Method for preparing aliphatic polycarbonate through continuous solution polymerization method

A polycarbonate and aliphatic technology, applied in the field of polymer compound preparation, can solve problems such as poor radial mass transfer effect and cycle power limitation, and achieve the effects of reducing production energy consumption, stabilizing operating pressure, and improving processing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

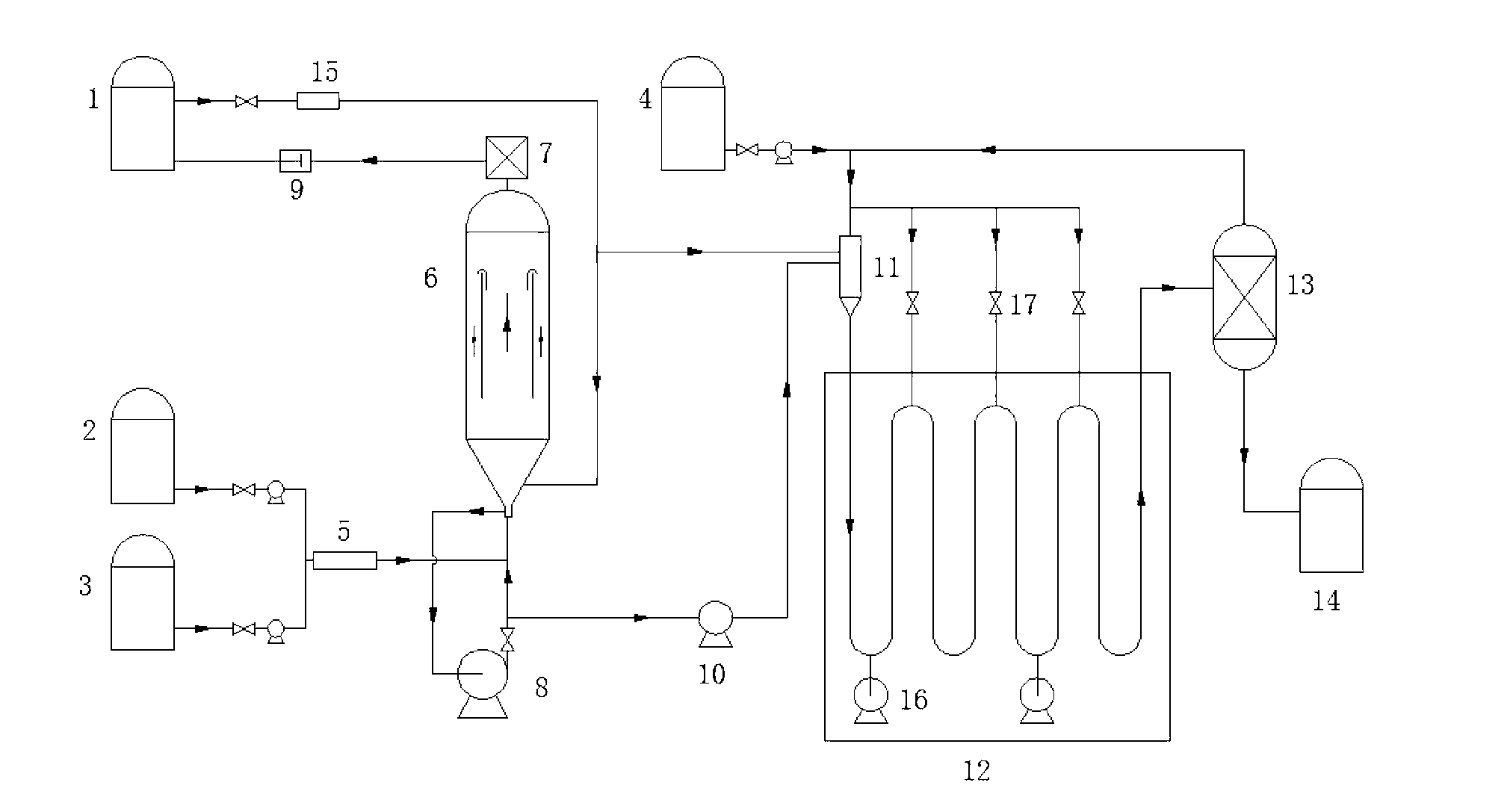

Embodiment 1

[0052] This embodiment is used for continuously preparing polypropylene carbonate. The solvent is dioxane.

[0053] The catalyst is prepared by the method described in Example 2 of Chinese Invention Patent Application No. 03105023.9, and contains 0.65 mol of ethyl zinc per liter of catalyst.

[0054] From catalyst storage tank 3 and epoxy storage tank 2, inject 253L catalyst and 508L propylene oxide in loop reactor 6 through mixer 5, make loop reactor 6 internal temperature keep on 70 ℃, pass carbon dioxide storage tank 1 to The internal pressure of the loop reactor 6 is supplemented to maintain the internal pressure of the reactor at 3.5 MPa. After 3 hours of reaction, 84 L / h of catalyst and 254 L / h of propylene oxide were continuously injected. The internal circulation path is: new epoxy, catalyst and carbon dioxide enter from the bottom of the reactor 6 and mix with the circulating material, flow upward from the inside of the draft tube, flow to the top of the draft tube ...

Embodiment 2

[0061] This embodiment is used to continuously prepare carbon dioxide-propylene oxide-epoxycyclohexane terpolymer, and the solvent is dioxane.

[0062] The catalyst is prepared by the method described in Example 2 of Chinese Invention Patent Application No. 03105023.9, and contains 0.65 mol of ethyl zinc per liter of catalyst.

[0063] From catalyst storage tank 3 and epoxide storage tank 2, inject 253L catalyst, 508L propylene oxide and epoxy cyclohexane 1 / 1 (v / v) mixed monomer by mixer 5 in loop reactor 6, make The internal temperature of the loop reactor 6 is maintained at 70° C., and the pressure in the loop reactor 6 is replenished through the carbon dioxide storage tank 1 to maintain the pressure in the reactor 6 at 3.5 MPa. After 3 hours of reaction, 84 L / h of catalyst and 170 L / h of mixed monomer of propylene oxide and cyclohexane oxide were continuously injected. The internal circulation path is: new epoxy, catalyst and carbon dioxide enter from the bottom of the rea...

Embodiment 3

[0070] This example is used to continuously prepare carbon dioxide-ethylene oxide-propylene oxide random terpolymer, and the solvent is dioxane.

[0071] The catalyst is prepared by the method described in Example 2 of Chinese Invention Patent Application No. 03105023.9, and contains 0.65 mol of ethyl zinc per liter of catalyst.

[0072] Reaction apparatus and condition are all identical with embodiment 1.

[0073] The initial feeding ratio is as follows:

[0074] Catalyst 253L

[0075] Propylene oxide 380L

[0076] Ethylene oxide 128L

[0077] After 4 hours of reaction, the continuous injection ratio is as follows:

[0078]Catalyst 63L,

[0079] Propylene oxide 95L

[0080] Ethylene oxide 32L

[0081] The total flow of dioxane used for dilution is 220L / h. Others are as in Example 1.

[0082] Add terminator (methanol), capping agent (maleic anhydride) and heat stabilizer (boric acid) etc. through the feeding port at the end of the tubular reactor 12 to realize in-situ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com