Natural-gas low-temperature helium extracting system and method

A natural gas and low temperature technology, applied in the field of natural gas low temperature helium extraction system, can solve the problems of high requirements on tower material, small average temperature difference, poor ability to change working conditions, etc., and achieve the effects of abundant adjustment means, high operating pressure and stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

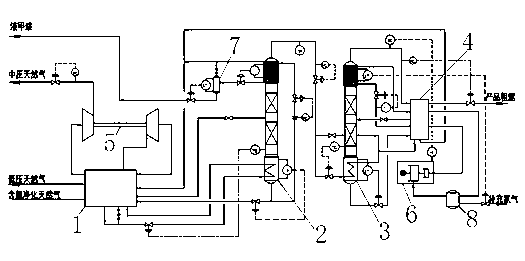

[0028] A natural gas cryogenic helium extraction system, such as figure 1 As shown, it includes: feed gas cooler 1, primary concentration tower 2, secondary concentration tower 3, deep cooler 4, expansion unit 5, nitrogen compressor 6, cooling capacity adjustment tank 7, nitrogen buffer tank 8, etc. ,in:

[0029] The inlet on the left side of raw material gas cooler 1 is connected to purified natural gas containing helium, and the outlet and inlet at the bottom of raw gas cooler 1 are respectively connected to the inlet and outlet of the evaporator at the bottom of primary enrichment tower 2 through pipelines; the right side of raw gas cooler 1 The outlet is connected to the middle inlet of the primary concentration tower 2 through a pipeline; the middle inlet on the right side of the feed gas cooler 1 is respectively connected to the upper outlet of the top condenser of the primary concentration tower 2 and the low-pressure gas outlet at the bottom of the cryocooler 4 through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com