Six-tank circulating type marsh gas double-path SOFC anode fuel supply system

A fuel supply system, cyclic technology, applied in fuel cells, fuel cell additives, solid electrolyte fuel cells, etc., can solve the problems of inability to guarantee the continuous operation of SOFC power generation systems, lack of practical value, etc., and achieve biogas supply flow. Continuous and uninterrupted, conducive to maintenance, stable operation of biogas flow and pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 6

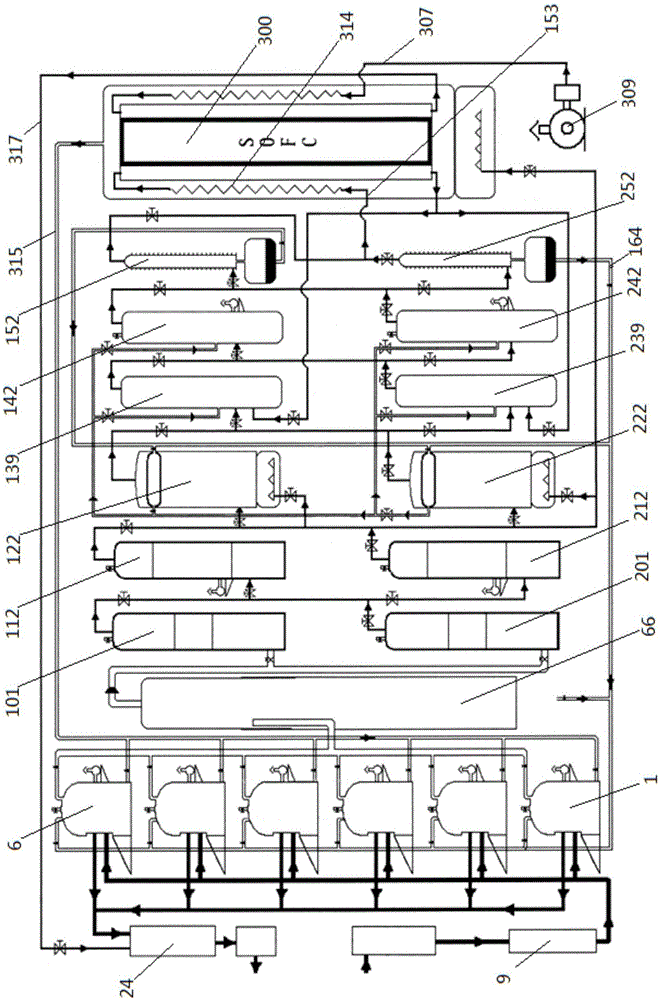

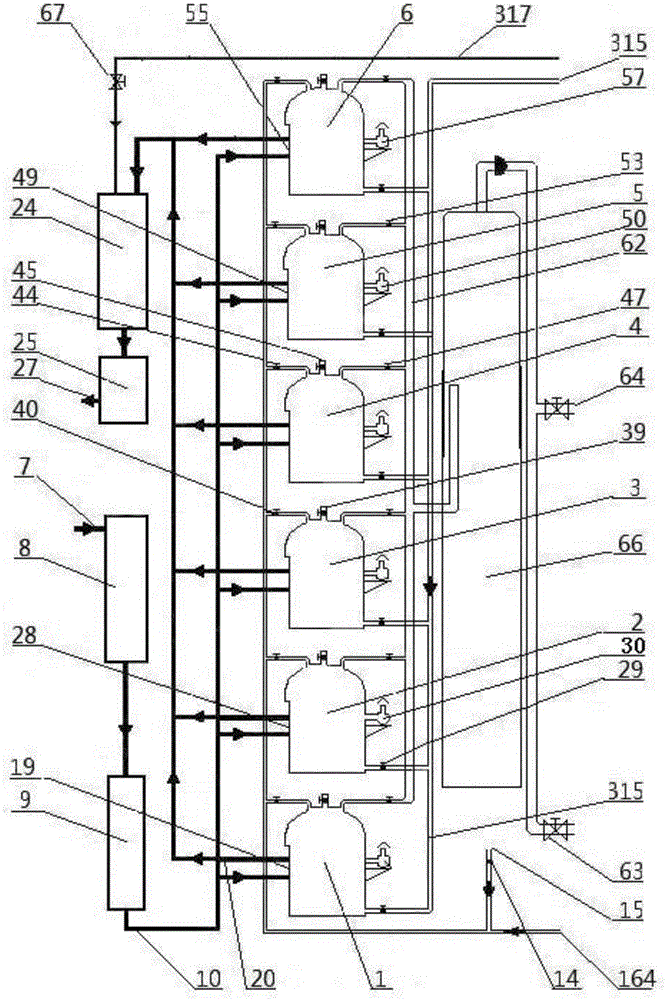

[0020] Embodiment 1 six fermenter circulation type biogas generation system

[0021] Such as figure 1 with figure 2 shown. The structure of the biogas generation system includes a total of 6 fermentation tanks for generating biogas, which are No. 1 fermenter 1, No. 2 fermenter 2, No. 3 fermenter 3, No. 4 fermenter 4, No. 5 fermenter 5 and No. 6 fermenter tank 6, a grinder 8 for crushing straw 7, a mixer 9 for mixing straw and methane fermenting bacteria, and a biogas storage tank 66; the biogas generation system has 6 sets to form a six-tank circulation type biogas generation system; the output of the mixer 9 is The crushed straw and methane fermentation bacteria enter the fermentation tanks respectively through the conveyor belt 10, and the working conditions of the 6 fermentation tanks are different at the same time; the biogas produced by the 6 fermentation tanks enters the biogas storage tank 66 through the output valve, and then passes through the anode fuel The suppl...

Embodiment 2

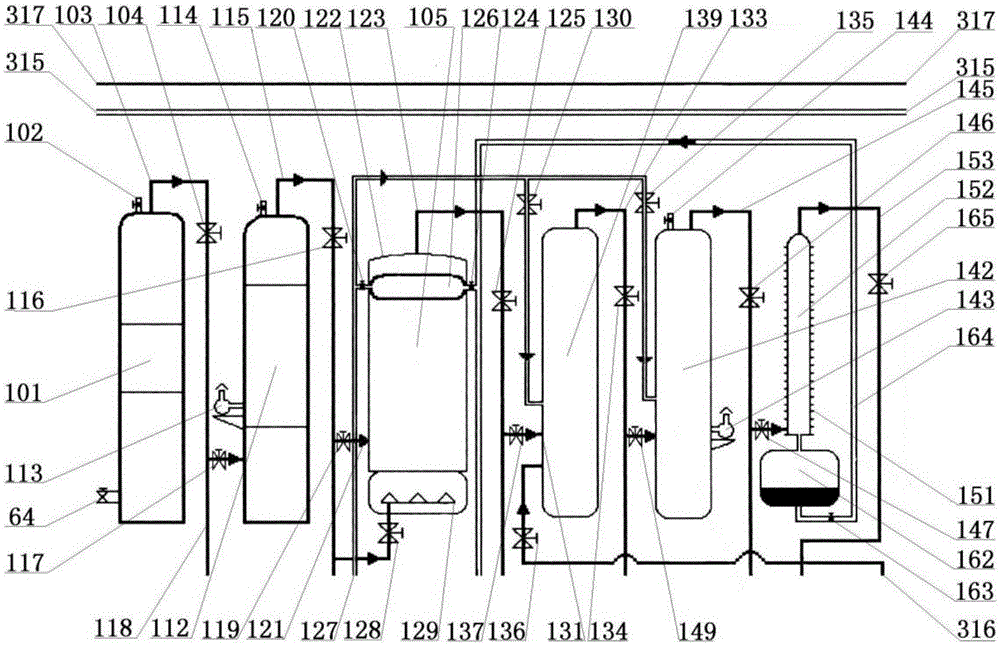

[0039] Example 2 Two-way Solid Oxide Fuel Cell Anode Fuel Supply System

[0040] Such as figure 1 , image 3 , Figure 4 As shown, the structure of the anode fuel supply system includes a biogas desulfurization device, a methane purification device, a fuel heating and steam generation device, a high-temperature reforming device, a low-temperature reforming device, a gas-water separation device, and the front and rear devices of the anode fuel supply system. There is a pipeline connection between them; in order to ensure the continuous operation requirements of the SOFC anode fuel supply system, the present invention is designed as a dual-channel anode fuel supply system. For simplicity of description, the two-way anode fuel supply systems are referred to as "A-way system" and "B-way system" respectively. figure 1 , image 3 , Figure 4 Among them, 101 is a biogas desulfurization device of A route, 201 is a biogas desulfurization device of B route, and their input ends are...

Embodiment 3

[0060] Embodiment 3 SOFC power generation system

[0061] Such as figure 1 with Figure 5 As shown, the SOFC power generation system is mainly composed of SOFC main body 300; anode fuel 153; anode fuel preheating chamber 314; anode fuel heat exchanger 313; anode fuel chamber 311; cathode fuel 307; cathode fuel preheating chamber 304; 303; cathode fuel chamber 301; starting burner 305; cathode fuel blower 309 and filter 308. Because, the normal operating temperature of the SOFC power generation system is 800°C. To start the SOFC power generation system, first, use the figure 2 Route A methane purification device 112 supplies fuel gas to the start burner 305 through the A route methane purification output pipeline 115 and the anode fuel valve 318, and the heat emitted by the start burner 305 is used for the SOFC main body 300, the anode fuel 153, and the anode fuel preheating chamber 314, the anode fuel heat exchanger 313, the cathode fuel 307, the cathode fuel preheating c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com