Full-temperature-range simulated rotating moving bed pressure swing adsorption process for extracting H2 and NH3 from synthetic ammonia purge gas

A technology of synthetic ammonia degassing and pressure swing adsorption, which is applied in the direction of ammonia preparation/separation, separation methods, bulk chemical production, etc., and can solve the problems of discounted mass transfer efficiency, non-standard deamination and impurity removal, and fluctuations in ammonia content and other issues to achieve the effect of reducing manufacturing complexity and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

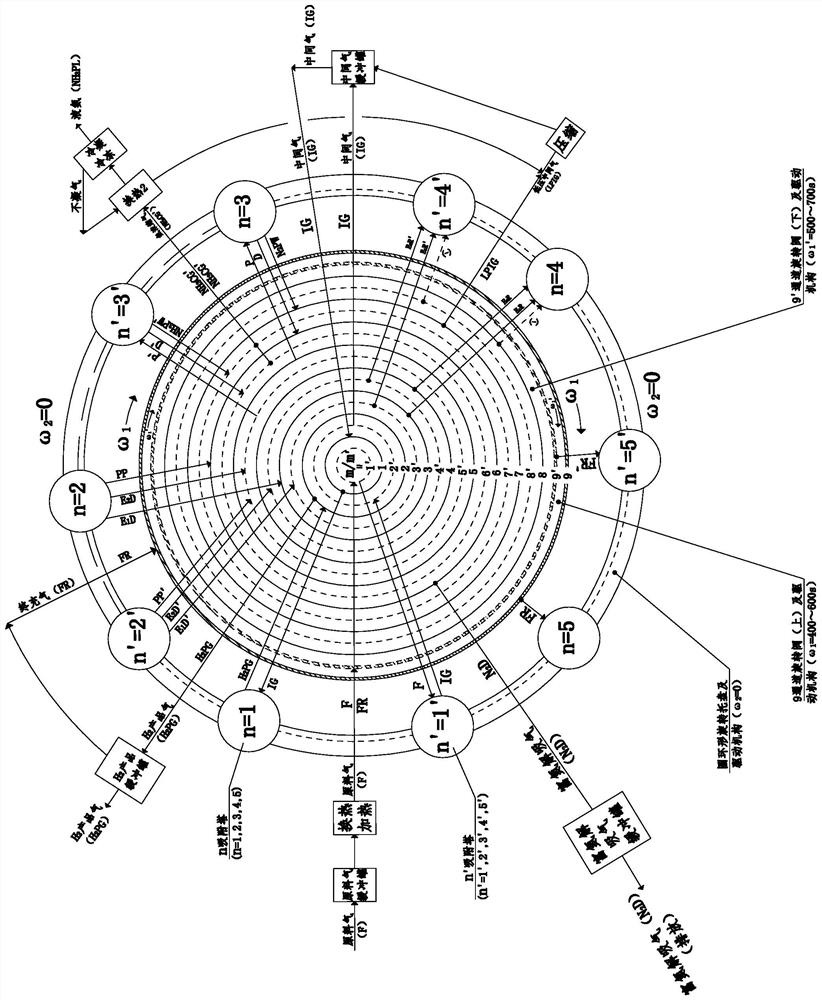

[0032] like figure 1 As shown, the described one extracts H from the synthetic ammonia purge gas 2 with NH 3The full temperature range simulated rotary moving bed pressure swing adsorption process, in which the full temperature range simulated rotary moving bed pressure swing adsorption (FTrSRMPSA) system is composed of 5 (n'=5') axial flow and A fixed composite bed adsorption tower with a height-to-diameter ratio of 3 and a fixed composite of 5 (n=5) axial flows loaded with aluminum oxide, silica gel, activated carbon, molecular sieve / carbon molecular sieve and a height-to-diameter ratio of 4.5 to 5.0 The bed adsorption tower is installed in a rotating speed of ω 2 The adsorption tower (n'+n=10) and the corresponding drive mechanism on the annular rotating tray with =0, the number of channels are m'=9 and m=9 respectively, and they are placed in the center of the annular tray, and respectively Take the rotation speed as ω 1 ’=500~700s and ω 1 = 400~600s upper and lower t...

Embodiment 2

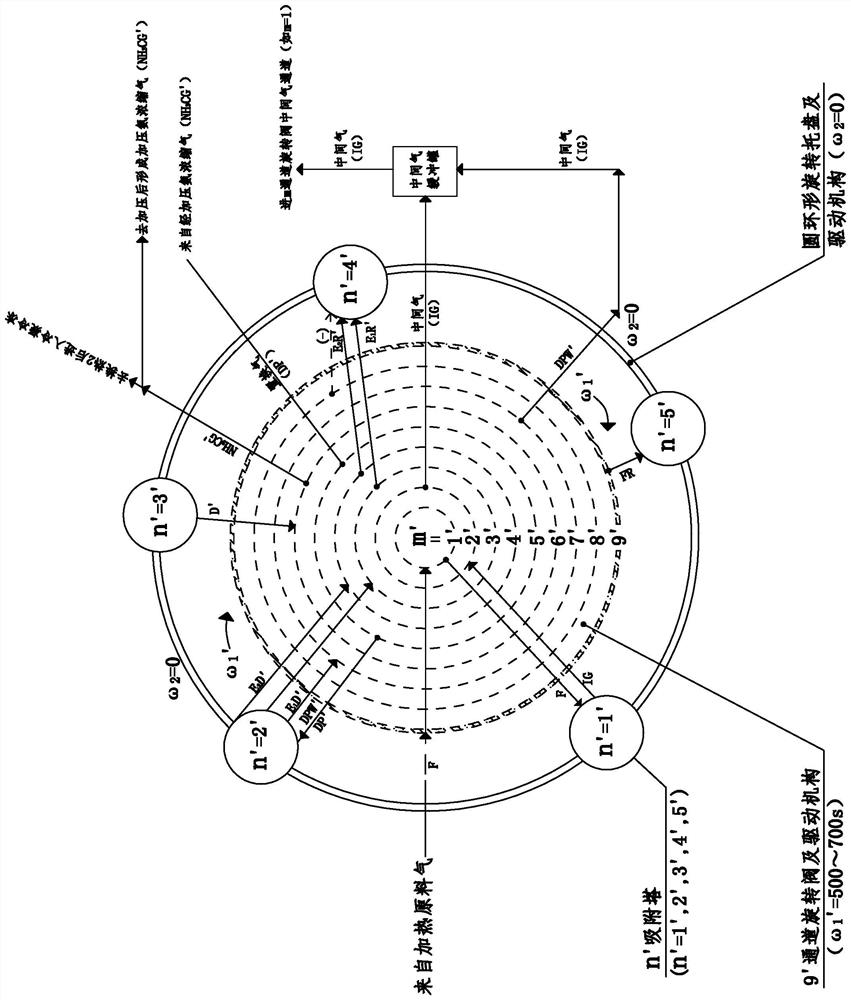

[0034] like figure 2 As shown, on the basis of Example 1, the cyclic operation steps of PSA adsorption and desorption in the medium and high temperature pressure swing adsorption ammonia concentration system are followed by replacement (DP') after the adsorption (A') step is completed. step, using a concentrated ammonia gas (NH 3 CG) as a replacement gas (DP') to replace (DP'), and after the replacement (DP') step is completed, a first pressure drop (E1D') and a second pressure drop (E2D') are carried out. The sloping (PP') step is cancelled, and the corresponding m' channel of the rotary valve (such as m'=5') is used as the replacement gas (DP') channel, and the replacement gas (DPW) generated by the replacement (DP') step is used. '), which flows through the original ammonia-rich flushing exhaust gas (NH 3 PW') channel (such as m'=7') and as intermediate gas (IG) into the intermediate gas (IG) buffer tank for recycling, after the secondary pressure equalization (E2D') ste...

Embodiment 3

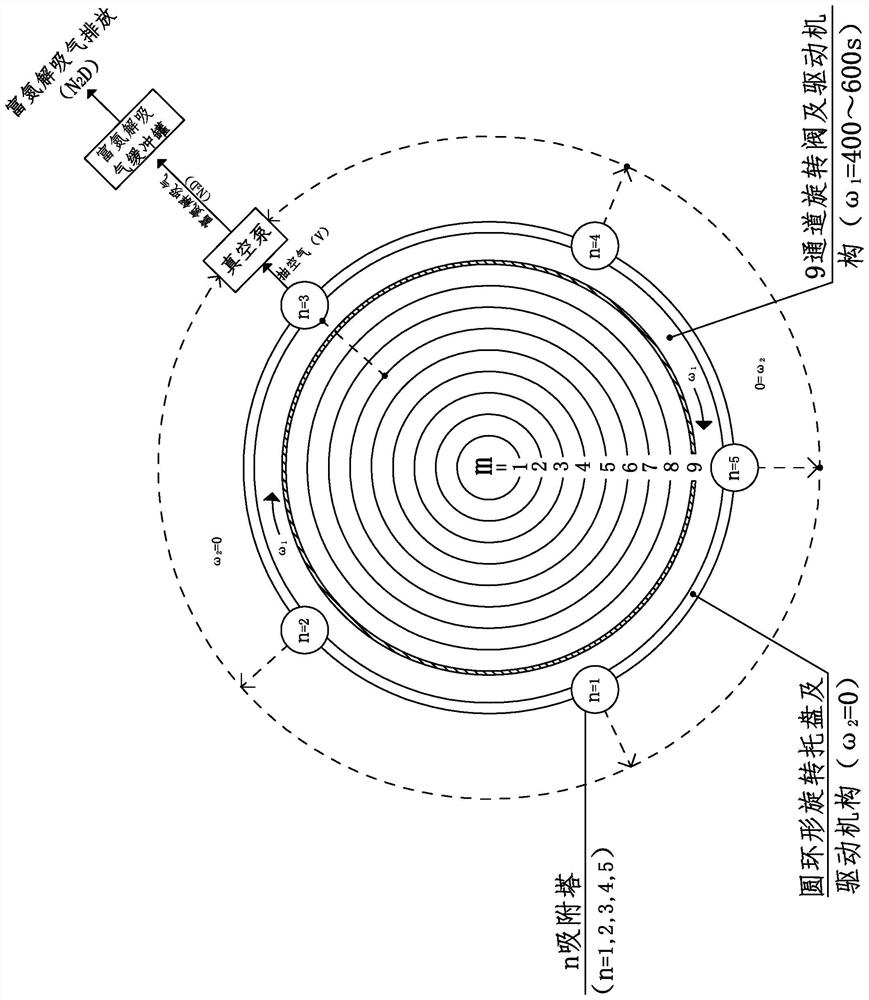

[0036] like image 3 As shown, on the basis of Examples 1 and 2, in the intermediate gas pressure swing adsorption hydrogen extraction system, the vacuum (V) desorption step is used to replace the reverse discharge (D) step of the ammonia concentrated adsorption phase, and the vacuum (V) is formed. Nitrogen-rich stripping gas (N 2 D) From the outlet of n (such as n=3) adsorption tower, it flows through the external pipeline connected to the outlet of the adsorption tower on the annular rotating tray, and the external pipeline is equipped with a vacuum pump and a control valve to control the flow and enter the rich Nitrogen stripping gas (N 2 D) Buffer tank, the maximum vacuum degree is -0.08MPa, the original reverse degassing (D) channel (such as m=6) in the corresponding m-channel rotary valve becomes an empty channel, and the adsorbent in the n adsorption tower is completely desorbed, get H 2 Product gas (H 2 PG) purity is greater than or equal to 99.99%, the yield is gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com