Three-cycle natural gas liquefaction device and method suitable for ultra-large scale

A super-large-scale, liquefaction device technology, applied in liquefaction, refrigeration, liquefaction, solidification, etc., can solve the problems that cannot meet the needs of LNG device construction, and achieve the effect of rich system adjustment means, less process equipment, and good operation adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

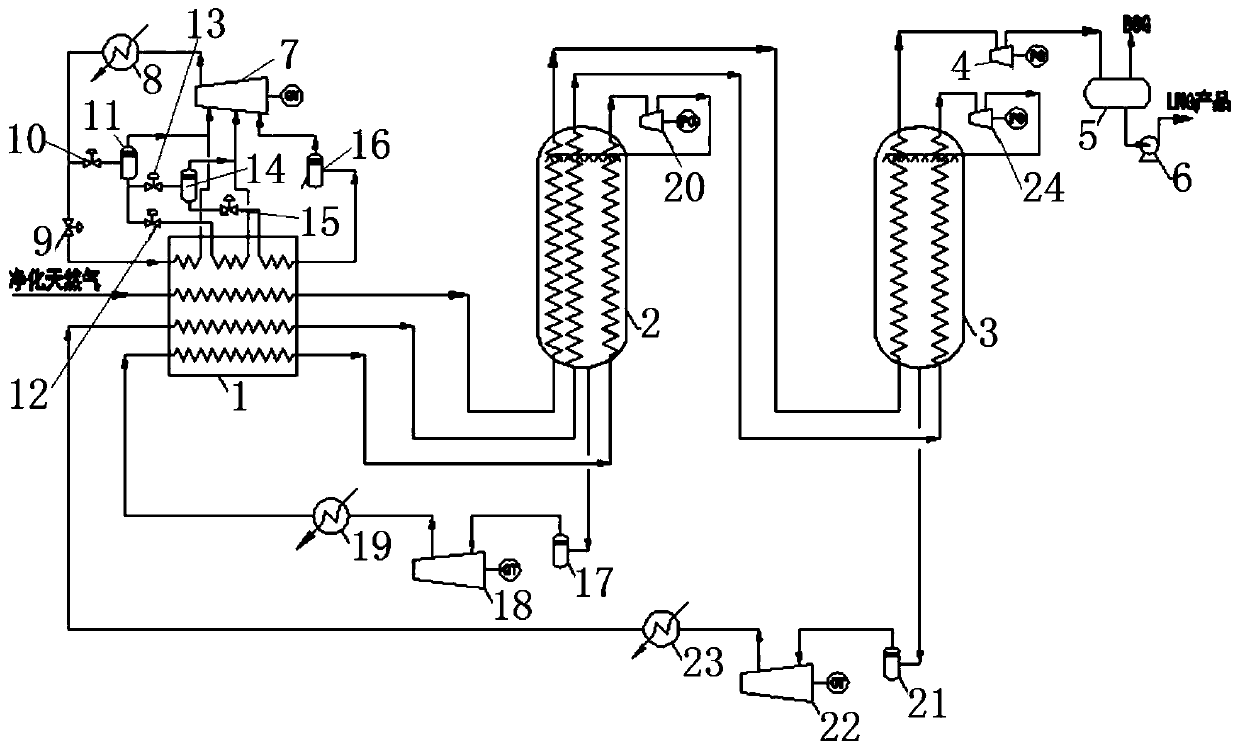

[0030] A three-cycle natural gas liquefaction device suitable for ultra-large scale, such as figure 1 As shown, including: propane pre-cooling plate-fin heat exchanger 1, WMR coiled tube heat exchanger 2, CMR coiled tube heat exchanger 3, LNG hydraulic turbo expander 4, LNG flash tank 5, LNG Booster pump 6, propane compressor 7, propane compressor outlet cooler 8, first high-pressure propane throttle valve 9, second high-pressure propane throttle valve 10, high-pressure propane gas-liquid separation tank 11, first medium-pressure propane section Throttle valve 12, second medium-pressure propane throttle valve 13, medium-pressure propane gas-liquid separator tank 14, low-pressure propane throttle valve 15, low-pressure propane gas-liquid separator tank 16, WMR compressor inlet buffer tank 17, WMR compressor Machine 18, WMR compressor outlet cooler 19, WMR hydraulic turbo expander 20, CMR compressor inlet buffer tank 21, CMR compressor 22, CMR compressor outlet cooler 23, CMR hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com