Method and system for producing high concentration carbon dioxide of carbon-13

A carbon dioxide, high-concentration carbon technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of inability to directly obtain carbon-13 products, large investment and energy consumption, and high requirements for instruments, so as to prevent blockage accidents. , the effect of saving energy consumption and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

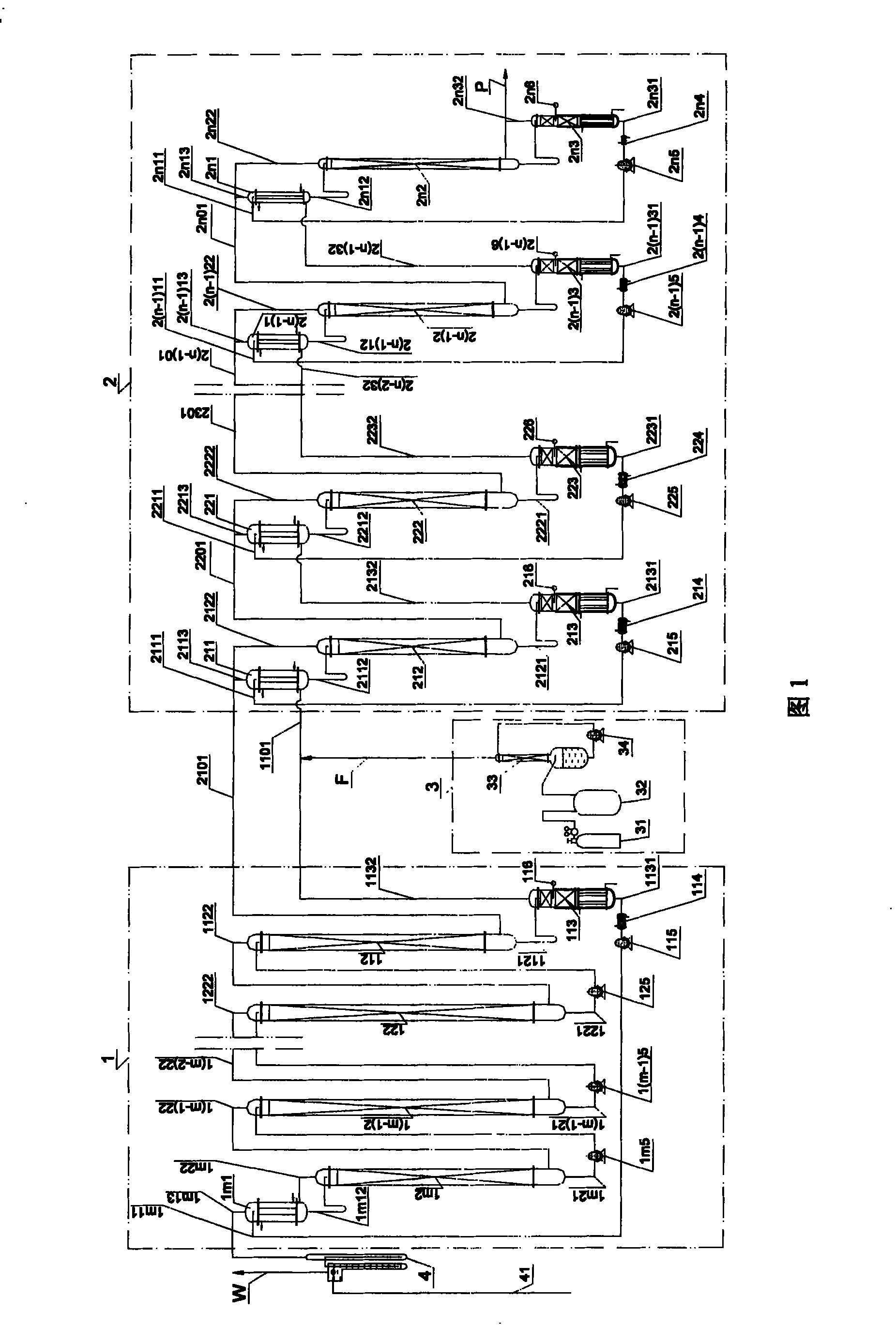

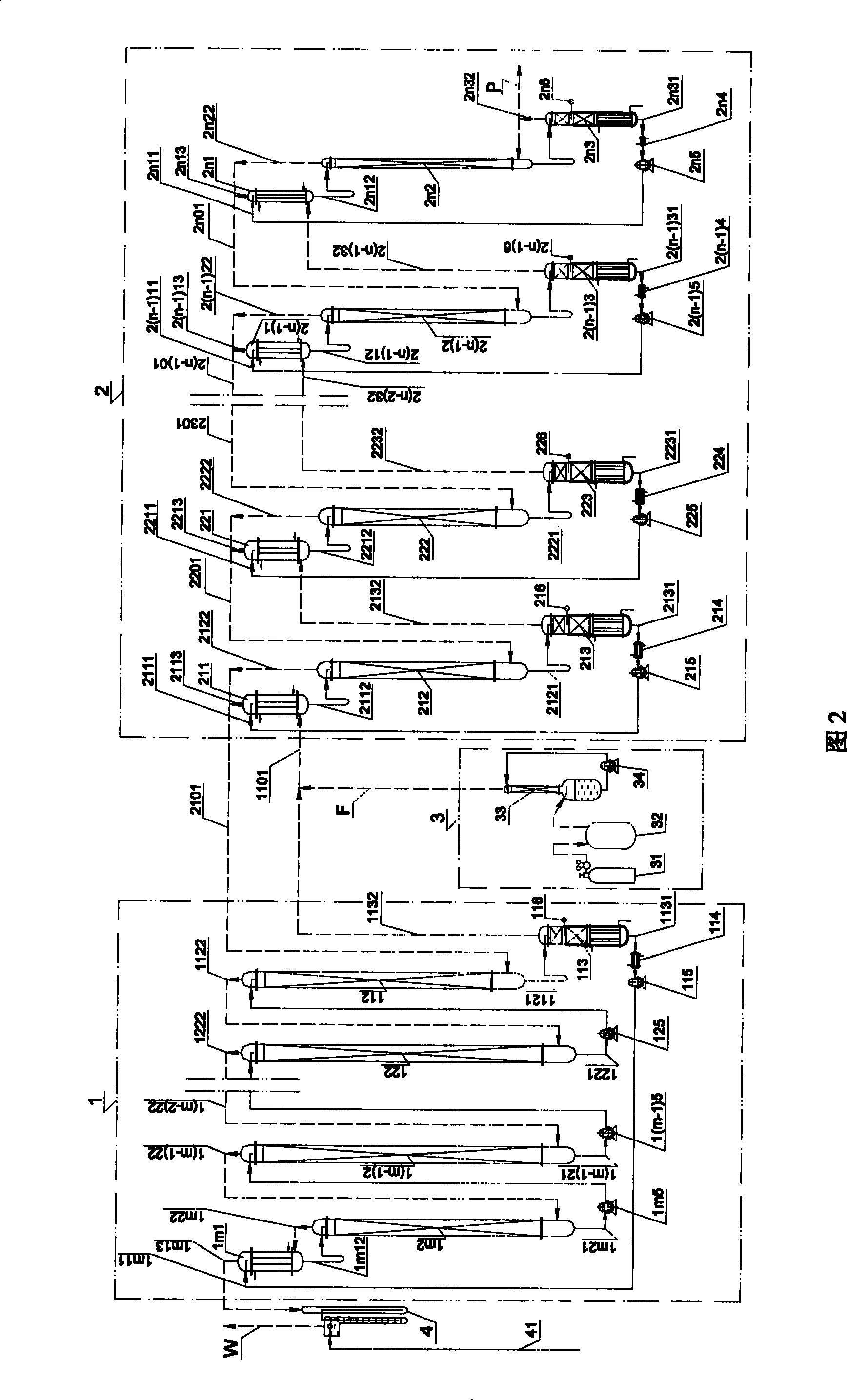

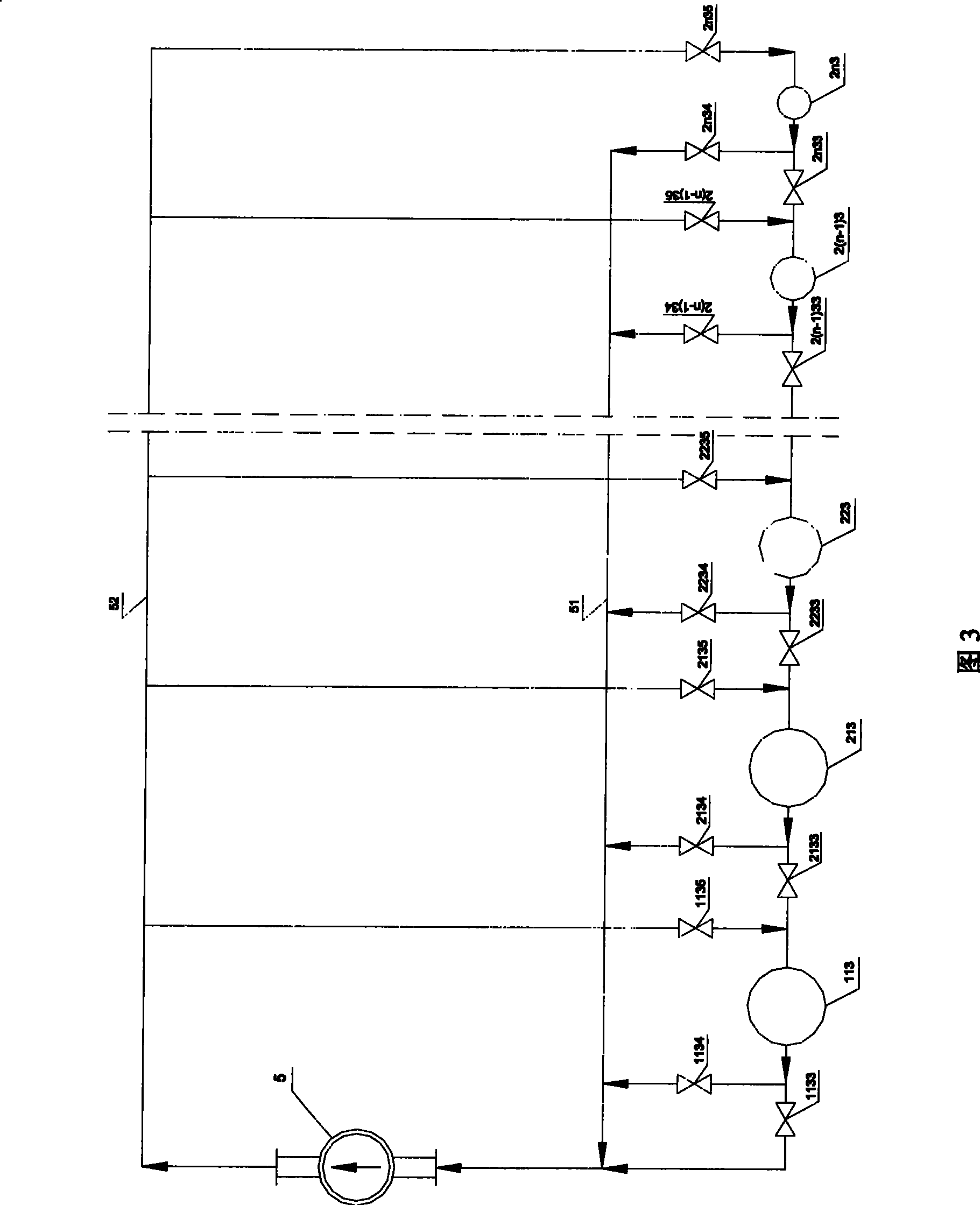

[0044] Figure 1 shows an embodiment of the system for producing high-concentration carbon-13 carbon dioxide according to the present invention. The system for producing high-concentration carbon-13 carbon dioxide includes a concentration cascade subsystem 2 for the concentration section, an extraction cascade subsystem 1 for the extraction section, a raw material supply subsystem 3 , and a tail gas scrubbing constant pressure device 4 .

[0045] In this embodiment, the concentration cascade subsystem 2 includes n-level concentration units connected by pipelines in a cascade manner, where n is a positive integer. Each level of concentration unit includes a concentration tower 212 (the corresponding other concentration towers are marked as 222, ... 2(n-1) 2, 2n2), and a cold reflux tower 211 ( The markings of other corresponding cold reflux towers are 22...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com