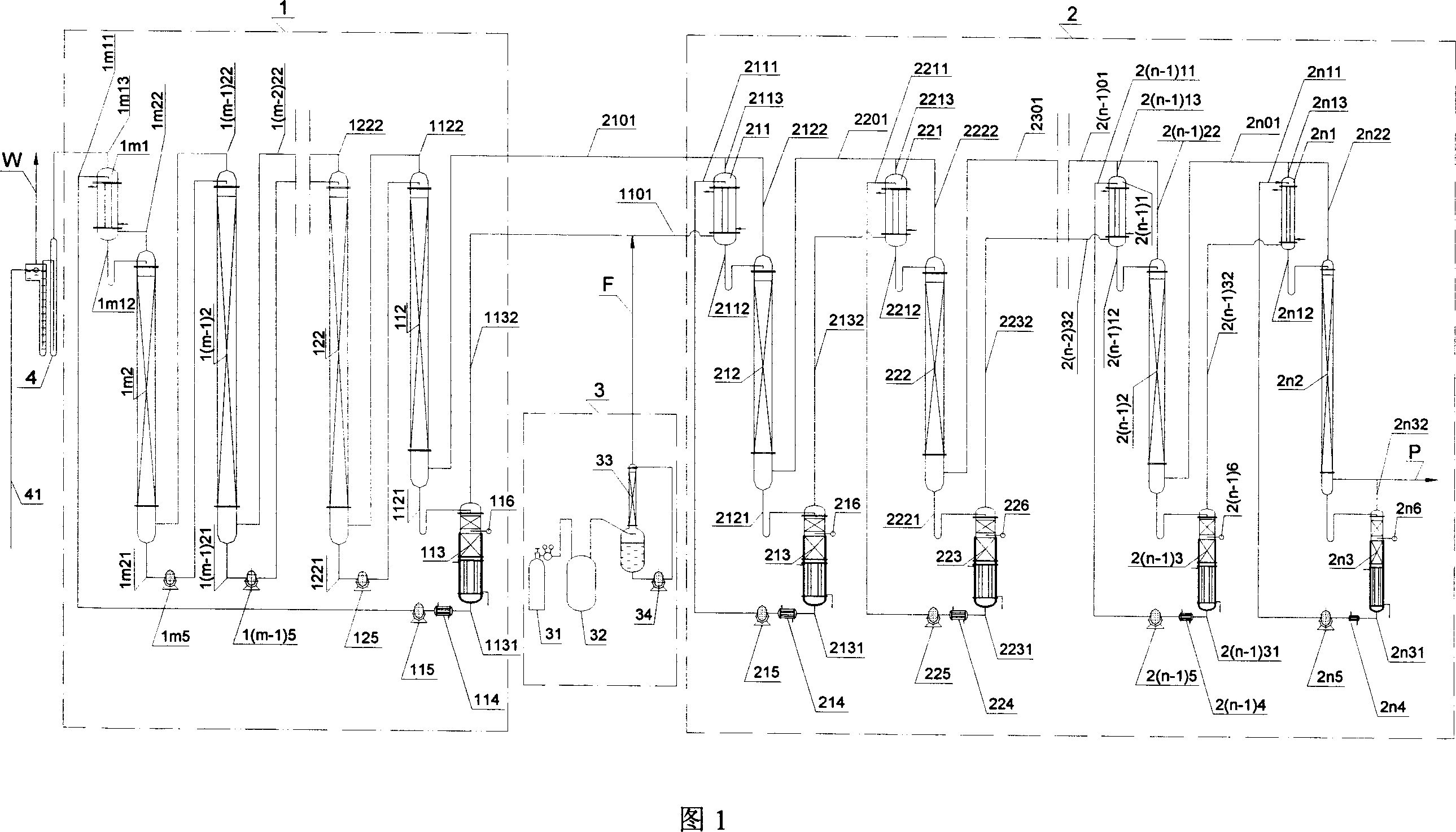

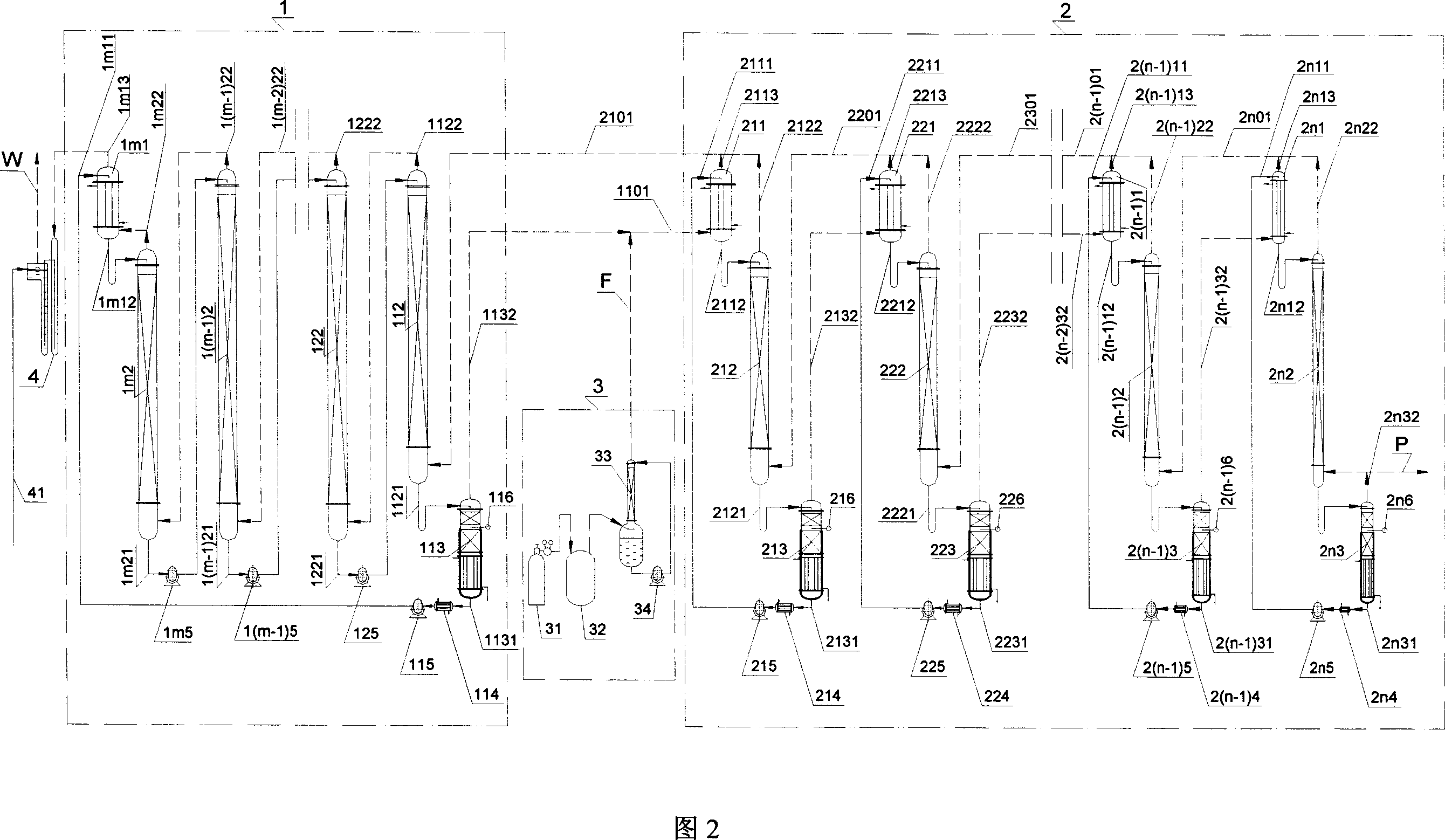

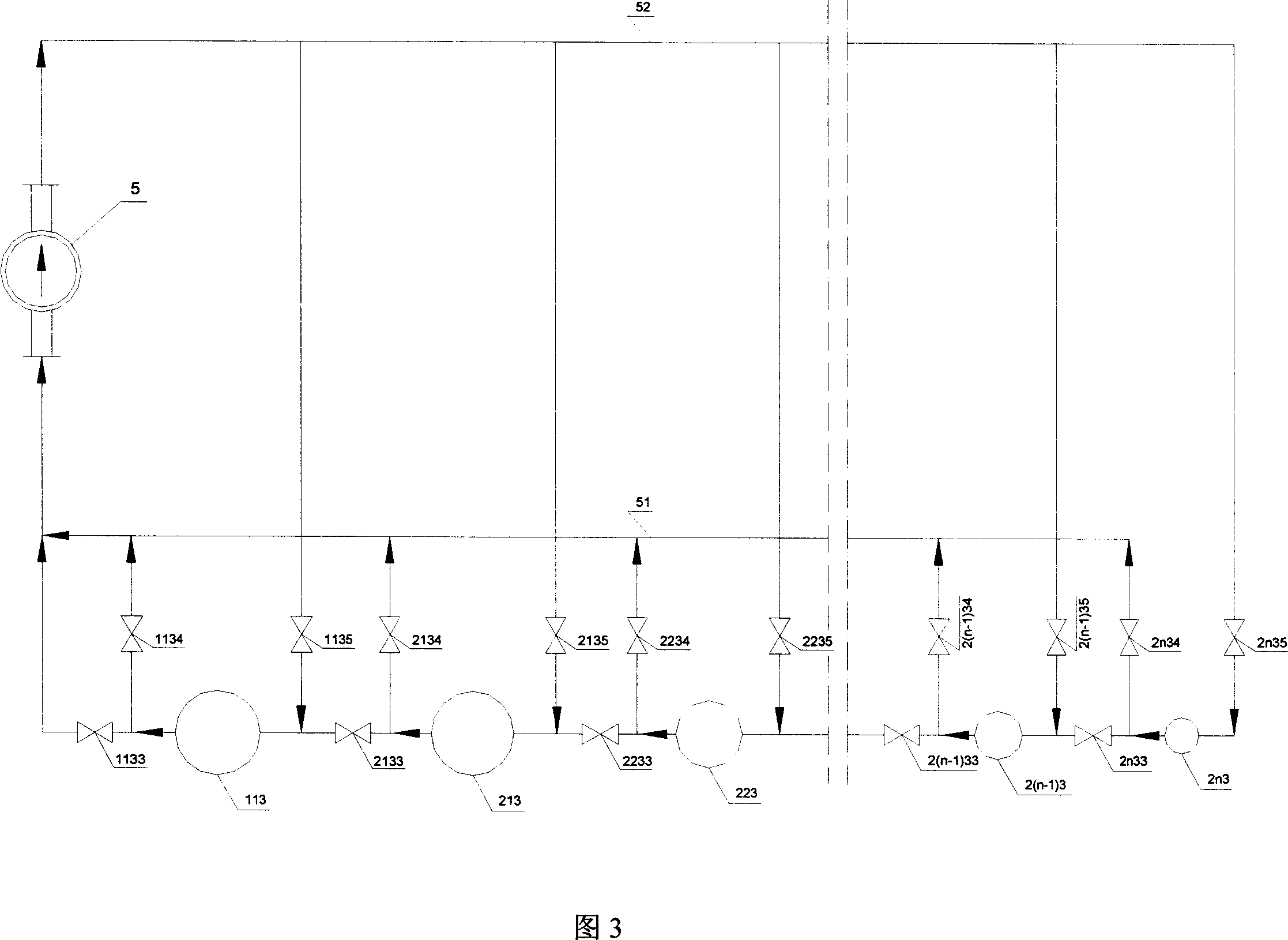

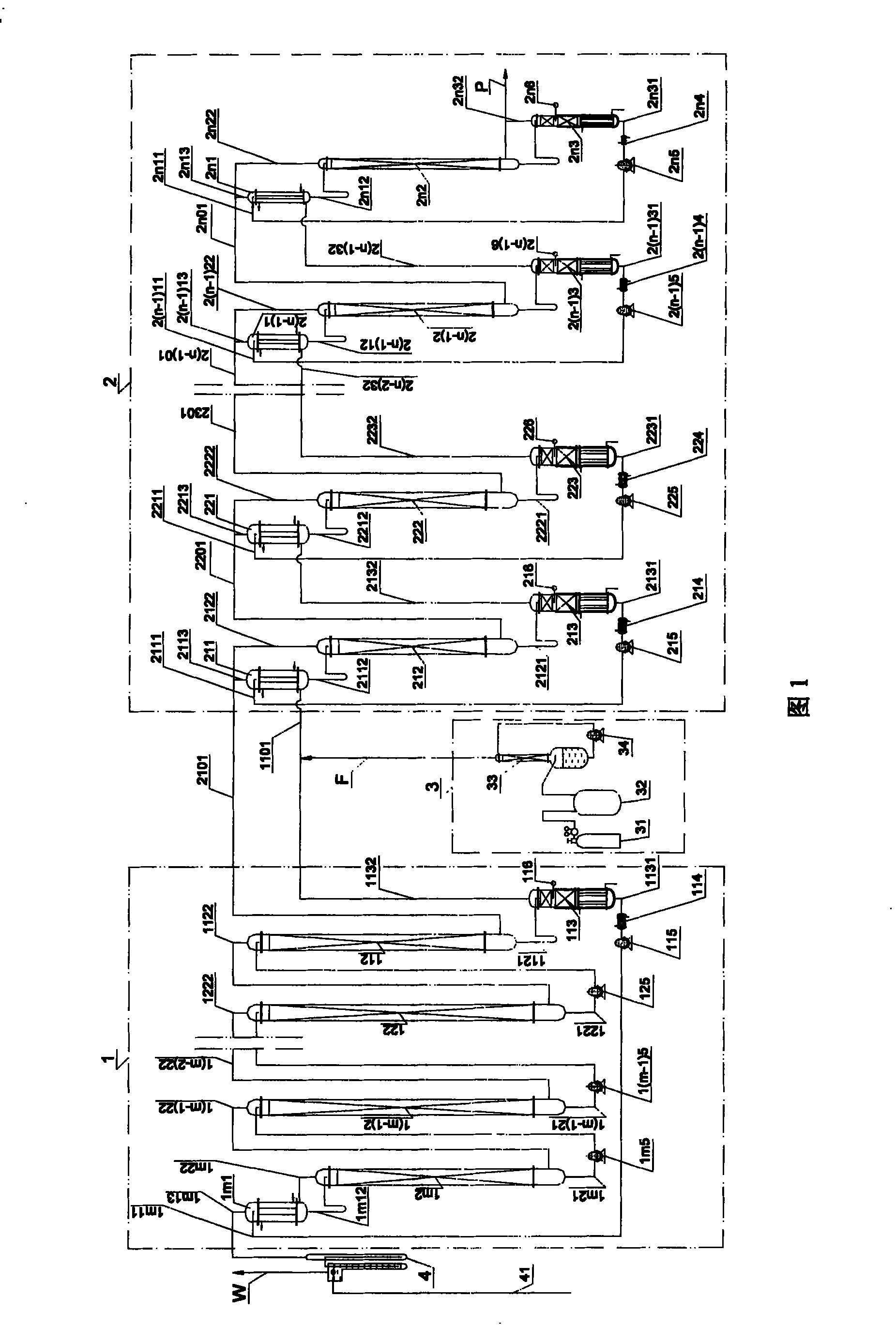

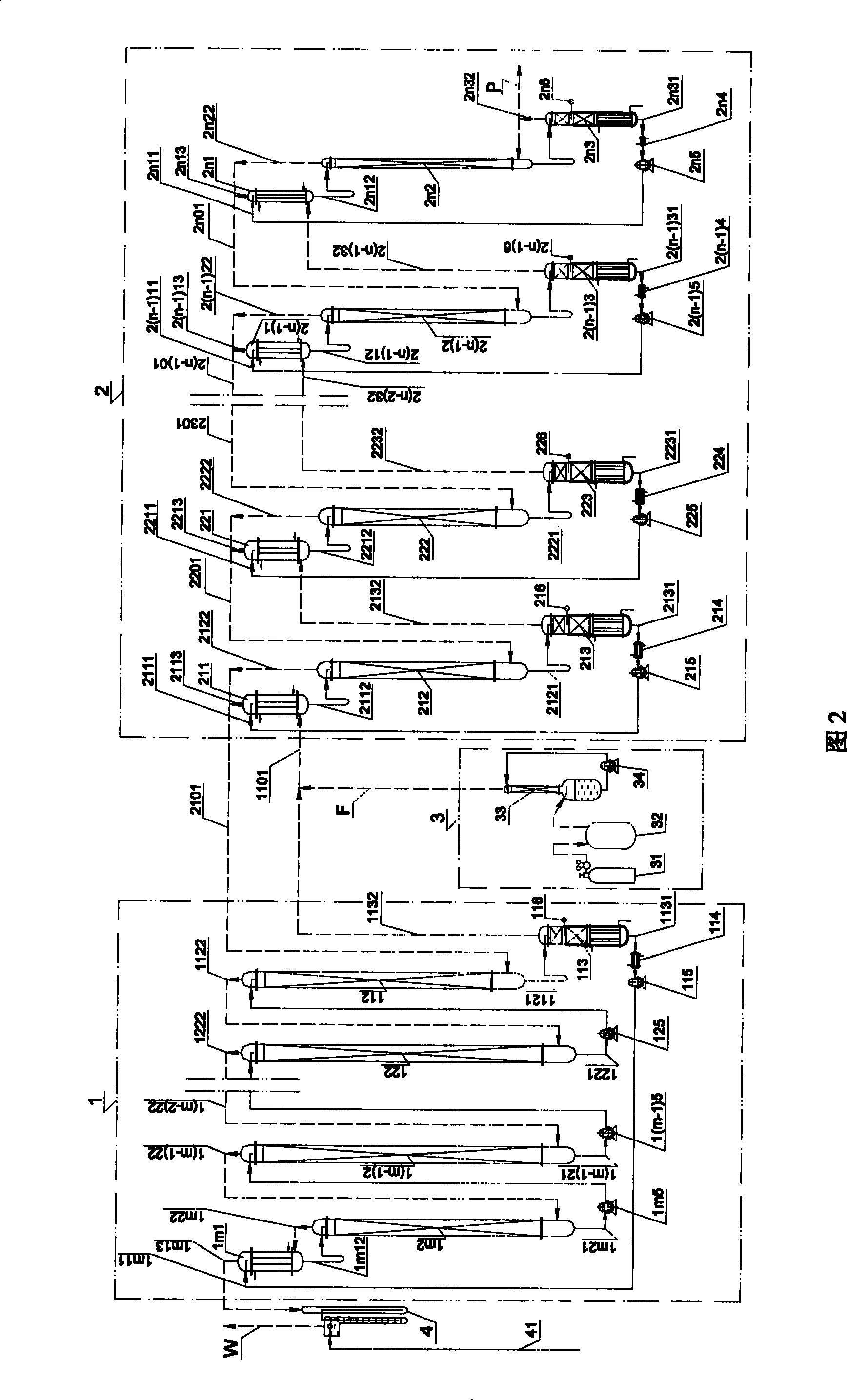

Method and system for producing high concentration carbon dioxide of carbon-13

InactiveCN101054177AReduce manufacturing costAvoid clogging accidentsCarbon compoundsAir quality improvementHigh concentrationSolvent

The present invention relates to a method and a system for preparing C-13 carbon dioxide with a high concentration, belonging to the preparing technical field of stable isotope C-13. The present invention discloses a method and system for the industrialized production of high concentration C-13; wherein the concentration of isotope is more than 99%, the natural carbon dioxide serves as raw material, the carbon dioxide / dinbutylamine / octane serves as the isotope exchange system, and a cold-hot refluxing method is adopted. In the present invention, the technical measures of raw gas presaturation, extractor segment and kettle liquid circulation are adopted, thereby the dosage of raw gas and the solvent consumption are reduced by 99% or so, and the concentration of the working solution of the system is stabilized, so that the concentration effect of the isotope is improved and the production cost is reduced. Furthermore, a hot reflux tower with a direct heat exchange-cool liquid leaching segment is adopted, and the operating temperature and the control requirement are reduced, thereby the crystallizing choking phenomenon is prevented, the operating is convenient and stable, and the energy consumption is saved.

Owner:杨国华

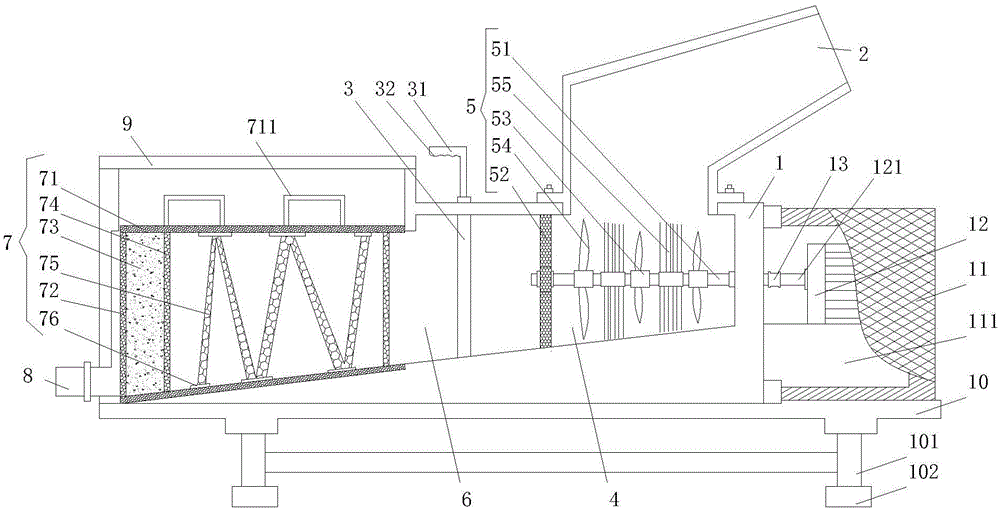

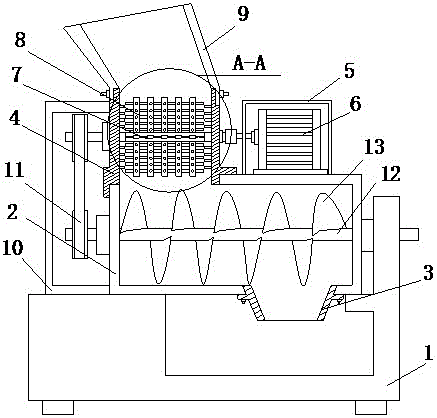

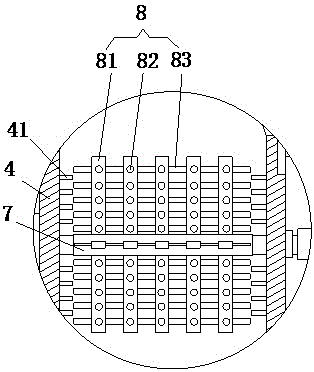

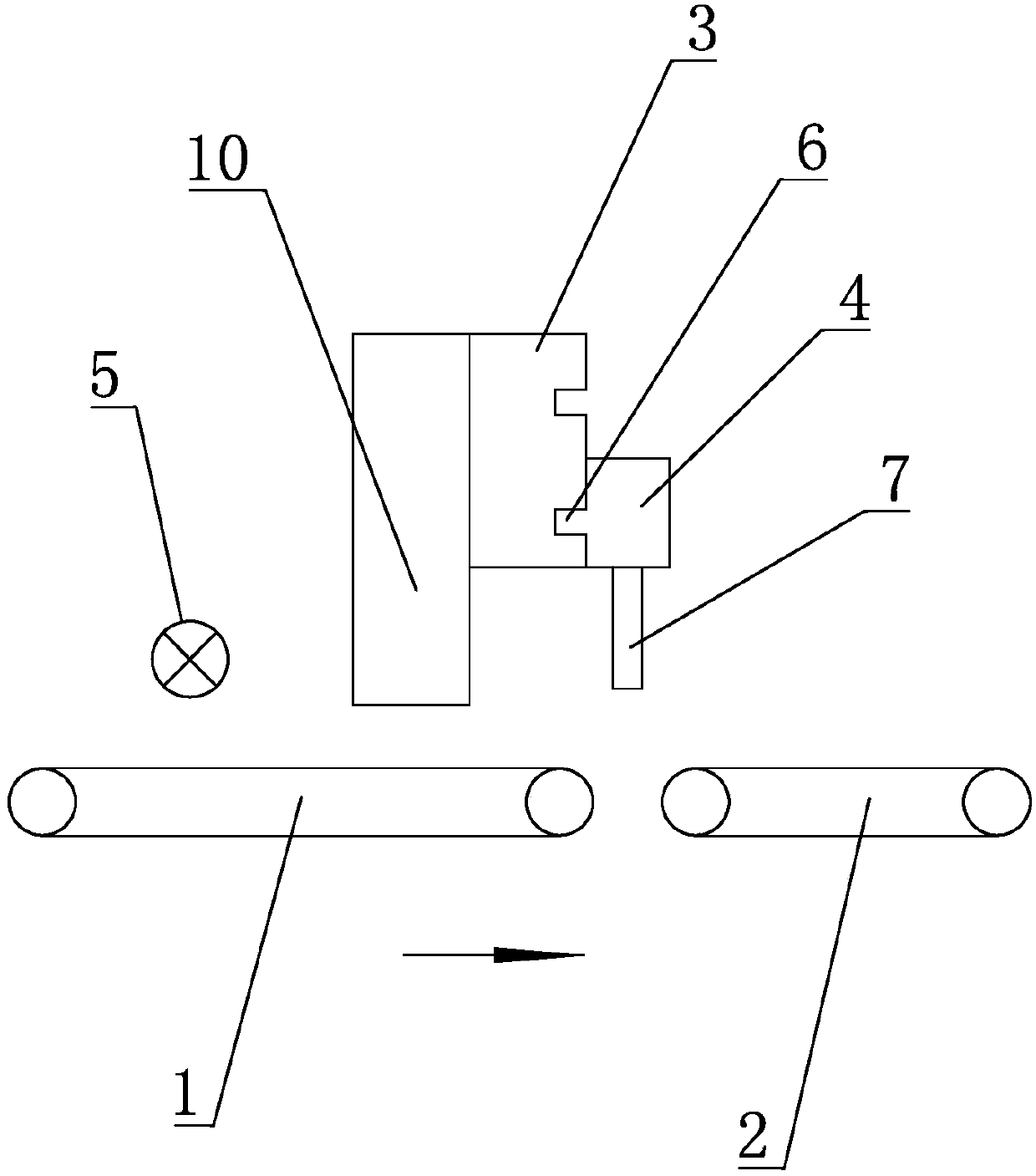

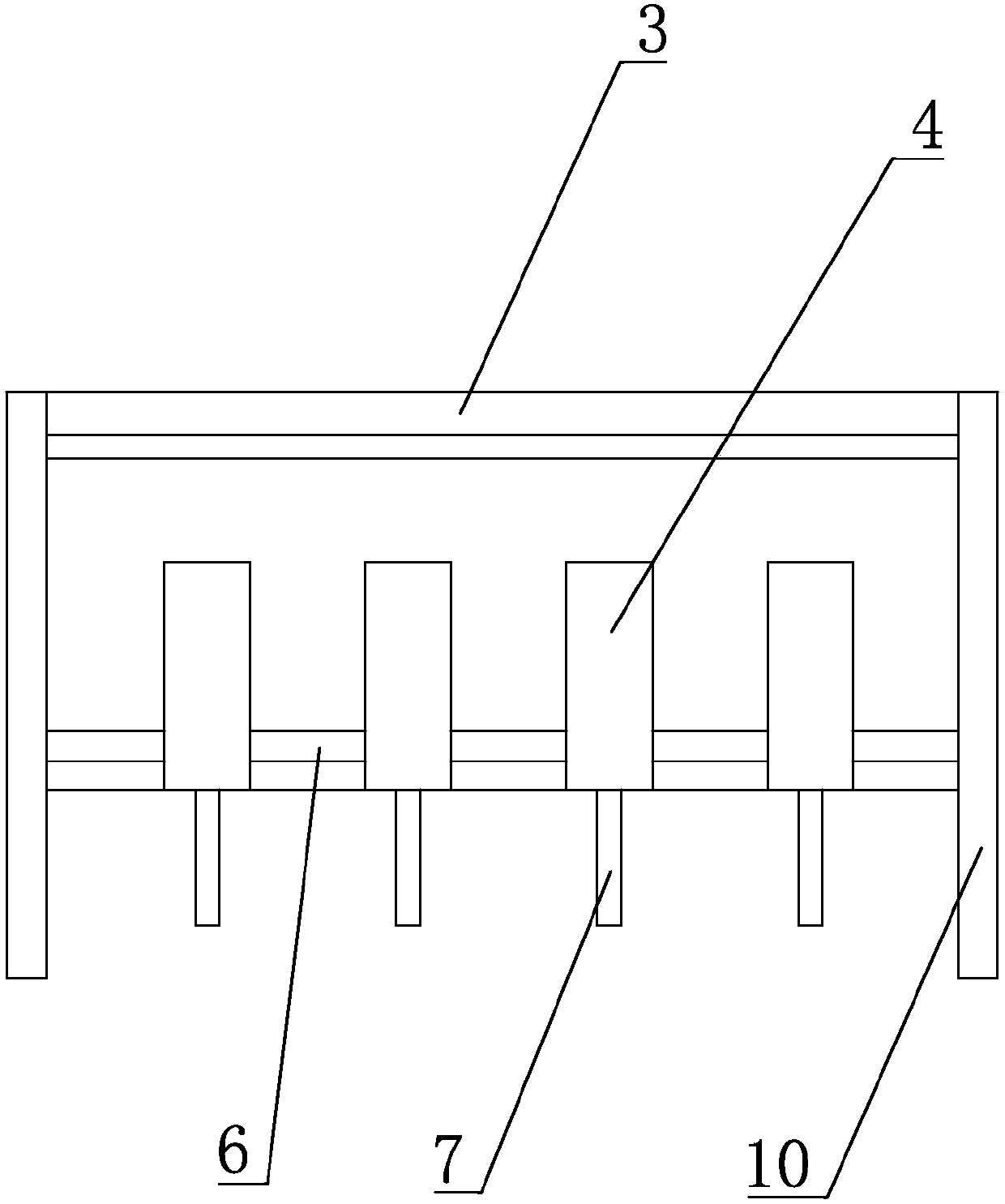

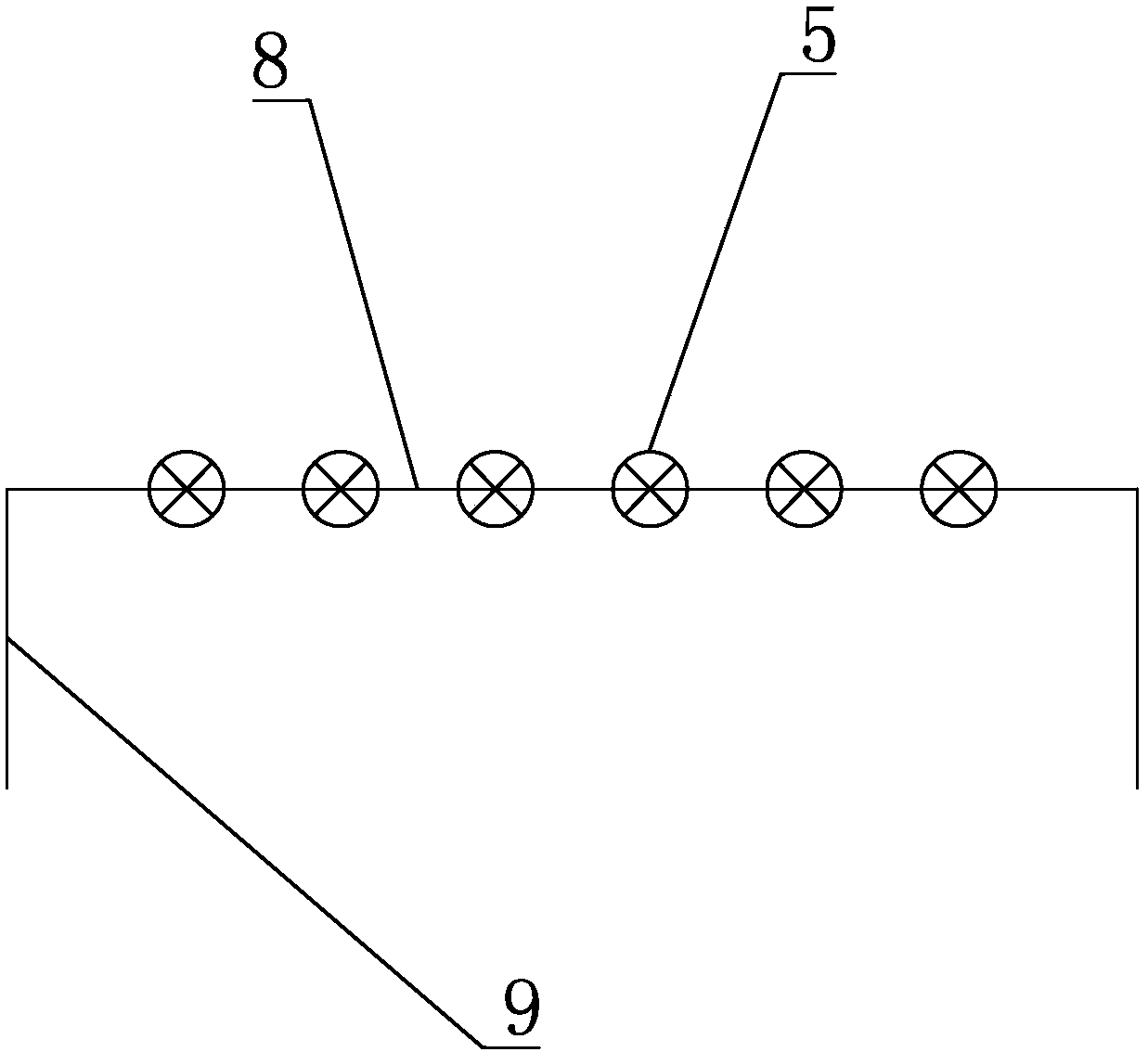

Ceramic large rock plate broken brick automatic crushing system

The invention discloses a ceramic large rock plate broken brick automatic crushing system. The system involves a first green brick conveying belt, a second green brick conveying belt and a machine frame, wherein the first green brick conveying belt and the second green brick conveying belt are arranged in an end-to-end mode, a plurality of crushing devices which are arranged above gaps between thefirst green brick conveying belt and the second green brick conveying belt are arranged on the machine frame, a plurality of infrared induction probes are further arranged on the first green brick conveying belt, and the infrared induction probes are connected with the crushing devices. According to the crushing system, broken bricks are monitored through the infrared induction probes, the brokenbricks are knocked off and crushed along the gaps between the two sections of conveying belts through the crushing devices, the problem of cleaning after the large rock plate green bricks are brokenis effectively solved, manual cleaning of the broken brick is not needed in the whole process, the automatic level is high, so that the cleaning efficiency is effectively improved; the broken bricks are automatically cleaned in time, the bricks are effectively prevented from being hidden in the gap between the conveying belts and roller ways, the phenomena of blocking accidents of a roller way kiln caused by the fact that the broken bricks enter the high-temperature sintering roller way kiln are prevented, the production efficiency is improved, and loss of green bricks is reduced.

Owner:广东金牌陶瓷有限公司

A method for extracting coalbed methane from the complex old goaf area formed by the lower knife column method

The invention discloses an extraction method for coal bed gas in a composite old mined-out area formed through a lower tool post method. The method comprises the steps that a horizontal well is constructed at a middle rock layer between an upper old mined-out area and a lower old mined-out area, extraction is carried out, and the coal bed gas extraction amount within the unit time is recorded as Q1; when the extraction amount is decreased to be below 10-20% of Q1, fracturing is carried out for extraction again, and the coil bed gas extraction amount is recorded as Q2; when the extraction amount is decreased to be below 10-20% of Q2, fracturing is carried out again, and the extraction amount is recorded as Q3; when the extraction amount is decreased again to be 10-20% of Q3, carbon dioxide displacement is carried out; then, extraction is carried out again and not stopped until the extraction amount is decreased to 6 m<3> / min. By means of the method, the problems that only a ground vertical well drilling method is adopted for extracting the old mined-out area in the prior art, the effect contact area of an extraction drilling well and an old mined-out area storage layer is small, and the extraction range is limited are solved; sources near the upper old mined-out area coal bed layer are extracted together with lower old mined-out coal bed gas, and the cost is saved.

Owner:TAIYUAN UNIV OF TECH

A combined mining method for collapsed old goaf and lower coal seam coalbed methane

ActiveCN105927192BAvoid clogging accidentsAvoid recyclingFluid removalGas removalHorizontal wellsCoal

Owner:TAIYUAN UNIV OF TECH

A method for cooperatively extracting coalbed methane from the knife-pillar type old goaf area and the lower coal seam

ActiveCN106089290BAvoid recyclingAvoid collapse accidentsFluid removalDrainageEnvironmental engineeringCo operative

The invention discloses a method of synergetic extraction of coal bed gas of a tool post type mined area and a lower coal bed. The method comprises the steps that firstly, a mine is surveyed; after the floor failure depth is determined, a horizontal well is constructed; the coal bed gas of the mined area is extracted; when the extraction amount of the coal bed gas during unit time is decreased to 20-40% of Q1, the extraction pressure is decreased circularly so that coal bed gas extraction can be continued; when the extraction amount is decreased to 10-18% of Q1, supercritical CO2 is injected for displacement; when the extraction mount is decreased below 20% of Q1 again, oriented fracturing is conducted, a vertical discharge well is arranged on the other side of the horizontal well, and discharging equipment is arranged for conducting coal bed gas extraction; and when the extraction amount of the coal bed gas is decreased below 20% of Q2, the supercritical CO2 is used for displacement again, and extraction is stopped till the extraction amount is decreased to 10% of Q2. By the adoption of the method, coal bed gas resources close to a thin coal seam is extracted along with the coal bed gas in the tool post type mined area, and recovery of gas resources in abandoned still coal seams is achieved.

Owner:TAIYUAN UNIV OF TECH

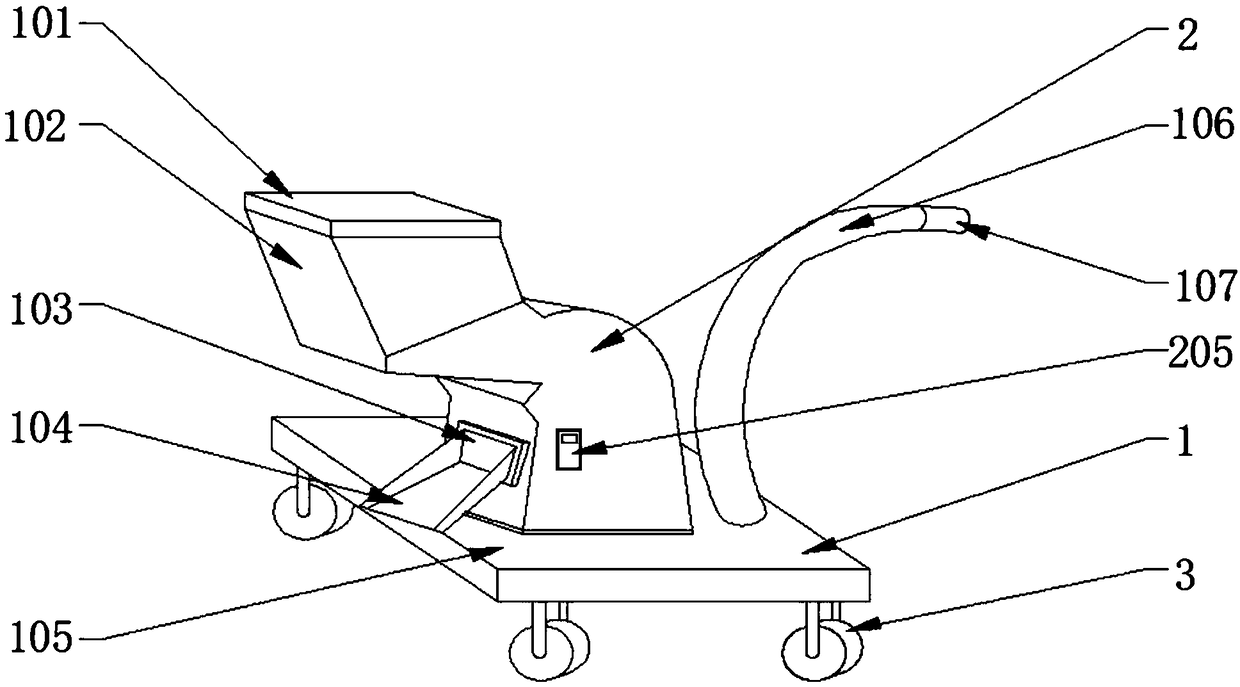

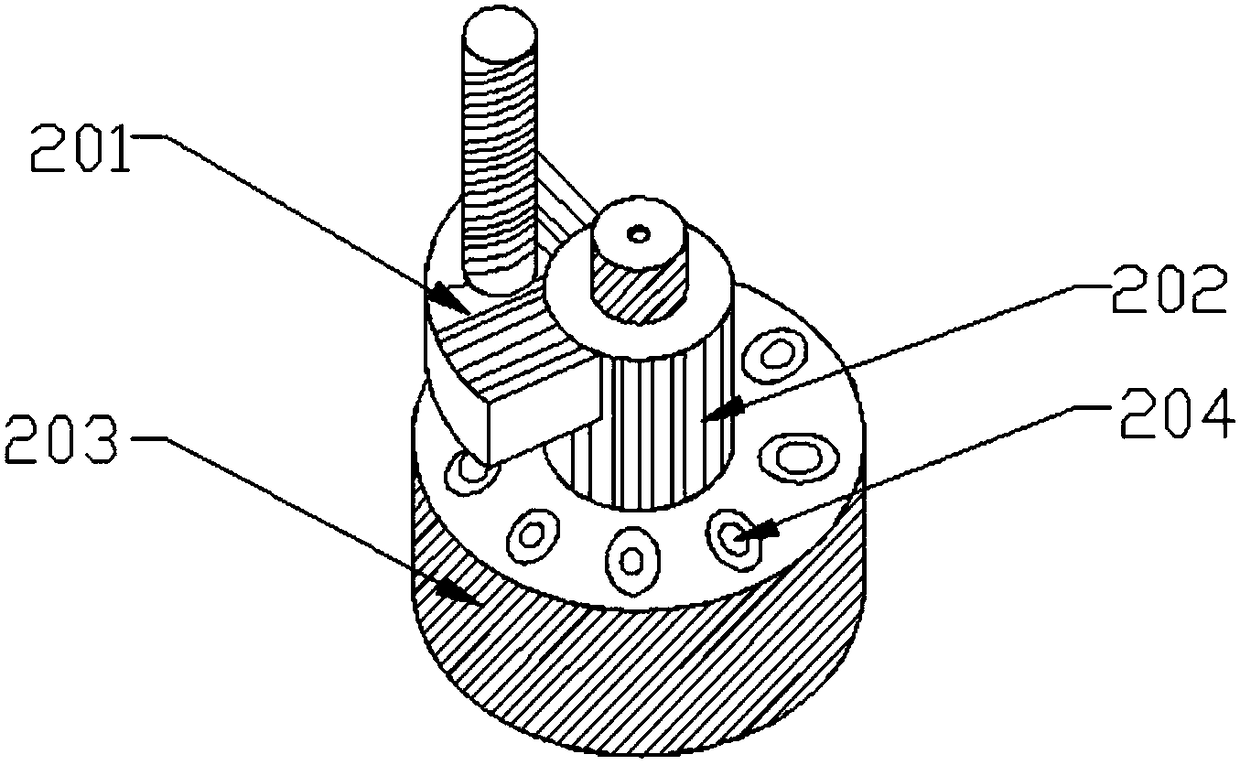

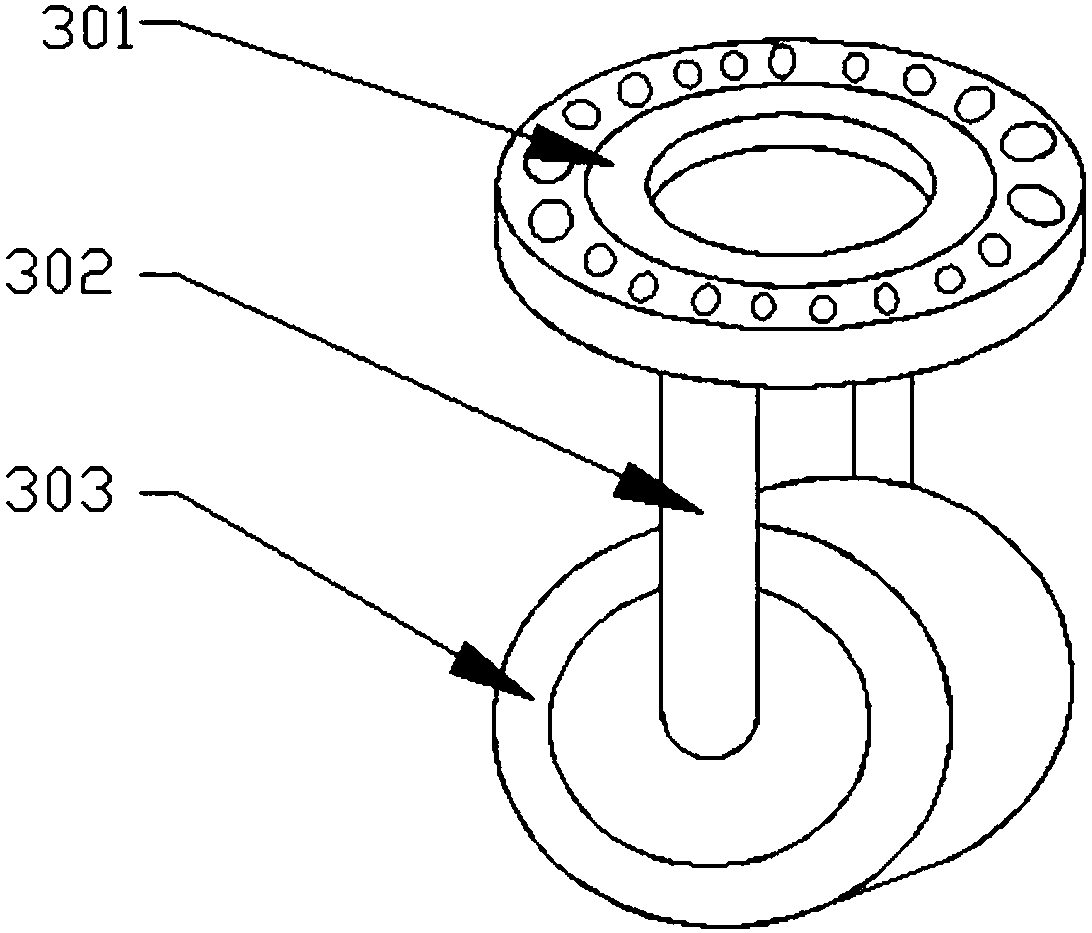

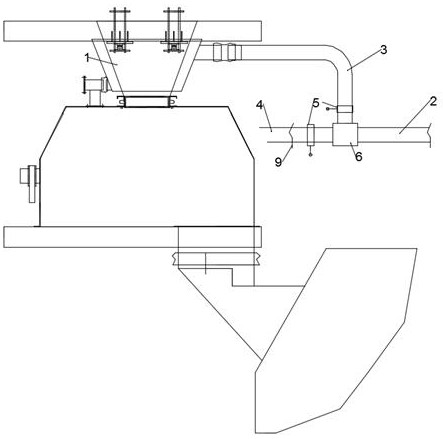

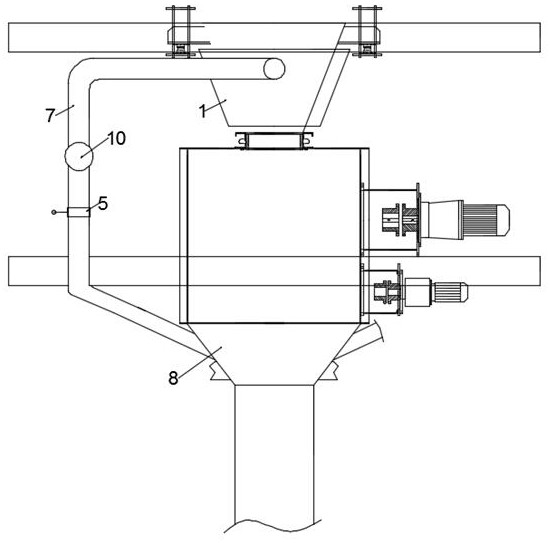

Movable hopper of compound fertilizer production equipment

InactiveCN108408277ADistribute in timeImprove practicalityLarge containersEngineeringWear resistance

The invention discloses a movable hopper of compound fertilizer production equipment. The movable hopper comprises a hopper main frame, a vibrator and a moving unit, wherein a hopper container is arranged at the top end of the hopper main frame; the hopper container is fixedly connected with the hopper main frame; a material outlet is formed in the middle part of the hopper main frame; the material outlet is connected with the hopper main frame in an embedded manner; a material discharging guide plate is arranged at a hollow part of the material outlet; the material discharging guide plate isconnected with the material outlet in a penetrating manner; a base is arranged at the bottom end of the hopper main frame; and during transferring of prepared compound fertilizer materials, a container with the compound fertilizer materials is required to lean against a position at the top end of the hopper in each process of pouring the materials into the hopper, and after a lot of transferring work, the top end, particularly the top end of the hopper, and the container with the compound fertilizer materials are greatly worn, but an anti-wear border with wear resistance property can prevent multiple problems such as the influence on the appearance due to severe wear of the hopper, so that the movable hopper has a wide use prospect in the future.

Owner:袁文林

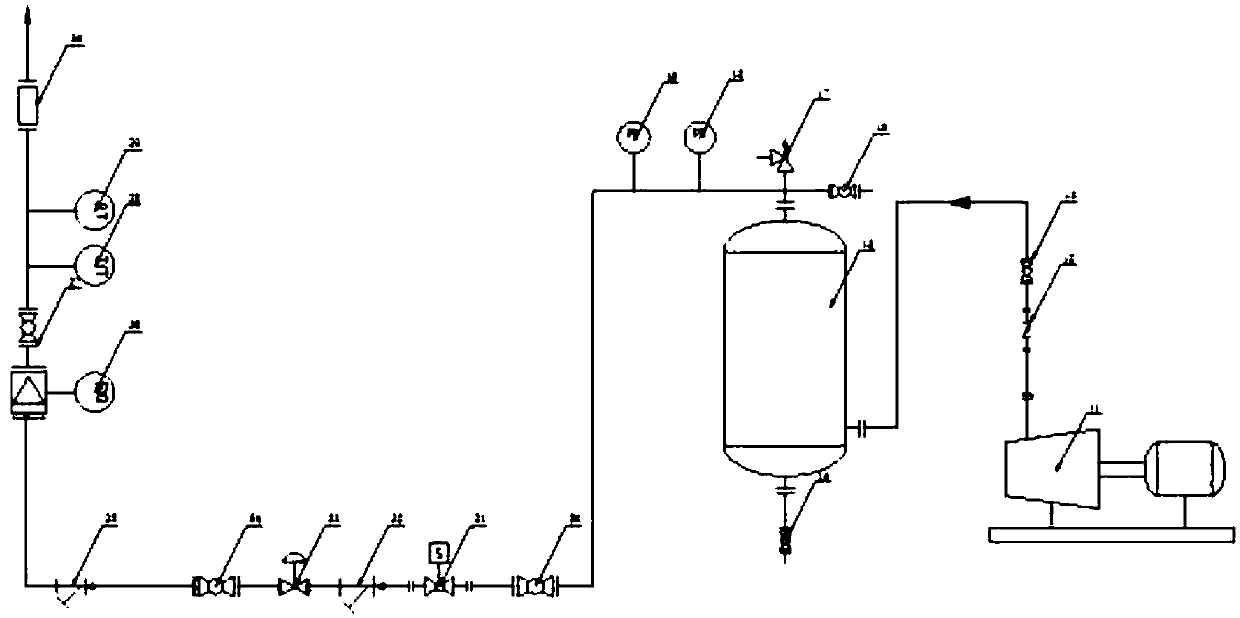

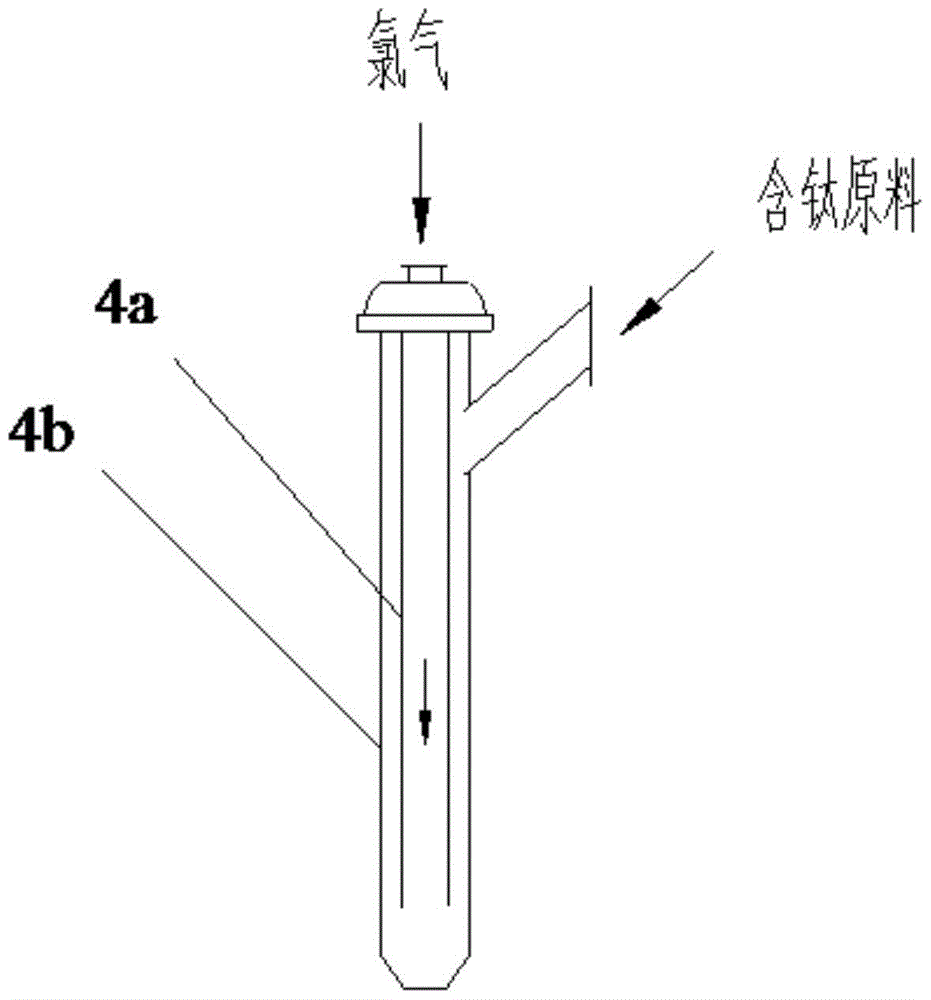

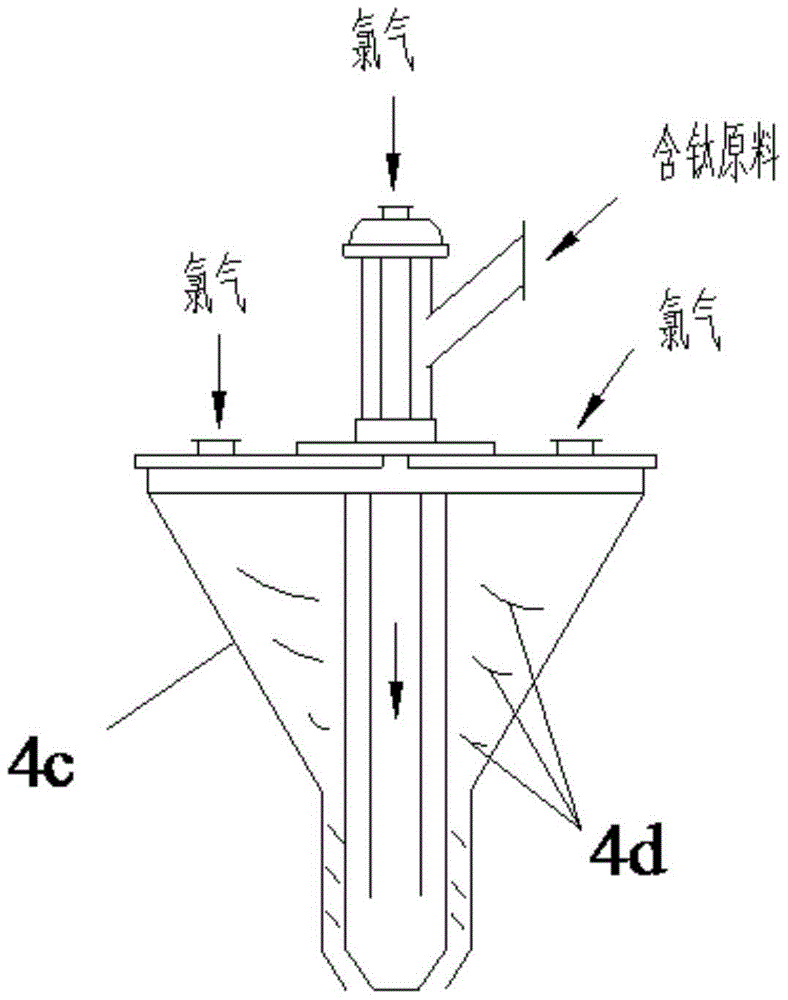

A flash suspension chlorination method for titanium-containing raw materials

ActiveCN105197989BAvoid clogging accidentsGuaranteed separation efficiencyTitanium tetrachlorideReducing atmosphereTitanium tetrachloride

The invention relates to a flash suspension chlorination method for raw materials containing titanium. The flash suspension chlorination method includes the steps that a reaction furnace with a reaction chamber and an evacuation chamber is used for reaction, a partitioning plate is used for separating the reaction chamber from the evacuation chamber, and the bottoms of the reaction chamber and the evacuation chamber are communicated to form a U-shaped communicated structure; a reducing atmosphere condition is formed inside the reaction chamber, chlorine is used as carrier gas, and the raw materials containing titanium are sprayed into the reaction chamber from the top or the top side of the reaction chamber, the raw materials containing titanium and chlorine are kept in a stable suspension state inside the reaction furnace, and the temperature is stabilized below 500-1200 DEG C for reaction; a residue discharging opening is formed in the bottom of the reaction furnace, solid powder and fused adhesive impurities generated by the reaction are discharged from the residue discharging opening, and generated crude titanium tetrachloride products are collected at an outlet in the top of the evacuation chamber. The invention further discloses a chlorination reaction furnace device used for the reaction. According to the chlorination technology, the raw materials, containing titanium, high in CaO and MgO content can be used, and the problem that low-melting-point molten mass blocks equipment is solved.

Owner:SICHUAN HONGDA (GRP) CO LTD

A coalbed methane extraction method for complex old goaf areas formed by lower caving mining

Owner:TAIYUAN UNIV OF TECH

Multi-purpose liquid dressing device capable of preventing overflow and leakage

PendingCN113499727AStir wellImprove the mixing effectRotary stirring mixersMixer accessoriesBLENDER/MIXEREngineering

The invention discloses a multi-purpose liquid dressing device capable of preventing overflow and leakage, which comprises a base, a placement groove, a control panel, heating plates, a filtering and filling mechanism, overflow and leakage preventing mechanisms and a fixing seat, wherein supporting columns are arranged on the two sides of the base, a top plate is fixedly connected to the top ends of the supporting columns, the placement groove is formed in the top plate, a stirring barrel is arranged above the placement groove, the control panel is arranged on the outer side of the stirring barrel, the heating plates are arranged on the two sides of the interior of the stirring barrel, the filtering and filling mechanism is arranged below the discharging pipeline, the overflow and leakage preventing mechanisms are arranged on the two sides of the top end of a liquid dressing bottle, a precipitation preventing mechanism is arranged in the liquid dressing bottle, and a fixing base is arranged at the bottom of the liquid dressing bottle. According to the multi-purpose liquid dressing device capable of preventing overflow and leakage, the stirring mechanism and the filtering and filling mechanism are arranged, liquid dressing raw materials can be evenly stirred through the stirring mechanism, impurities in liquid dressings can be conveniently filtered through the filtering and filling mechanism, and the situation that a filling head is blocked during filling is avoided.

Owner:江苏德康医疗器械有限公司

A method for cooperatively extracting coalbed methane from caving old gobs and lower coal seams

ActiveCN106089291BAvoid recyclingAvoid clogging accidentsConstructionsFluid removalEnvironmental engineeringCo operative

The invention discloses a method for synergetic extraction of coal bed gas in a caving type gob area and a lower coal bed. The method comprises the steps that firstly, a mine is explored, a horizontal well is constructed from the ground to a base plate of the gob area, carbon dioxide is compressed into the well for cleaning, and coal bed gas extraction is carried out; when the extraction amount of coal bed gas in unit time drops to 20%-40% of Qi, running and stopping circulate, the extraction pressure is reduced, and the re-extraction process is carried out again; when the extraction amount drops to be below 20% of Qi, carbon dioxide is injected for replacement, and extraction is carried out again; when the extraction amount drops to be below 20% of Q1 again, the horizontal well and a coal and rock strata of the lower coal bed are subjected to fracture, and coal bed gas discharge and extraction are carried out; when the extraction amount drops to be below 20% of Q2, supercritical carbon dioxide replacement is carried out; and when the extraction amount drops to 10% of Q2 through extraction, extraction is stopped. By means of the method, synergetic extraction of coal bed gas in the carving type gob area and coal bed gas near a low coal seam is achieved, cost is reduced, and the coal bed gas resource is extracted to the greatest extent.

Owner:TAIYUAN UNIV OF TECH

Zirconium corundum mullite brick for hazardous waste rotary kiln and preparation method

PendingCN114413619ALarge temperature differenceReduce widthRotary drum furnacesFurnace coolingBrickMullite

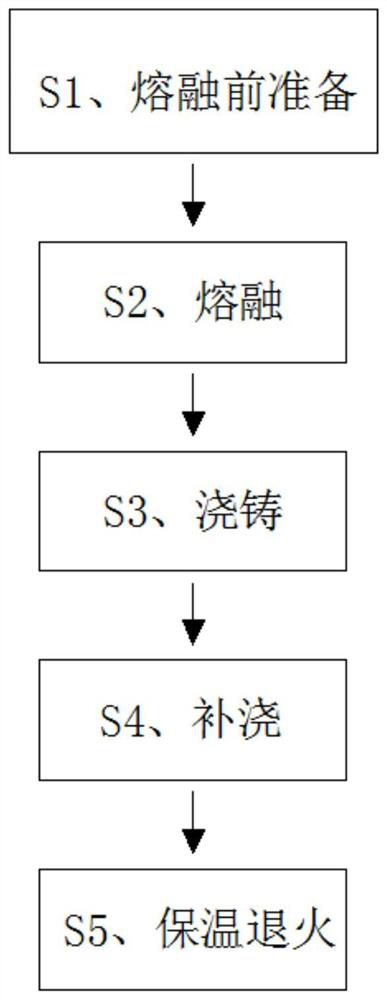

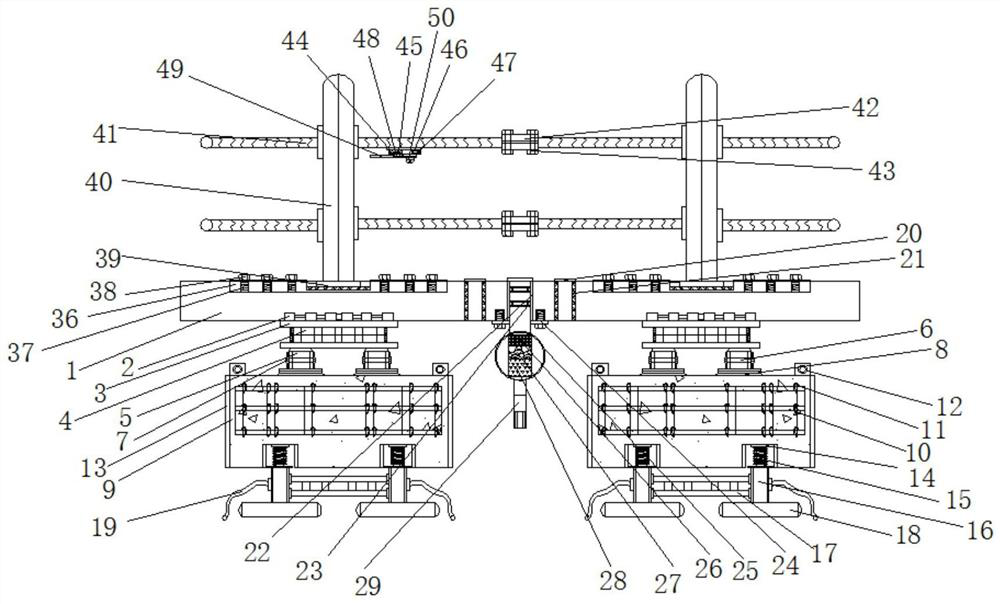

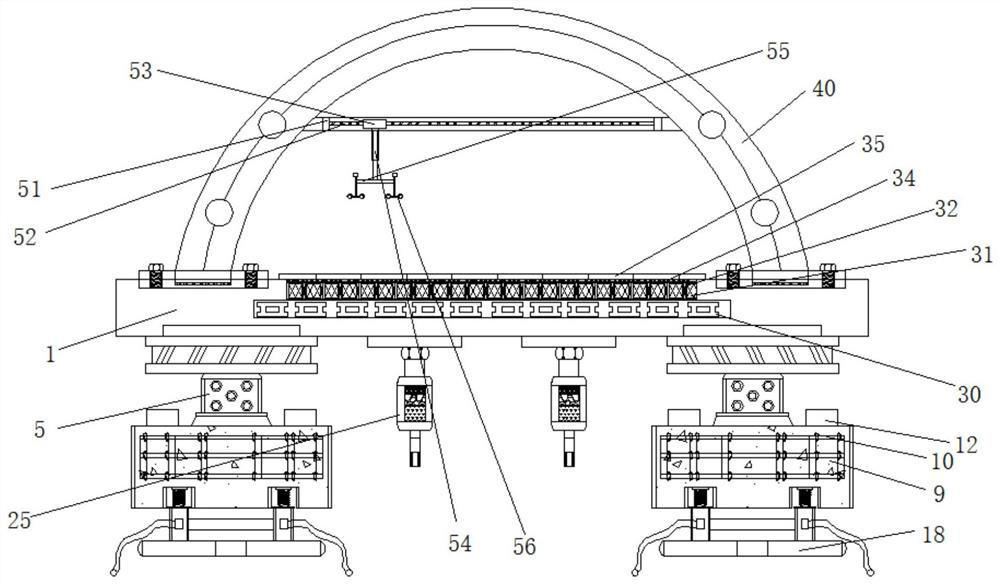

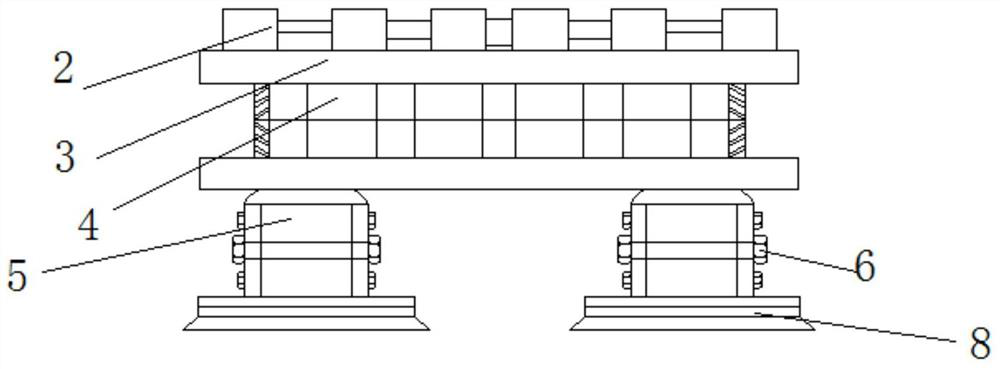

The invention relates to the technical field of fused alumina zirconia mullite bricks, and discloses a fused alumina zirconia mullite brick for a hazardous waste rotary kiln and a preparation method thereof.The preparation method comprises the steps that aluminum oxide, alkali powder, zircon sand and other raw materials are added into an electric furnace, the raw materials are subjected to high-temperature oxidation melting, oxygen is blown into melt, then the melt is directly poured into a casting mold from the electric furnace, and after casting of a casting is completed, the fused alumina zirconia mullite brick is obtained; after cold contraction for a period of time, the melt is fully cast in a shrinkage cavity, and the casting mold is cooled in advance before casting, so that the temperature difference between the casting and the casting mold is increased, the width of a solidification area of the casting from the surface to the inside is reduced, the solidification shrinkage speed of the casting is slowed down, and the possibility of hot cracking when the core part of the casting is finally solidified is reduced; meanwhile, in the casting process, the outside of the casting mold is cooled, so that the situation that the temperature of the casting mold rises, material components of the casting mold are decomposed and gasified and chemically react with molten liquid is avoided, and the possibility that a pore layer appears on a casting or insufficient casting occurs is reduced.

Owner:江苏朗耐德耐火材料有限公司

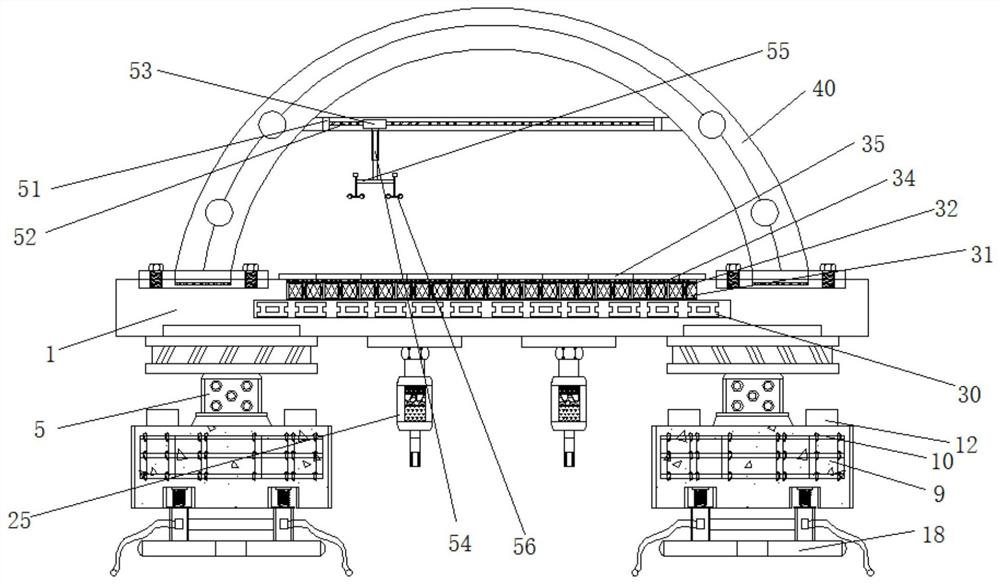

Foundation base of air film building

ActiveCN112814012AEasy to liftEasy to fixProtective foundationExtraordinary structuresArchitectural engineeringAdhesive glue

The invention relates to a foundation base of an air film building. The foundation base comprises a platform plate and pressure reduction steel feet, wherein steel block clamping teeth are connected to the lower portion of the platform plate in a buckled mode, a rolled steel plate is arranged below the steel block clamping teeth, and a rubber patch is attached to the inner side of the rolled steel plate; the pressure reduction steel feet are arranged below the rolled steel plate, pin bars are connected to the inner sides of the pressure reduction steel feet in a penetrating mode, and hexagonal rivets are arranged at the two ends of each pin bar; and expansion rubber mats are arranged below the pressure reduction steel feet, a concrete layer is attached to the lower portions of the expansion rubber mats, reinforcing steel bars are mounted in the concrete layer, and binding wires are arranged on the outer sides of the reinforcing steel bars. The foundation base of the air film building has the beneficial effects that aluminum alloy plates are mounted on the foundation base of the air film building and can be closely bonded together through adhesive glue to form a honeycomb structure, supporting keels are arranged in the aluminum alloy plates for supporting, thus the strength of equipment can be enhanced, and the effect of mass reduction can be achieved.

Owner:SHENZHEN ZHONGDE MEMBRANE STRUCTURE CO LTD

A method of recycling fly ash from domestic waste incineration

ActiveCN108273825BFlexible control of the amount of fly ashContinuous industrial productionTransportation and packagingSolid waste disposalParticulatesPhosphate

The invention relates to a recycling method for domestic waste incineration fly ash. A diverter device is installed at the lower end of the dust collector of the waste incineration flue gas treatment system to control the amount of fly ash that circulates into the medialess grinder and prevent the fly ash from agglomerating in the grinding medium or Bonding on the inner wall of the grinder affects the grinding effect. After the fly ash is crushed in the grinding chamber, the high-pressure centrifugal fan will bring the ground powder into the classifier, and the fine powder that meets the fineness requirements enters the circulation system with the airflow, Coarse particles that meet the fineness requirements are returned to the grinding bin to continue grinding, ensuring that the particle size of the ground fine powder is uniform and kept within a certain range, fully exposing unreacted calcium hydroxide, increasing the specific surface area of fly ash, and improving fly ash. The utilization rate of calcium hydroxide in the ash is more than 80%, and continuous industrial production can be realized. At the same time, phosphate is added to the medialess grinder to pre-stabilize heavy metals, reduce the amount of subsequent deacidification agents, and play a grinding role; add strong oxidants to desulfurize and denitrify and promote the decomposition of dioxins.

Owner:TIANJIN YIMING ENVIRONMENTAL TECH CO LTD

Novel backwashing water intake system for water purification building

InactiveCN102146694BLow costLarge backwash water flowMultistage water/sewage treatmentDrinking water installationInfiltration galleryWater flow

The invention discloses a novel backwashing water intake system for a water purification building. The system comprises an infiltration gallery, a clean water tank and the water purification building directly arranged in a river, wherein the infiltration gallery is communicated with the clean water tank through a bottom through hole; the clean water tank is communicated with the bottom of the water purification building through a pipeline; infiltration gallery bell mouth bases are symmetrically arranged at the bottoms of both sides of the infiltration gallery and are provided with bell mouths; the bell mouths are arranged obliquely downwards from the outside to the inside of the infiltration gallery; the pipeline comprises a water inlet pipe, a backwashing pipe and a water outlet pipe; the water outlet pipe is arranged on the water purification building; a horizontal centrifugal pump is arranged at the bottom of the water purification building; the water inlet pipe is arranged on the horizontal centrifugal pump; one end of the water inlet pipe is communicated with the clean water tank, and the other end of the water inlet pipe is communicated with the water outlet pipe; the backwashing pipe is arranged on the water inlet pipe; and one end of the backwashing pipe is communicated with another clean water tank. The water intake system has the characteristics of high backwashing water flow, high water pressure, capabilities of ensuring the engineering quality and the backwashing effect, saving materials and lowering the construction cost and difficulty in blocking.

Owner:浙江净水楼建设投资有限公司

A foundation base for an air film building

ActiveCN112814012BEasy to liftEasy to fixProtective foundationExtraordinary structuresArchitectural engineeringAdhesive glue

Owner:SHENZHEN ZHONGDE MEMBRANE STRUCTURE CO LTD

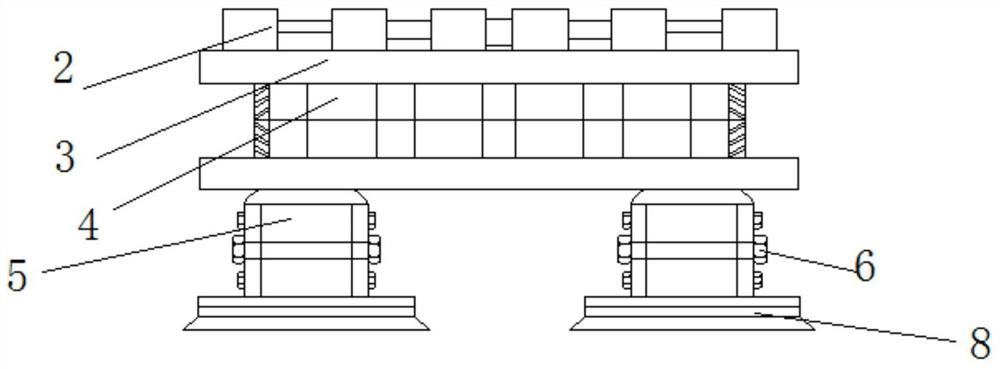

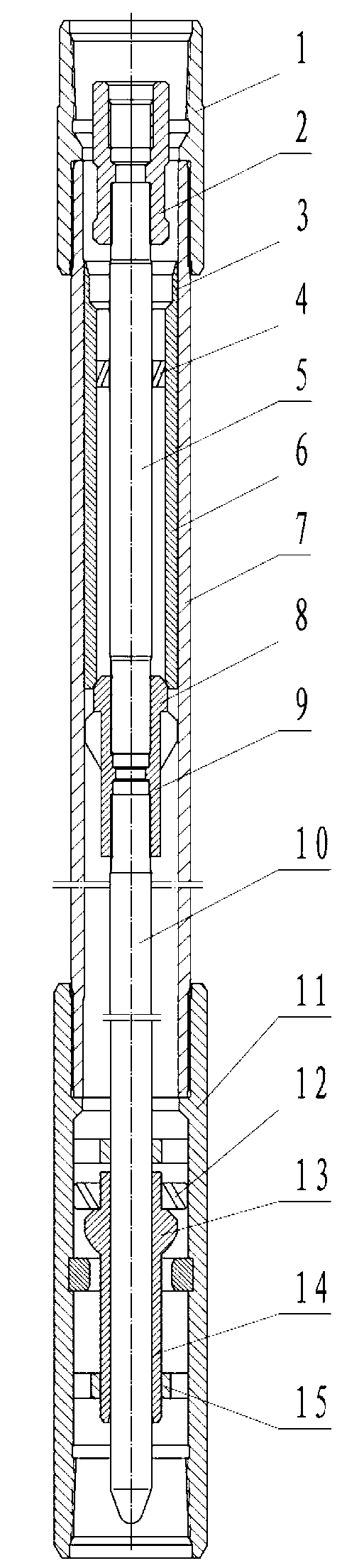

Horizontal sand prevention vicious pump

InactiveCN103174630AAvoid stuck pumpsAvoid Strain AccidentsPositive displacement pump componentsFlexible member pumpsCouplingEngineering

A horizontal sand prevention vicious pump comprises a pump cylinder assembly, a fixing valve assembly and a plunger piston assembly. The plunger piston assembly is inserted into the pump cylinder assembly and the fixing valve assembly. The pump cylinder assembly comprises a pump cylinder coupling, an upper pump cylinder, a gap bridge outer tube and a guide sleeve. The fixing valve assembly comprises a fixing valve and a lower pump cylinder. The plunger piston assembly comprises a pull rod coupling, a pull rod, an upper plunger piston, a travelling valve, a pull rod joint and a lower plunger piston. A strike-off cup with an inward small end is arranged at the upper end of the upper plunger piston, the upper end of the pull rod is connected with an oil pumping rod pillar through the pull rod coupling, and the lower end of the pull rod is in series connection with the lower plunger piston into a whole through the pull rod joint. The upper plunger piston is sleeved outside the pull rod, and can move vertically along the pull rod. The horizontal sand prevention vicious pump can effectively reduce accidents of pump clamping, pulling and plugging caused by sand production of an oil well, removes eccentric wear between the pump cylinders and the plunger pistons, and has mechanical forced on and off function.

Owner:CSIC ZHONGNAN EQUIP

Structure and method for preventing blockage of vertical mill feeding system

PendingCN114570510ASolve the problem of blockage and shutdownAvoid clogging accidentsDrying gas arrangementsClinker productionStructural engineeringProcess engineering

The invention discloses an anti-blocking structure and method for a vertical mill feeding system, and relates to the field of cement raw material grinding, the anti-blocking structure comprises a vertical mill system, the vertical mill system comprises a small bin box body, a chain plate scale and a mill feeding scraper-trough conveyer, and the anti-blocking structure further comprises an air heating main pipeline, and an air outlet of the air heating main pipeline is connected with a hot air induced pipe; a three-way valve is arranged at one end of the hot air inducing pipe, an air outlet of the three-way valve is respectively connected with a first air inducing pipe and a second air inducing pipe, the first air inducing pipe is communicated with the bottom of the small bin box body, and the second air inducing pipe is communicated with a chain plate scale; the air outlet pipe is arranged on the back face of the small bin box body, the end, penetrating out of the small bin box body, of the air outlet pipe is connected with the mill inlet scraper-trough conveyer, the pressure at the mill inlet pipeline and the pressure difference at the mill inlet scraper-trough conveyer in the mill are utilized, the small sealed bin is of a box body type through structure, and circulating hot air is formed. And the circulating hot air dries the materials entering the warehouse, the scale body and the grinding scraper-trough conveyer.

Owner:康达(山东)水泥有限公司

Method and system for producing high concentration carbon dioxide of carbon-13

InactiveCN101054177BReduce manufacturing costAvoid clogging accidentsCarbon compoundsAir quality improvementHigh concentrationSolvent

The present invention relates to a method and a system for preparing C-13 carbon dioxide with a high concentration, belonging to the preparing technical field of stable isotope C-13. The present invention discloses a method and system for the industrialized production of high concentration C-13; wherein the concentration of isotope is more than 99%, the natural carbon dioxide serves as raw material, the carbon dioxide / dinbutylamine / octane serves as the isotope exchange system, and a cold-hot refluxing method is adopted. In the present invention, the technical measures of raw gas presaturation, extractor segment and kettle liquid circulation are adopted, thereby the dosage of raw gas and the solvent consumption are reduced by 99% or so, and the concentration of the working solution of the system is stabilized, so that the concentration effect of the isotope is improved and the production cost is reduced. Furthermore, a hot reflux tower with a direct heat exchange-cool liquid leaching segment is adopted, and the operating temperature and the control requirement are reduced, thereby the crystallizing choking phenomenon is prevented, the operating is convenient and stable, and the energy consumption is saved.

Owner:杨国华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com