A flash suspension chlorination method for titanium-containing raw materials

A titanium raw material, titanium tetrachloride technology, applied in the direction of titanium tetrachloride, titanium halide, etc., can solve the problems of strict impurity indicators of titanium-containing raw materials, achieve sufficient gas-solid contact area and time, ensure separation efficiency, and run The long-term effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

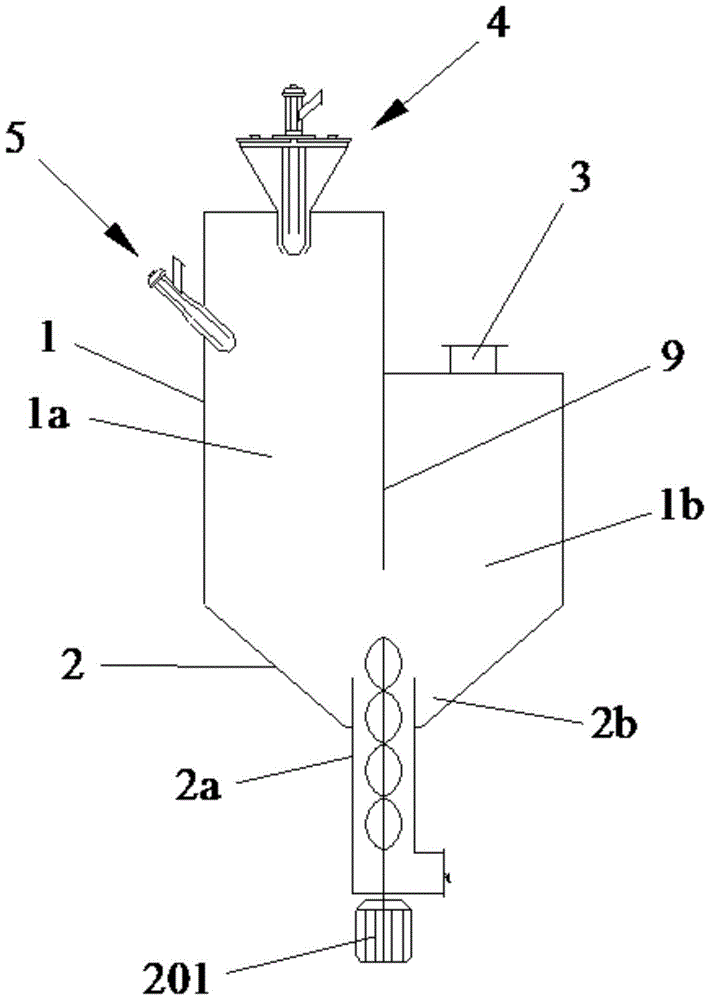

[0054] This embodiment is a flash suspension chlorination method for titanium-containing raw materials, and its schematic diagram is as follows figure 1 shown.

[0055] The reaction is carried out by using a reaction furnace with a reaction chamber and an evacuation chamber. The reaction chamber and the evacuation chamber are separated from each other by a partition to form a U-shaped communication structure. When the flash suspension chlorination process is working, first use the heat preservation nozzle in the furnace to spray natural gas and air into the furnace to raise the temperature in the furnace. The hot air makes the temperature in the furnace reach 550~1000°C, and slowly inject carbon-containing fuel through the heat preservation nozzle. At this time, the charcoal-containing fuel is ignited in the furnace, so that the temperature in the furnace reaches the normal reaction temperature of 600~1000°C. After maintaining this temperature, stop adding air into the furnace...

Embodiment 2

[0077] Reactor equipment

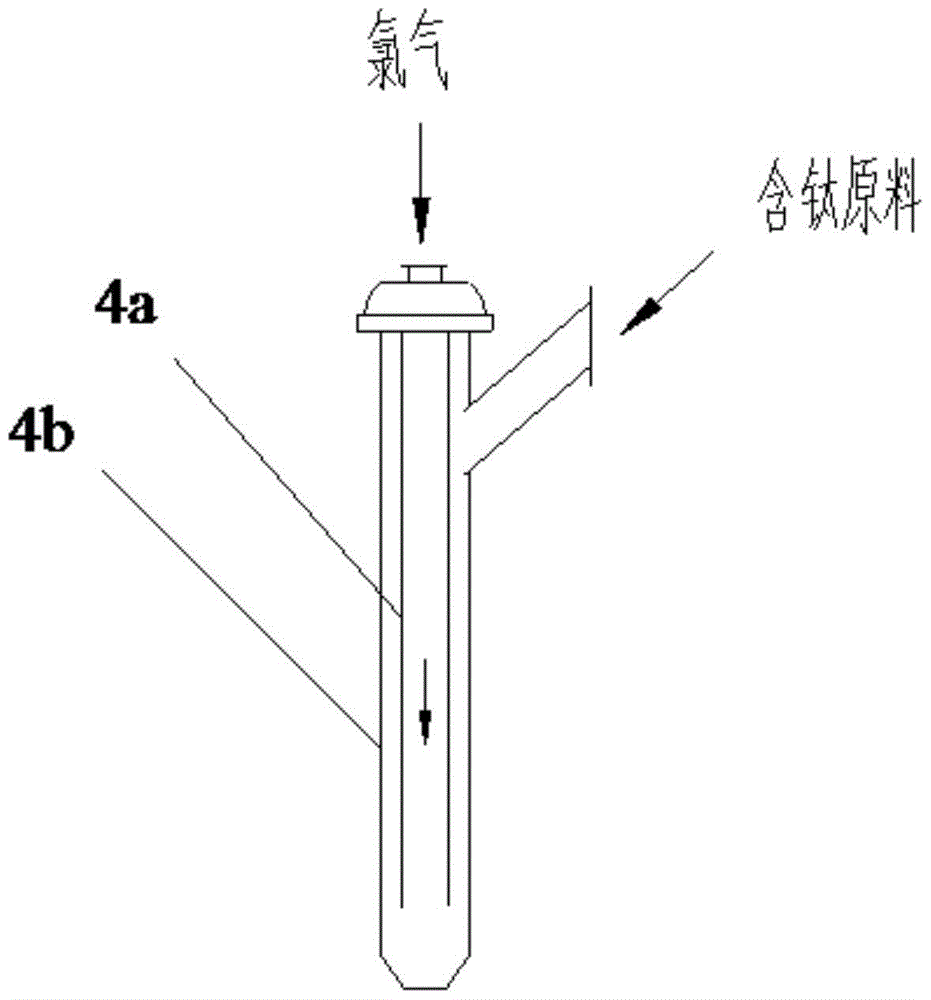

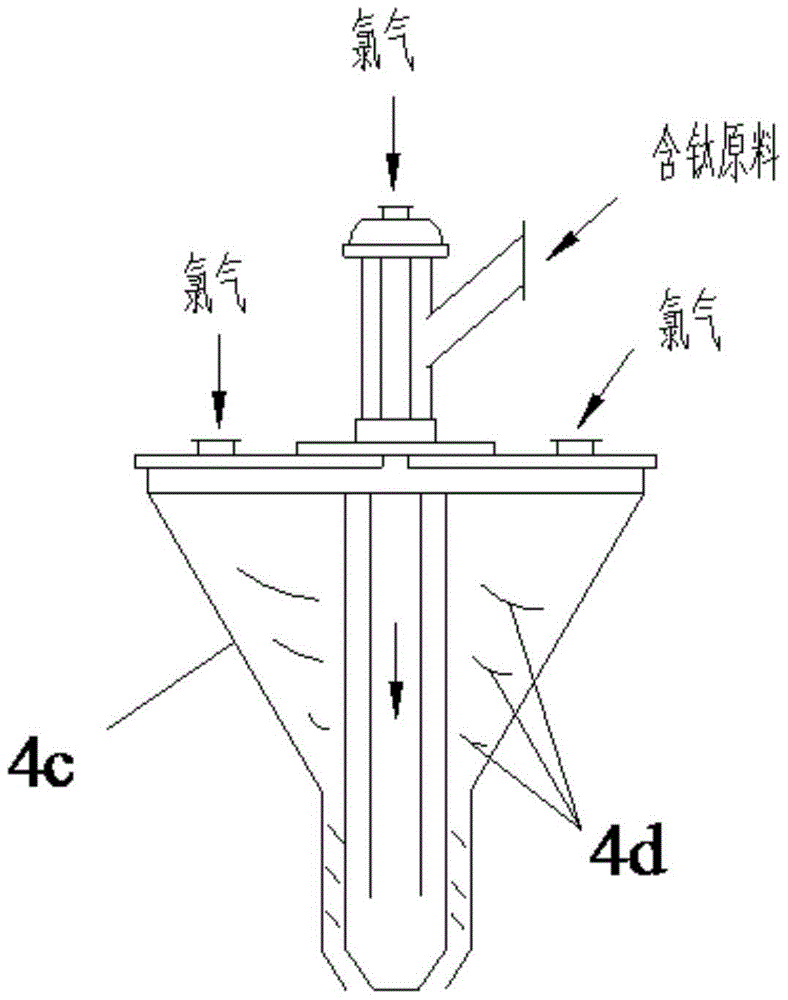

[0078] Such as Figure 1-4 As shown, the suspension chlorination furnace for producing titanium tetrachloride includes a vertical furnace body 1, and a partition plate 9 is arranged in the middle of the vertical furnace body 1 to separate the furnace chamber into a reaction chamber 1a and an emptying chamber 1b. The lower part of the reaction chamber 1a and the evacuation chamber 1b are connected, and the two form a U-shaped flow channel. The conical furnace bottom 2 is arranged at the bottom of the vertical furnace body 1, and the conical furnace bottom 2 has a slagging outlet 2a. An exhaust flue 3 is provided in the upper part of the evacuation chamber 1b. A swirl flow dispersing nozzle 4 is installed on the top of the reaction chamber 1 a for spraying chlorine gas and titanium-containing raw materials into the reaction chamber 1 a in the vertical furnace body 1 . A furnace heat preservation nozzle 5 is installed on the side of the reaction cha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com