Full-temperature-range simulated rotating moving bed pressure swing adsorption process for extracting H2 and NH3 from GaN-MOCVD tail gas

A pressure swing adsorption, full temperature range technology, applied in the preparation/separation of ammonia, separation method, separation using solid contact hydrogen, etc. Gas and other problems, to achieve the effect of reducing manufacturing complexity and cost

Pending Publication Date: 2022-06-03

ZHEJIANG TIANCAIYUNJI TECH CO LTD

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] Several existing traditional methods mainly recover NH from ammonia-containing waste gas. 3 For example, it mainly includes freezing method, water washing method (water washing) method, sulfuric acid absorption method, phosphoric acid (ammonium) absorption and rectification coupling method, organic solvent absorption method, adsorption method (TSA-based), adsorption and rectification Coupling method, catalytic combustion method, catalytic ammonia decomposition method, etc., mostly have a long process and can only be used as intermediate products such as industrial ammonia water or amine fertilizer, and cannot directly recover ammonia gas and return it to the GaN-MOCVD process for recycling

The temperature swing adsorption (TSA) method is only suitable for deammonization purification of tail gas with low ammonia concentration. The purified gas meets the emission requirements and is discharged, but the desorbed gas after adsorption is enriched with ammonia, or it is absorbed by water, etc. Make ammonia water, ammonia fertilizer, etc. for use, or use catalytic combustion to catalyze and oxidize combustible components such as ammonia, hydrogen, and methane in the tail gas at high temperature, and perform follow-up treatment to meet the emission standards, but ammonia cannot be directly recovered for reuse ; The catalytic ammonia decomposition method is to catalytically decompose the tail gas with high ammonia concentration into H at high temperature. 2 and N 2 , and then recover H2 or N2 after treatment, and ammonia cannot be recovered and reused

[0005] Recovery of H from GaN-MOCVD process tail gas 2 with NH 3 Among the existing new technologies, typical ones include the Chinese patent "A Method for Recovery and Reuse of Full-Temperature Pressure Swing Adsorption and Full Components of Tail Gas from LED-MOCVD Process (CA 201810532108.0)", the US Patent "Methods of Extracting and Recycling Hydrogen from MOCVD Process ExhaustGas by FTrPSA (US 16 / 423,167)" and "Methods of Extracting and RecyclingAmmonia from MOCVD Process Exhaust Gas by FTrPSA (US 16 / 423,181)", etc., the process is a section of ammonia concentration consisting of 5~6 adsorption towers In the pressure swing adsorption process, the maximum concentration is about 90%, and the H 2 In the purification process, the non-adsorbed phase gas produced by the ammonia concentration process has a relatively high ammonia residual concentration in the second-stage PSA hydrogen extraction raw material gas, which greatly reduces the hydrogen extraction efficiency of the second-stage PSA. It is necessary to add water washing to absorb residual ammonia and change temperature. Adsorption (TSA) purification removes trace amounts of ammonia, which leads to relatively long process, high investment, and large area occupation, especially the number of program control valves and regulating valve groups used in the second-stage axial flow fixed bed PSA process is too large. It greatly affects the stable operation and cost of the device. At the same time, when the yield of ammonia reaches 98%, H 2 The yield is only 75~85%, and the H 2 / NH 3 Simultaneous recovery of high purity and high yield "double high"

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

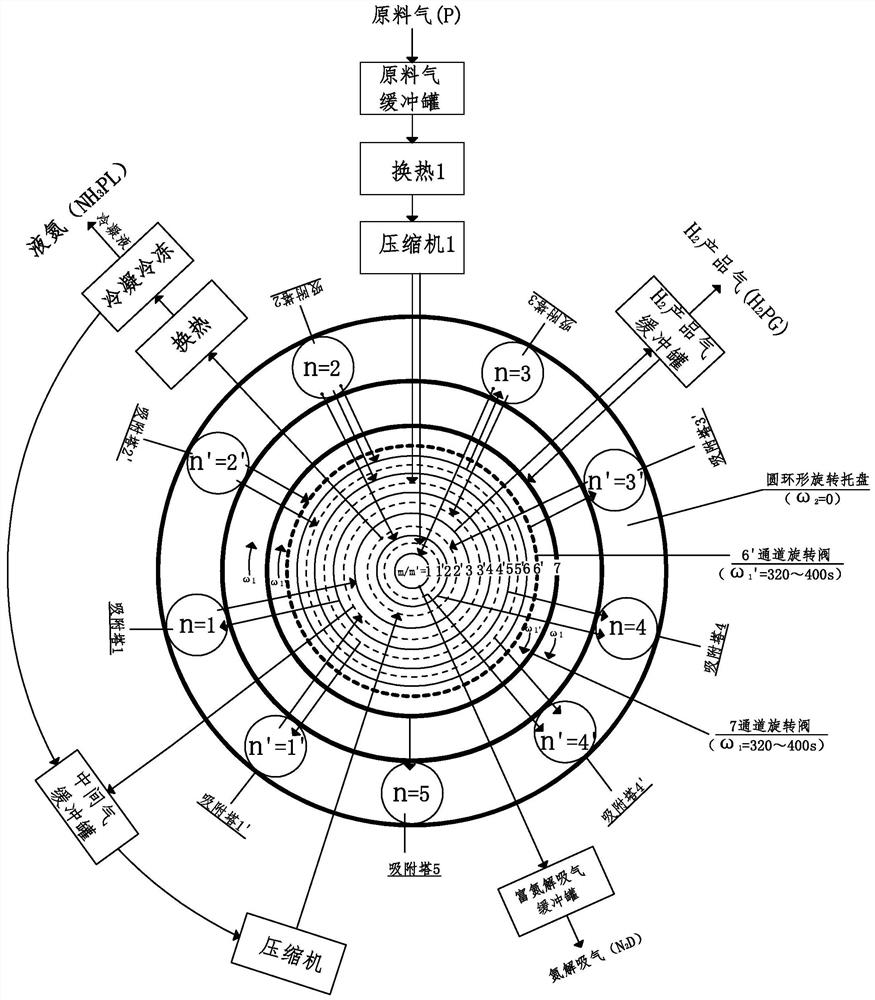

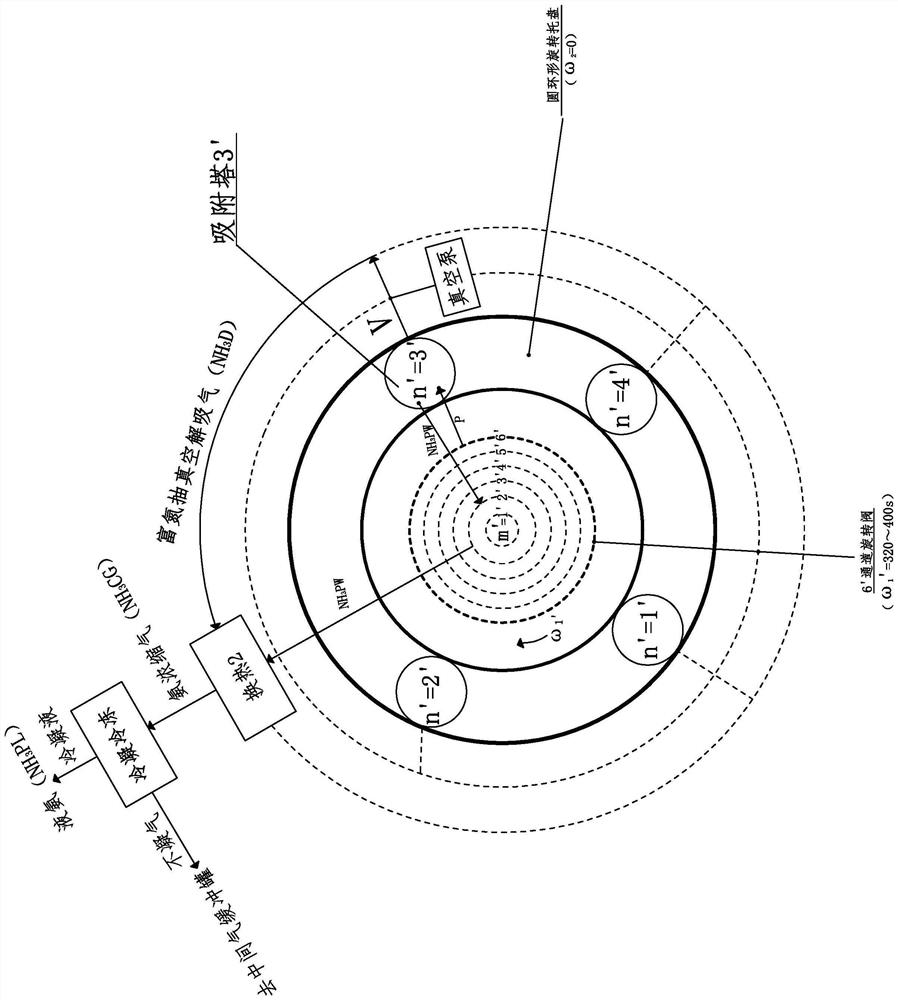

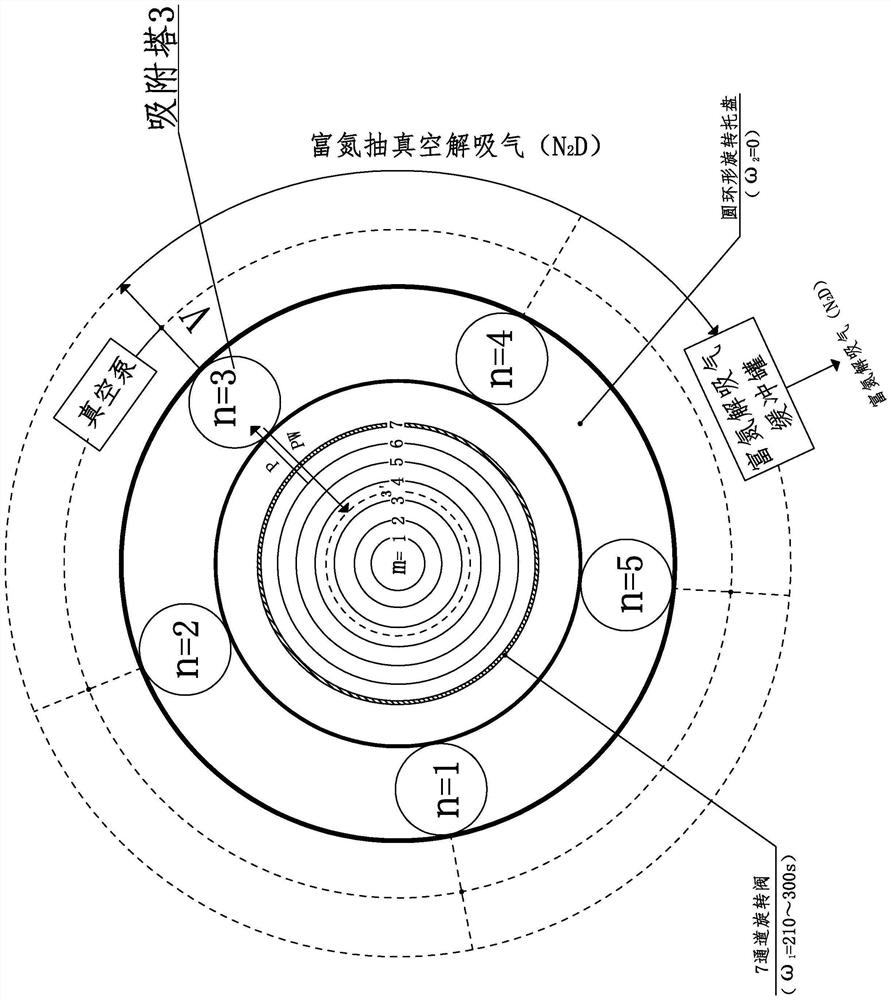

The invention discloses a full-temperature-range simulated rotating moving bed pressure swing adsorption process for extracting H2 and NH3 from GaN-MOCVD tail gas. A medium-high-temperature pressure swing adsorption ammonia concentration system composed of a plurality of axial flow fixed bed adsorption towers and a rotating speed mechanism is arranged in the center of an upper multi-channel rotating valve and a lower multi-channel rotating valve, and the periphery of the multi-channel rotating valve is arranged on a circular rotating tray. According to the gas pressure swing adsorption hydrogen extraction system, gas flowing through a rotary valve channel, pipelines at the inlet and outlet ends of adsorption towers and adsorption bed layers rotates at the inlet and outlet positions of each adsorption tower and each adsorption bed layer, and mass transfer of respective adsorption and desorption steps is completed at the same time, so that a pressure swing adsorption process of simulating a rotary moving bed is formed; the pressure swing adsorption process of the rotary moving bed is simulated on the basis of pressure swing adsorption of the axial flow fixed bed, and H2 and NH3 products are obtained in a high-purity and high-yield manner and are returned to the GaN-MOCVD process to be recycled.

Description

technical field [0001] The invention relates to the semiconductor industry containing hydrogen (H 2 ) and ammonia (NH 3 ) in the field of pressure swing adsorption (PSA) separation and purification of gas, more specifically, it relates to a gallium nitride metal oxide chemical vapor deposition (GaN-MOCVD) process exhaust gas extraction of H 2 / NH 3 The full temperature range of a rotary moving bed pressure swing adsorption process is simulated. Background technique [0002] MOCVD (Metal Oxide Chemical Vapor Deposition) process (equipment) is a modern method and means for the research and production of compound semiconductor materials. , photocathode and other products, is an indispensable method and equipment for the optoelectronics and semiconductor industries. For example, blue and violet LEDs, which are widely used in the market, are produced using gallium nitride (GaN)-based materials. Among them, the MOCVD epitaxy process uses high-purity metal oxide (MO) as the MO...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B01D53/08C01B3/56C01C1/12

CPCB01D53/08C01B3/56C01C1/12Y02C20/40

Inventor 钟娅玲汪兰海陈运唐金财钟雨明蔡跃明

Owner ZHEJIANG TIANCAIYUNJI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com