Method of synergetic extraction of coal bed gas of tool post type mined area and lower coal bed

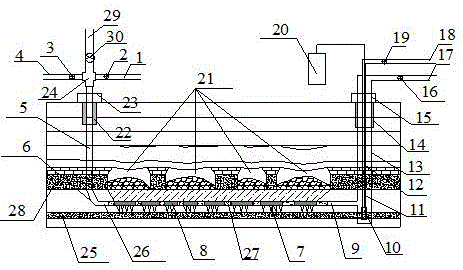

A technology for old gobs and coalbed methane, which is applied in the field of collaborative extraction of knife-pillar old gobs and coalbed methane in lower coal seams, which can solve problems such as limited drainage range, waste of coal resources, and small contact surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030]Taking a certain working face of Jinsheng Yongan Hongtai Coal Mine as an example, the inventive method is explained below: Jinsheng Yongan Hongtai Coal Mine is located in the Qinshui Coalfield, and the mineable coal seams in the coalfield are the No. 3 coal seam of Shanxi Formation and Taiyuan Coal Seam. No. 9 and No. 15 coal seams of the group. Among them, the average coal thickness of the No. 3 coal seam in the main mining seam is 6.34 meters. Since the 1960s, due to the backward mining methods and the serious phenomenon of random mining and digging in small coal mines, the main coal mining method of the No. 3 coal seam in the main mining seam is Coal mining by the knife column method has a low recovery rate, and a large amount of coal is left underground, and the old goaf area is quite rich in coalbed methane resources. The No. 9 coal is a thin coal seam with a distance of about 52 meters. Its average coal thickness is 0.63 meters. It is a pity to discard this part o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com