Solid particle ejecting distributor and online decoking device

A technology of solid particles and distributors, which is applied in the direction of cleaning heat transfer devices, non-rotating equipment cleaning, lighting and heating equipment, etc., can solve the problems of increased device consumption, increased operating pressure of reactors, and increased resistance of tube and pipe, etc. Achieve the effect of stabilizing pipeline resistance and maintaining consumption level and prolonging operation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

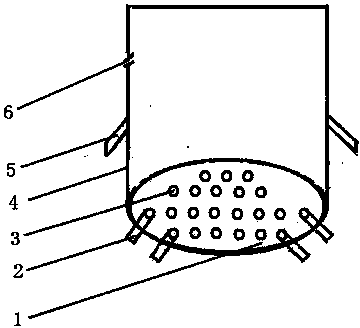

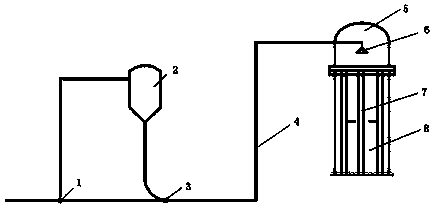

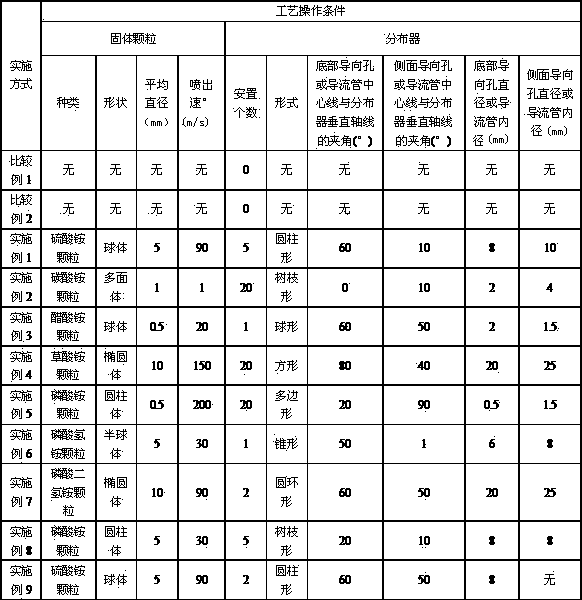

[0043] An online coke cleaning device containing solid particle spray distributors. Five cylindrical solid particle spray distributors are placed in the upper head of the cooler. The centerline of the bottom guide tube of the spray distributors is 60° to the vertical axis of the distributors. Included angle, the inner diameter of the diversion pipe is 8mm, the center line of the side diversion pipe and the vertical axis of the distributor form an included angle of 10°, and the inner diameter of the diversion pipe is 10mm. With the inert gas nitrogen as the power, the spherical sulfate solid particles with an average diameter of 5mm are transported to the solid particle spray distributor, and the solid particles are evenly distributed to the ammoxidation reaction gas at a spray speed of 90m / s after being sprayed by the distributor. In each tube of the cooler, the solid particles were sprayed smoothly and evenly distributed, and the coke in the tubes was removed. When the acrylon...

Embodiment 2

[0046] An online coke cleaning device containing solid particle spray distributors, 20 dendritic solid particle spray distributors are placed in the upper head of the cooler, and the centerline of the bottom guide pipe of the spray distributors is 0° to the vertical axis of the distributor Included angle, the inner diameter of the diversion tube is 2mm, the centerline of the side guide hole and the vertical axis of the distributor form an included angle of 10°, and the inner diameter of the diversion tube is 4mm. The pressure drop of the reaction gas cooler at the initial stage of start-up is 4kPa, and the polyhedral carbonate solid particles with an average diameter of 1mm are transported to the solid particle spray distributor with air as the power. The ejection speed is distributed to each tube of the ammoxidation reaction gas cooler, the solid particles are sprayed smoothly and evenly distributed, and the coke in the tubes is removed. When the acrylonitrile unit runs contin...

Embodiment 3

[0049] An online coke cleaning device containing a solid particle spray distributor. A spherical solid particle spray distributor is placed in the upper head of the cooler. The center line of the bottom guide hole of the spray distributor and the vertical axis of the distributor form an included angle of 60° , the diameter of the guide hole is 2mm, the center line of the side guide hole and the vertical axis of the distributor form an angle of 50°, and the diameter of the guide hole is 1.5mm. The pressure drop of the reaction gas cooler at the initial stage of start-up is 4kPa, and the inert gas nitrogen is used as the power to transport the spherical acetate solid particles with an average diameter of 0.5mm to the solid particle injection distributor. After being sprayed by the distributor, the solid particles are The ejection velocity of 20m / s is distributed to each column tube of the ammoxidation reaction gas cooler. The solid particles are sprayed smoothly and evenly distri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com