Patents

Literature

36results about How to "Stable operating pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing aliphatic polycarbonate through continuous solution polymerization method

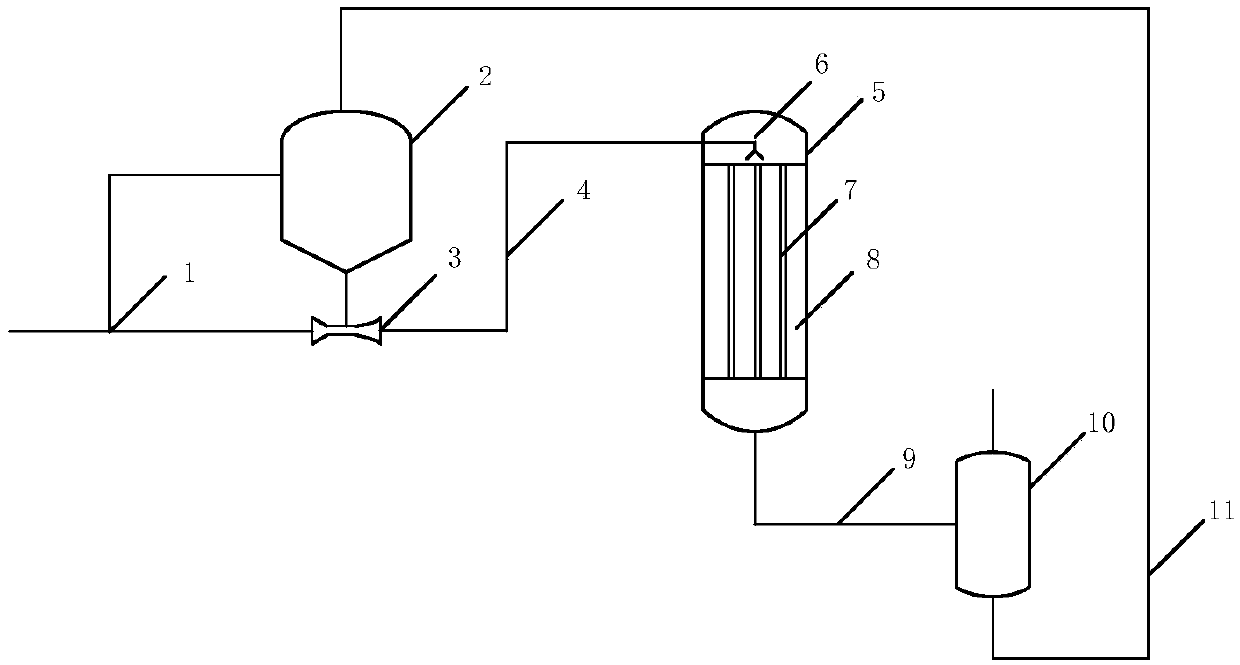

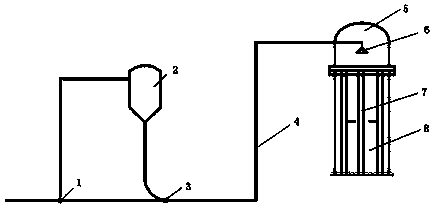

The invention provides a method for preparing aliphatic polycarbonate through a continuous solution polymerization method. The method comprises the following steps of a, injecting an epoxy monomer, carbon dioxide and catalyst into a circulation flow reactor through a continuous way, utilizing a circulation pump to provide power for the reaction materials, circularly returning partial reaction materials to the circulation flow reactor, driving one part of the reaction materials to leave the circulation flow reactor at a speed being identical to the feeding speed to enter a tubular reactor with a built-in static mixer; b, controlling the retention time of the pulp in the tubular reactor through the ratio of the pipe length and the flowing linear speed of the reaction materials, and gradually charging a solvent step by step through a plurality of feeding ports along the length of the tubular reactor; c, feeding an end sealing agent and a stabilizer through a feeding port on the tail end of the tubular reactor to carry out the in-situ chemical or physical modification; d, ensuring the reaction endpoint pulp which continuously flows out of a discharging end to enter a middle-pressure flash evaporator, carrying out the flash evaporation by utilizing the reaction pressure, removing the solvent, and returning the pulp to the tubular reactor after the pulp is condensed; and e, devolatilizing and drying the pulp to obtain a polymerization product.

Owner:BEIJING RISUN TECH CO LTD +1

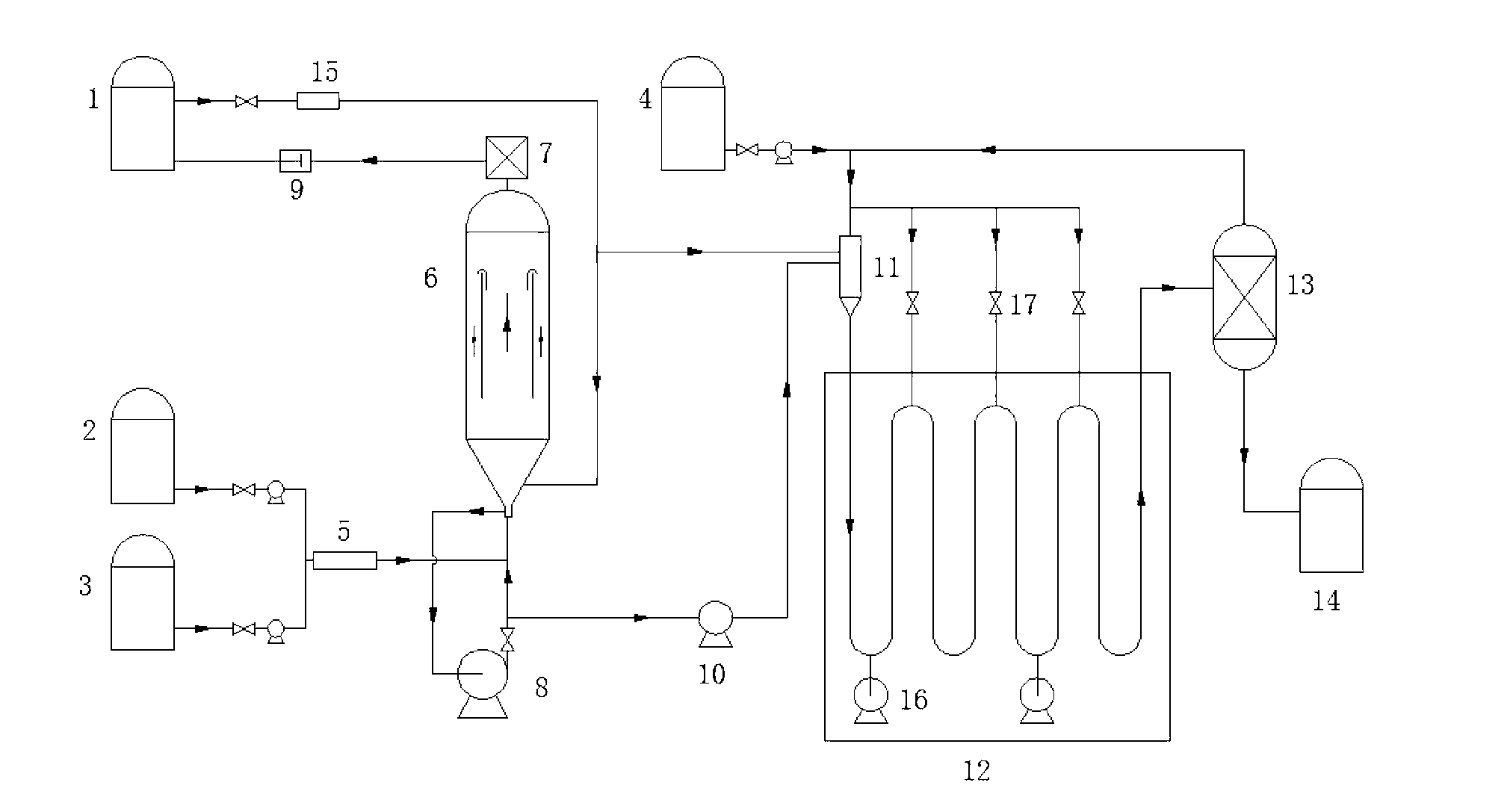

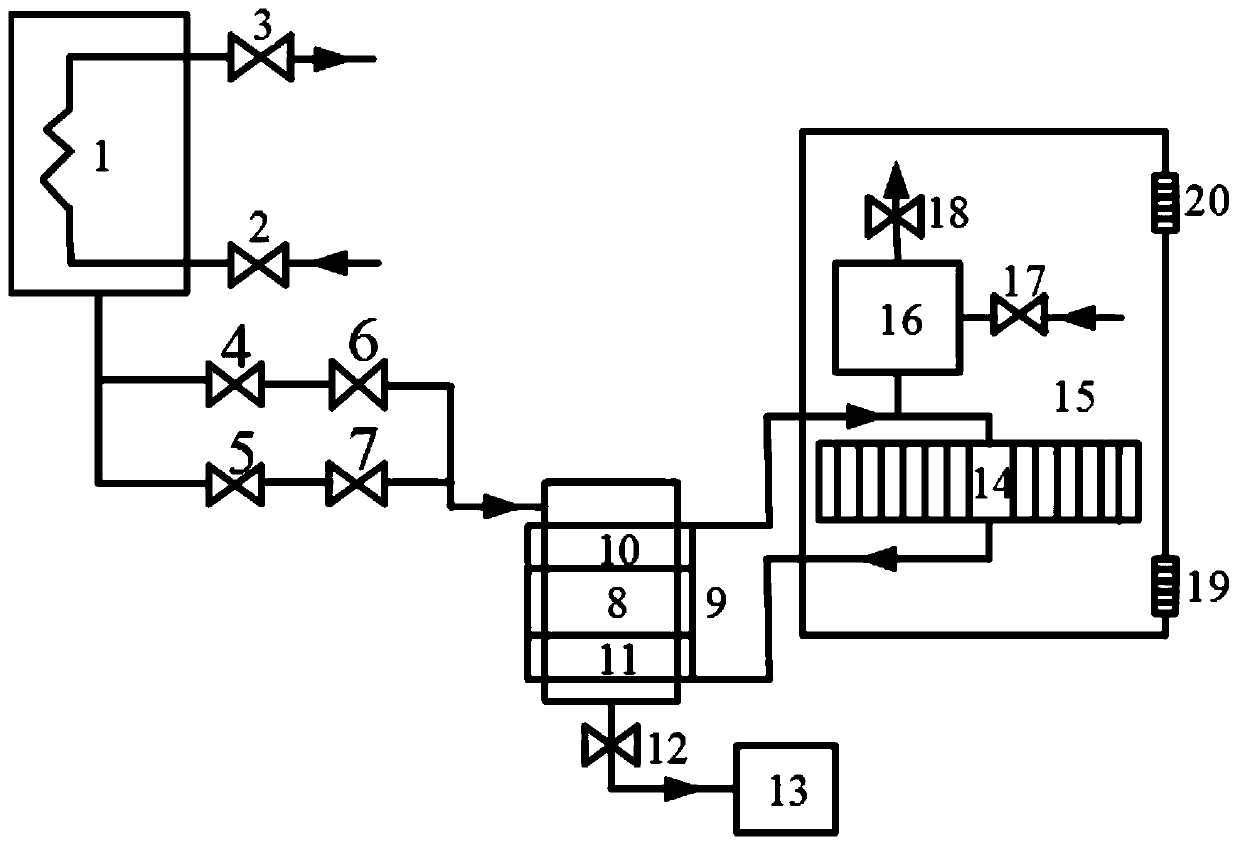

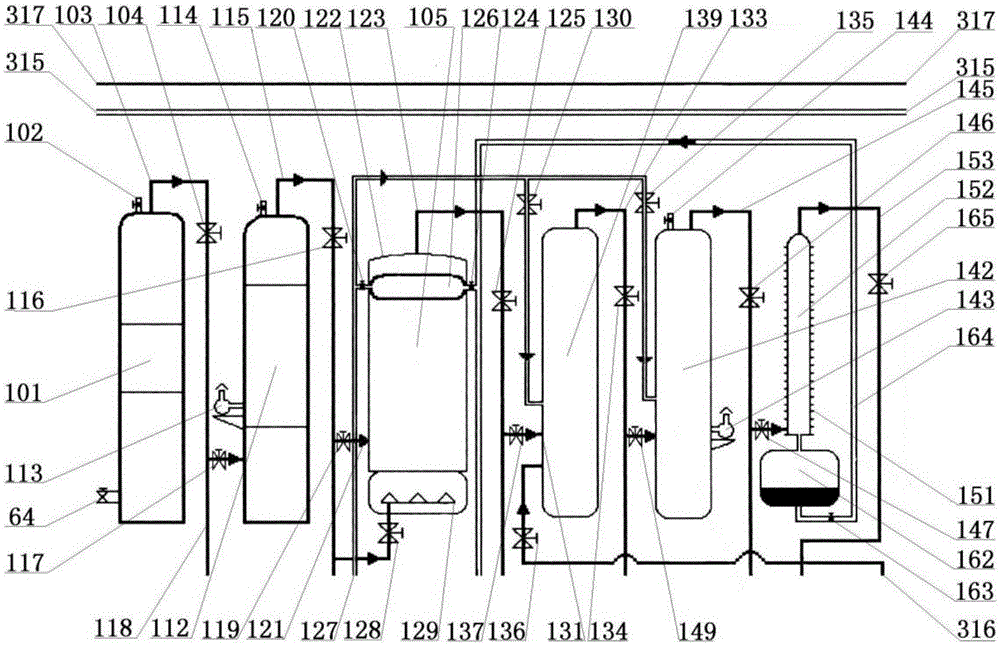

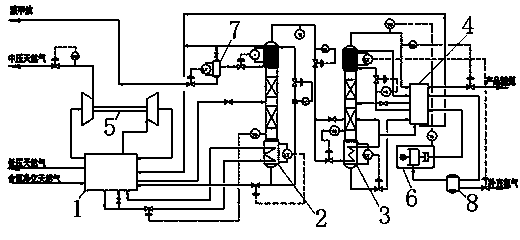

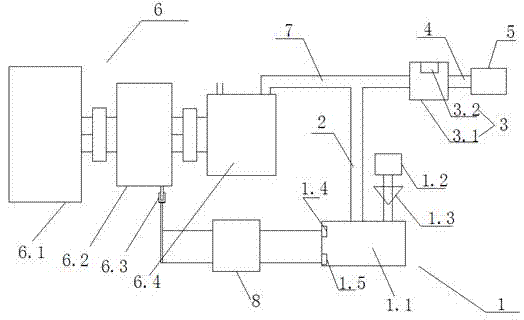

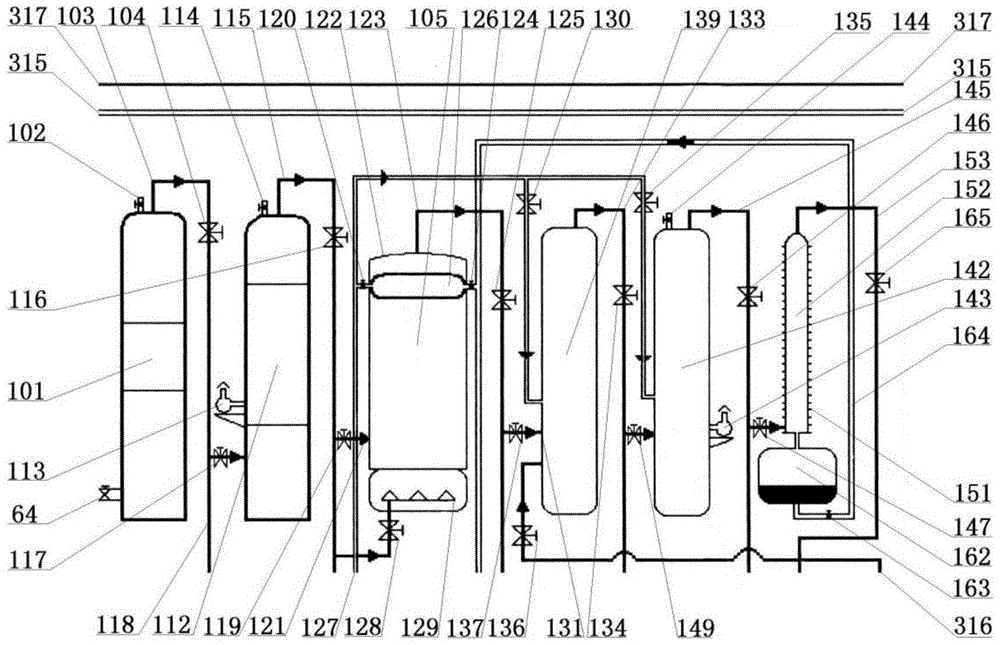

Natural-gas low-temperature helium extracting system and method

ActiveCN102937369ARich adjustment meansReduce energy consumptionSolidificationLiquefactionHigh concentrationEngineering

The invention discloses a natural-gas flow-temperature helium extracting system and a natural-gas flow-temperature helium extracting method. According to the system and the method, the post-expansion and nitrogen circulating refrigerating two-column separating technology is carried out for fully recovering the cooling capacity of the device in order to pre-cool the natural gas which serves as the raw material, and thereby the system can be applied to the natural gas which has an extremely low content of helium, and has the characteristics of being low in energy consumption, high in helium recovery rate, small in investment, flexible in operation, and high in adaptability to variable working conditions. The system and the method have the positive effects that little helium in the helium-containing natural gas can be extracted by a pre-cooling system and a low-temperature rectifying system, an independent nitrogen circulating refrigerating system is adopted and used for supplying an ultralow-temperature cold source required in helium concentration, and the independent system is rich in adjusting means and cannot be influenced by upstream operations; and a post-expansion refrigerating system is adopted, so that the natural-gas low-temperature helium extracting system has the operation pressure higher than that in conventional technology, and higher concentration of the helium can also be obtained at the same refrigerating temperature.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

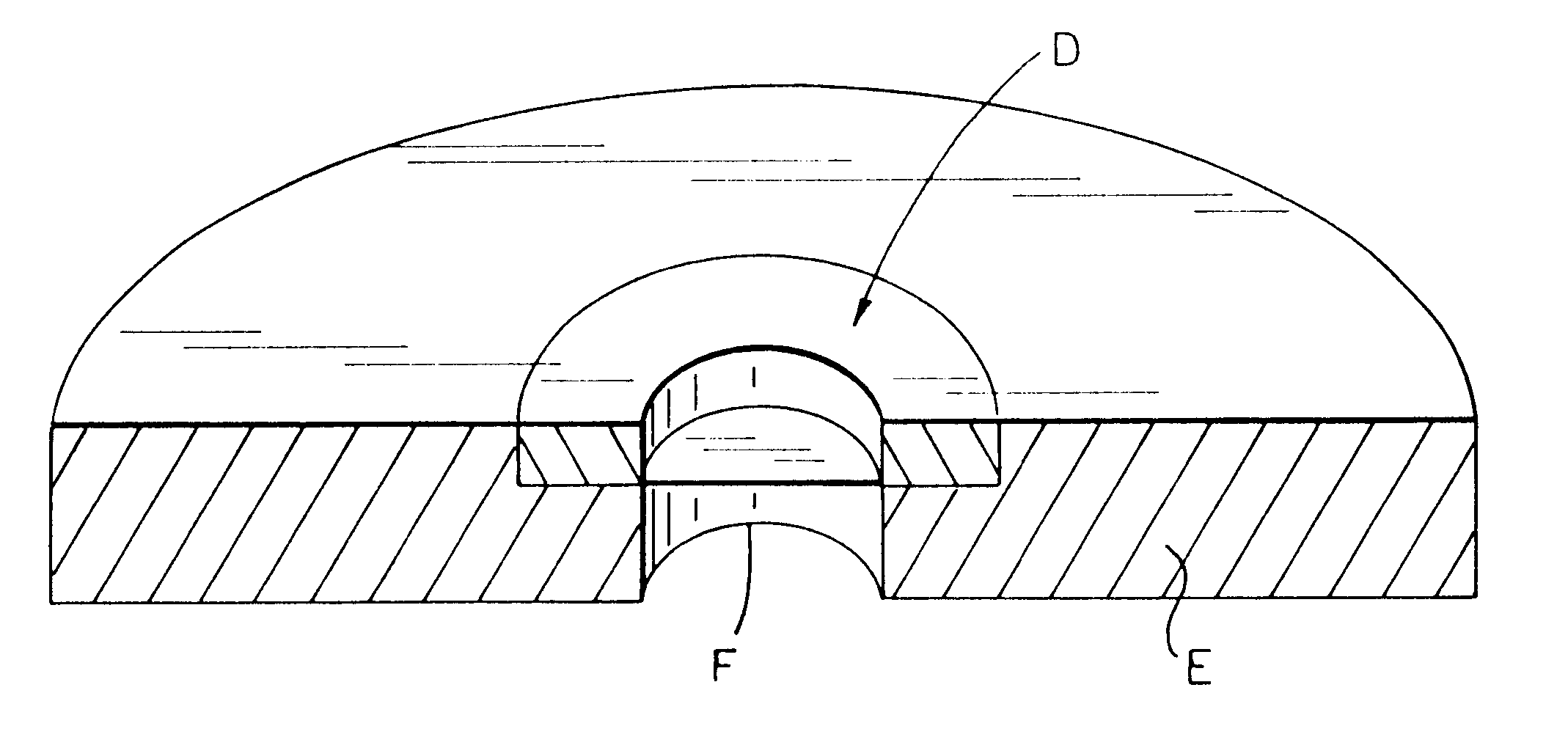

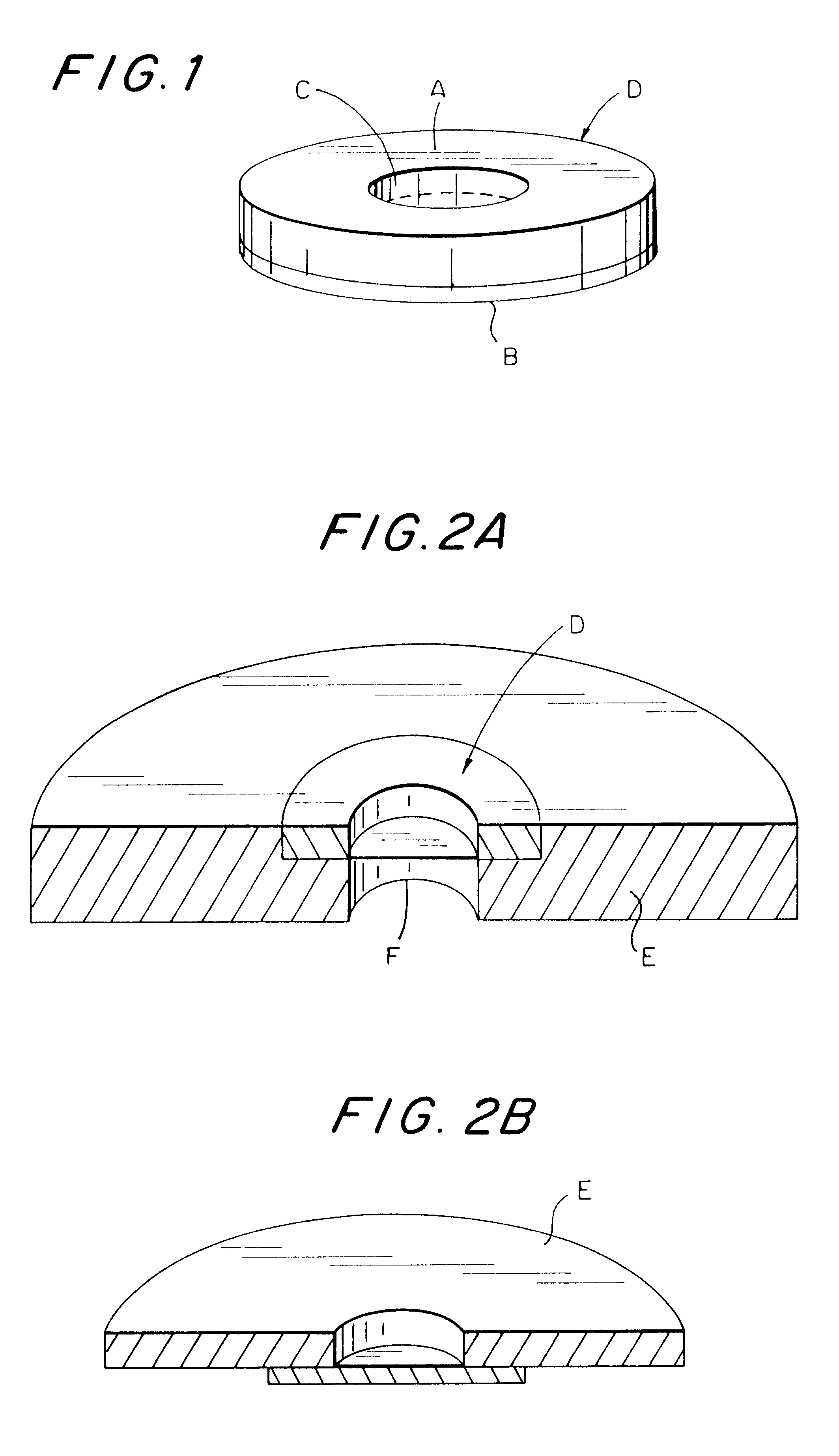

Safety valve element for capacitor and capacitor case lid with safety valves

InactiveUS6257267B1Guaranteed uptimeEasy to manufactureClosuresLarge containersInternal pressureMetal foil

The object of the present invention is to provide safety valve elements for condenser use, which rupture precisely at a predetermined pressure especially stably in a low pressure range so as to release inner pressure outside and can be manufactured readily, and to provide a condenser which incorporates the safety valve elements.The safety valve elements for condenser use according to the present invention comprises a metal substrate A which is provided with a perforated opening C and a metal foil B laid over the metal substrate A to close the perforated opening C.

Owner:TOYO KOHAN CO LTD

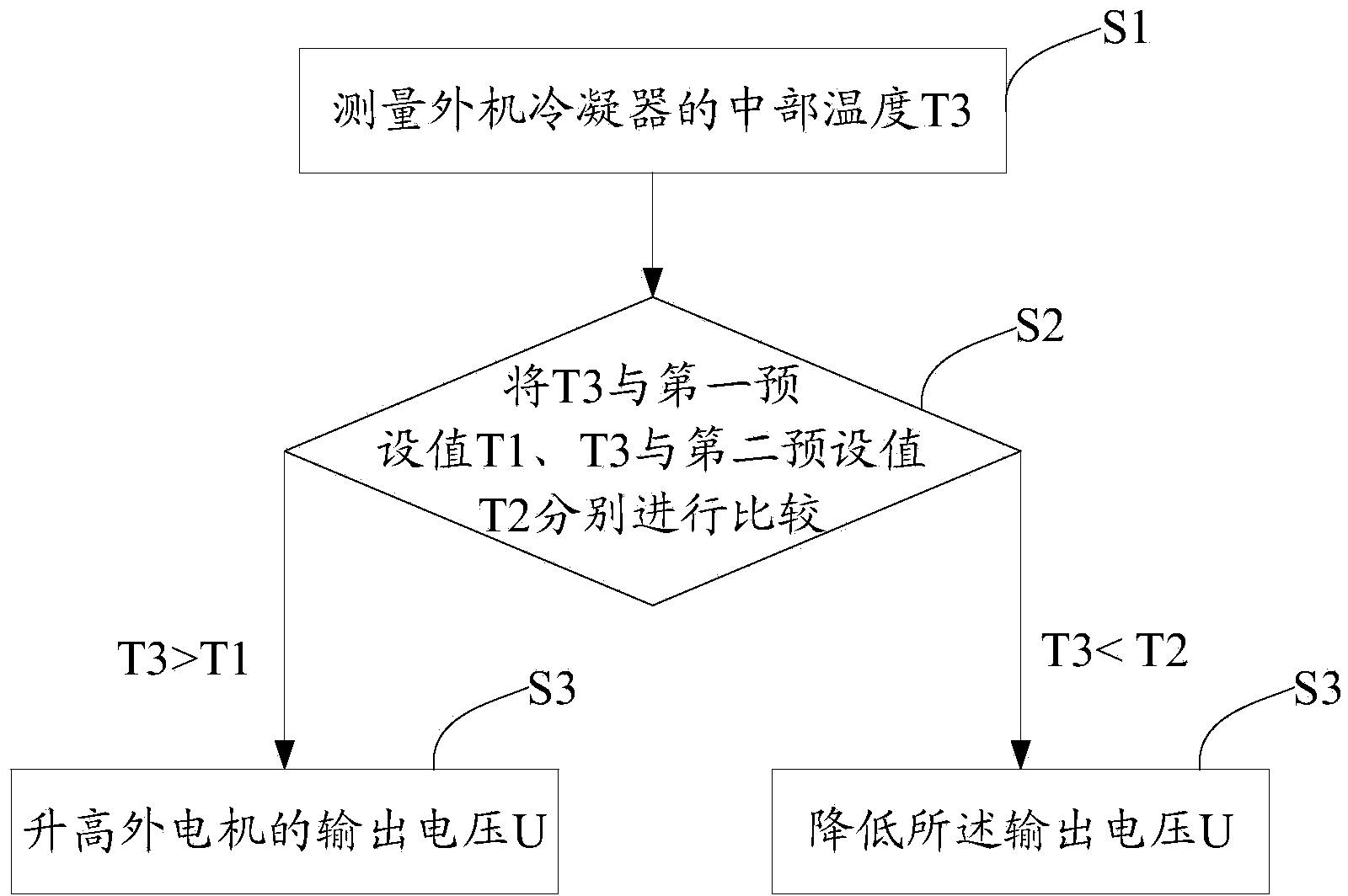

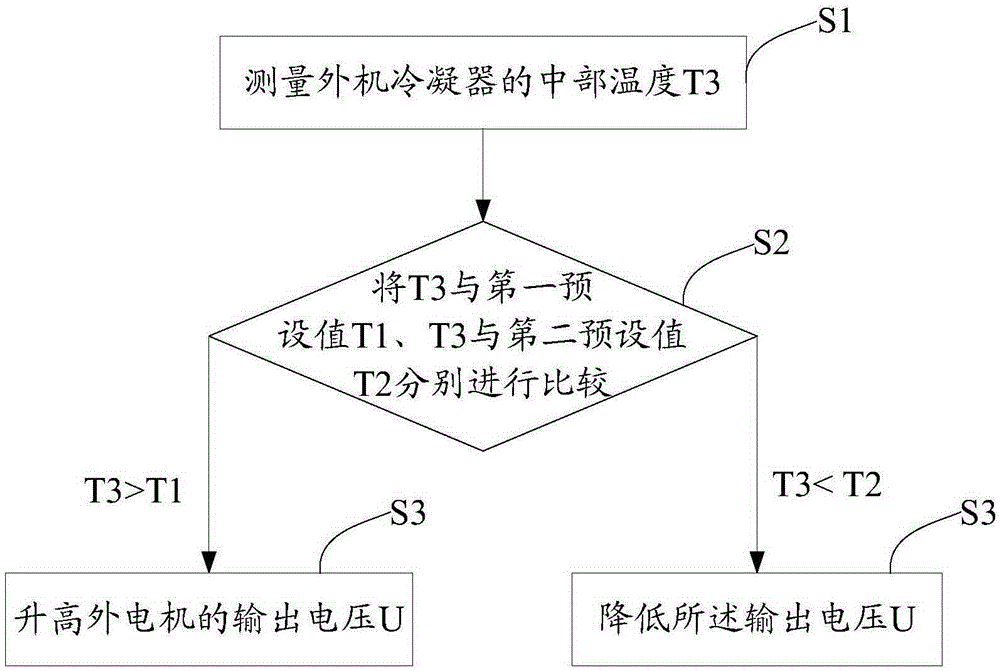

Method for controlling low temperature refrigeration of air conditioner

ActiveCN103411292AIncrease speedReduce speedSpace heating and ventilation safety systemsLighting and heating apparatusElectric machineWorking pressure

The invention provides a method for controlling low temperature refrigeration of an air conditioner. The method comprises the following steps: (1) measuring middle temperature T3 of an outer unit condenser; (2) comparing T3 with first preset values T1 and T3 and a second preset value T2 respectively, wherein T1 is greater than T2; (3) when T3 is greater than T1, raising output voltage U of an external motor so as to increase the rotating speed of an external fan; when T3 is smaller than T2, decreasing the U so as to reduce the rotating speed of the external fan. According to the method for controlling the low temperature refrigeration of the air conditioner, the output voltage U of the external motor is adjusted according to the middle temperature T3 of the condenser so as to adjust the rotating speed of the external fan, and then the T3 is stabilized in a range of T2 to T1. The T3 can reflect the system operation pressure of the air conditioner better, thus the T3 stabilized in the certain range can ensure the working pressure of the condenser, thus the system operation pressure is controlled better; therefore, stable operation of the system is ensured during the low temperature refrigeration of the air conditioner, thus the start and stop times of a compressor are reduced, and the comfort of room is improved.

Owner:GUANGDONG CHIGO HEATING & VENTILATION EQUIP CO LTD

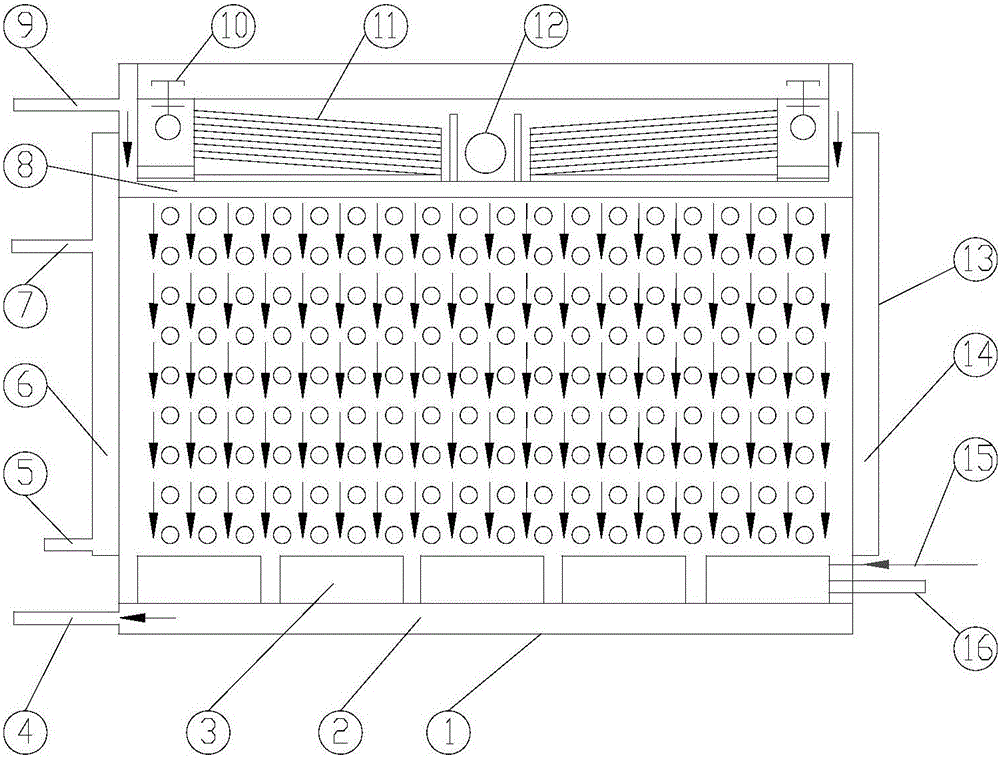

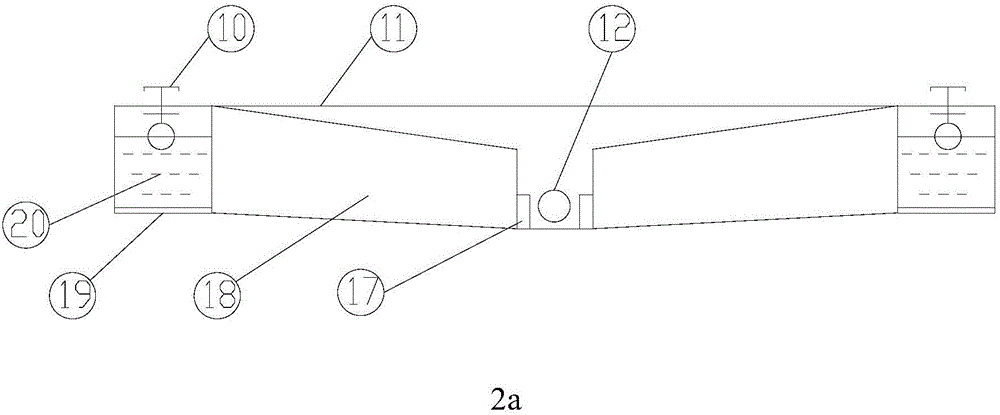

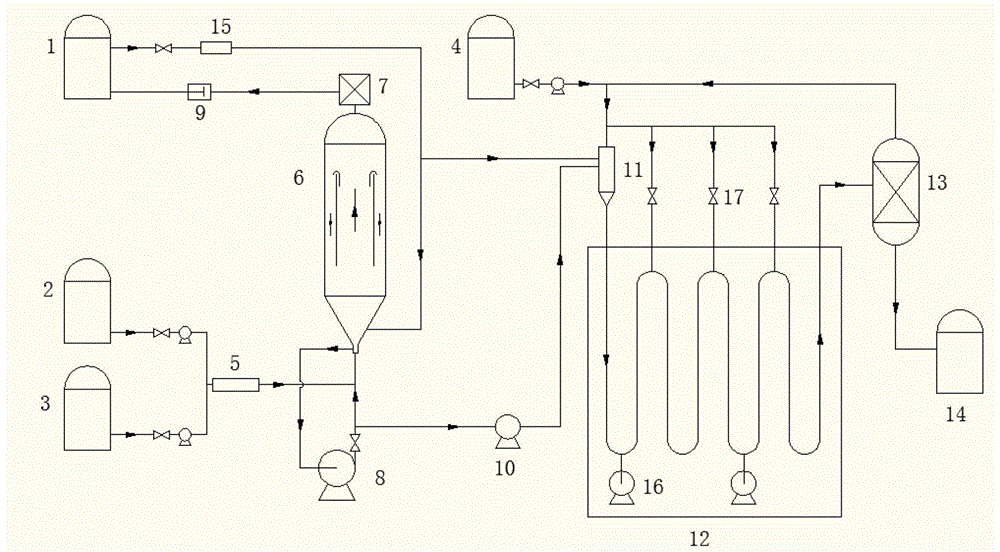

Extraction device and method

ActiveCN106139638AReduce backmixingSolve the problem of strong stirring and mixing extractionLiquid solutions solvent extractionProcess efficiency improvementGas phaseEngineering

The invention provides an extraction device and method. A mixed settler extractor comprises a mixing chamber, an organic liquid film generator, a gas-liquid separation device and a liquid-liquid coalescence separation device. The mixing chamber is provided with a heavy phase input port and a first heavy phase discharge port. The organic liquid film generator is connected with the mixing chamber and provided with a light phase input port and a gas inlet. The gas-liquid separation device is connected with the mixing chamber. The liquid-liquid coalescence separation device is connected with the gas-liquid separation device and provided with a liquid inlet, a first light phase discharge port and a second heavy phase discharge port. The extraction device can be provided with no clarifying chamber, the integrated structure of the mixing chamber and the clarifying chamber is well achieved, the problem of heavy phase liquid distribution uniformity of a mixing chamber and the problem about light phase, heavy phase and gas phase separation of the mixing chamber are solved, the occupied area is small, energy consumption is low, a high-flow water solution containing a to-be-separated target object can be treated, and back-mixing of a high-position extraction tower can be relieved.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

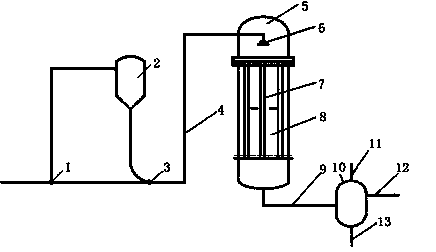

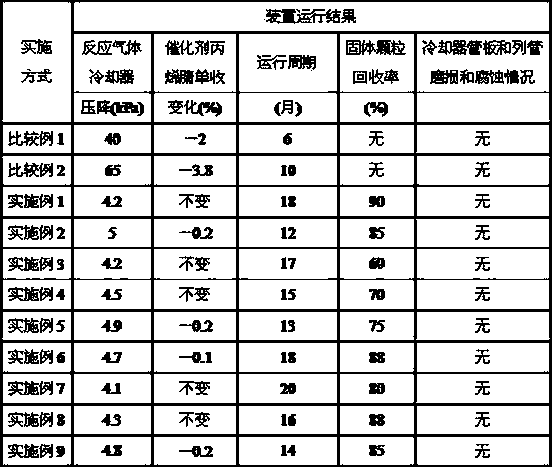

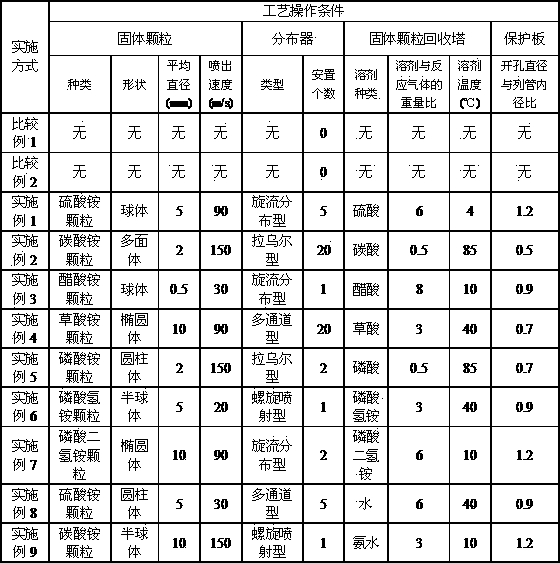

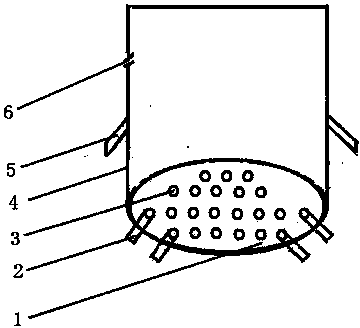

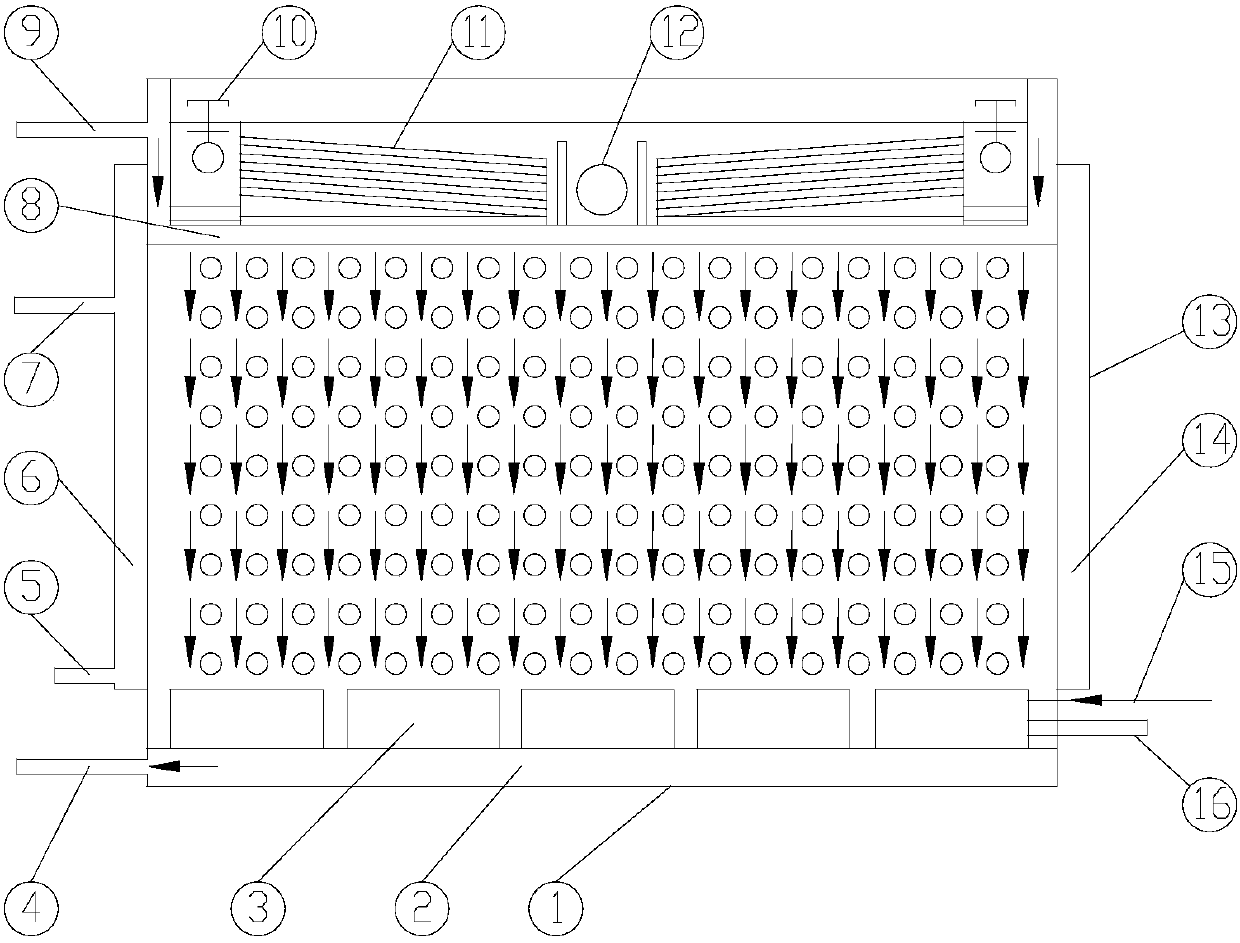

Online decoking device and decoking method

InactiveCN104279914AEven spray distributionAvoid enteringNon-rotary device cleaningGas coolerSolid particle

The invention relates to an online decoking device and a decoking method. The online decoking device and the decoking method mainly solve the problems that in the prior art, because accumulated coking materials in a tube nest of an ammoxidation gas cooler are hard to remove, the operating pressure of a reactor rises, the reaction performance of catalysts is reduced, device consumption is increased, and the cycle of operation is shortened. The online decoking device comprises an ammoxidation gas cooler, a solid particle storage tank and a solid particle recovery tower. The ammoxidation gas cooler comprises a hollow upper sealing head and a heat exchange segment, the tube nest is distributed all over the heat exchange segment, at least one solid particle ejection distributor is arranged in the upper sealing head, the outlet of the solid particle storage tank is communicated with the solid particle ejection distributor after being connected with an inlet for the inert gas generated in ammoxidation in parallel, and the solid particle recovery tower is arranged at the outlet of the cooler. According to the technical scheme, reaction gas makes contact with solvent so that solid particle components can be recovered in the recovery tower, the problems are well solved, and the online decoking device and the decoking method can be applied to industrial devices used for online decoking of the ammoxidation gas cooler.

Owner:CHINA PETROLEUM & CHEM CORP +1

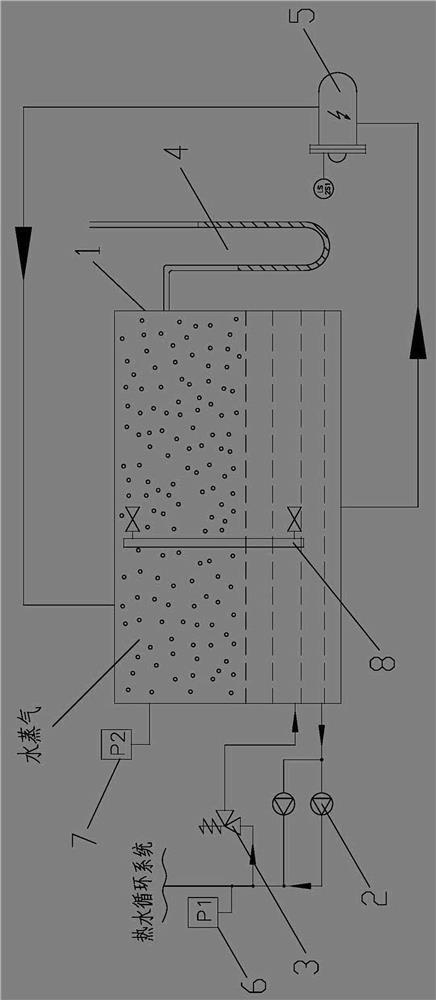

Passive accident discharge and cooling system and method of steam generator in nuclear power station

PendingCN109994230ARapid coolingPromote recoveryNuclear energy generationCooling arrangementExpansion tankCooling tower

The present invention discloses passive accident discharge and cooling system and method of a steam generator in a nuclear power station. The system includes a main water feeding pipe, a main water feeding isolation valve, the steam generator, a main steam isolation valve, a discharge tank, a water cooling wall upper header, a water cooling wall lower header, a discharge liquid recovery unit, an air cooler, an elevated expansion tank, an exhaust valve and an air cooling tower. The system and method can quickly and reliably cool and recover a radioactive high-temperature steam water mixture without relying on an external power source when a heat transfer pipe breaks in the steam generator of the nuclear power station.

Owner:XIAN THERMAL POWER RES INST CO LTD

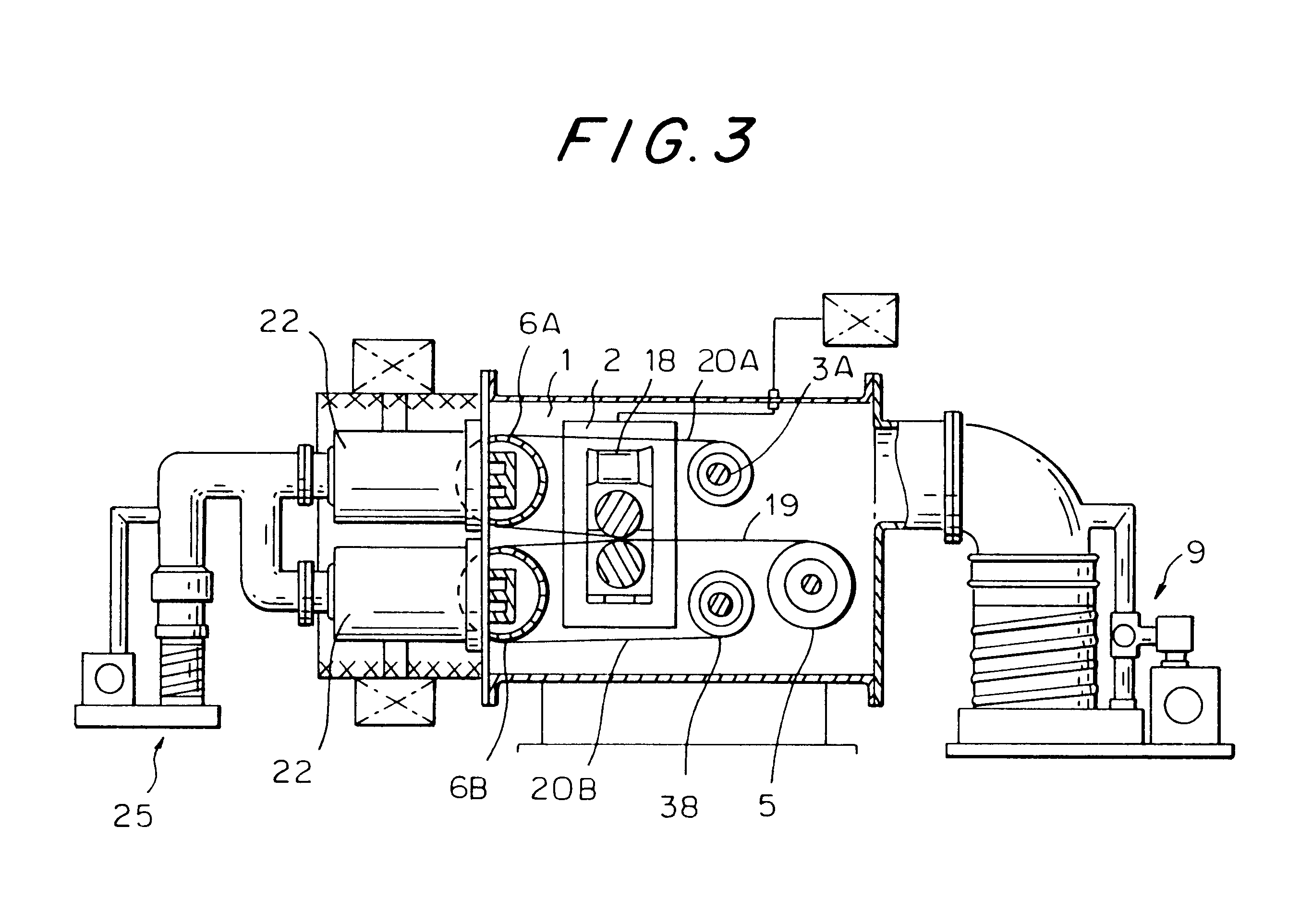

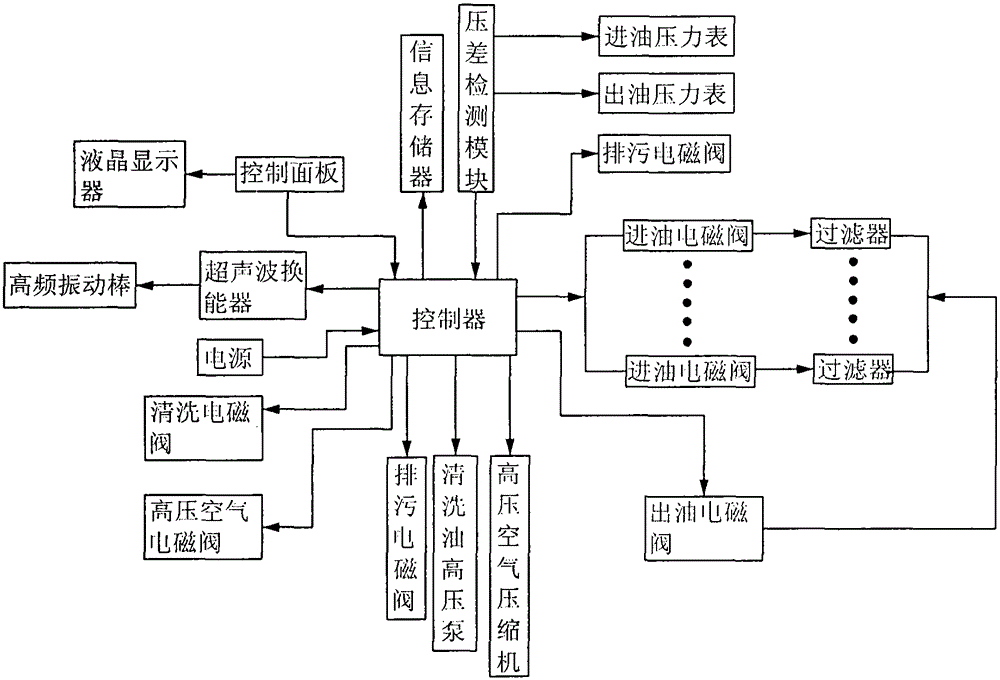

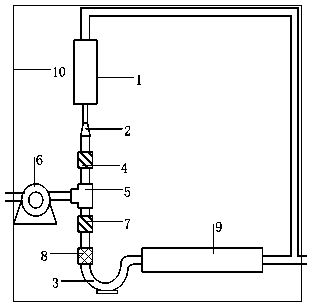

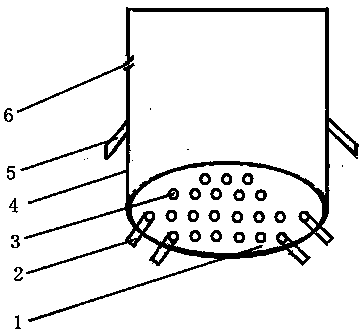

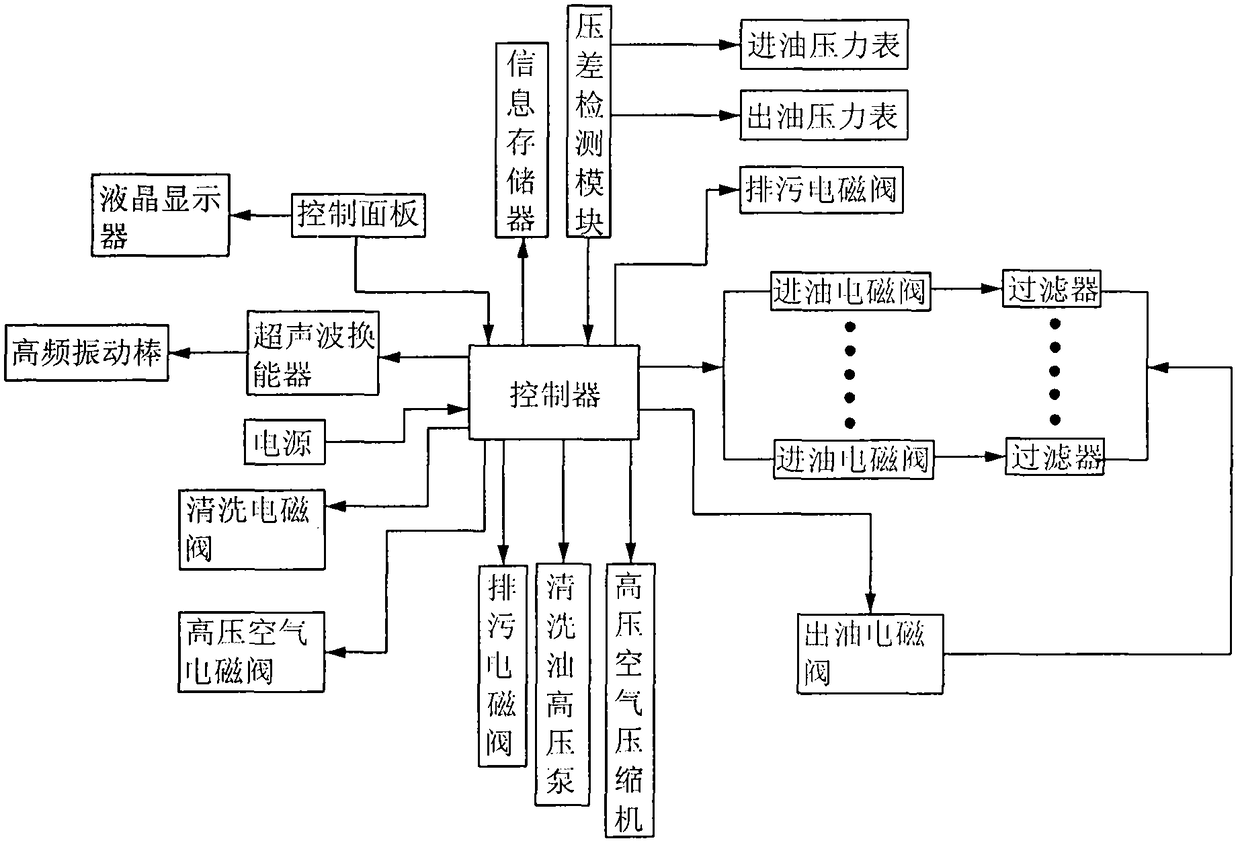

Marine diesel engine fuel oil filter with ultrasonic cleaning device and filtering method

ActiveCN105065159AReduce failureExtended service lifeMachines/enginesLiquid fuel feedersUltrasonic sensorMechanical energy

The invention discloses a marine diesel engine fuel oil filter with an ultrasonic cleaning device. The marine diesel engine fuel oil filter with the ultrasonic cleaning device comprises a filter shell, wherein the filter shell is provided with an oil inlet, an oil outlet and a sewage outlet used for discharging impurities. The ultrasonic cleaning device acting on the interior of a filter cavity is arranged on the filter shell. The ultrasonic cleaning device comprises an ultrasonic transducer fixed to the filter shell, and a high-frequency vibrating bar which extends into the filter cavity and is used for converting high-frequency electric energy into mechanical energy is connected to the ultrasonic transducer. A filtering method comprises the steps that firstly, a procedure is set; secondly, conventional cleaning is conducted, and conventional cleaning includes (1) high-pressure oil cleaning and (2) high-pressure air reverse-blowing cleaning; and thirdly, deep cleaning is conducted, namely ultrasonic cleaning is conducted. According to the filter, regular automatic cleaning control can be achieved, the automation degree is greatly increased, and the labor intensity of workers is effectively relieved; faults, caused by quality problems of diesel oil, of a diesel engine are reduced, and remarkable economical benefits are obtained on the aspects of saving oil, prolonging the service life of the diesel engine and the like.

Owner:THE FIRST INST OF OCEANOGRAPHY SOA

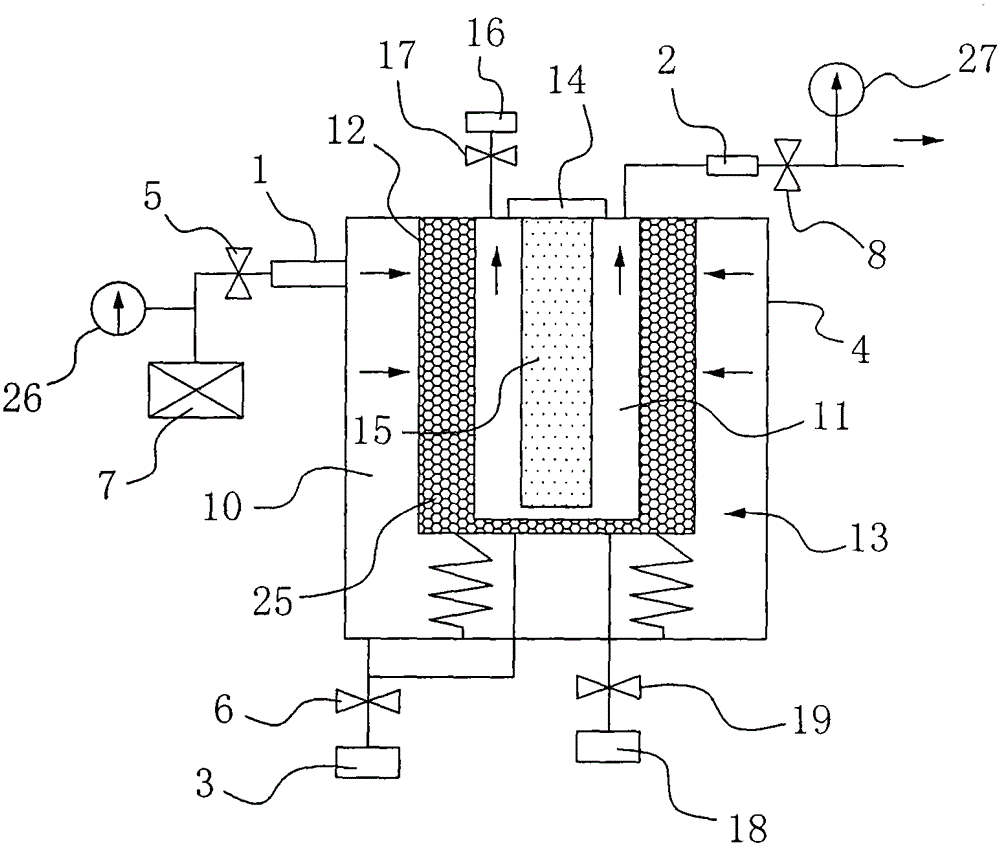

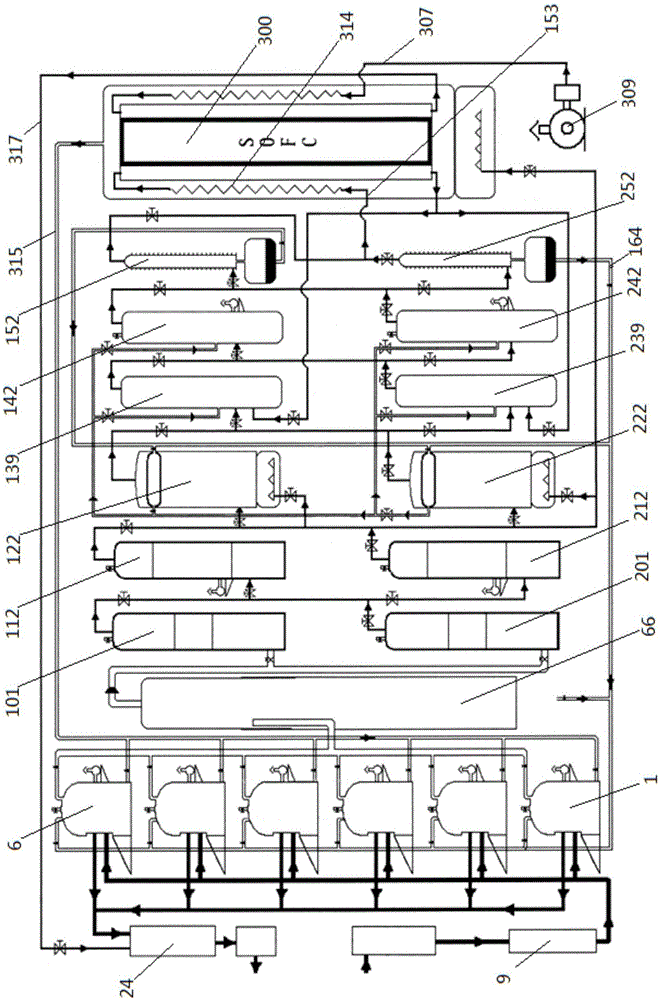

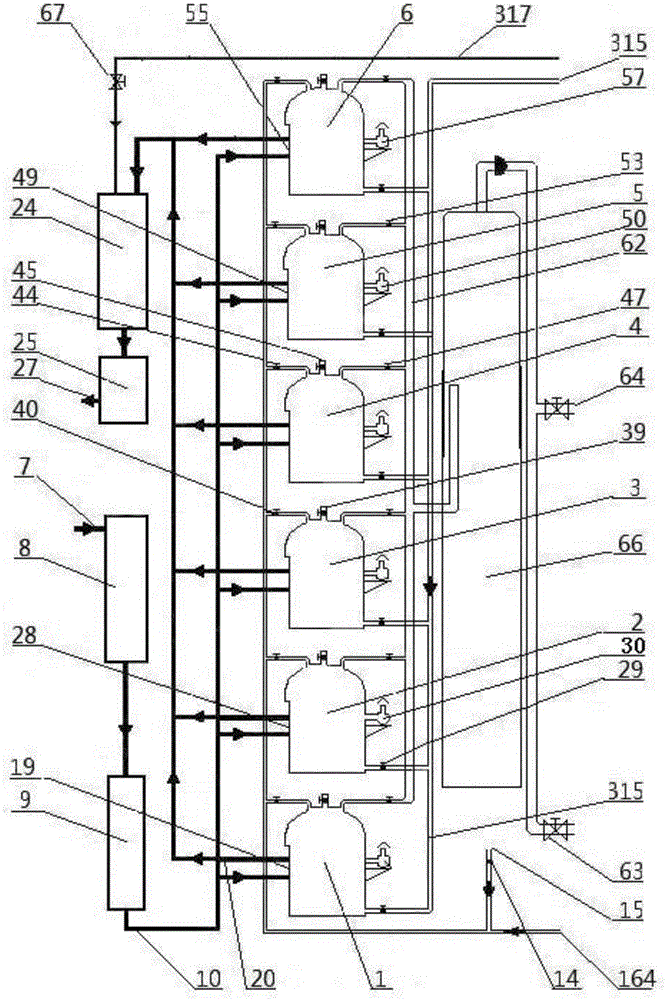

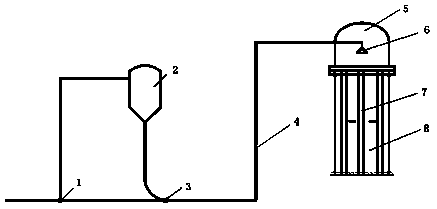

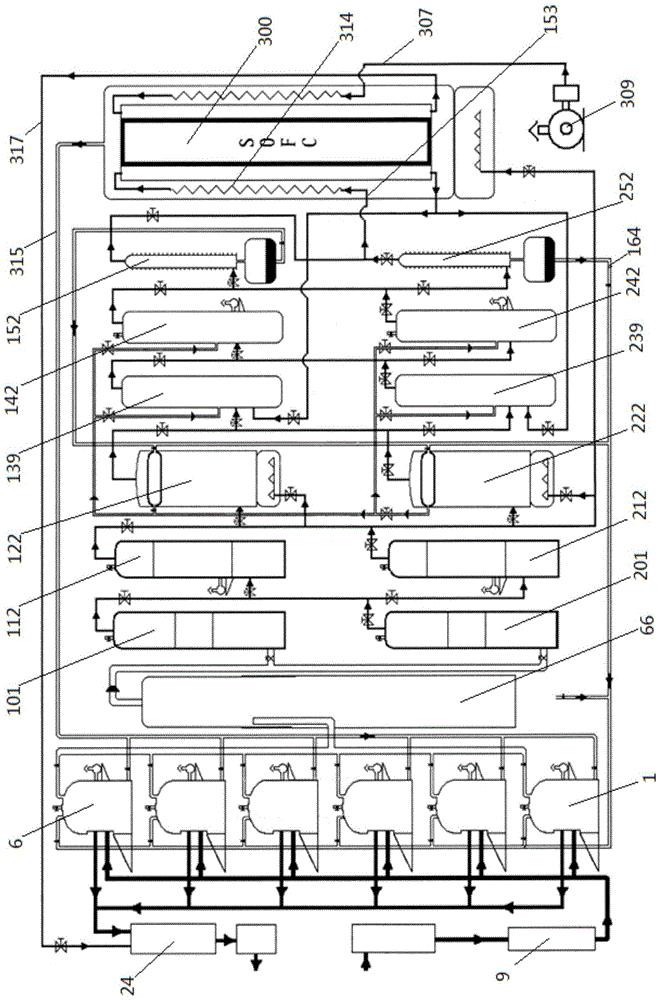

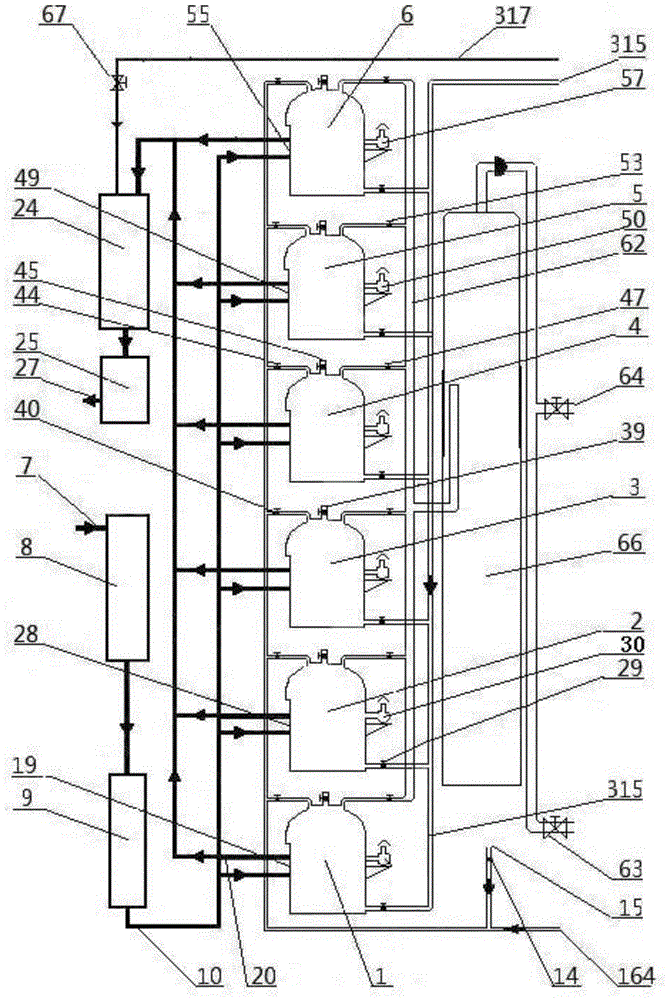

Six-tank circulating type marsh gas double-path SOFC anode fuel supply system

InactiveCN105140547AGuaranteed uninterrupted supplyLarge biogas flowFinal product manufactureFuel cell auxillariesFuel cellsNew energy

The invention belongs to the field of new energy, and particularly relates to a six-tank circulating type marsh gas double-path SOFC anode fuel supply system. Crop straw is adopted as raw materials of the system, six fermentation tanks are designed to enter a marsh gas production period in sequence, two fermentation tanks are kept supplying marsh gas at the same time, and the output flow of the two fermentation tanks is kept to be output in a staggering peak mode. The SOFC anode fuel supply system is designed into a double-path supply system, namely, an A-path system and a B-path system. The A-path system and the B-path system alternately bear a work state and a maintenance and standby state. When a certain device in the anode fuel supply system in the work state breaks down, a corresponding device in the system in the maintenance and standby state is immediately switched to replace the device breaking down to work. The SOFC anode fuel supply system has the advantage of being large and stable in marsh gas supply flow, the needs of SOFC generated power for continuous supplying to the anode fuel supply system are met.

Owner:JILIN UNIV

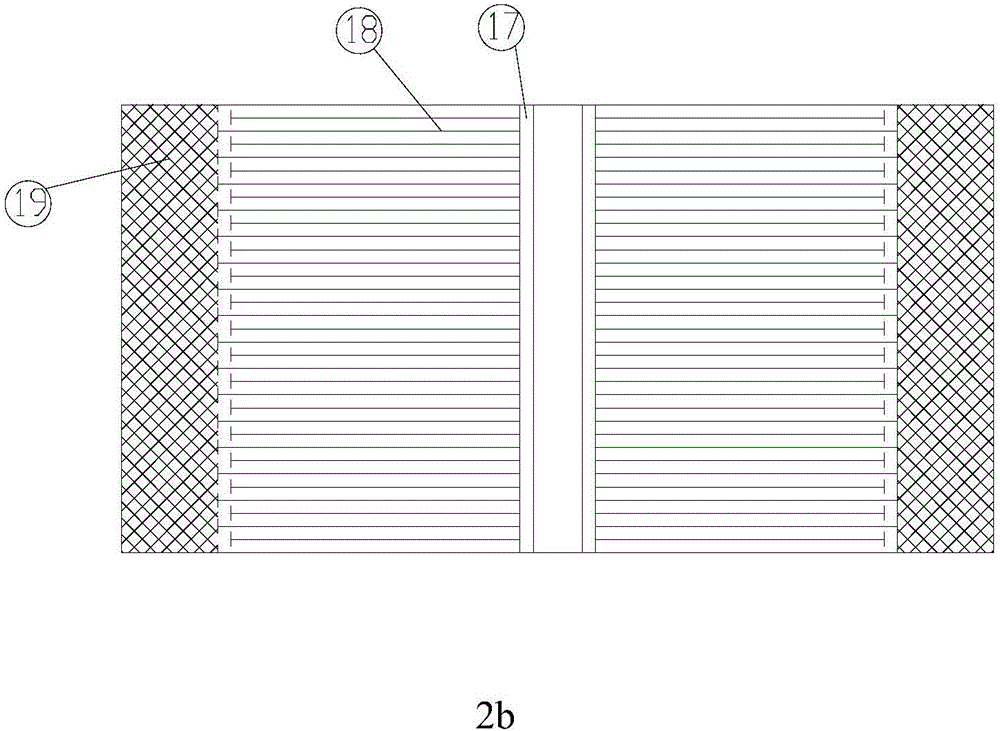

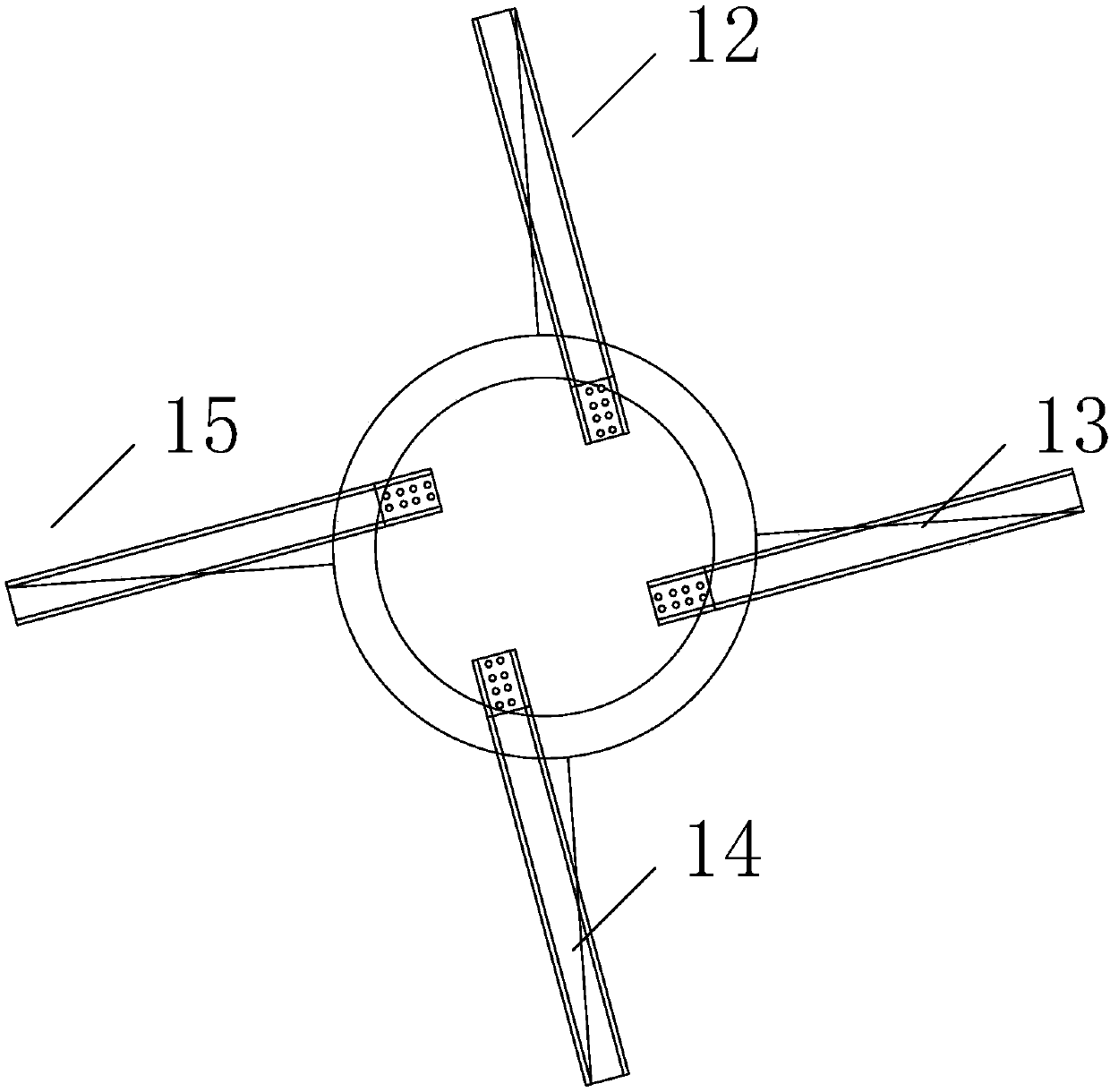

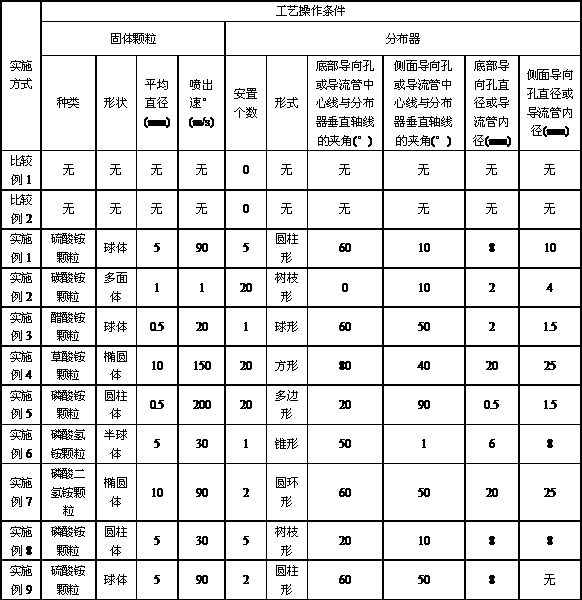

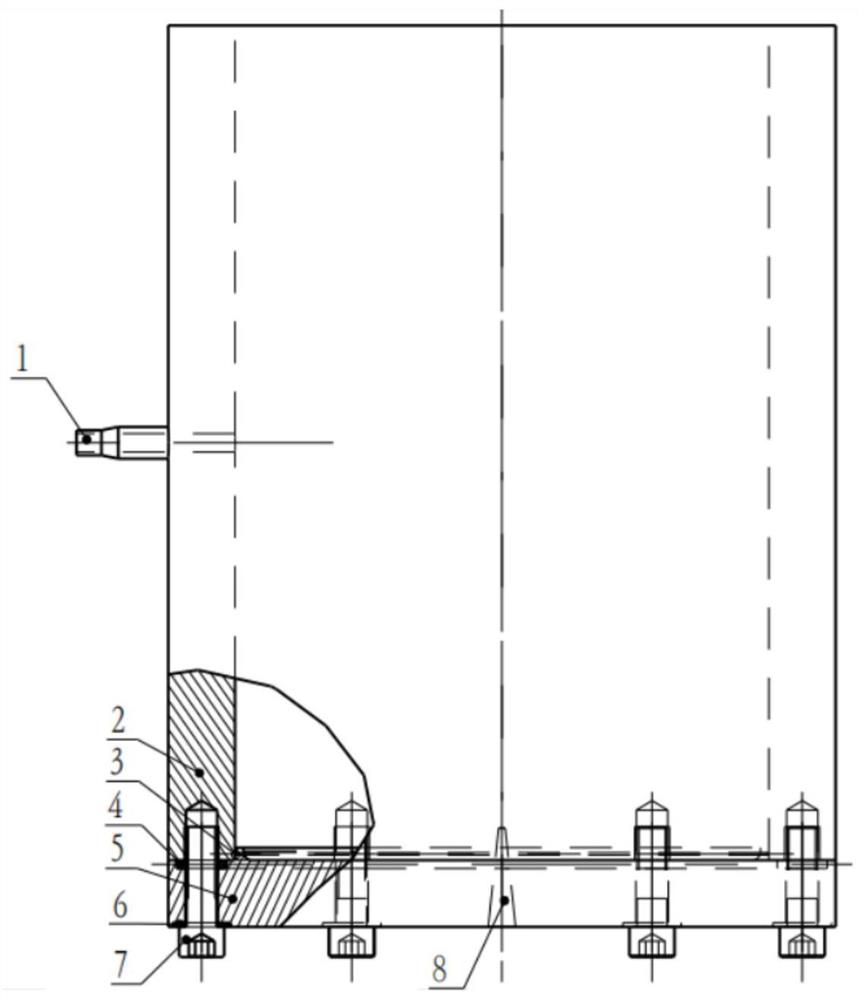

Opposed type solid particle spraying distributor online coke cleaning device

ActiveCN109696079AEnhance gas-solid mixing effectFully diffusedNon-rotary device cleaningSpray nozzleEngineering

The invention relates to an opposed type solid particle spraying distributor online coke cleaning device. The device main solves the problem in the prior art of the hard removing of coke accumulated in gas cooler tubes. The device includes a solid particle storage tank, an ammonia oxidation reaction gas cooler, a solid particle unloading device, a solid particle spraying distributor and gas-solidseparators; the ammonia oxidation reaction gas cooler includes a hollow upper head and a heat exchange section distributed with the tubes; the upper part of the heat exchange section is provided witha protection plate; the solid particle spraying distributor is placed in the upper head along an axial direction; a solid particle distributor is arranged in an opposed manner at least by more than two nozzles which are in opposed arrangement or inclined at a certain angle; the inlet of inert gas communicates with the solid particle spraying distributor after being parallel with the outlet of thesolid particle storage tank; and the outlet of the cooler is provided with at least one gas-solid separator to recycle solid particles. Thus, the problem can be well solved, so that the device can beused for online coke removing industrial devices.

Owner:CHINA PETROLEUM & CHEM CORP +1

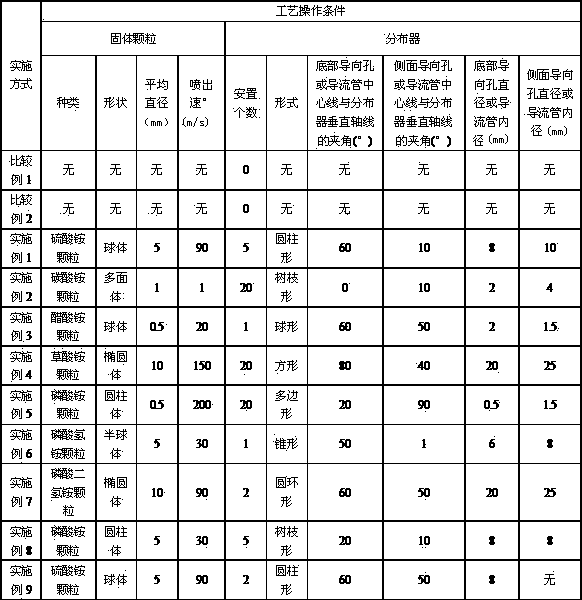

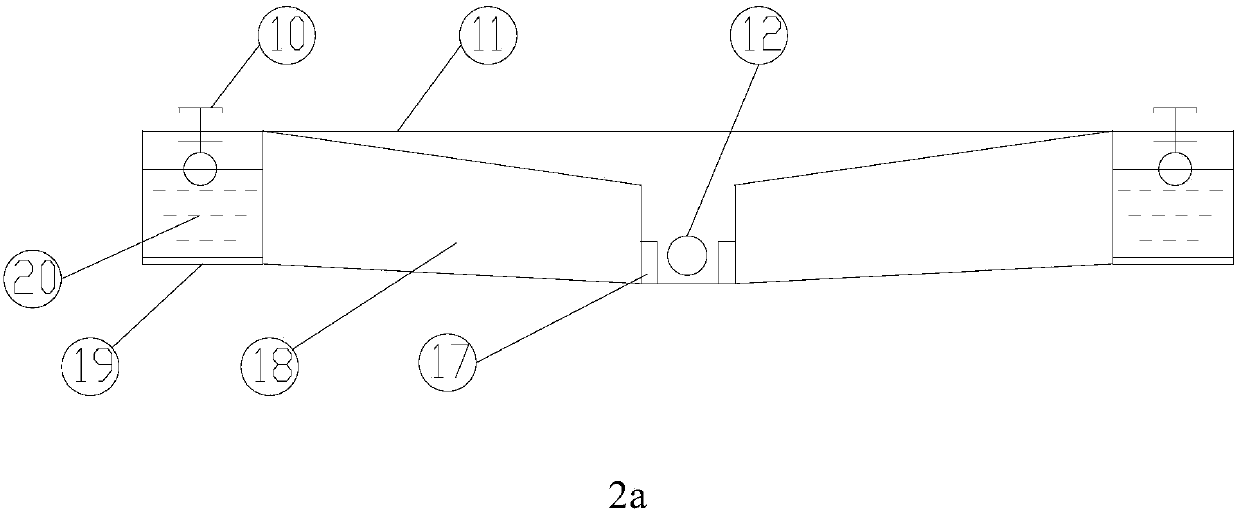

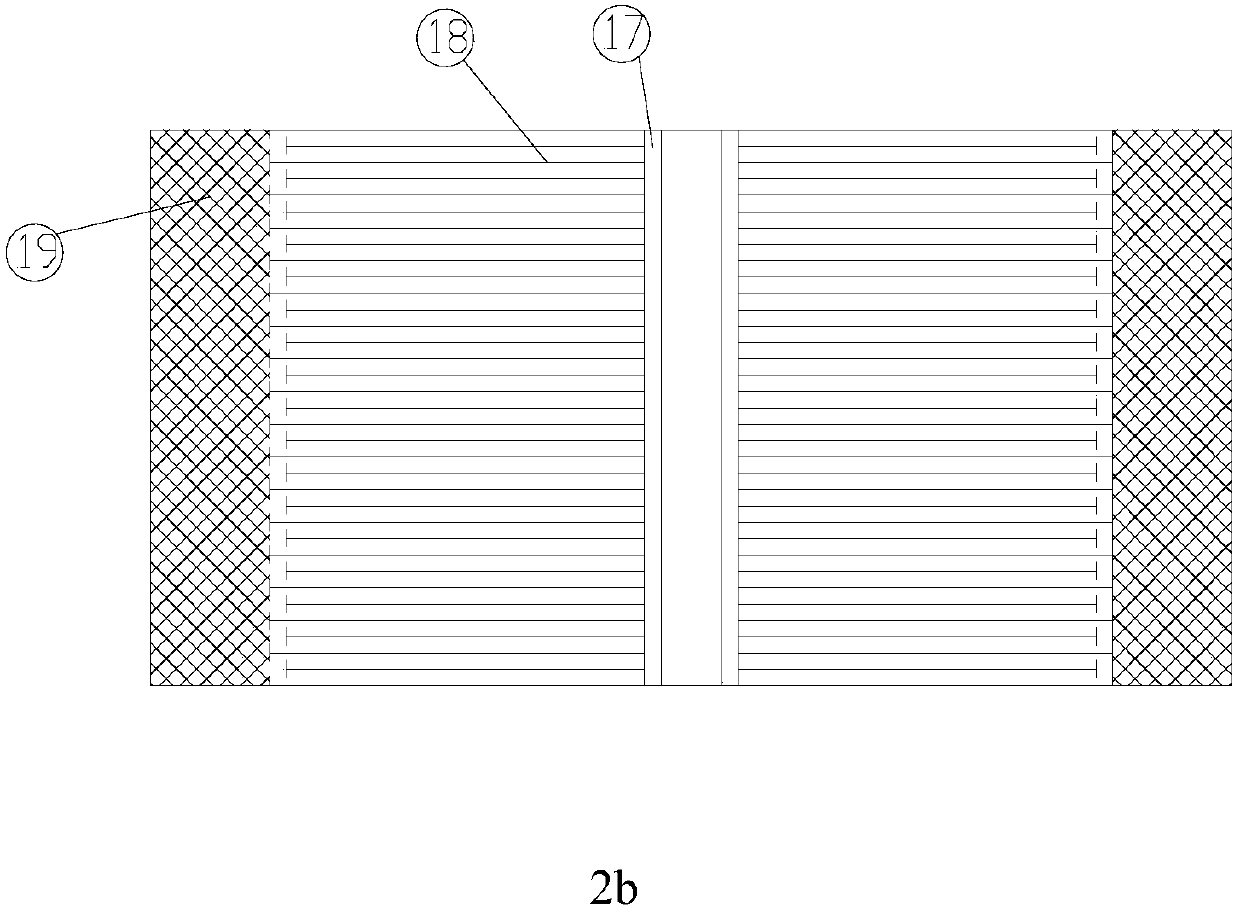

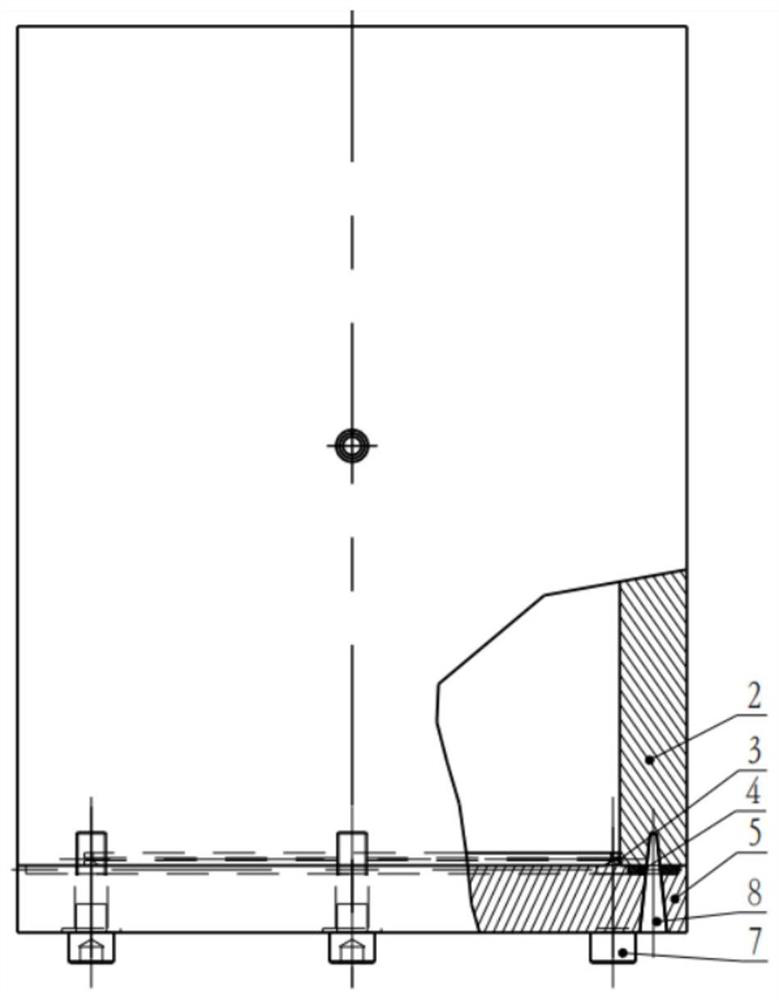

Solid particle ejecting distributor and online decoking device

ActiveCN104279915ASpray evenlyEven spray distributionNon-rotary device cleaningEngineeringGas cooler

The invention relates to a solid particle ejecting distributor and an online decoking device. The solid particle ejecting distributor and the online decoking device mainly solve the problems that in the prior art, when a solid particle ejecting distributor is used for ammoxidation, adhering and accumulated coking materials in a gas cooler tube nest are difficult to remove, the resistance of a pipeline of the cooler tube nest is increased, the operation pressure of a reactor is increased, the reaction performance of catalysts is lowered, device consumption is increased, and an operation cycle is shortened. The technical scheme that the body of the solid particle ejecting distributor is cylindrical or conical or spherical or square or polygonal or in the shape of a branch, at least one of the bottom and the side face of the ejecting distributor is provided with a guiding hole or a guiding pipe, the included angle between the center line of the guiding hole or the guiding pipe in the bottom and the perpendicular axis of the distributor is 0-80 degrees, and the included angle between the center line of the guiding hole or the guiding pipe of the side face and the perpendicular axis of the distributor is 1-90 degrees is adopted, the problem is well solved, and the solid particle ejecting distributor and the online decoking device can be used in an industrial plant for online decoking of an ammoxidation gas cooler.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of extraction device and extraction method

ActiveCN106139638BReduce contentEmission minimizationLiquid solutions solvent extractionProcess efficiency improvementGas phaseEngineering

The invention provides an extraction device and an extraction method, the mixing and clarifying extraction tank includes a mixing chamber, an organic liquid film generator, a gas-liquid separation device and a liquid-liquid coalescence separation device; the mixing chamber is provided with a heavy phase input port and the first heavy phase outlet; the organic liquid film generator is connected to the mixing chamber, and a light phase input port and an air inlet are provided; the gas-liquid separation device is connected to the mixing chamber; the liquid-liquid coalescence separation device It is connected with the gas-liquid separation device, and is provided with a liquid inlet, a first light phase discharge port and a second heavy phase discharge port. The device does not need to be equipped with a clarification chamber, which better realizes the integrated structure of the mixing chamber and the clarification chamber, solves the problem of uniform distribution of the heavy phase liquid in the mixing chamber and the separation of light phase, heavy phase and gas phase in the mixing chamber, and occupies a small area. Low consumption, can handle a large flow of aqueous solution containing the target to be separated, and can reduce back-mixing in the high-level extraction tower.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

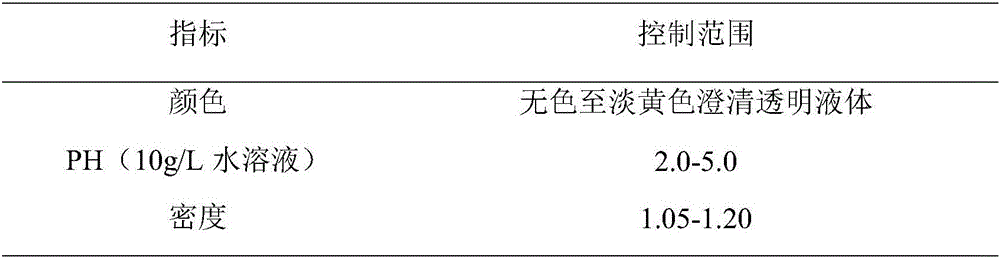

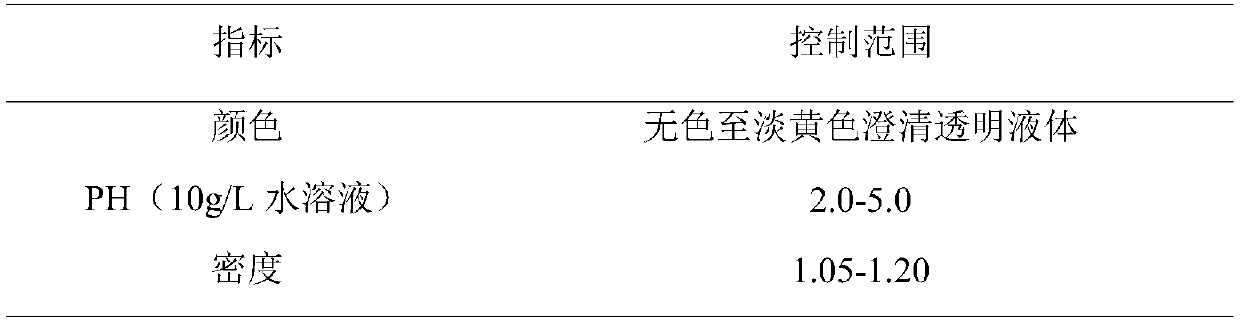

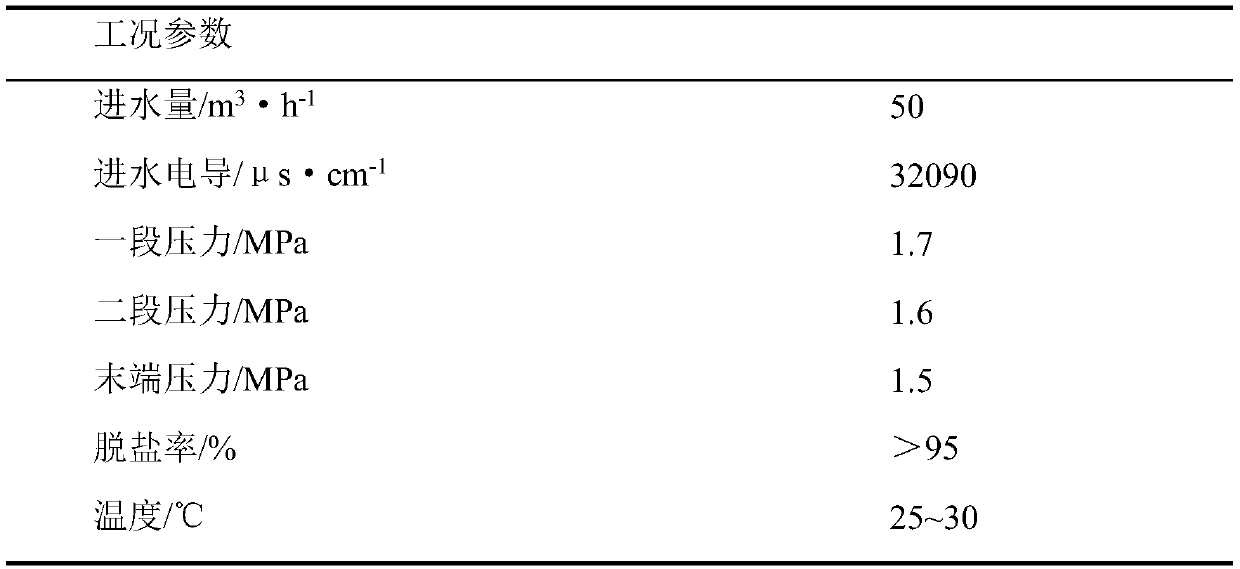

Reverse-osmosis scale inhibitor

ActiveCN106268346AExtended service lifeIncrease water productionSemi-permeable membranesSpecific water treatment objectivesFiltrationReverse osmosis

The invention mainly relates to a reverse-osmosis and ultra-filtration scale inhibitor with the wide suitable salinity range. The inhibitor has the good scale inhibition effect within the wide ionic strength range, and is prepared from one or more of amino trimethylene phosphonic acid (ATMP), phosphono-carboxylic acid (POCA), polyaspartic acid (PASP) and polyamino polyether methylene phosphonate (PAPEMP); by means of the reverse-osmosis and ultra-filtration scale inhibitor, membrane face scaling can be effectively prevented, fouling of a membrane is prevented, and the service life of a membrane system is prolonged. The working pressure and the water production efficiency of the membrane system are kept, and it is prevented that due to fouling, energy consumption of the system is increased. According to the reverse-osmosis and ultra-filtration scale inhibitor with the wide suitable salinity range, the reverse-osmosis scale inhibitor can be suitable for the wide water-quality salinity range (electric conductance is 0 microsecond to 30,000 microseconds) through compounding, and the using effect of the reverse-osmosis inhibitor can be guaranteed within the range.

Owner:湖北兴发环保科技有限公司

Method for preparing aliphatic polycarbonate through continuous solution polymerization method

Owner:BEIJING RISUN TECH CO LTD +1

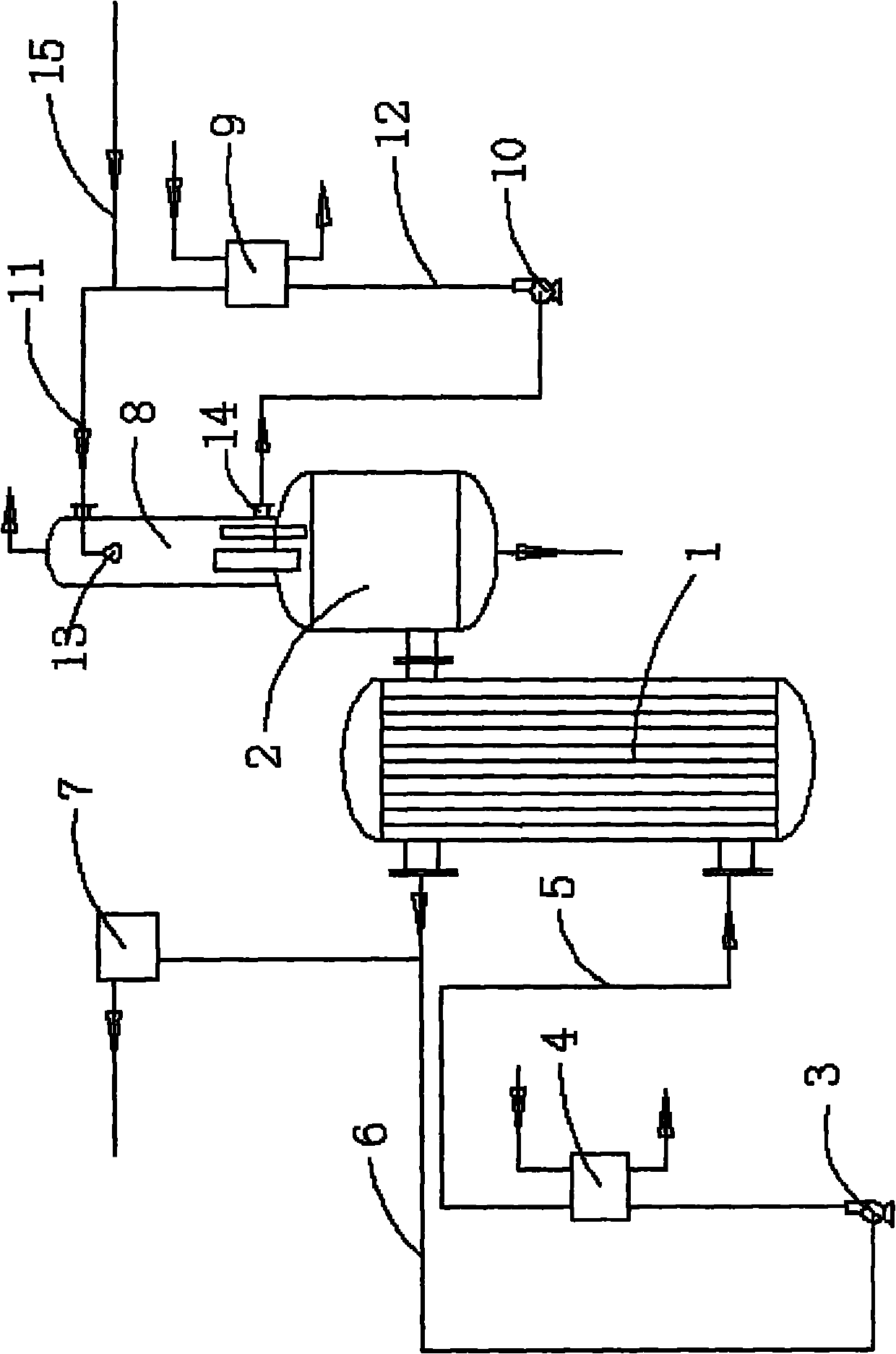

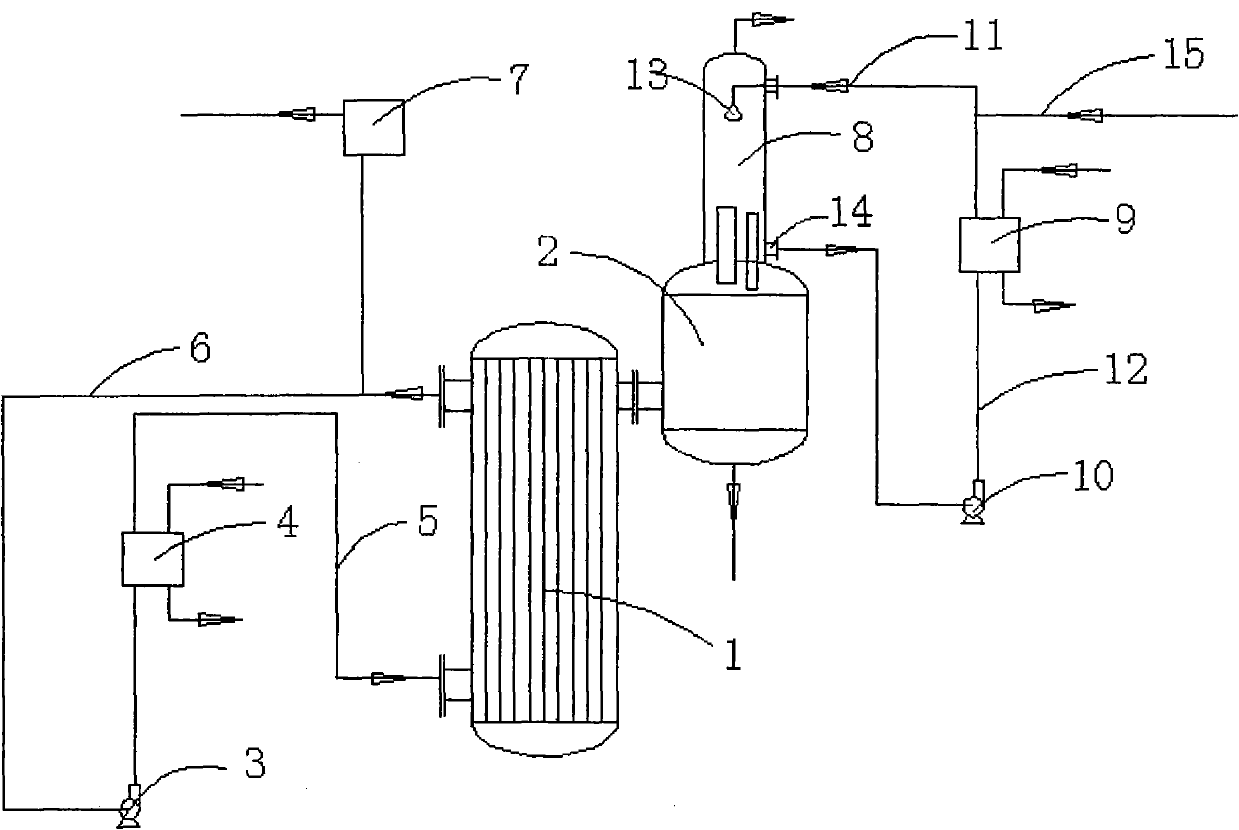

Improved device of low-pressure system of carbon dioxide air stripping urea device

InactiveCN102020590AThere will be no shortage of waterIncrease washing sectionUrea derivatives preparationProductsEngineeringChiller

The invention discloses an improved device of a low-pressure system of a carbon dioxide air stripping urea device. The device comprises a low-pressure methylamine condenser, a liquid level tank, a first pump group, a first circulating cooler, a first circulated cooling water inlet pipe and a first circulated cooling water outlet pipe, wherein any section of the first circulated cooling water inlet pipe or the first circulated cooling water outlet pipe is communicated with a water supply tank. In the invention, the water supply tank is additionally arranged to continuously supply water to the system so as to balance the working pressure of low-pressure circulating water; and after the improved device is used, the pressure and the temperature of the system do not greatly fluctuate any more, and the circulating water system cannot be short of water, thereby the operation pressure and the operation temperature of the system are stabilized. A washing section is additionally arranged between the liquid level tank and a subsequent section device, thus system carries less liquid, absorbs less pressure and recovers more energy, the consumption is lowered and the output is increased.

Owner:江苏晋煤恒盛化工股份有限公司

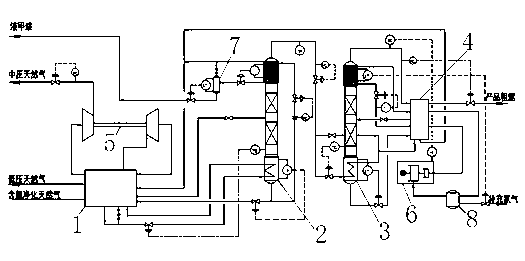

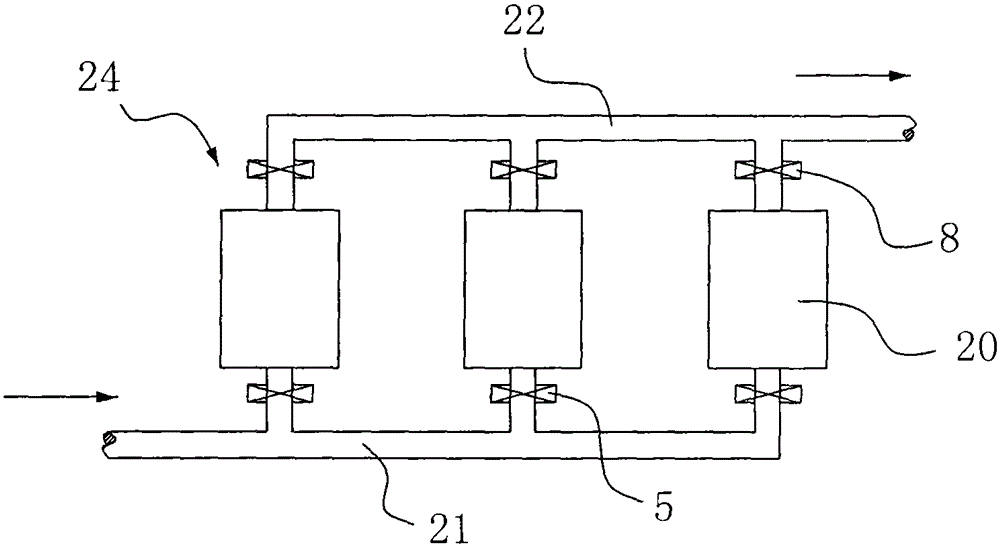

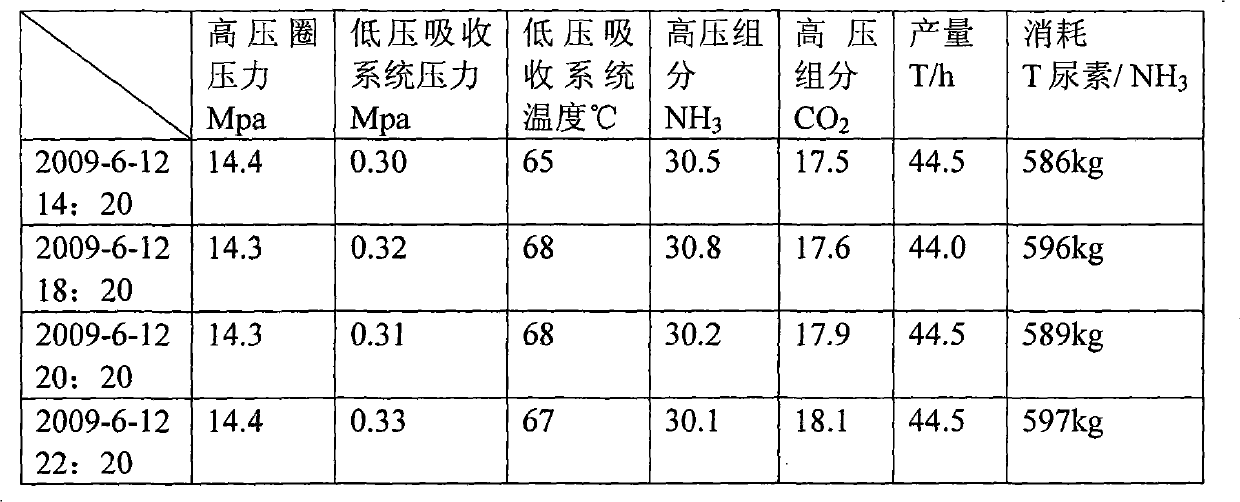

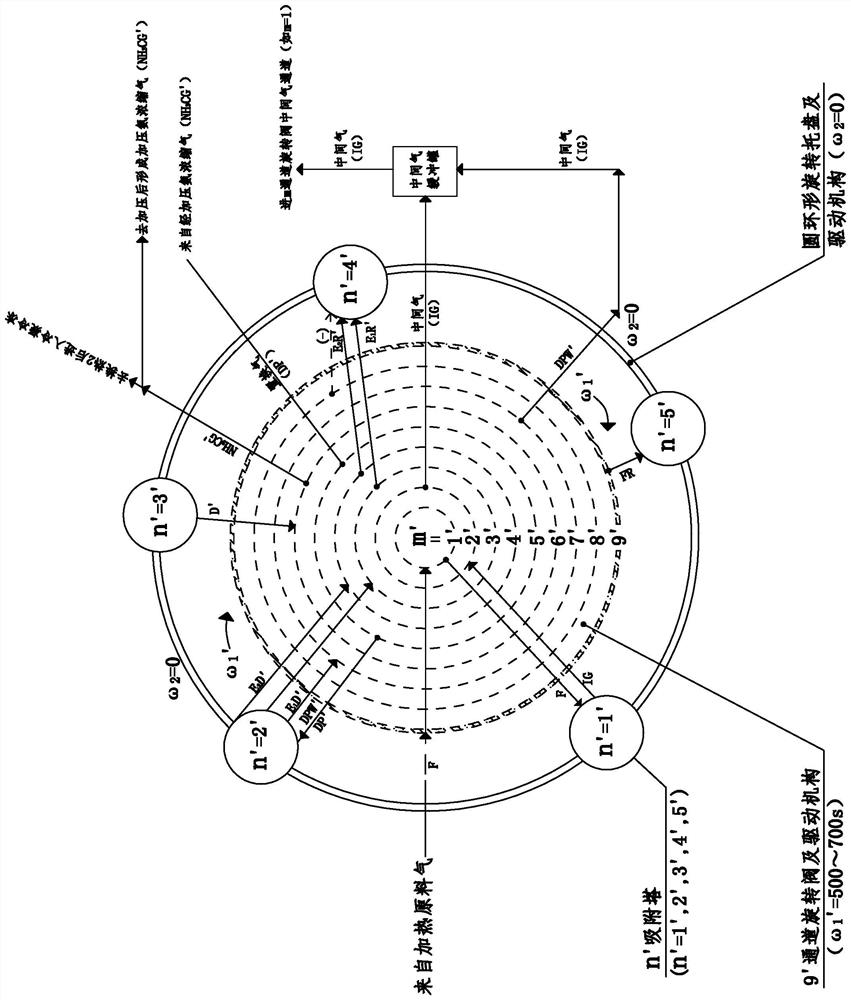

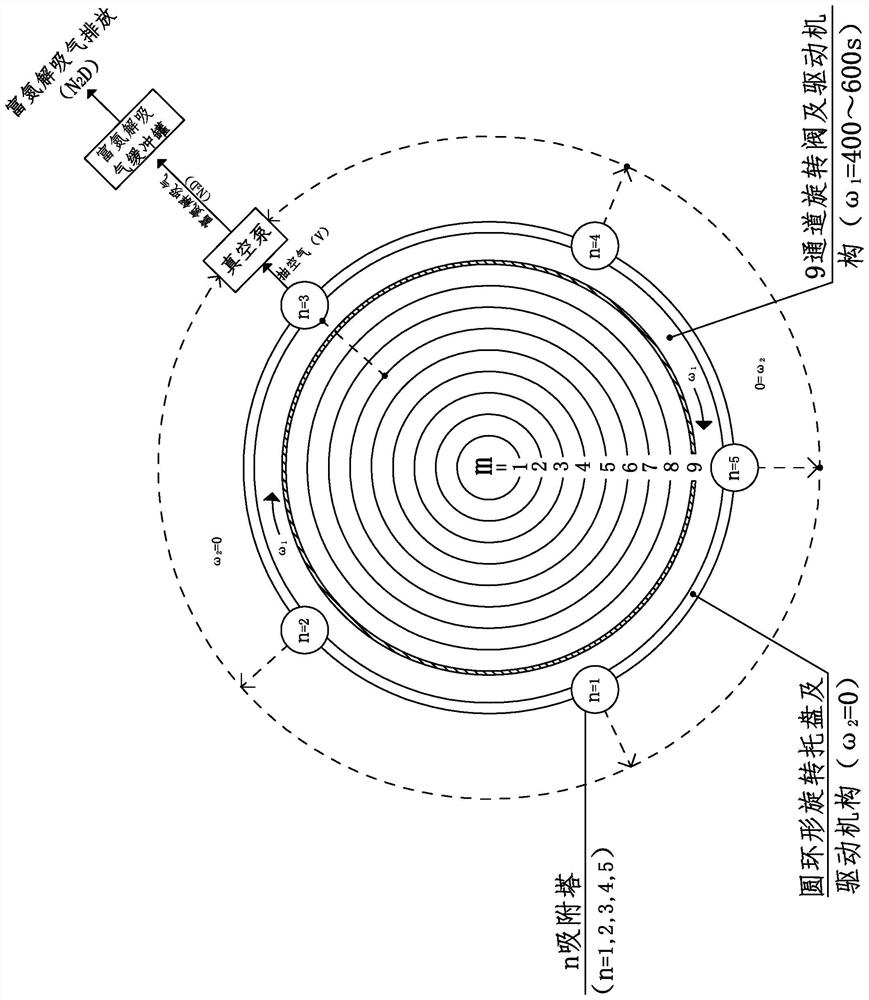

Full-temperature-range simulated rotating moving bed pressure swing adsorption process for extracting H2 and NH3 from synthetic ammonia purge gas

PendingCN114588749AReduce manufacturing complexity and costImprove efficiencyHydrogen separation using solid contactDispersed particle separationAmmonia productionRotary valve

The invention discloses a full-temperature-range simulated rotating moving bed pressure swing adsorption (FTrSRMPSA) process for extracting H2 and NH3 from synthetic ammonia purge gas. The middle-high temperature pressure swing adsorption ammonia concentration system and the middle gas pressure swing adsorption hydrogen extraction system are formed by a plurality of axial flow fixed bed adsorption towers and a rotating speed mechanism, wherein the axial flow fixed bed adsorption towers are arranged in the center of an upper multi-channel rotating valve and a lower multi-channel rotating valve, and are arranged on a circular ring-shaped rotating tray around the multi-channel rotating valve; gas flowing through a rotary valve channel, pipelines at the inlet and outlet ends of the adsorption towers and the adsorption bed layers can complete mass transfer of respective adsorption and desorption steps at the inlet and outlet positions of each adsorption tower and at each adsorption bed layer while rotating, so that a pressure swing adsorption process of simulating a rotary moving bed is formed; according to the invention, a simulated rotating moving bed pressure swing adsorption process on the basis of axial flow fixed bed pressure swing adsorption is realized, and H2 and NH3 products are obtained with high purity and high yield and are returned to a synthetic ammonia production process for recycling.

Owner:ZHEJIANG TIANCAIYUNJI TECH CO LTD

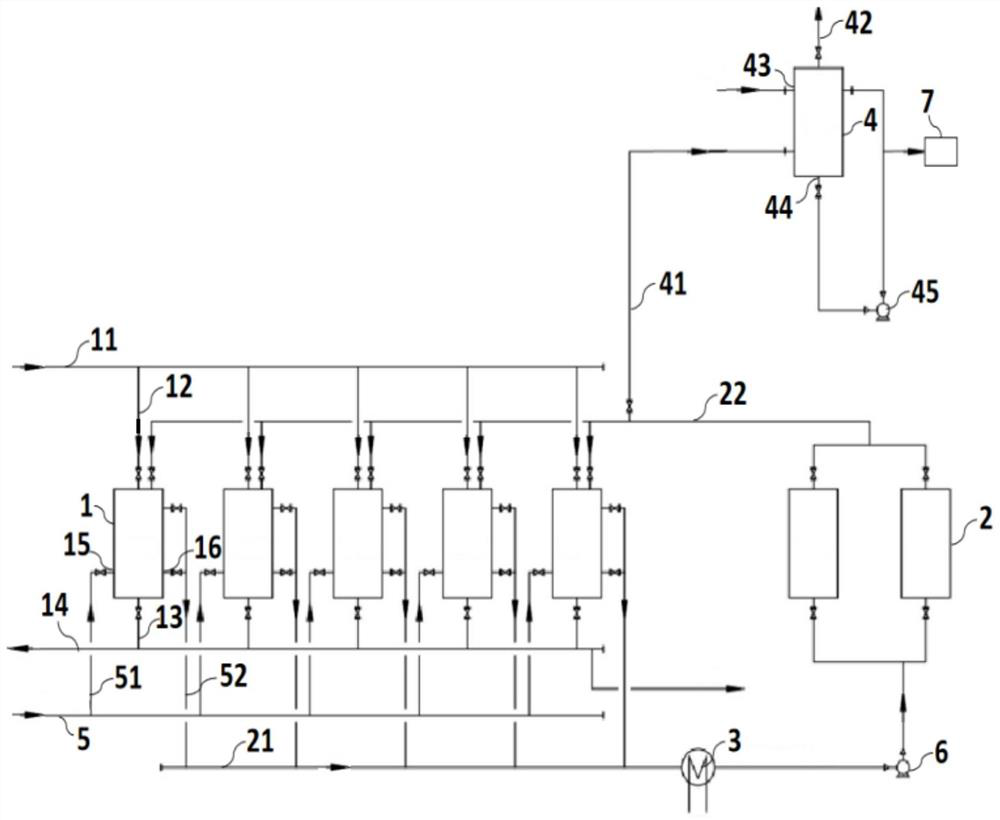

Fine desulfurization device and method for coke oven gas

ActiveCN113881464ALong working hoursAvoid cloggingGas treatmentDispersed particle separationThermodynamicsPtru catalyst

The invention discloses a fine desulfurization device and method for coke oven gas, belonging to the technical field of gas desulfurization. The fine desulfurization device comprises an adsorption tower, a washing tower and a conversion tank, wherein a gas inlet of the adsorption tower communicates with a main gas inlet pipe, and a gas outlet of the adsorption tower communicates with a main purified gas outlet pipe; a gas inlet of the conversion tank communicates with the adsorption tower through a circulating desorbed gas inlet pipe, and a gas outlet of the conversion tank communicates with the adsorption tower through a circulating desorbed gas outlet pipe; a heating device and a desorption fan are arranged on the circulating desorbed gas inlet pipe, and the circulating desorbed gas outlet pipe communicates with the washing tower through a desorbed gas discharge inlet pipe. According to the invention, the continuous working time of the adsorption tower can be effectively prolonged, the efficiency of removing organic sulfur in coke oven gas, blast furnace gas and gasifier gas can be improved while the adsorbent is prevented from being easily blocked and the catalyst is prevented from being easily poisoned, and energy consumption in the whole process is reduced.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Natural-gas low-temperature helium extracting system and method

ActiveCN102937369BRich adjustment meansIncrease operating pressureSolidificationLiquefactionHigh concentrationNitrogen

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

High-pressure scale removing water system and control method thereof

InactiveCN104741398AEasy to controlStable operating pressureWork treatment devicesMetal rolling arrangementsWater storage tankEngineering

The invention relates to a high-pressure scale removing water system which comprises an energy-storage tank set. The energy-storage tank set is connected to an injection valve set through a first pipeline, and the injection valve set is connected to a scale removing header through a second pipeline. The high-pressure scale removing water system further comprises a water supply pump set which is connected to the energy-storage tank set and the injection valve set through a third pipeline. The water supply pump set comprises a pump set motor, a speed regulating coupler connected with the pump set motor, a coupler speed regulating oil cylinder connected with the speed regulating coupler, and a water pump, the water pump is connected to the third pipeline, and a PLC is further arranged between the energy-storage tank set and the coupler speed regulating oil cylinder. The energy-storage tank set comprises a high-pressure gas storage tank, and a pressure sensor and a liquid level sensor are arranged on a water storage tank and connected to the PLC. By means of the high-pressure scale removing water system and a control method, the problem of system water pressure large-range fluctuation caused by lagging of the response of the pump set and the delayed supply of water for removing scales can be well solved, and the stable water pressure needed by the scale removing technology is maintained.

Owner:SHANDONG IRON & STEEL CO LTD

A method for controlling low-temperature refrigeration of an air conditioner

ActiveCN103411292BIncrease speedReduce speedSpace heating and ventilation safety systemsLighting and heating apparatusControl systemWorking pressure

The invention provides a method for controlling low temperature refrigeration of an air conditioner. The method comprises the following steps: (1) measuring middle temperature T3 of an outer unit condenser; (2) comparing T3 with first preset values T1 and T3 and a second preset value T2 respectively, wherein T1 is greater than T2; (3) when T3 is greater than T1, raising output voltage U of an external motor so as to increase the rotating speed of an external fan; when T3 is smaller than T2, decreasing the U so as to reduce the rotating speed of the external fan. According to the method for controlling the low temperature refrigeration of the air conditioner, the output voltage U of the external motor is adjusted according to the middle temperature T3 of the condenser so as to adjust the rotating speed of the external fan, and then the T3 is stabilized in a range of T2 to T1. The T3 can reflect the system operation pressure of the air conditioner better, thus the T3 stabilized in the certain range can ensure the working pressure of the condenser, thus the system operation pressure is controlled better; therefore, stable operation of the system is ensured during the low temperature refrigeration of the air conditioner, thus the start and stop times of a compressor are reduced, and the comfort of room is improved.

Owner:GUANGDONG CHIGO HEATING & VENTILATION EQUIP CO LTD

Fair current and countercurrent double-current calcium carbonate filter

InactiveCN104208945APrevent backflowGuaranteed flow rateFiltration circuitsIndustrial water treatmentCalcium carbonate

The invention discloses a fair current and countercurrent double-current calcium carbonate filter belonging to the field of industrial water treatment. The structure of the filter comprises a water pump, a three-way diverter, a calcium carbonate filtration column, submerged elbow with cover, a valve, a check valve and a shell. The filter can be used as a conventional calcium carbonate filter for fair current filtering, or can conduct a better countercurrent filtering mode by opening the pump, so as to increase the fault tolerance rate of the whole system, bring out the residual bubbles in the filter and ensure working of the filter at a constant pressure; therefore, the filter can ensure the flow velocity of water and filtering effect.

Owner:无锡利淼环保科技有限公司

A reverse osmosis antiscalant

ActiveCN106268346BExtended service lifeIncrease water productionSemi-permeable membranesSpecific water treatment objectivesReverse osmosisWater production

The invention mainly relates to a reverse-osmosis and ultra-filtration scale inhibitor with the wide suitable salinity range. The inhibitor has the good scale inhibition effect within the wide ionic strength range, and is prepared from one or more of amino trimethylene phosphonic acid (ATMP), phosphono-carboxylic acid (POCA), polyaspartic acid (PASP) and polyamino polyether methylene phosphonate (PAPEMP); by means of the reverse-osmosis and ultra-filtration scale inhibitor, membrane face scaling can be effectively prevented, fouling of a membrane is prevented, and the service life of a membrane system is prolonged. The working pressure and the water production efficiency of the membrane system are kept, and it is prevented that due to fouling, energy consumption of the system is increased. According to the reverse-osmosis and ultra-filtration scale inhibitor with the wide suitable salinity range, the reverse-osmosis scale inhibitor can be suitable for the wide water-quality salinity range (electric conductance is 0 microsecond to 30,000 microseconds) through compounding, and the using effect of the reverse-osmosis inhibitor can be guaranteed within the range.

Owner:湖北兴发环保科技有限公司

Solid particle spray distributor and online coke cleaning device

ActiveCN104279915BSpray evenlyEven spray distributionNon-rotary device cleaningGas coolerSolid particle

The invention relates to a solid particle ejecting distributor and an online decoking device. The solid particle ejecting distributor and the online decoking device mainly solve the problems that in the prior art, when a solid particle ejecting distributor is used for ammoxidation, adhering and accumulated coking materials in a gas cooler tube nest are difficult to remove, the resistance of a pipeline of the cooler tube nest is increased, the operation pressure of a reactor is increased, the reaction performance of catalysts is lowered, device consumption is increased, and an operation cycle is shortened. The technical scheme that the body of the solid particle ejecting distributor is cylindrical or conical or spherical or square or polygonal or in the shape of a branch, at least one of the bottom and the side face of the ejecting distributor is provided with a guiding hole or a guiding pipe, the included angle between the center line of the guiding hole or the guiding pipe in the bottom and the perpendicular axis of the distributor is 0-80 degrees, and the included angle between the center line of the guiding hole or the guiding pipe of the side face and the perpendicular axis of the distributor is 1-90 degrees is adopted, the problem is well solved, and the solid particle ejecting distributor and the online decoking device can be used in an industrial plant for online decoking of an ammoxidation gas cooler.

Owner:CHINA PETROLEUM & CHEM CORP +1

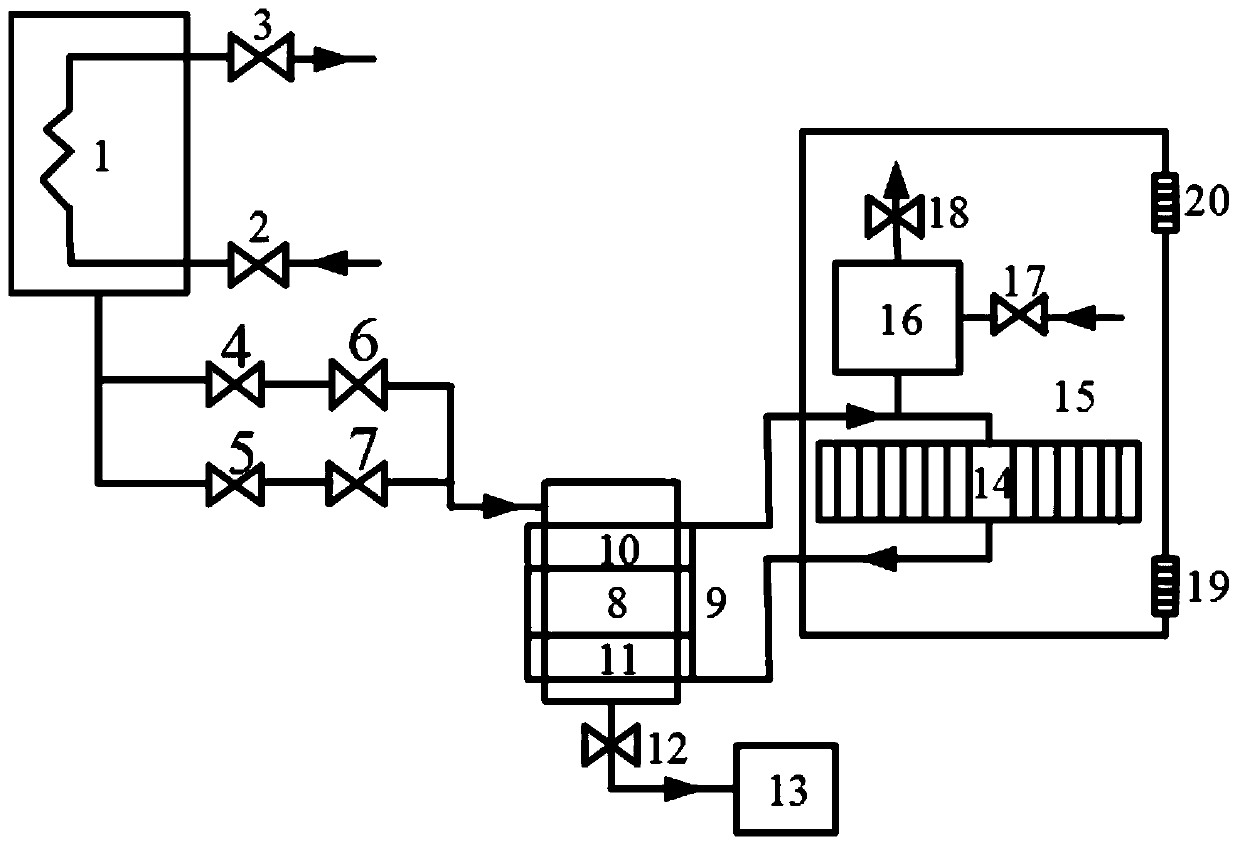

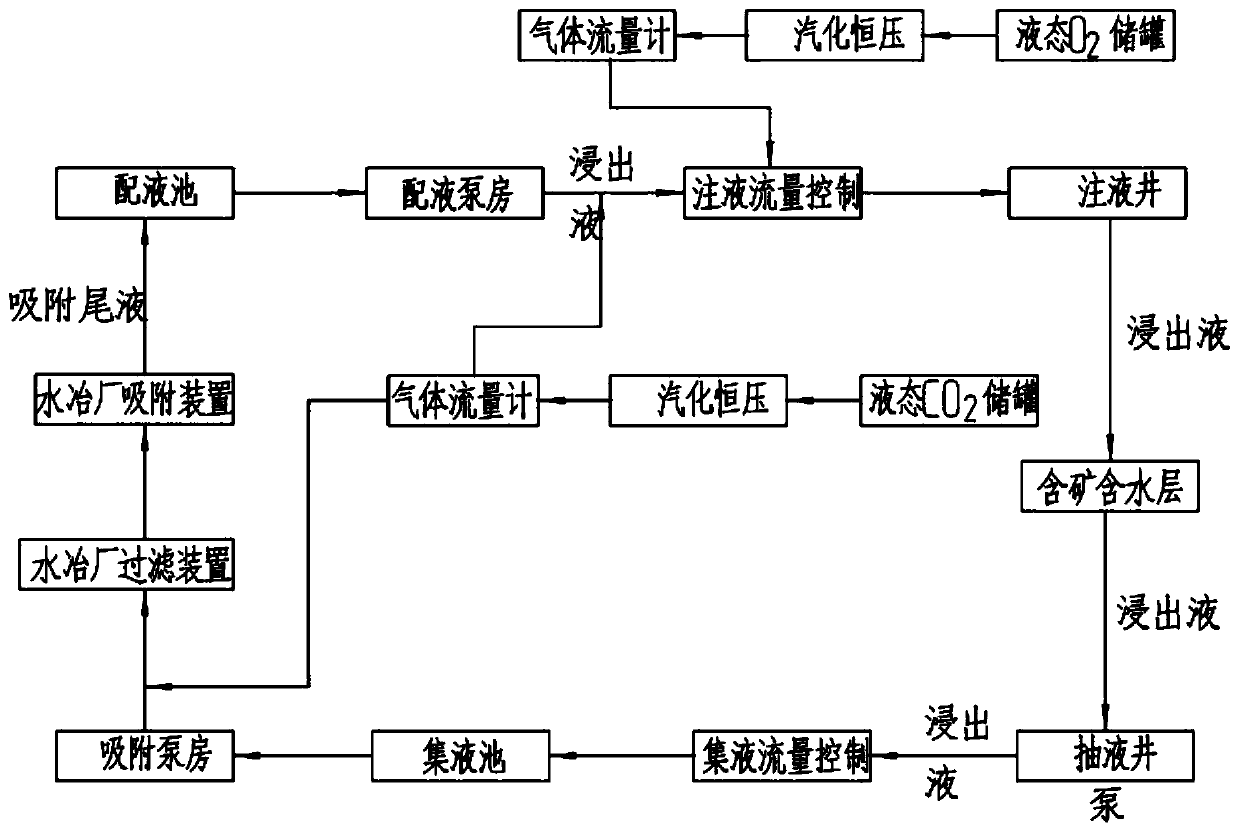

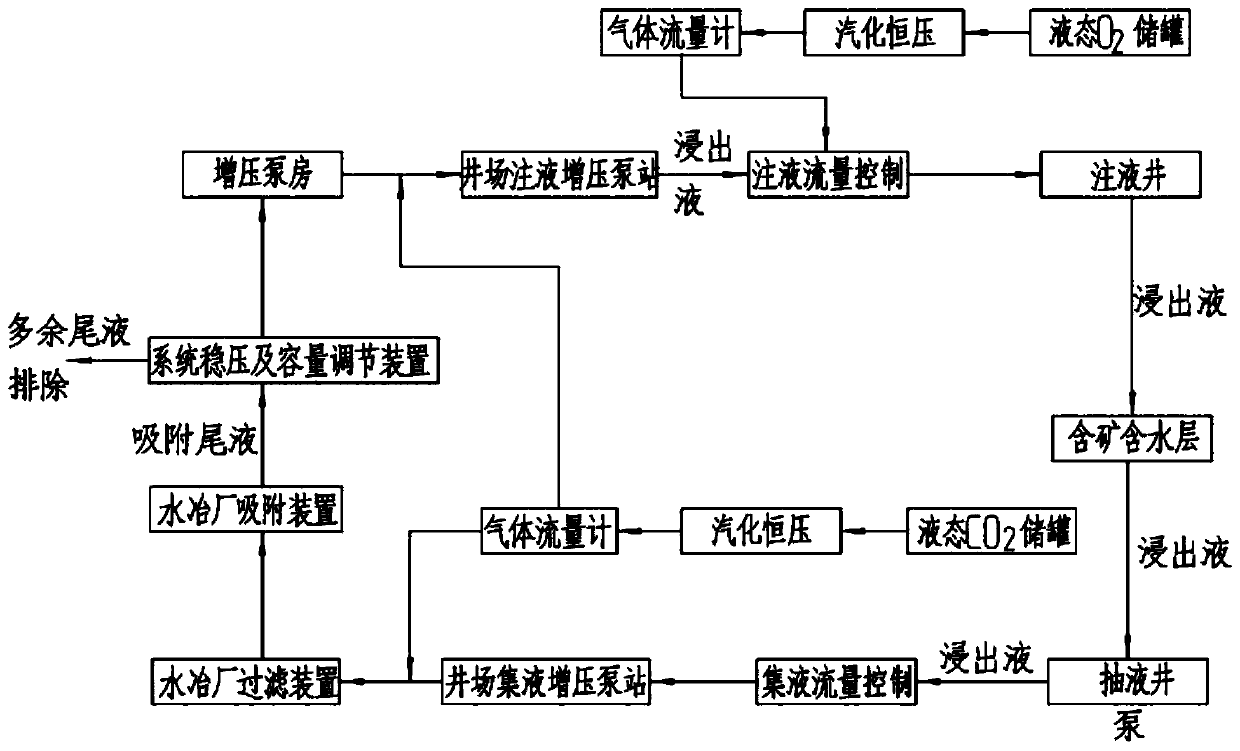

In-situ leaching uranium mining mine advanced closed solution pumping and injecting system

InactiveCN111335865AGuaranteed uptimeStable operating pressureFluid removalPregnant leach solutionRadon gas

The invention discloses an in-situ leaching uranium mining mine advanced closed solution pumping and injecting system. The system comprises a booster pump room, a wellsite solution injecting booster pump station, solution injecting flow control, a solution injecting well, a solution pumping well, solution pumping flow control, a wellsite solution collecting booster pump station, a water treatmentplant filtering device, a water treatment plant adsorption device and a system pressure stabilizing and flow adjusting device. The system pressure stabilizing and flow adjusting device communicates with the booster pump room. According to the in-situ leaching uranium mining mine advanced closed solution pumping and injecting system provided by the invention, the working form that a solution collecting reservoir and a solution preparation reservoir are arranged in an existing open solution pumping and injecting system is omitted, full-closed operation of pumping and injecting of a leaching solution is achieved, energy wasting caused by pressure relief is avoided, the operating cost is lowered, meanwhile, the release amount of radioactive radon gas in the leaching solution can be decreased easily, and environment pollution is alleviated; and the system provided by the invention adopts a two-stage booster solution injecting mode that the wellsite solution injecting booster pump stations are arranged on all mining area well sites, and the system can effectively adapt to the realistic demand that the leaching solution injecting pressure is different for different mining areas.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

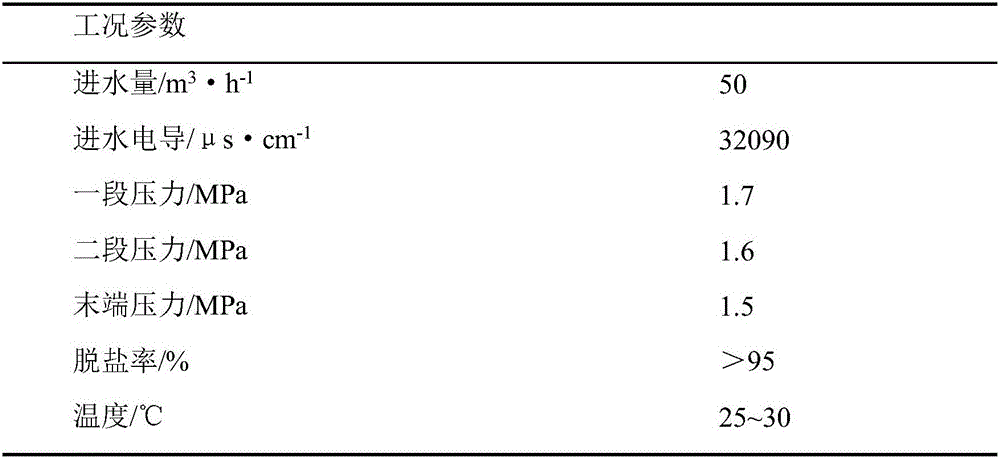

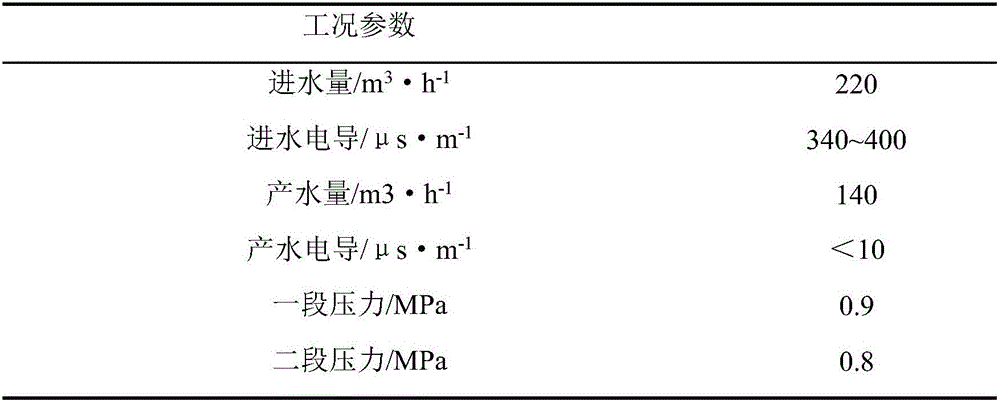

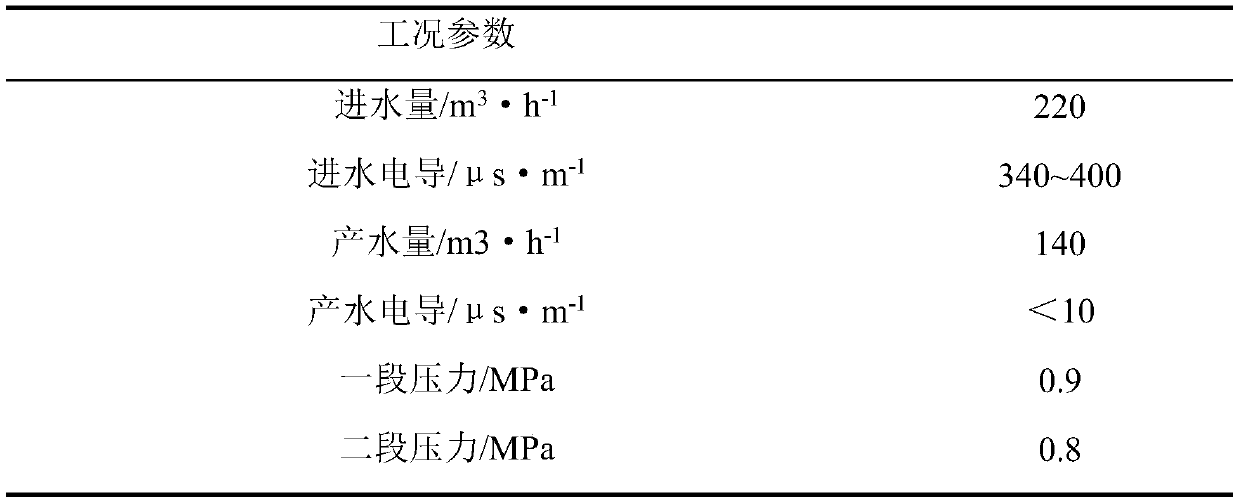

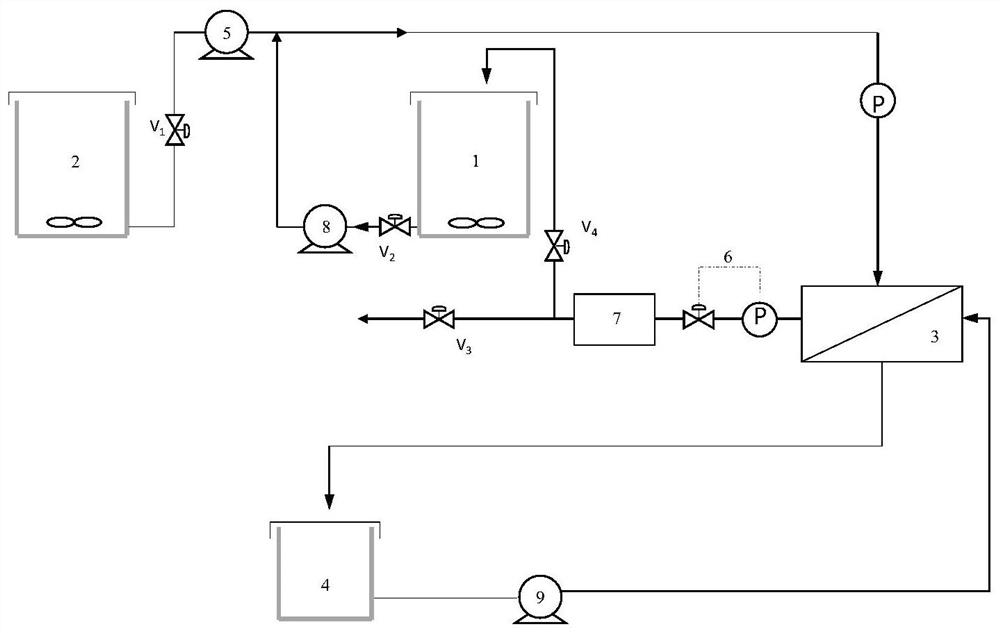

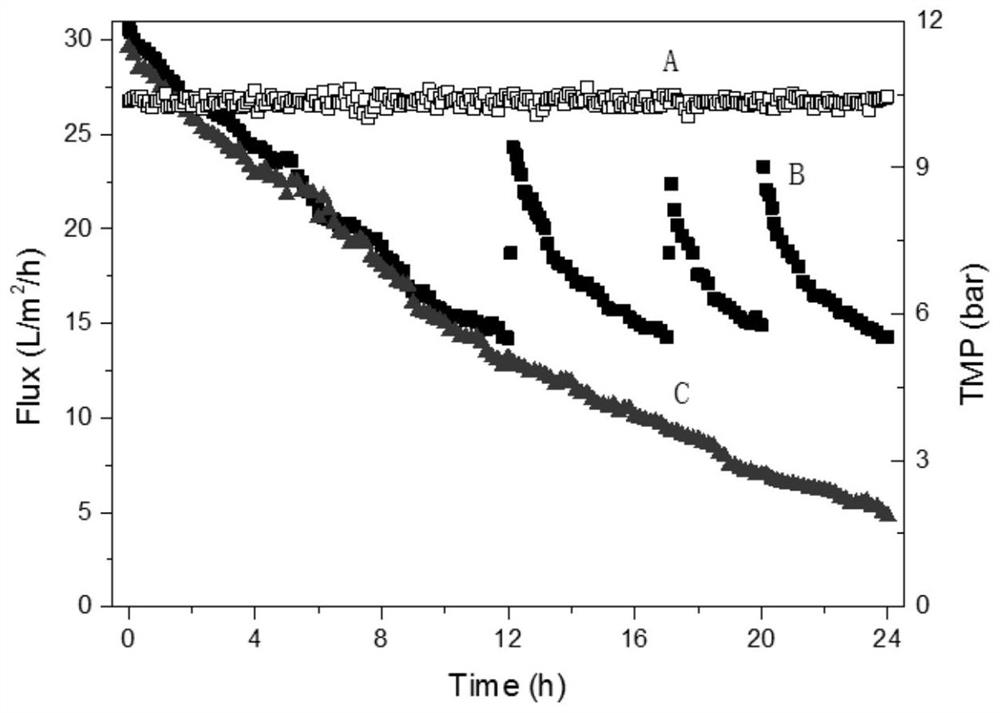

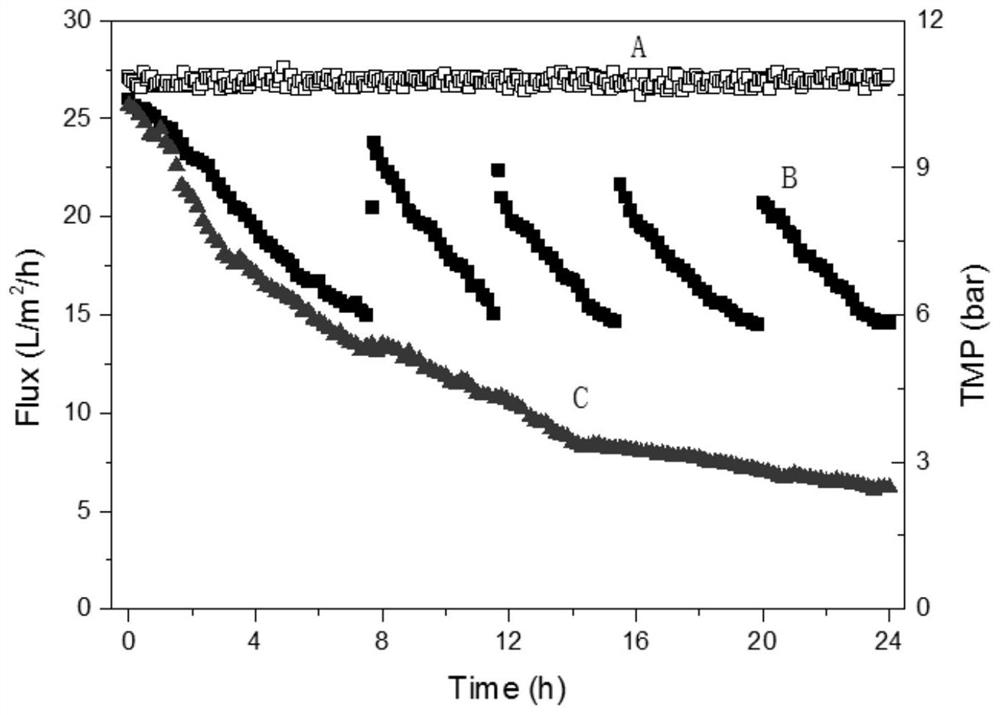

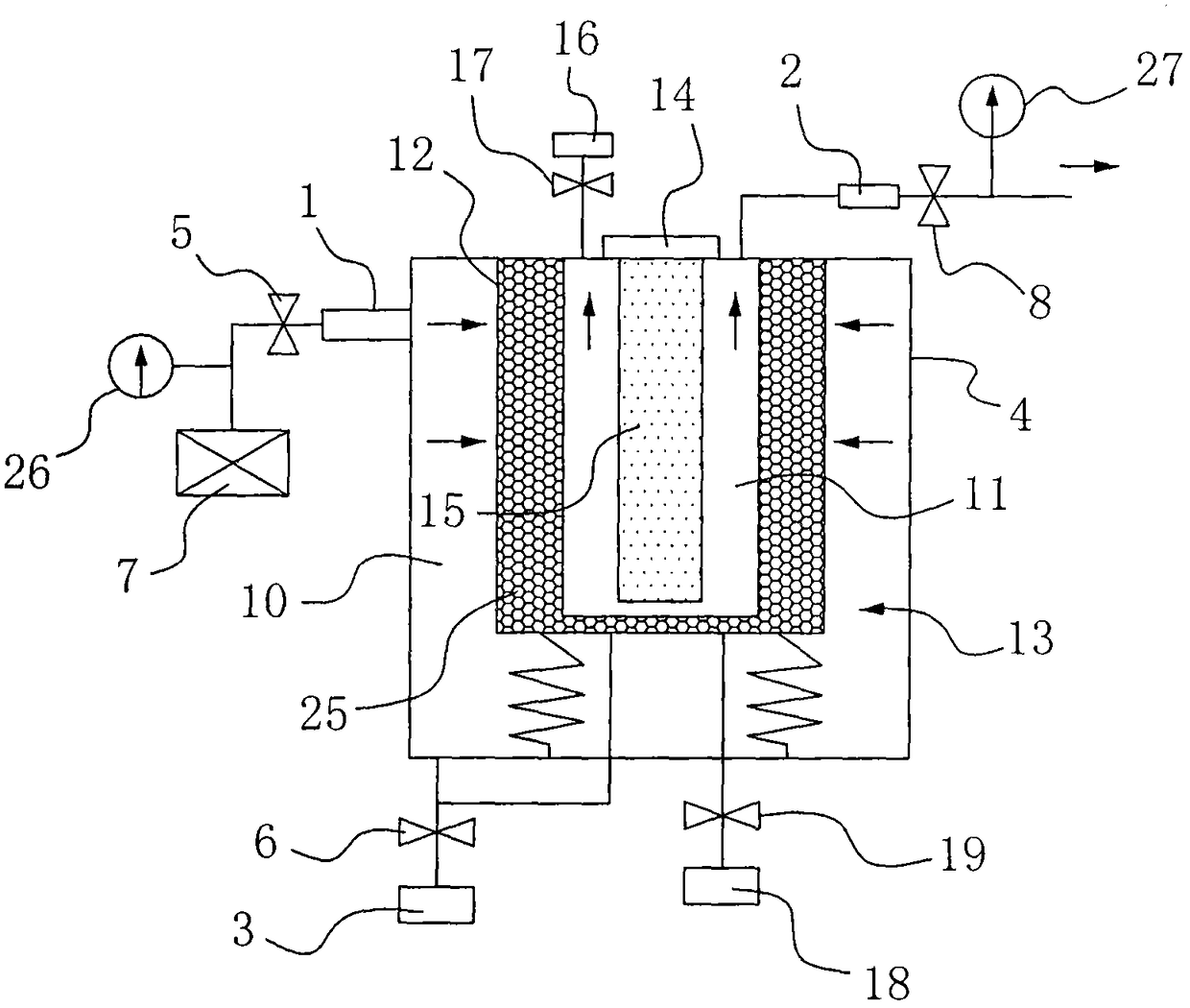

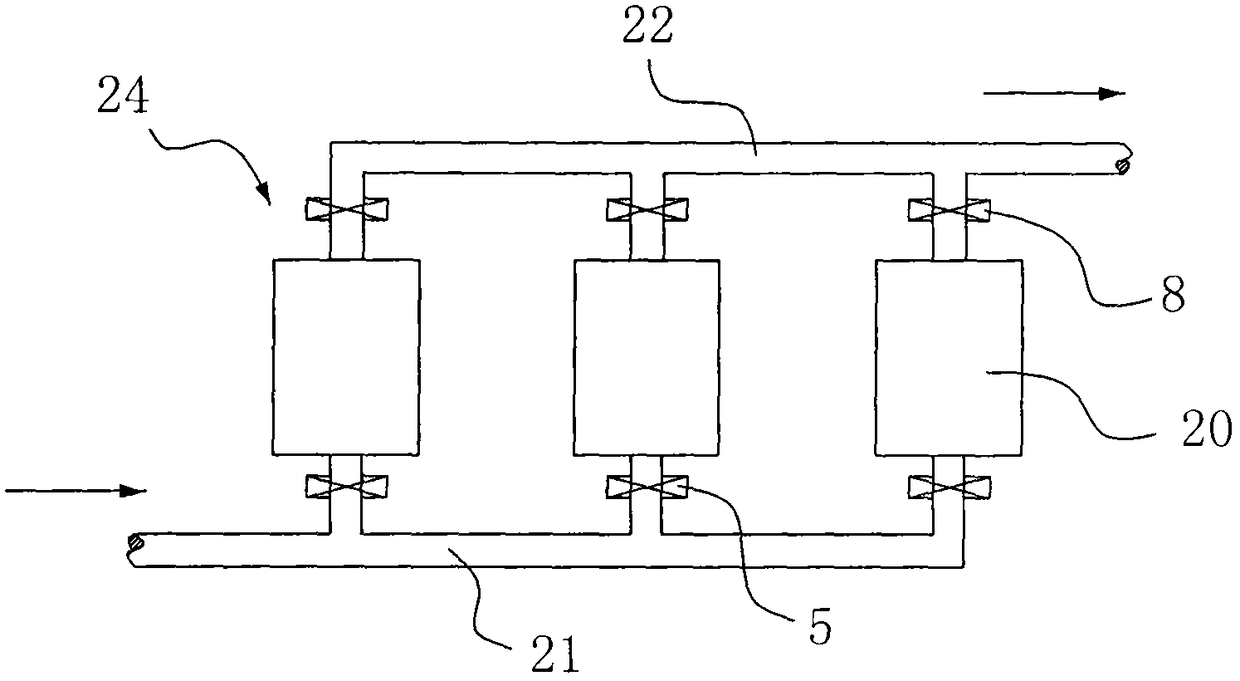

Backwashing type high-pressure reverse osmosis membrane filtration system

PendingCN113149132ARealize online anti-cleaningStable operating pressureWater/sewage treatment bu osmosis/dialysisReverse osmosisConcentration polarizationReverse osmosis

The invention provides a backwashing type high-pressure reverse osmosis membrane filtration system, belonging to the technical field of water treatment. The invention aims to solve various problems such as concentration polarization and pollution generated in a high-pressure reverse osmosis membrane filtration process. The backwashing type high-pressure reverse osmosis membrane filtration system comprises a high-concentration brine tank, a high-pressure pump, pressure gauges before and behind reverse osmosis membrane reactors, a rear pressure regulator and a flowmeter. In a normal filtering process, the reverse osmosis membrane filtration system normally runs (wherein a high-pressure reverse cleaning route is in a closed state); and when a flux is obviously reduced due to pollution, the high-pressure reverse cleaning system is opened, high-concentration saline water is injected into the water inlet side of the reactor, and the generated osmosis pressure exceeds the pressure of a high-pressure water pump, so filtered water reversely flows, and the effect of backwashing a membrane is achieved. The backwashing type high-pressure reverse osmosis membrane filtration system is applied to the field of water treatment.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Marine diesel engine fuel filter with ultrasonic cleaning device and filtering method

ActiveCN105065159BReduce failureExtended service lifeMachines/enginesLiquid fuel feedersUltrasonic sensorMechanical energy

The invention discloses a marine diesel engine fuel oil filter with an ultrasonic cleaning device. The marine diesel engine fuel oil filter with the ultrasonic cleaning device comprises a filter shell, wherein the filter shell is provided with an oil inlet, an oil outlet and a sewage outlet used for discharging impurities. The ultrasonic cleaning device acting on the interior of a filter cavity is arranged on the filter shell. The ultrasonic cleaning device comprises an ultrasonic transducer fixed to the filter shell, and a high-frequency vibrating bar which extends into the filter cavity and is used for converting high-frequency electric energy into mechanical energy is connected to the ultrasonic transducer. A filtering method comprises the steps that firstly, a procedure is set; secondly, conventional cleaning is conducted, and conventional cleaning includes (1) high-pressure oil cleaning and (2) high-pressure air reverse-blowing cleaning; and thirdly, deep cleaning is conducted, namely ultrasonic cleaning is conducted. According to the filter, regular automatic cleaning control can be achieved, the automation degree is greatly increased, and the labor intensity of workers is effectively relieved; faults, caused by quality problems of diesel oil, of a diesel engine are reduced, and remarkable economical benefits are obtained on the aspects of saving oil, prolonging the service life of the diesel engine and the like.

Owner:THE FIRST INST OF OCEANOGRAPHY SOA

Six-tank circulating biogas dual-path sofc anode fuel supply system

InactiveCN105140547BGuaranteed uninterrupted supplyLarge biogas flowFinal product manufactureFuel cell auxillariesNew energyFermentation

Owner:JILIN UNIV

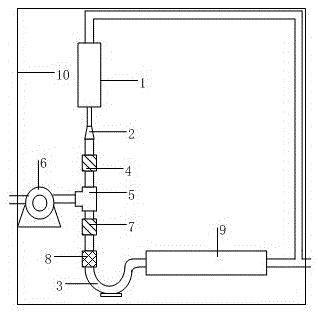

Constant-pressure expansion system for high-capacity high-temperature hot water

InactiveCN112797470AGuaranteed uptimeGuaranteed safe operationSteam generation heating methodsEfficient regulation technologiesExpansion tankEngineering

The invention provides a constant-pressure expansion system for high-capacity high-temperature hot water. The constant-pressure expansion system is applied to a hot water circulation system and comprises a closed expansion tank, wherein a water seal is arranged on the upper side of the expansion tank, a steam generator used for generating steam in the expansion tank is further connected to the expansion tank, a pressure relief pipeline and a water replenishing pipeline connected with the pressure relief pipeline in parallel are arranged between the expansion tank and the hot water circulation system, a pressure relief valve is arranged on the pressure relief pipeline, and a variable-frequency constant-pressure water replenishing pump is arranged on the water replenishing pipeline. The constant-pressure expansion system can prevent the expansion tank and the hot water circulation system from being corroded.

Owner:周协峰

Forward and reverse double flow calcium carbonate filter

InactiveCN104208945BPrevent backflowGuaranteed flow rateFiltration circuitsFault toleranceFiltration

The invention discloses a forward and reverse double-flow calcium carbonate filter in the field of industrial water treatment. The structure includes a water pump, a three-way diverter, a calcium carbonate filter column, a submerged elbow with a cover, a gate valve, a check valve, and a casing. The filter can be filtered according to the conventional calcium carbonate filter in the downstream mode, or it can be filtered in a better countercurrent mode by turning on the water pump, which increases the fault tolerance rate of the entire system and can bring out the air bubbles remaining in the filter, ensuring The filter works under a constant pressure to ensure the water flow rate and filtering effect.

Owner:无锡利淼环保科技有限公司

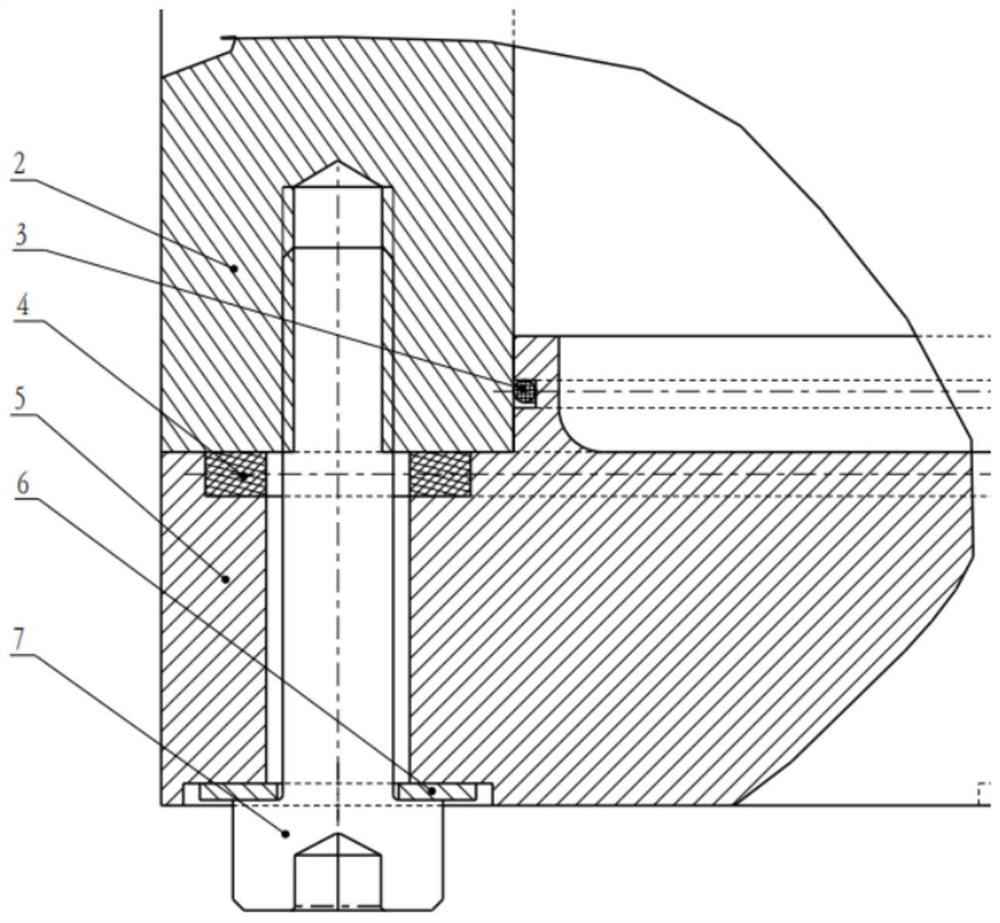

Detachable header device applied to coiled pipe high-pressure heaters

PendingCN112902732AShorten the processing cycleGuaranteed reliabilityHeat exhanger sealing arrangementHeat exchanger casingsButt weldingStructural engineering

The invention discloses a detachable header device applied to coiled pipe high-pressure heaters. The detachable header device comprises a cylindrical header, an end self-sealing manhole cover and a plurality of fixing parts, wherein the end self-sealing manhole cover is provided with a protrusion; the protrusion is inserted into an opening in the cylindrical header; each fixing part penetrates through the end self-sealing manhole cover and is inserted into the side wall at the opening position of the cylindrical header; and a sealing part is arranged between the side wall of the protrusion and the inner wall of the cylindrical header. Through the device, various problems caused by butt welding seams can be avoided; meanwhile, leakage is prevented.

Owner:XIAN THERMAL POWER RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com