High-pressure scale removing water system and control method thereof

A high-pressure, controller technology, applied in metal rolling, manufacturing tools, metal rolling, etc., can solve the problems of less than one descaling water consumption, difficult to maintain descaling water pressure, large water pressure fluctuation range, etc., to achieve The design principle is reliable, the substantive features are highlighted, and the effect of solving the response lag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments. The following embodiments are explanations of the present invention, but the present invention is not limited to the following embodiments.

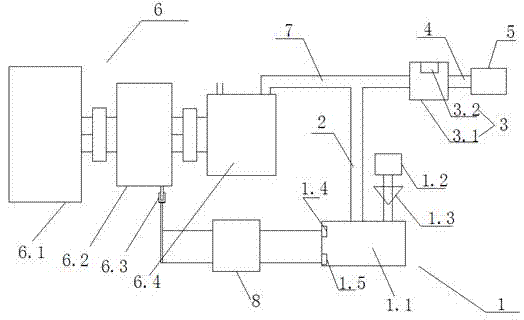

[0029] Such as figure 1 As shown, a high-pressure descaling water system provided by the present invention includes an energy storage tank group 1, the energy storage tank group 1 is connected to the injection valve group 3 through the first pipeline 2, and the injection valve group 3 is connected to the injection valve group 3 through the second The pipeline 4 is connected to the descaling header 5; the high-pressure descaling water system also includes a water supply pump group 6, and the water supply pump group 6 is connected to the energy storage tank group 1 and the injection valve group 3 through a third pipeline 7. The water pump set 6 includes a pump set motor 6.1, a speed regulating coupler 6.2 con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com