Novel backwashing water intake system for water purification building

A technology for backwashing and water purification building, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, water supply devices, etc. problem, to achieve the effect of significant backwashing effect, saving project cost and saving project investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

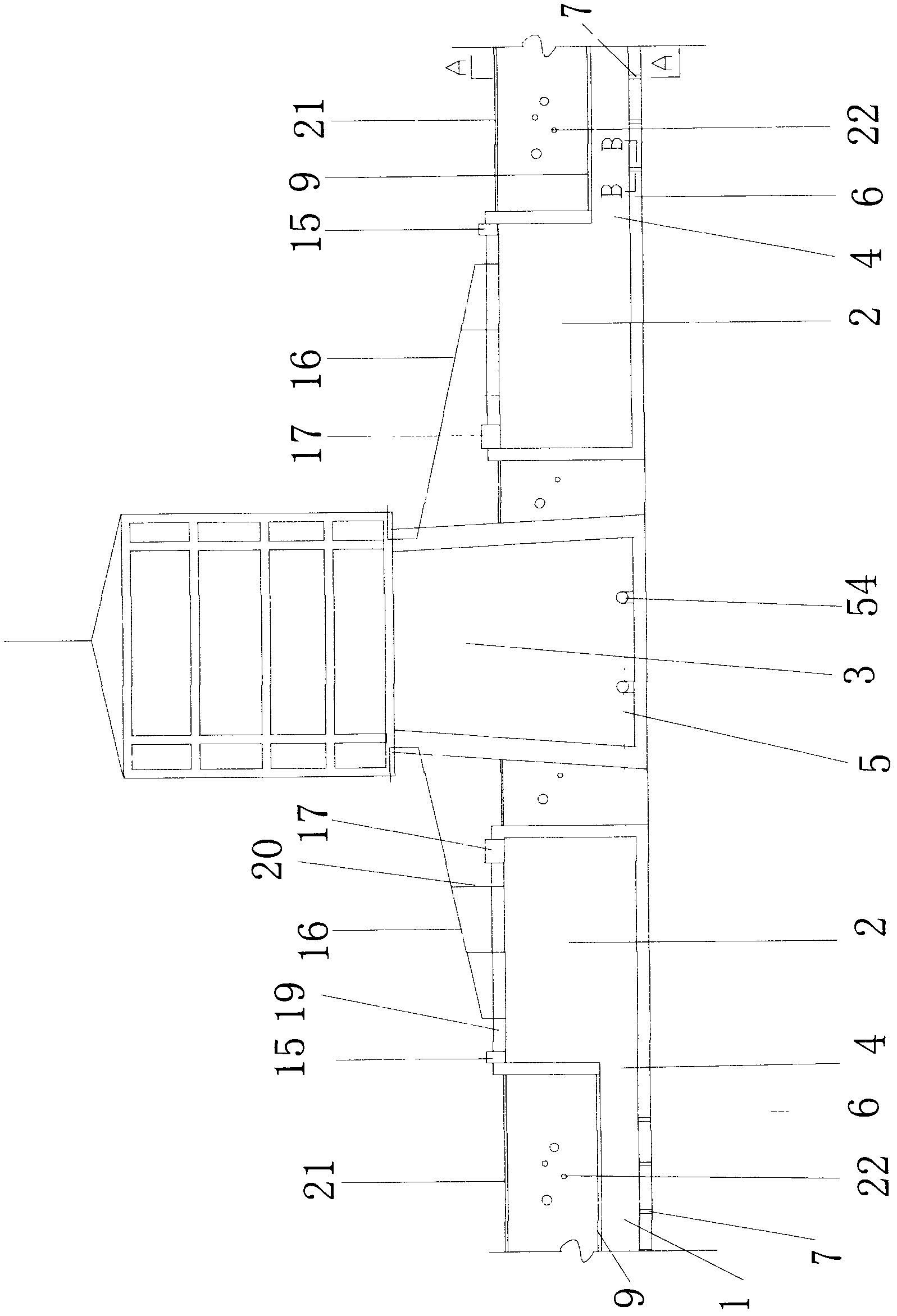

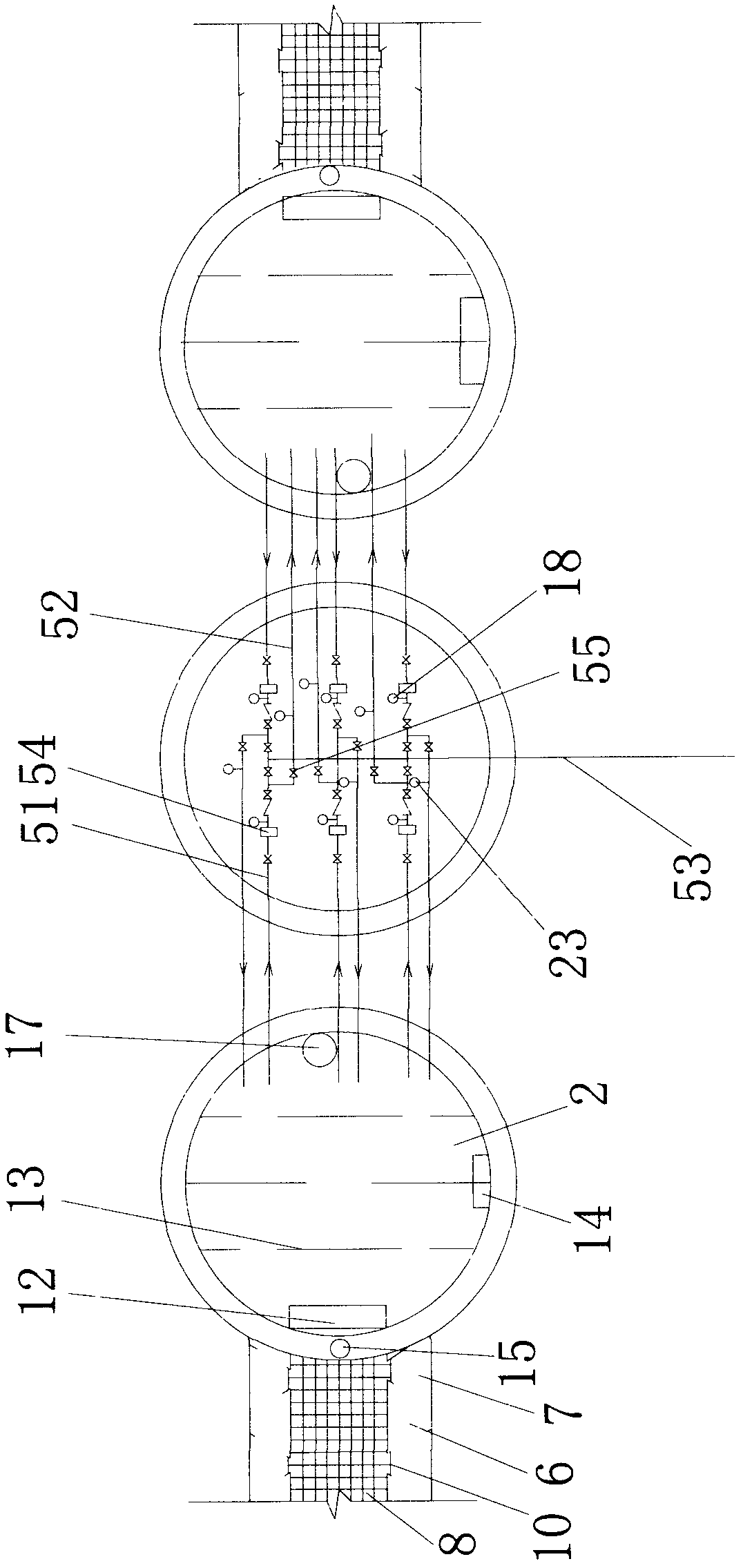

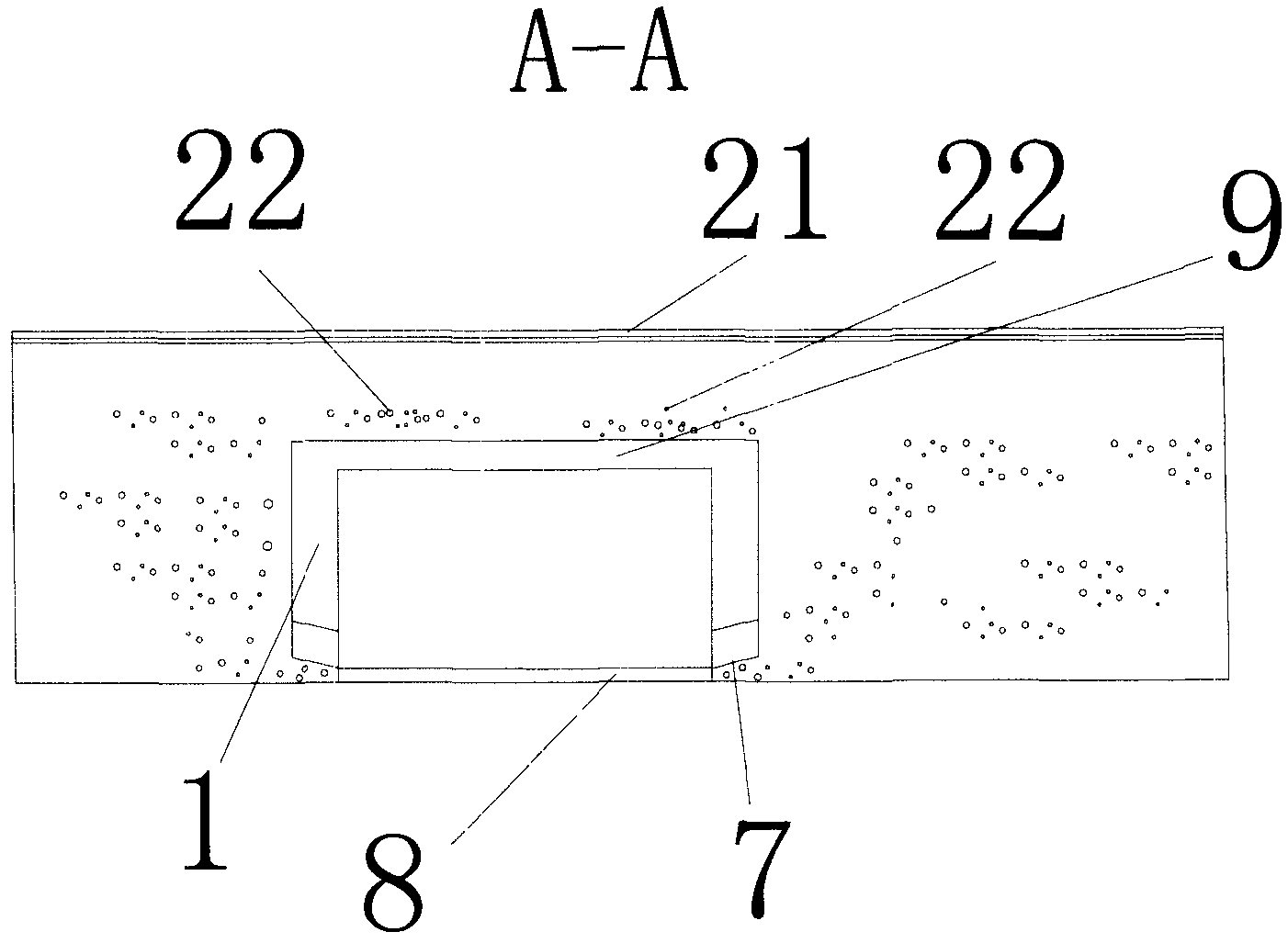

[0026] A kind of water intake system of the novel backwashing of water purification building of the present embodiment, as figure 1 , figure 2 As shown, it includes the infiltration channel 1, the clear water pool 2 and the water purification building 3 directly arranged in the river, and the filter layer 22 is distributed in the river, and the filter layer 22 is sand and pebbles. The filter layer 22 is provided with a filter layer 21, and the filter layer 21 is composed of fine sand and mud. The seepage canal 1 and the clear water pool 2 are communicated through the through hole 4 at the bottom, and the through hole 4 is provided with a gate 12; the clear water pool 2 and the bottom of the water purification building 3 are connected through a pipeline 5, and a diversion wall is installed in the clear water pool 2 13. The clear water tank 2 is provided with inspection holes 14, the reserved holes for adding chlorine in the clear water tank 15, and the clear water tank manhol...

Embodiment 2

[0035] A backwash water intake system in this embodiment, wherein the bell mouth 7 is designed to be inclined downward from the outside to the seepage ditch 1, the inclination angle β is 6°, and the centripetal angle α of the seepage canal bell mouth 1 is 20° °. All the other are with embodiment 1. The contribution of the setting of the inclination angle in this embodiment to the energy-saving effect is shown in Table 2.

Embodiment 3

[0037] A backwashing water intake system of this embodiment, wherein the bell mouth 7 is designed to be inclined downward from the outside to the seepage ditch 1, the inclination angle β is 7°, and the centripetal angle α of the seepage canal bell mouth 1 is 21 °. All the other are with embodiment 1. The contribution of the setting of the inclination angle in this embodiment to the energy-saving effect is shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com