Large-capacity efficient ultra-supercritical tower-type baffle temperature-adjusting brown coal boiler matched with fan mill

An ultra-supercritical, large-capacity technology, applied in the field of boilers, can solve problems such as low efficiency, difficulty in reheating the design value, and inability to guarantee full-load denitrification, and achieve the effect of enriching adjustment means

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

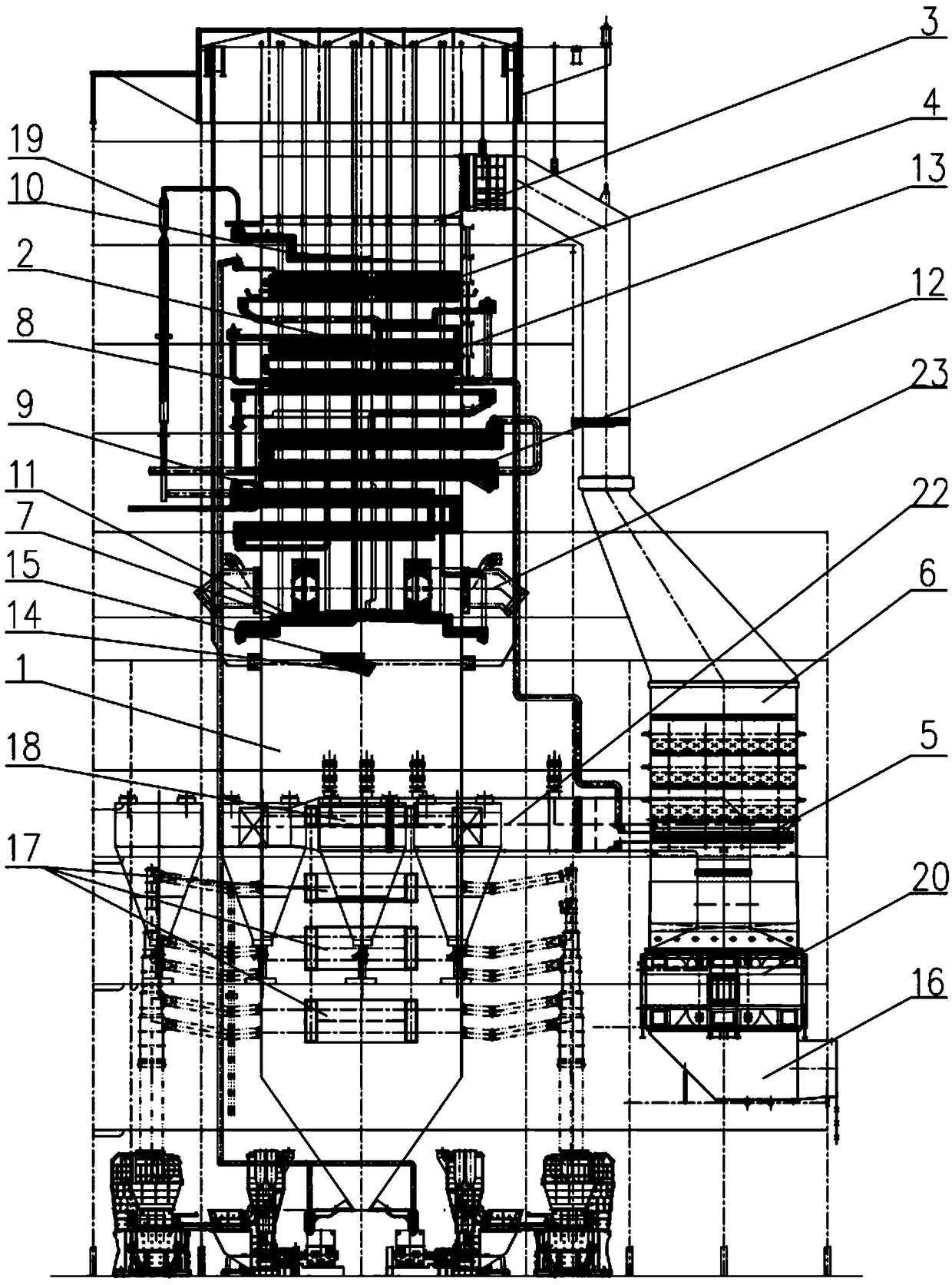

[0014] A large-capacity and high-efficiency ultra-supercritical tower-type temperature-regulated lignite boiler with a fan mill of the present invention includes a boiler body, and the furnace 1 of the boiler body is equipped with an economizer system, a superheater system and a reheater system. A partition wall 2 is provided above the furnace 1 to divide the flue gas into two paths; a flue gas regulating baffle 3 is provided above the partition wall 2 to adjust the ratio of flue gas on both sides of the partition wall 2;

[0015] The economizer system includes a furnace economizer 4 and a flue economizer 5, the furnace economizer 4 and the flue economizer 5 are connected through an economizer connecting pipe; Between the gas regulating baffles 3, the flue economizer 5 is installed in the outlet flue 6 of the denitrification SCR reactor; the heating surfaces in the furnace of the economizer system are arranged in series;

[0016] The superheater system includes a primary super...

specific Embodiment approach 2

[0023] The difference between the second embodiment and the first embodiment is that the inlet tube panel 10 of the primary superheater and the outlet tube panel 11 of the primary superheater are connected and fixed by hanging pipes.

specific Embodiment approach 3

[0024] The difference between the third embodiment and the first embodiment is that the furnace 1 includes a water cooling wall system, and the water cooling wall system includes a spiral coil water cooling wall 14 and a vertical tube coil water cooling wall 15, and the spiral tube coil water cooling wall 14 is used as the middle part of the furnace 1 and the lower part, the vertical tube coil water cooling wall 15 is used as the upper part of the furnace 1, and the spiral tube coil water cooling wall 14 and the vertical tube coil water cooling wall 15 are connected by a mixing header.

[0025] The furnace is surrounded by a water-cooled wall system, which includes two parts, namely, the vertical tube coil water-cooled wall 15 and the spiral tube coil water-cooled wall 14, which are bounded by a mixing header.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com