Detachable header device applied to coiled pipe high-pressure heaters

A high-pressure heater and serpentine tube technology, which is applied in the field of detachable header devices for serpentine tube high-pressure heaters, can solve problems such as stress concentration, welding defects, hindering maintenance and operability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

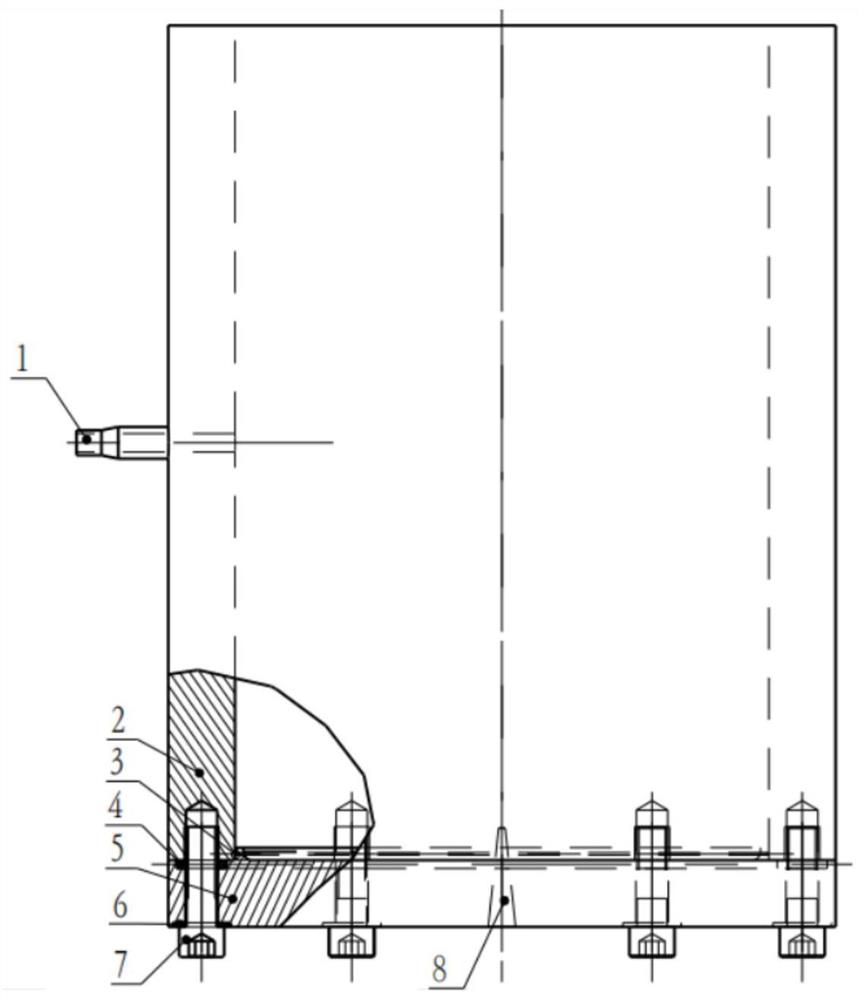

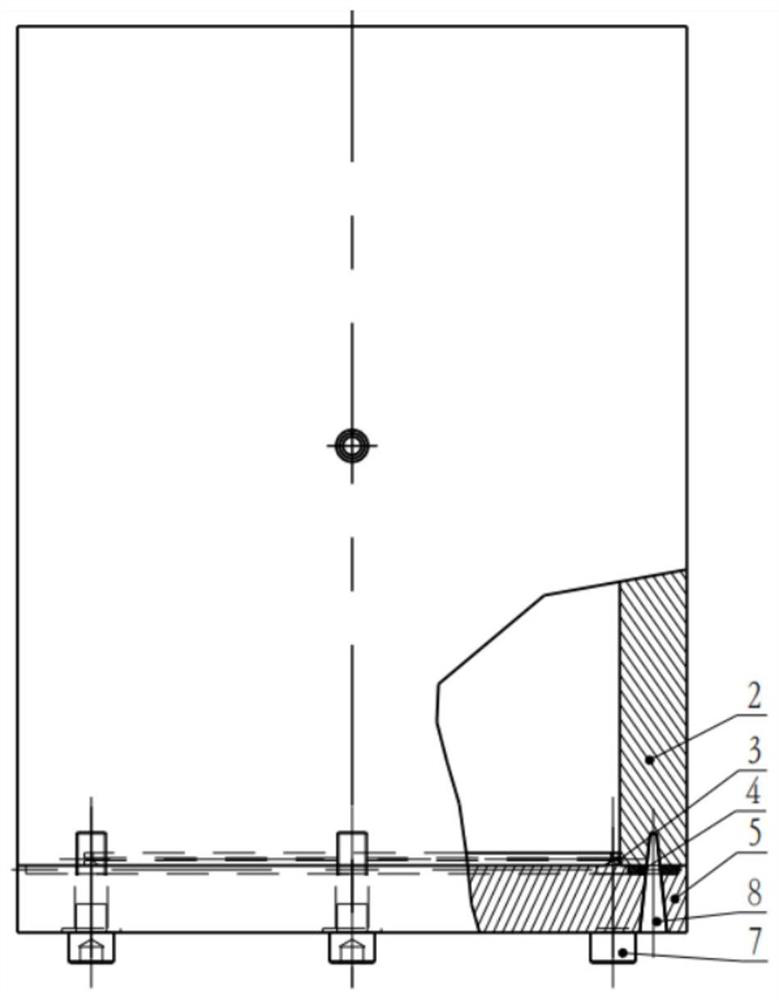

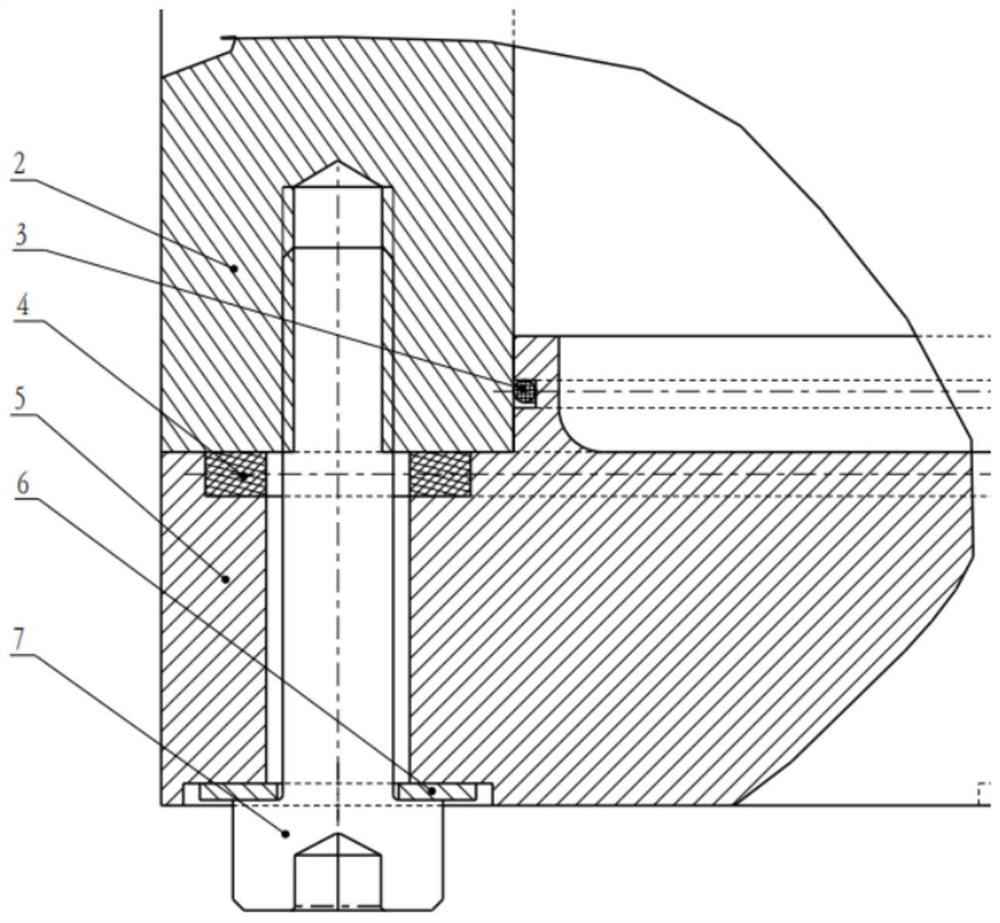

[0023] The present invention is described in further detail below in conjunction with accompanying drawing:

[0024] refer to Figure 1a and Figure 1b , the detachable header device for the serpentine tube high-pressure heater of the present invention includes a cylindrical header 2, a self-sealing manhole cover 5 at the end and a plurality of fixing parts 7, wherein the serpentine heat exchange tube 1 and the cylinder The cylindrical header 2 is connected, and the end self-sealing manhole cover 5 is provided with a protrusion, which is inserted into the opening on the cylindrical header 2, and each fixing piece 7 passes through the end self-sealing The manhole cover 5 is inserted into the side wall at the opening position of the cylindrical header 2, and the fixing pieces 7 are evenly distributed along the circumference, and a seal is arranged between the raised side wall and the inner wall of the cylindrical header 2 3.

[0025] Further, the fixing part 7 is a bolt, speci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com