A method for adjusting axial gap between stator and rotor of screw pump

A technology of axial clearance and adjustment method, which is applied in pumps, pump control, earthwork drilling and production, etc., and can solve problems such as the diameter increase of coaxial double hollow sucker rods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

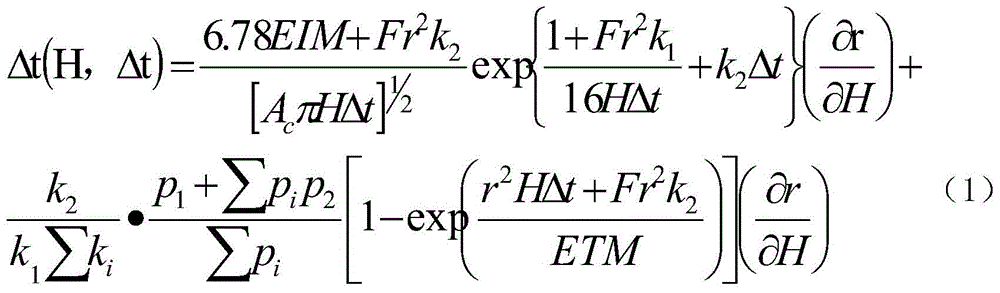

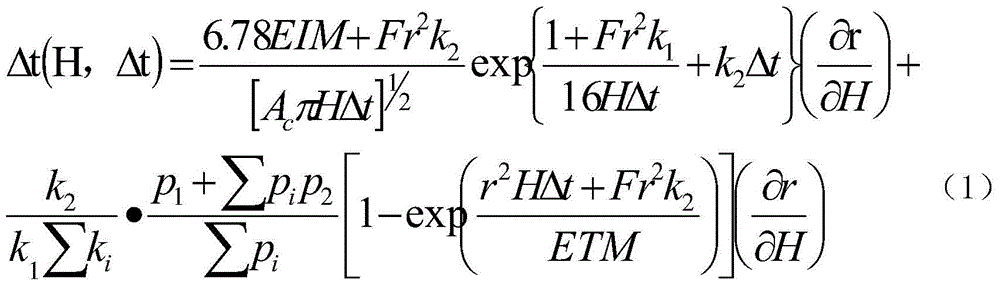

[0046] Taking well X-67 as an example, the method of adjusting the length of the axial clearance between the stator and rotor of the screw pump is explained.

[0047] Contains the steps of measuring the stator and rotor data of the screw pump;

[0048] Data include: coaxial double hollow sucker rod running depth, temperature difference between inlet and outlet;

[0049] The length of the axial gap between the stator and the rotor of the screw pump; the quality of the heat carrier softened water in the coaxial double hollow sucker rod, the flow rate of the heat carrier softened water in the coaxial double hollow sucker rod; the coaxial double hollow sucker rod The pressure of the circulating water in the internal circulation, the cross-sectional area of the oil pipe, the radius of the coaxial double hollow sucker rod body, the elongation per kilometer of the coaxial double hollow sucker rod, and the elasticity of the coaxial double hollow sucker rod Modulus, the polar moment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com