Passive accident discharge and cooling system and method of steam generator in nuclear power station

A steam generator and accidental discharge technology, applied in nuclear power generation, cooling devices, nuclear engineering, etc., can solve the problems of how to cool and recycle the high-temperature steam-water mixture without considering the radioactivity, and achieve high reliability, stable operating pressure, Compensate for the effect of water volume changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

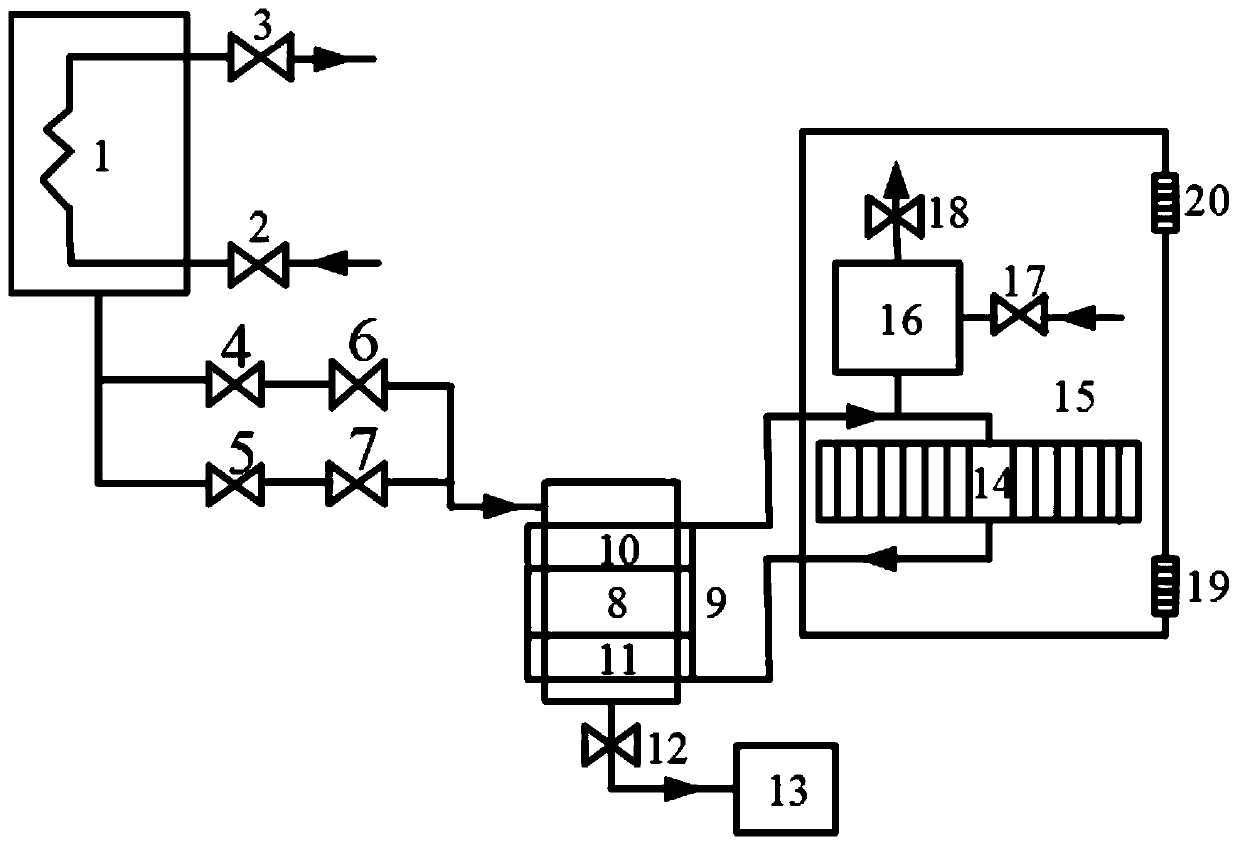

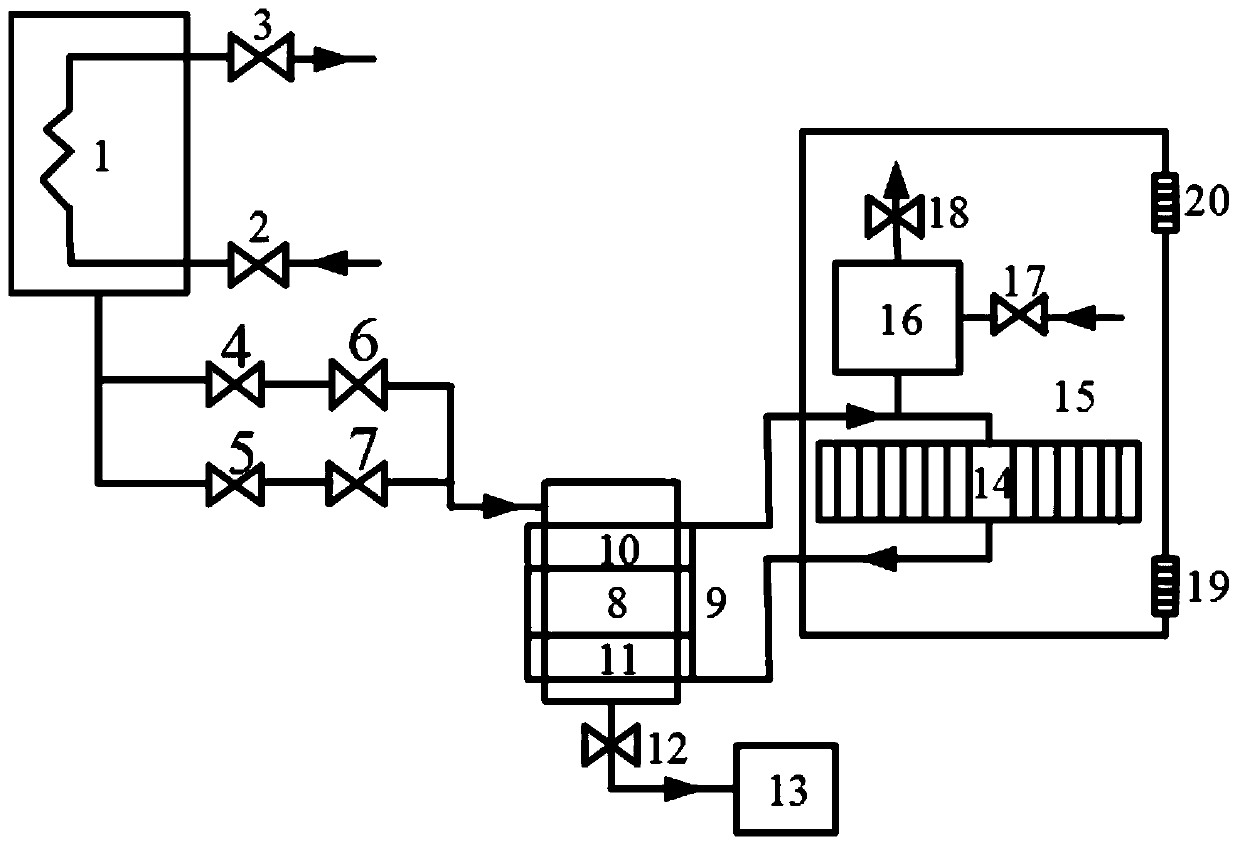

Embodiment 1

[0035] In this embodiment, the pressurized water reactor nuclear power unit is taken as an example. The steam generator 1 of the pressurized water reactor nuclear power unit is a saturated steam generator 1 with a steam-water separator, which is a vertical U-shaped tube natural circulation structure. Each 1000MW pressurized water reactor nuclear power unit needs three steam generators 1, the tube bundle of the steam generator 1 is the reactor primary loop system coolant, and the tube shell side is the secondary loop steam-water mixture. The design pressure of the primary side is 17.23MPa, and the design temperature is 343°C; the design pressure of the secondary side is 8.6MPa, and the design temperature is 316°C. When any one of the steam generators 1 has a heat transfer tube rupture (SGTR) emergency, the passive accident discharge and cooling process of the steam generator 1 is as follows:

[0036] Since the pressure on the primary side of the steam generator 1 is much higher...

Embodiment 2

[0043] This embodiment takes a high temperature gas-cooled reactor nuclear power unit as an example. The steam generator 1 of the high-temperature gas-cooled reactor nuclear power unit is a vertical, direct-flow spiral tube assembly structure. Each 200MW high-temperature gas-cooled reactor nuclear power unit has two steam generators 1, and the tube bundle of the steam generator 1 is a secondary circuit steam-water mixture. The side of the tube shell is helium in the primary circuit of the reactor, the operating pressure of the primary circuit is 7MPa, and the average temperature is 750°C; the operating pressure of the secondary circuit is 13.9MPa, the feedwater temperature is 205°C, and the steam temperature is 566°C. In the event of a steam generator 1 heat transfer tube rupture (SGTR) emergency, the passive accident discharge and cooling process of the steam generator 1 is as follows:

[0044] The pressure of the primary circuit of steam generator 1 is much lower than that o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com