Forward and reverse double flow calcium carbonate filter

A calcium carbonate and filter technology, applied in the direction of filtration separation, filtration circuit, chemical instruments and methods, etc., can solve problems such as blockage and low fault tolerance rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

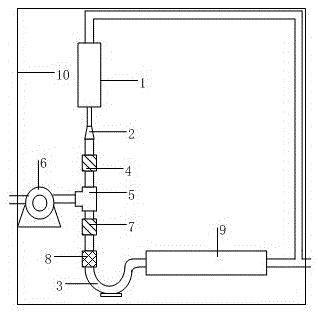

[0009] The present invention consists of a first calcium carbonate filter column 1, a shell 10, a second calcium carbonate filter column 9, a water pump 6, a three-way diverter 5, a submerged elbow with a cover 3, a first gate valve 4, a second gate valve 7, a stop valve The return valve 8 and the large and small head 2 are composed; one end of the water pump 6 is connected to the water inlet, and the other end is connected to the middle hole of the three-way splitter 5; the middle hole of the three-way splitter 5 is connected to the water pump 6, and the upper part is connected to the small head 2 and the first gate valve 4 in turn. 1. The first calcium carbonate filter column 1, the lower part is sequentially connected with the second gate valve 7, the check valve 8, the submerged elbow with cover 3, and the second calcium carbonate filter column 9, and the whole system is encapsulated by the shell 10;

[0010] Specifically, the shell is made of plexiglass;

[0011] Specific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com