Improved device of low-pressure system of carbon dioxide air stripping urea device

A carbon dioxide and urea plant technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of large operating pressure and temperature fluctuations, reduced cooling effect, heavy production load, etc., to reduce consumption, increase The effect of recovering energy and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

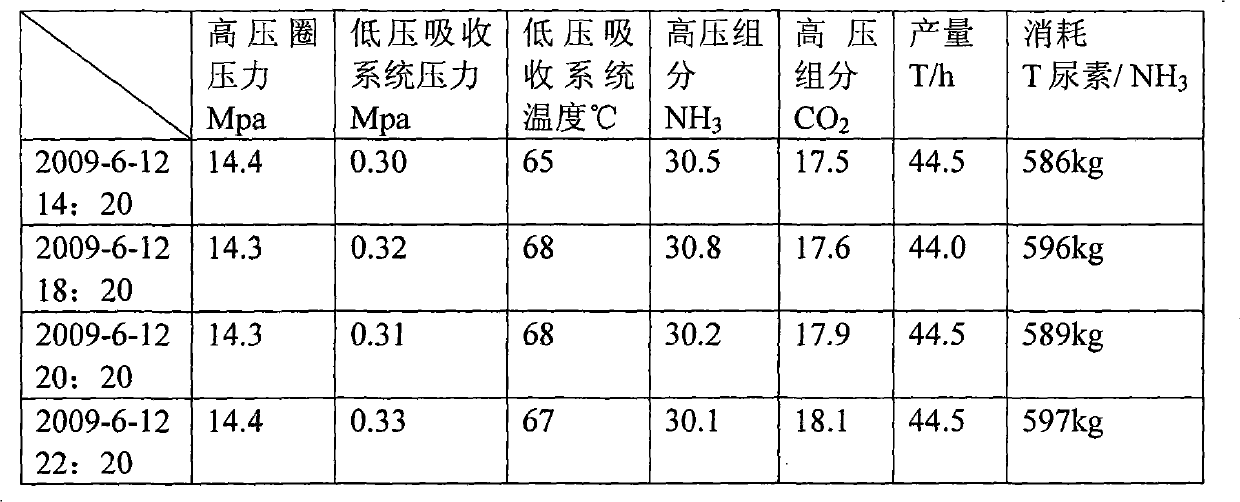

Examples

Embodiment

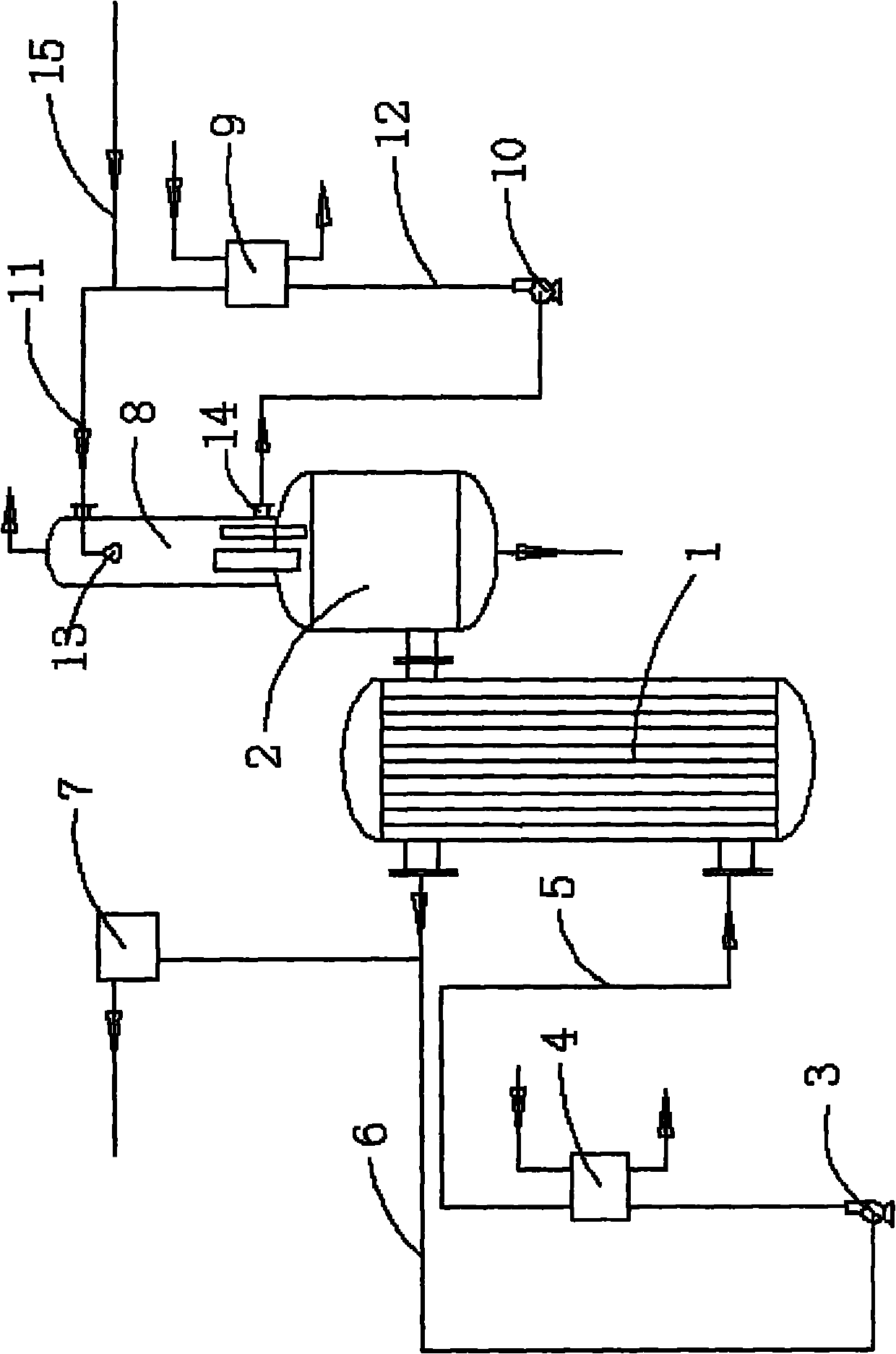

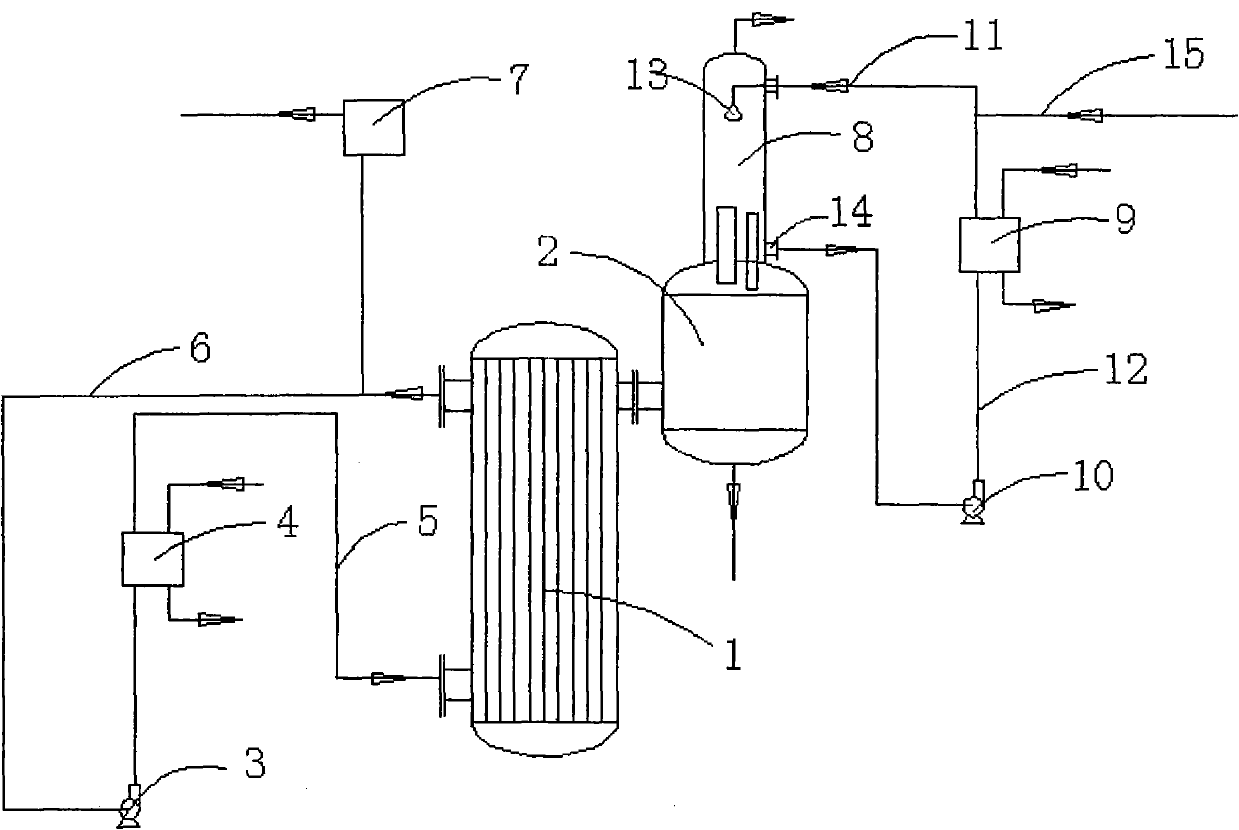

[0014] An improved device for the low-pressure system of a carbon dioxide stripping urea plant, comprising a low-pressure methylamine condenser 1, a liquid level tank 2, a first pump group 3, a first circulating cooler 4, a first circulating cooling water inlet pipe 5 and a first Circulating cooling outlet pipe 6 is based on the direction of use, and one end of the first circulating cooling inlet pipe and one end of the first circulating cooling outlet pipe are respectively connected with the low-pressure methylamine condenser, and the first circulating cooling inlet The other end of the water pipe and the other end of the first circulating cooling outlet pipe are respectively connected with the first circulating cooler, and the first pump set is arranged on the first circulating cooling inlet pipe and the first circulating cooling outlet. On any pipe section of one of the two water pipes, the liquid level tank is connected with the low-pressure methylamine condenser, the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com