A combined mining method for collapsed old goaf and lower coal seam coalbed methane

A technology of combined mining and old empty area, which is applied in the direction of mining fluid, mining equipment, earthwork drilling and mining, etc., can solve the problems of infeasibility, small contact surface, waste of coal resources, etc., and achieve the goal of avoiding high drilling accident rate and saving costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is further illustrated by the following examples, but not limited to the following examples.

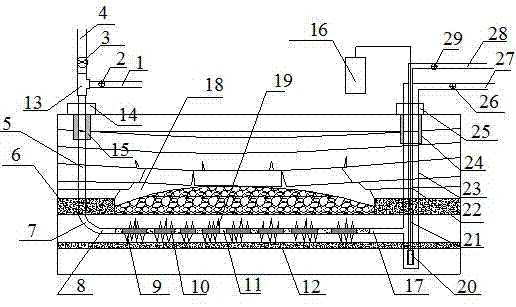

[0030] In order to have a clearer explanation of the technical objectives, features and effects of the present invention, a method for combined exploitation of caving old gobs and lower coalbed coalbed methane will now be described in detail in conjunction with the accompanying drawings.

[0031] Taking a certain working face of Yuecheng Mine of Shanxi Coal Group as an example below, the inventive method is illustrated. Yuecheng Mine is located in Qinshui Coalfield, which is one of the important coalfields rich in coalbed methane resources in my country. The recoverable coal seams in the coalfield are No. 3 coal seam of Shanxi Formation and No. 9 and No. 15 coal seams of Taiyuan Formation. Due to history and outdated mining methods, the recovery rate of No. 3 coal in the main coal seam in the coalfield is low, a large amount of coal is left underground, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com