Fine desulfurization device and method for coke oven gas

A coke oven gas and fine desulfurization technology, which is applied in separation methods, chemical instruments and methods, removal of gas pollutants, etc., can solve problems such as easy clogging of adsorbents, reduction of working efficiency of adsorption towers, and easy poisoning of catalysts, etc., to achieve The effect of reducing energy consumption, extending continuous working time, and stabilizing temperature and operating pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

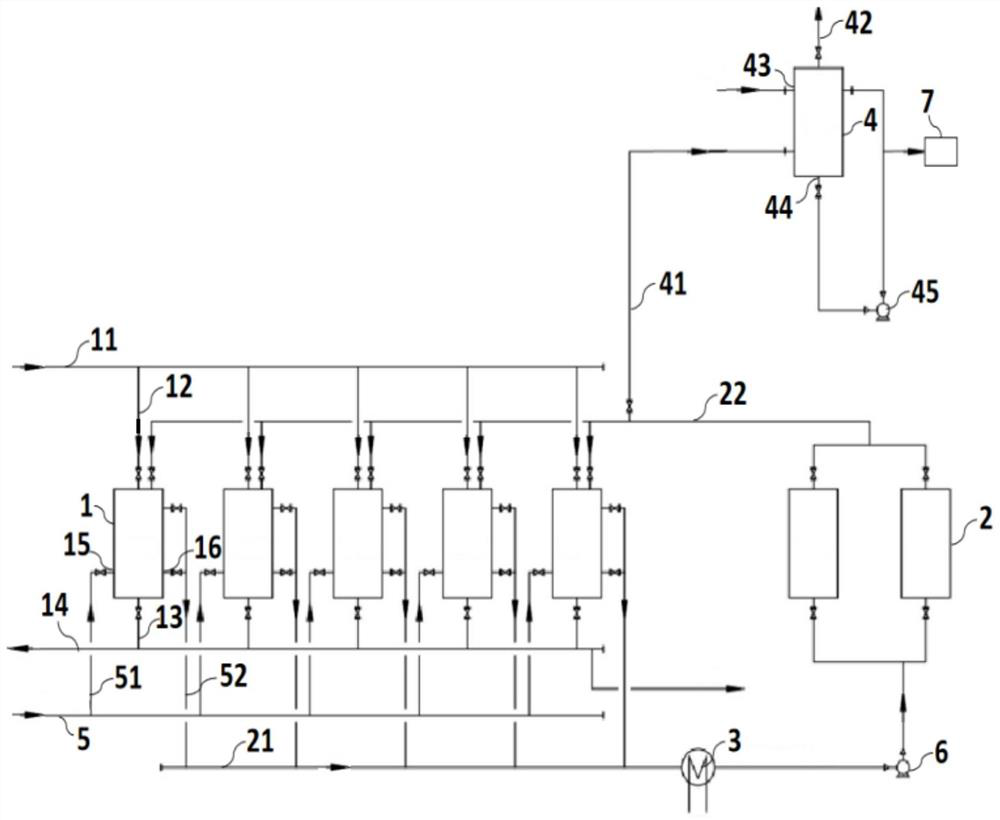

[0046] Such as figure 1 As shown, a fine desulfurization device for coke oven gas in this embodiment includes an adsorption tower 1, a conversion tank 2 and a washing tower 4. The gas outlet main pipe 14 is connected; the inlet port of the conversion tank 2 is connected with the adsorption tower 1 through the circulation analysis gas inlet pipe 21, and the gas outlet is connected with the adsorption tower 1 through the circulation analysis gas outlet pipe 22; A heating device 3 and a desorption fan 6 are provided, and the circulating analytic gas outlet pipe 22 communicates with the washing tower 4 through the analytic gas outlet pipe 41 . Wherein, the adsorption tower 1 is filled with an adsorbent, which can be a microcrystalline molecular sieve catalyst, or a microcrystalline molecular sieve or a molecular sieve with good adsorption properties; the conversion tank 2 is a hydrogenation conversion tank or a catalytic hydrolysis tank. In this example, the functions of adsorpti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com