Material feeder for glass strip chamfer angle edging

A feeding device, glass technology, applied in machine tools, grinders, grinding/polishing equipment, etc. suitable for grinding workpiece edges, to achieve the effect of reducing manufacturing complexity and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The feeding device for narrow glass chamfering and edging of the present invention is a practical transformation of the original double-sided machine, and the original movable bridge is omitted to become a flexible slider positioning combination. In this way, new requirements can be realized.

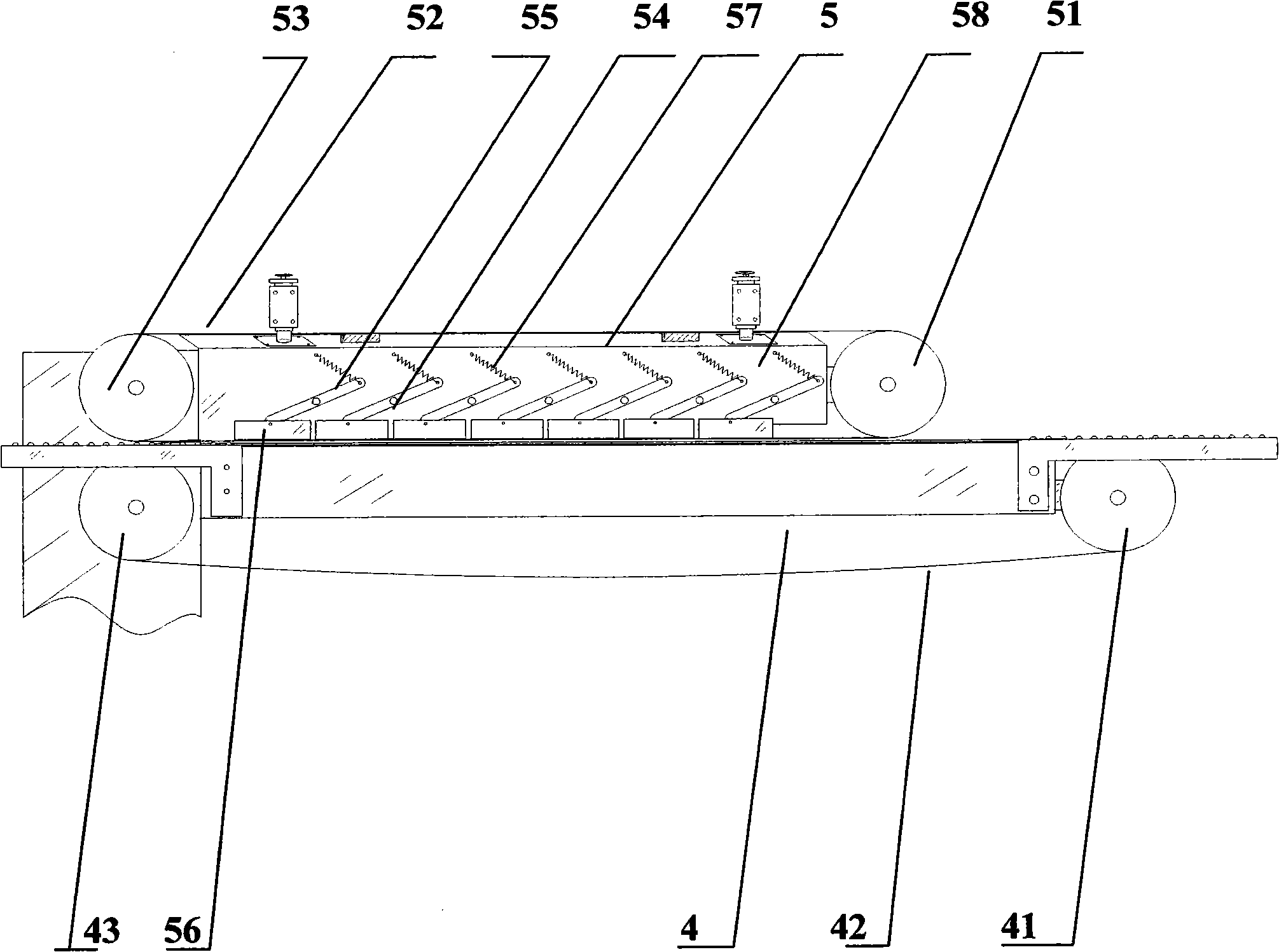

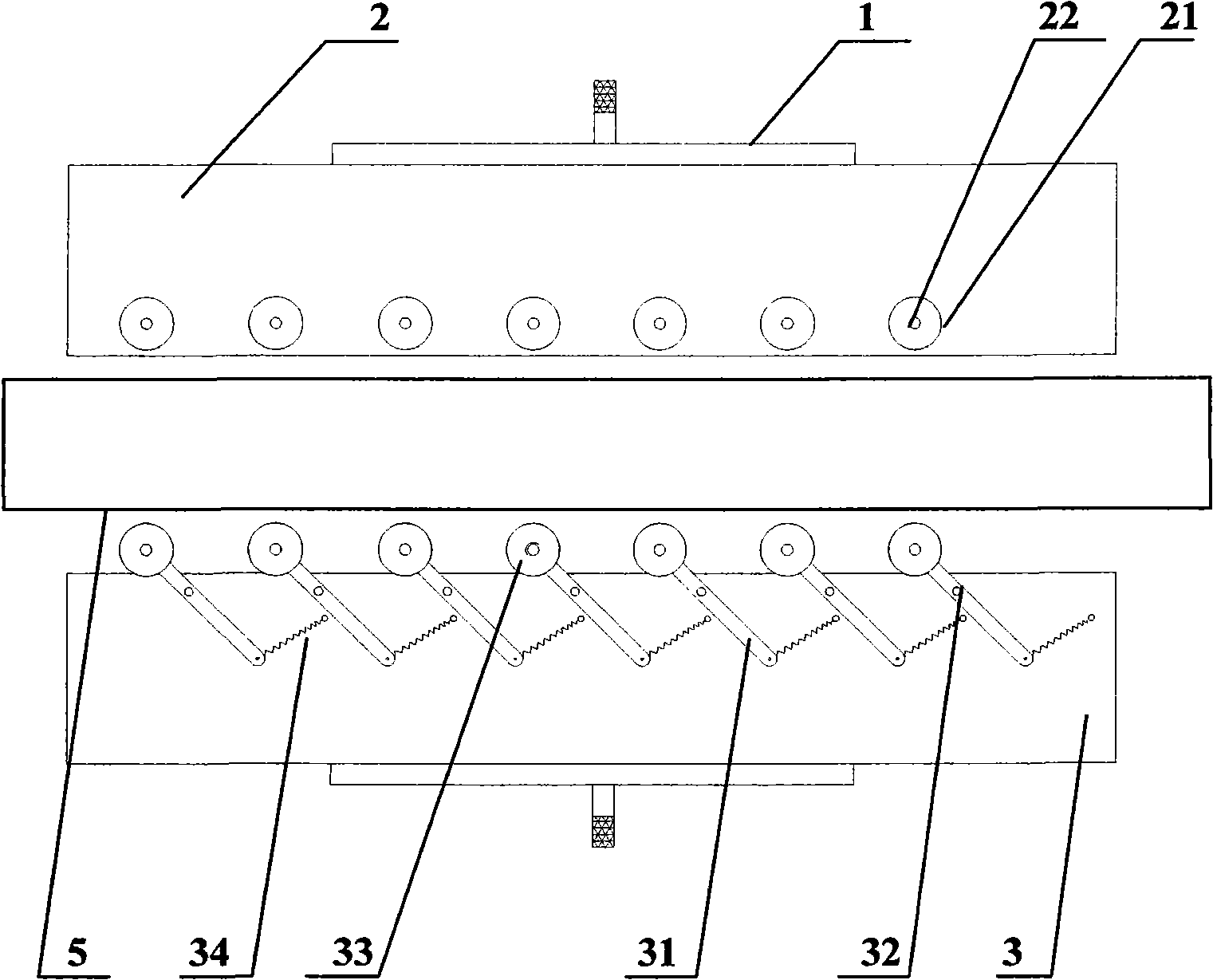

[0017] The device includes a conveyor belt part arranged up and down and a positioning part arranged left and right, and the two parts are arranged perpendicular to each other at the same position; wherein, the positioning part arranged left and right includes a slider body 1, a fixed block 2, and a movable block 3, and the movable block 3 is fixed On the slider body 1, when the slider body 1 slides, the movable block 3 is driven to adjust the distance between the fixed block 2 and the movable block 3, and a row of rotating shafts 22 are arranged on the upper surface of the fixed block 2 to position the rubber wheels 21. The central hole is sleeved on the rotating shaft 22; a row...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com