Horizontal sand prevention vicious pump

A sand control and horizontal technology, applied in the direction of pumps, pump components, variable capacity pump components, etc., can solve the problems of reduced pump efficiency, shortened pump inspection cycle of thickening pump, pump stuck, etc., and achieve the effect of improving pump efficiency and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

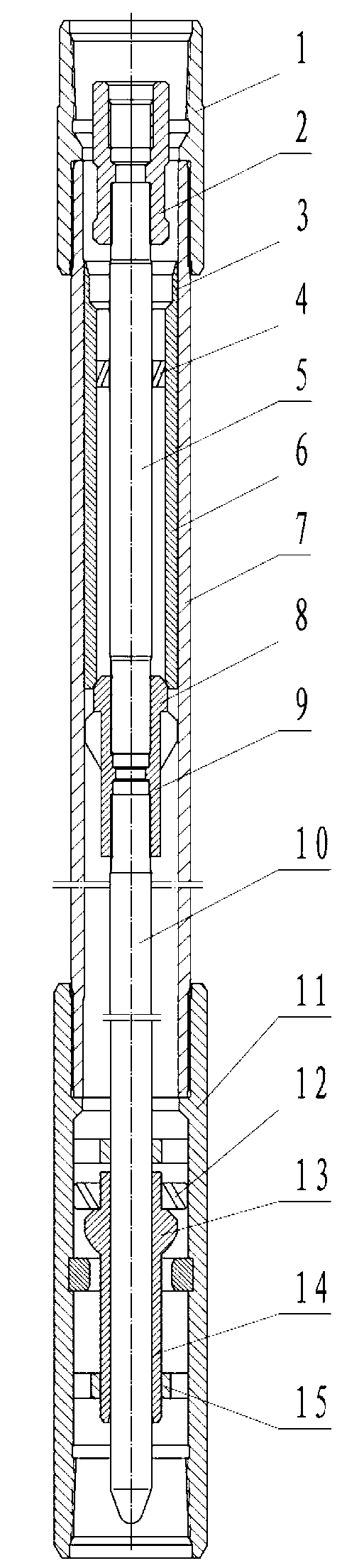

[0016] Such as figure 1 A horizontal sand control thickening pump is shown, which includes a pump barrel assembly, a fixed valve assembly and a plunger assembly, the plunger assembly is inserted into the pump barrel assembly and the fixed valve assembly, and the pump barrel assembly includes a pump barrel collar 1 , the upper pump barrel 7, the bridge outer pipe 11 and the guide sleeve 15; the fixed valve assembly includes the fixed valve 13 and the lower pump barrel 14; the plunger assembly includes the tie rod collar 2, the pull rod 5, the upper plunger 6. Swimming valve 8, tie rod joint 9 and lower plunger 10. The upper end of the upper plunger is designed with a sand scraping cup 3 with the small end facing inward. The upper end of the tie rod is connected to the sucker rod column through the tie rod coupling, and the lower end is connected to The lower plunger is connected in series, the upper plunger is set on the outside of the tie rod, and can move up and down along th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com