Ejection drill with internal drill chip discharge and single drill chip discharging port

A technology of jet suction drilling and internal chip removal, which is applied in the direction of drill repair, drilling tool accessories, drilling/drilling equipment, etc., which can solve the problems of increased use cost and chip blocking accidents, so as to prevent accumulation and improve chip removal capacity , the effect of reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

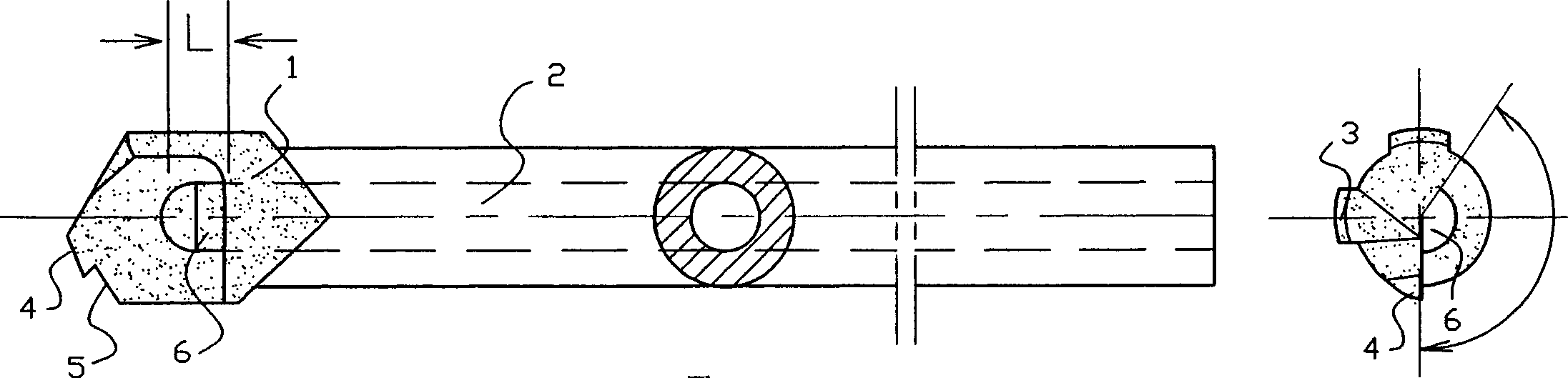

[0014] figure 1 Among them, the integrally sintered cemented carbide drill bit 1 and the cavity drill pipe 2 are butt-welded to each other. Two guide bars 3 and a cutting edge 4 are fired on the drill bit 1. The cutting edge 4 has no chip breaker, and the outer edge of the cutting edge 4 There is a chip splitting edge 5 ground behind the edge. The lower semicircle of the lower jaw cavity of the chip outlet 6 extends L=3mm toward the cutting edge 4, and the opening angle α of the chip outlet 6 is 150°.

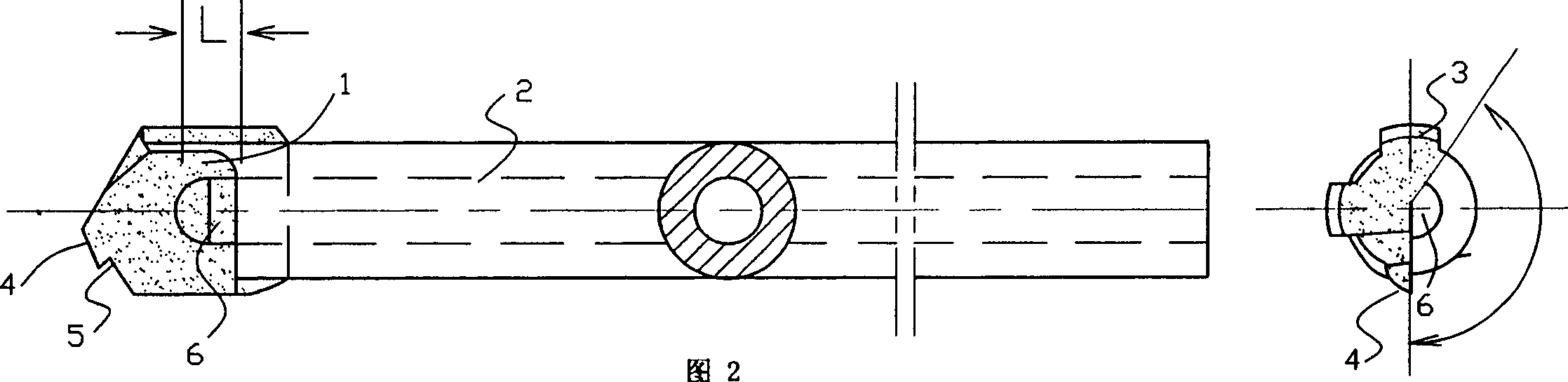

[0015] In Fig. 2, the guide bar 3 and the cutting edge 4 of the cemented carbide cutting part are wire cutting "T" shaped blades, and the rest of the structure and shape are the same as figure 1 same.

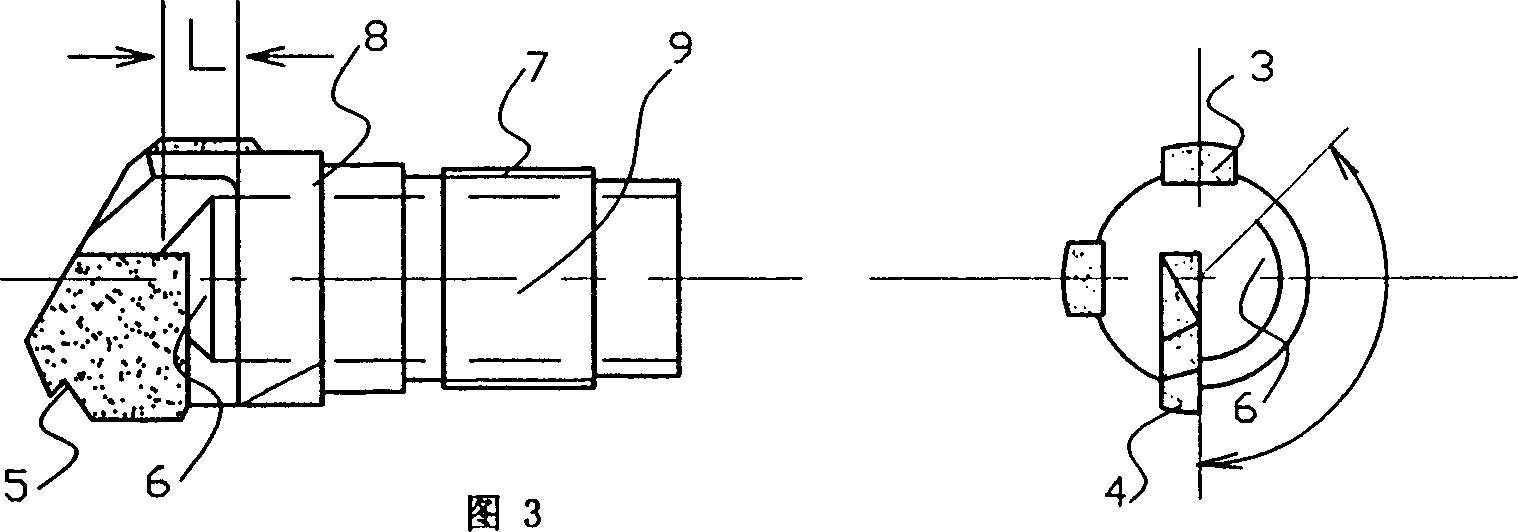

[0016] In Fig. 3, two carbide guide bars 3 and one carbide cutting edge 4 are welded on the steel alloy drill body 8, and the cutting edge 4 has no chip breaker. The shank 9 of the drill body 8 is provided with a square thread 7 for connecting with a drill rod. The outer edg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com