A reverse osmosis antiscalant

A technology of scale inhibitor and reverse osmosis, applied in the field of scale inhibitor, can solve the problems of affecting the scale inhibition effect of the scale inhibitor, affecting the stability of the scale inhibitor effect and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

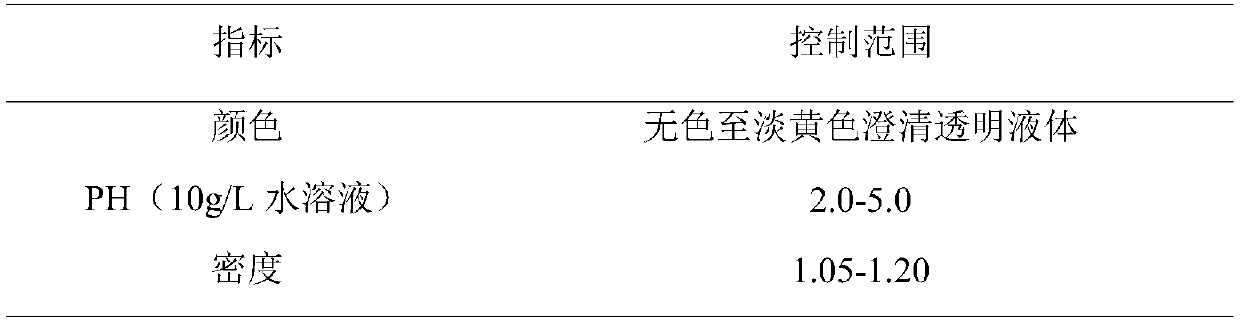

Method used

Image

Examples

Embodiment 1

[0021]

[0022] The reverse osmosis antiscalant includes: one of aminotrimethylene phosphonic acid (ATMP), phosphonocarboxylic acid (POCA), polyaspartic acid (PASP), polyamino polyether methylene phosphonic acid (PAPEMP) or several. The addition amount of each component is as follows:

[0023] ATMP: 15Kg

[0024] POCA: 5Kg

[0025] PASP: 5Kg

[0026] PAPEMP: 10Kg

[0027] Deionized water: 65Kg

[0028] The production method of the reverse osmosis antiscalant involved in the present invention is: first add 30 parts of deionized water, then add polyamino polyether group methylene phosphonic acid (PAPEMP), aminotrimethylene phosphonic acid (ATMP), phosphonocarboxylic acid (POCA), polyaspartic acid (PASP) and the remaining deionized water in a stirring tank, start the stirring rod, stir for about 60 minutes, and put it into a barrel through a filter device after standing for more than ten minutes.

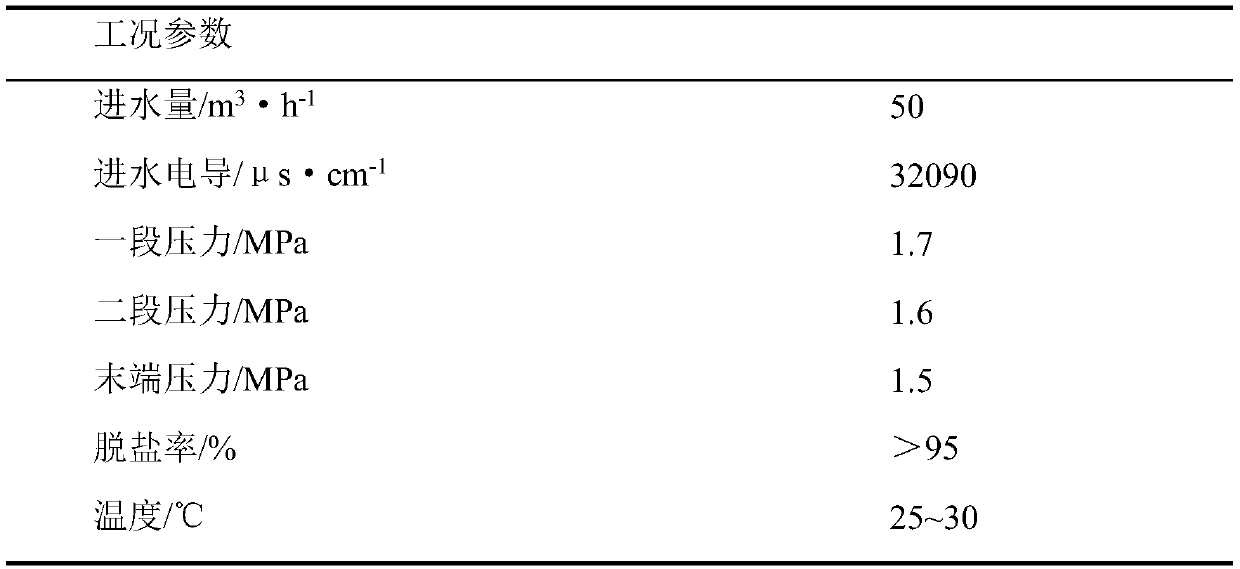

[0029] The use method of reverse osmosis scale inhibitor is continuous do...

Embodiment 2

[0031]

[0032] The reverse osmosis antiscalant includes: one of amino trimethylene phosphonic acid (ATMP), polyaminopolyether methylene phosphonic acid (PAPEMP), phosphonocarboxylic acid (POCA) and polyaspartic acid (PASP) or several. The addition amount of each component is as follows:

[0033] ATMP: 25Kg

[0034] POCA: 2.5Kg

[0035] PASP: 2.5Kg

[0036] PAPEMP: 5Kg

[0037] Deionized water: 75Kg

[0038] The use method of reverse osmosis scale inhibitor is continuous dosing. It is diluted and evenly added to the water containing iron hydroxide and aluminum hydroxide by the dosing pump. The general use concentration is 3-6ppm. After five years of field use, the in and out The flow rate of water, working pressure, inter-stage pressure, and conductance of produced water all remained stable without obvious fluctuations.

Embodiment 3

[0040]

[0041] The reverse osmosis antiscalant includes: one of aminotrimethylene phosphonic acid (ATMP), phosphonocarboxylic acid (POCA), polyaspartic acid (PASP), polyamino polyether methylene phosphonic acid (PAPEMP) or several. The addition amount of each component is as follows:

[0042] ATMP: 20Kg

[0043] POCA: 7.5Kg

[0044] PAPEMP: 10Kg

[0045] Deionized water: 65Kg

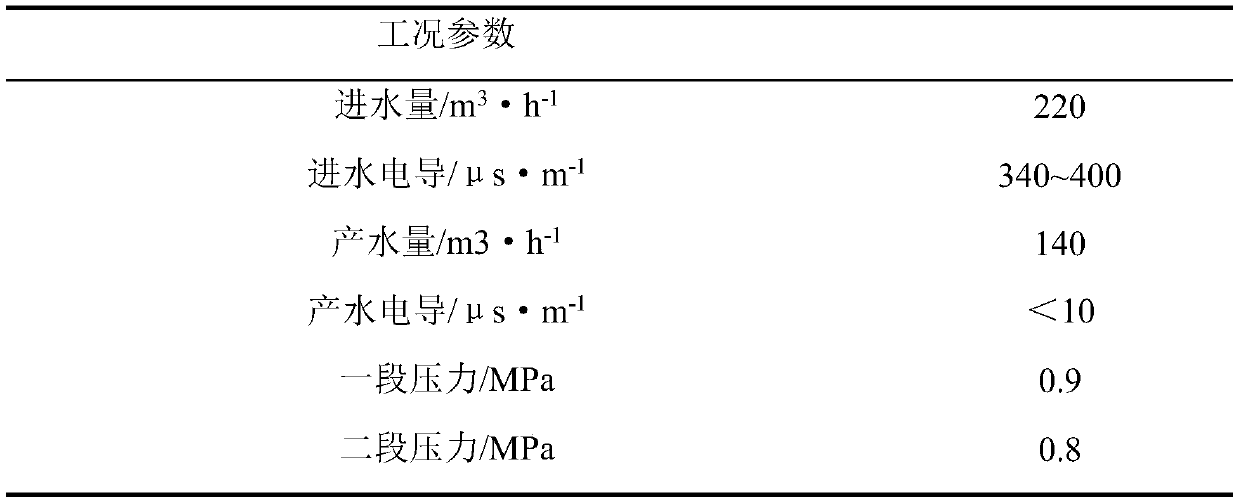

[0046] The use method of reverse osmosis antiscalant is continuous dosing. It is diluted and evenly added to the water body containing calcium sulfate and barium sulfate by the dosing pump. The general use concentration is 4-8ppm. The flow rate, working pressure, inter-stage pressure, and product water conductance all remain stable without obvious fluctuations.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com