Absorption tower for wet flue gas desulfurization

A technology of wet flue gas desulfurization and absorption tower, which is applied in the fields of flue gas desulfurization devices and wet flue gas desulfurization absorption towers. Effects of material and performance optimization, increased service life, and reduced maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

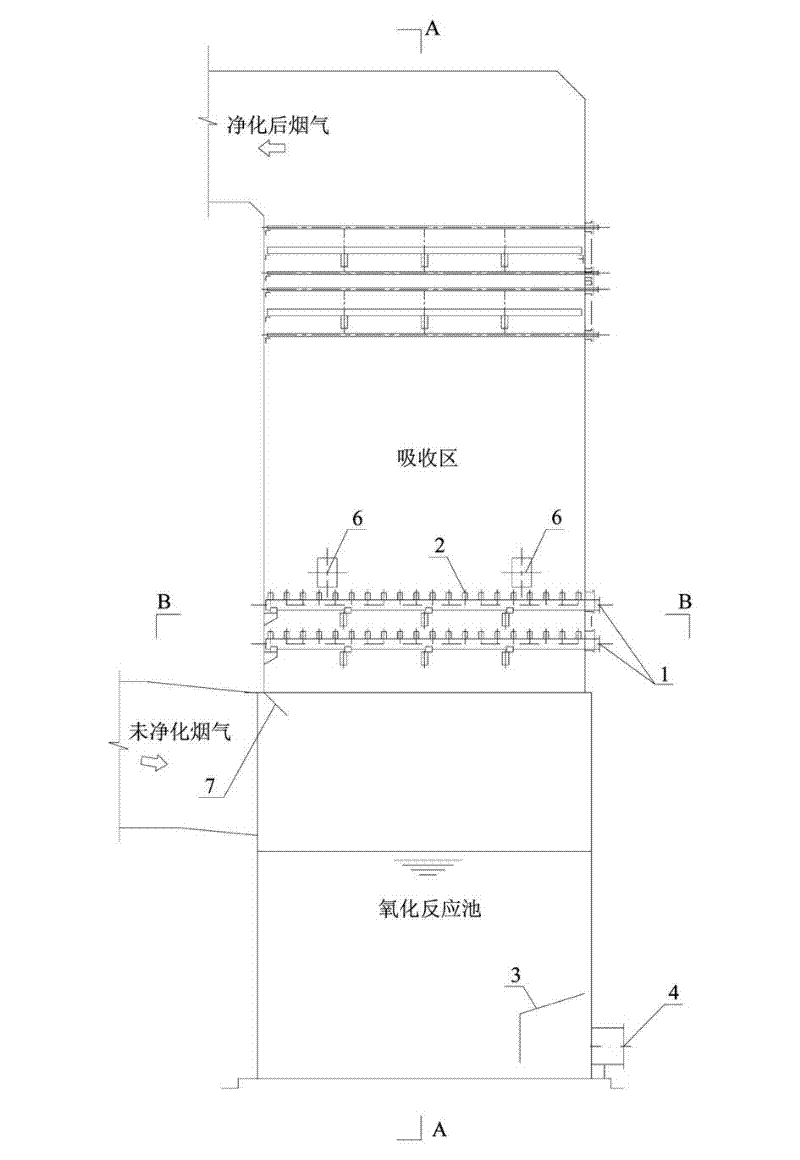

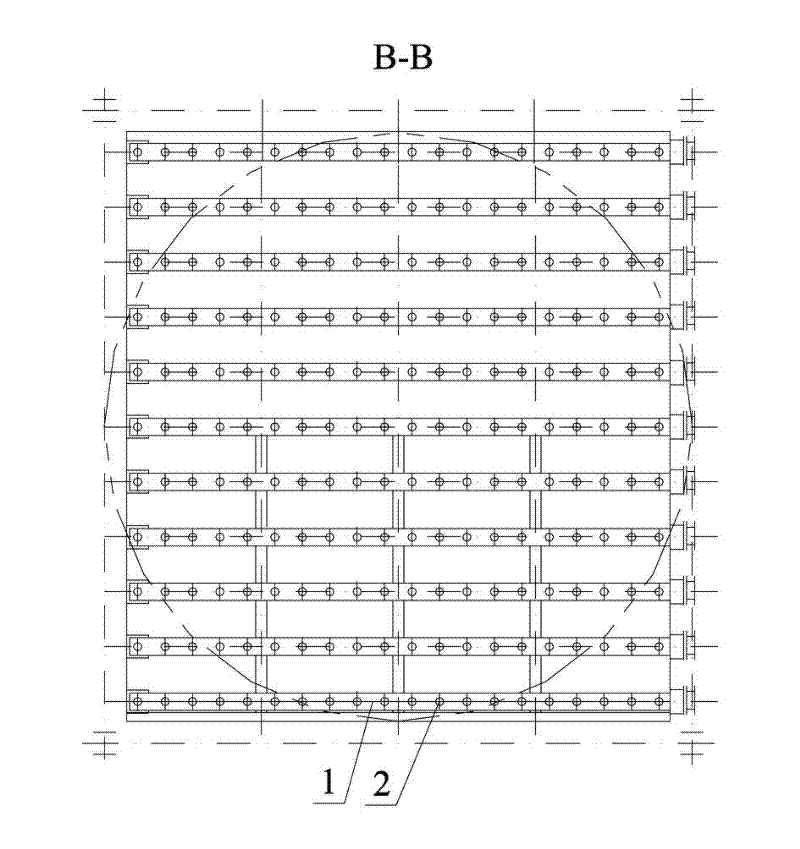

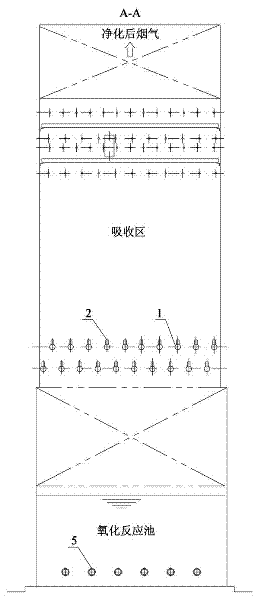

[0030] According to attached Figure 1~4, a wet flue gas desulfurization absorption tower adopts limestone-gypsum wet flue gas desulfurization technology, including two parts, an oxidation reaction pool and an absorption zone. A circular oxidation reaction pool is arranged below the absorption tower, and a square absorption zone is arranged above, and a spray pipe 1 and a nozzle 2 connected with the spray pipe are arranged in the lower part of the absorption zone. The spray pipe 1 is a concentric variable-diameter pipe with two layers, and the upper and lower layers are arranged in staggered layers. The spray pipe 1 and the nozzle 2 are connected by flanges. The installation angle of the nozzle 2 connected to the spray pipe 1 is vertically upward. The planar distribution of the absorption area is grid-shaped, the distance between nozzles is 450-550mm, and the distance between nozzles and the side wall of the absorption tower is 200-250mm. Side-entry agitators are evenly distr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com